Transducer Course

1. Definition of a transducer A transducer is a device that converts what we want to measure into something we can measure. It is actually a transfer of energy from one form into another.

What we want to measure is anything in engineering - temperature, pressure, mass, strain, velocity, acceleration - etc.

Read by eye instruments such as dials and thermometers usually rely on a needle or object moving from one place to another - such as a needle on a dial or where a liquid is on a thermometer's scale. In the context of this course what we can measure is electrical energy and all the transducers considered will develop a change in voltage, although all can be adapted so current changes, in response to the property we want to measure (the measurand).

Transducers are also known as sensors. The terms are almost interchangeable - a sensor can also be something that detects a change between a low level and a higher one, such as a pressure switch. With this definition a transducer can be used as a sensor but a sensor could not be used as a transducer. A transducer detects up to an infinite number of levels in its range of measurement while a switch only detects one.

The term transmitter may also be used. The term is usually reserved for transducers that develop a current that alters with the measurand instead of a voltage.

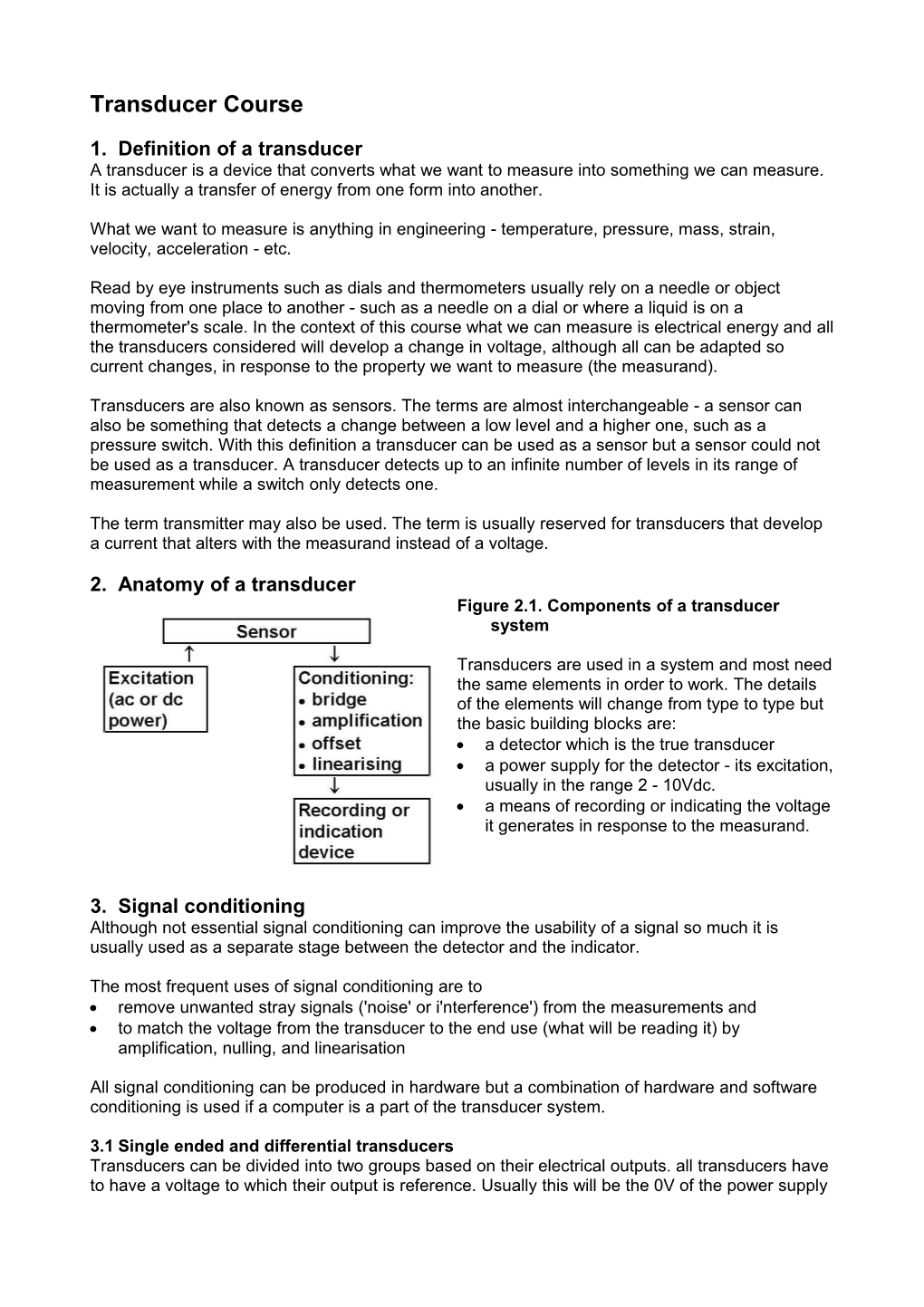

2. Anatomy of a transducer Figure 2.1. Components of a transducer system

Transducers are used in a system and most need the same elements in order to work. The details of the elements will change from type to type but the basic building blocks are: a detector which is the true transducer a power supply for the detector - its excitation, usually in the range 2 - 10Vdc. a means of recording or indicating the voltage it generates in response to the measurand.

3. Signal conditioning Although not essential signal conditioning can improve the usability of a signal so much it is usually used as a separate stage between the detector and the indicator.

The most frequent uses of signal conditioning are to remove unwanted stray signals ('noise' or i'nterference') from the measurements and to match the voltage from the transducer to the end use (what will be reading it) by amplification, nulling, and linearisation

All signal conditioning can be produced in hardware but a combination of hardware and software conditioning is used if a computer is a part of the transducer system.

3.1 Single ended and differential transducers Transducers can be divided into two groups based on their electrical outputs. all transducers have to have a voltage to which their output is reference. Usually this will be the 0V of the power supply that provides their excitation. In some the 0V can be used directly as a reference but if a bridge circuit is used the signal cannot be referenced directly to the power supply 0V

Transducers which can be referenced to 0V are called single ended. The output from many of these will be in the form of a train of pulses from which a frequency is derived. It is often possible to connect single ended transducers to a common 0V and only take one wire to the indicator or recording device.

Transducers using a bridge are called differential and require a differential input to a recording or indicating device. Most transducers are differential and where the type is unknown it is better to assume it is.

Figure 3.1 shows a differential transducer connected to the start of a differential indicating device and a single ended transducer connected to the start of a single ended indicating device.

Figure 3.1.1. Differential and single ended transducers

The voltage output from a differential transducer floats with respect to the power supply 0V. In figure 3.1 the differential transducer -ve differs from the reference by V1. The transducer +ve differs from the reference by V2. The required output from the transducer is V2 - V1. V1 and V2 can be any value but the difference between them for a given reading from the transducer will be the same.

The difference is measured in the differential input op amp which subtracts the voltage on pin 2 from that on pin 3. If the cable between the transducer and the signal conditioning is long 'noise' can be superimposed on the voltages in the wires. Since they are affected at the same time the noise pattern in both wires will be the same which means when the input op amp subtracts one voltage from the other it will also remove the noise and clean up the signal*: all it allows through is the differences in voltage. This is a great advantage of differential input signal conditioning.

(* for various reasons it won't clean up all the noise but it will make a great improvement)

The single ended transducer supplies a voltage that is already referenced to the power supply ground so the signal conditioning does not need to make the subtraction. The input stage in this case is an inverting amplifier, although a non-inverting one could have been used. Although the subtracting stage is not needed there is also no protection from noise. If this type of amplifier is used with a transducer the signal must be kept free from noise by other means or it will not be able to be removed within the rest of the conditioning.

A differential transducer cannot be connected to a single ended conditioning circuit. Differential signal conditioning circuits can have single ended transducers connected to them so for this reason, and because of their noise immunity, most general purpose signal conditioning circuits will be made with a differential input.

3.2 Wheatstone bridge based transducers Wheatstone bridges are used where the detector is resistive - its electrical resistance alters with the phenomenon being measured - which covers most transducers. The bridge is a way of getting the output as a voltage.

Figure 3.2 shows a Wheatstone bridge with three fixed resistors in three arms and one detector in the fourth. Between the arms are nodes. The upper and lower nodes have the excitation voltage across them. The left and right ones have the output voltage. Figure 3.2.1. Wheatstone bridge based transducer

If the resistors on the right were the same value the voltage at the right side node, V1, would be half the excitation voltage with respect to ground, Vcc/2. If the sensor resistance were the same as the resistor below it (but not necessarily the same as the other two resistors) the voltage at the left side node, V2, would also be Vcc/2 with respect to 0V.

The signal is the difference between the voltages at the left and right nodes, V2 - V1. With the conditions stated it is 0V and the bridge is said to be in balance. When the detector's resistance changes because of a change in the phenomenon it is measuring the V2 will increase or decrease in voltage putting the bridge out of balance but V1 remains the same, producing a signal. The change in resistance is usually quite small so the voltage difference is also small - the maximum (full scale deflection) is in the order of 2mV/Vcc. The output is quoted this way as the actual voltage is proportional to the excitation voltage. For instance at 2mV/V with 5V excitation the output would be 10mV fsd.

An arm of the bridge with a detector in it is said to be 'active' and it is possible to have two or four active arms as well as the one shown. These can be useful to add the effects of more than one detector to increase the signal size to measure smaller changes (sensitivity) or to subtract one from the other so one is now used as a reference to the other. This is useful if, say, small changes in pressure were being measured at an otherwise high pressure system. One would be kept at a constant high pressure, similar to the test pressure, and the other would measure the test pressure with its variations.

The most common form of bought detector is the additive version and the subtractive tends to have to be constructed by the user which can be done using two of the first type in two arms of a bridge constructed by the user.

It will be appreciated that even at fsd both signal voltages will be at around Vcc/2 above the power supply ground. This is a floating voltage. If the node carrying V1 were connected to a single ended signal conditioning circuit it would connect it directly to 0V, shorting resistor R2 and putting Vcc directly across resistor R1. Obviously this would prevent the bridge working correctly and is why a differeintial input conditioning circuit is required for it.

3.3 A basic signal conditioning circuit The most common form of signal conditioning is voltage amplification and nulling.

Amplification does not increase the voltage from the transducer. The transducer voltage is connected to the bases of a pair of transistors where it can make them conduct more or less , depending on its magnitude. The conducting transistors have a separate power supply - usually +/-15V connected across them. The more they are made to conduct by the transducer voltage the more of this is allowed to appear on the output of the circuit. With a few more components than described the circuit becomes an op amp. For the mechanical engineers: it's a bit like a dimmer switch - the more the knob is turned the greater the voltage to the lamp gets. For the electrical engineers: the lamp is the shiny thing hanging from the ceiling that gets more or less bright. The ratio of the voltage from the supply allowed to the output through to the voltage from the transducer is called the gain.

Nulling is being able to set the output of the signal conditioning to 0 when there is no input on the transducer. An op amp can also be used to perform this function. A simple circuit for both these functions is given in figure 3.3. There are three 741 amplifiers shown on the circuit and each forms a separate stage of the conditioning. The later stages work on the output of the previous one(s) but work together to produce a desired output. 741 amplifiers are not really suitable for this type of application but show the principles. Normally a purpose designed instrumentation amplifier would be used.

Figure 3.3.1. Basic signal condtioning circuit

The input stage of figure 3.3 is a differential input buffer as described in section 3.1. Its purpose is only to get the transducer's output referenced to 0V and reduce noise. It does not necessarily amplify or null but the one in the circuit used in the calibration exercise has a fixed gain of 10.

The second stage amplifies the cleaned and referenced signal to produce a larger voltage which will match the range of the instrument used to read it or to make it easier for a user to read off a value in the units required. The gain of the amplifier is usually adjustable so that different amounts of amplification can be set for different instruments to be attached or simply to calibrate it.

The third stage does not amplify but enables the voltage to be altered with respect to circuit ground. This is nulling and means the zero of the transducer can be altered as required.

The gain and nulling functions were used in the calibration exercise. The instruction sheet and LabVIEW program used in the exercise are available on the PIAE II web site.

Linearisation has been mentioned as a further form of signal conditioning and, if applied in hardware, would be a further stage. In most transducers the voltage output varies linearly with the measurand and the amplification described is also linear. The voltage read by a user would then vary linearly with the measurand making it easier for the user to interpret. Some transducers are not linear and the only function of linearising is to make it easier for the user to interpret the readings. A circuit would be produced which would change the rate at which the output varies with the measurand to create a linear relationship between the output and the measurand. Obviously to do this the characteristics of the true output need to be known and it will only work with one type of transducer.

4. A/D conversion As their name suggests analogue to digital converters digitise analogue voltages so that the data can be read directly by digital devices, including computers.

A/D conversion and the subsequent processing of the data by a computer is a form of signal conditioning. For instance when a computer is used for linearising an algorithm in the software reading the voltage can be substituted for a hardware lineariser making the process much simpler. While this is extremely useful it does have implications on the resolution of the data.

Figure 4.1. Effect of 'bits' in A/D converters

A/D converters compare the voltage signal they are reading with a reference and then assign a voltage level to it based on the number of discrete levels the converter can discriminate. The number of levels is based on the number of 'bits' the converter has. An 8 bit and a 12 bit converter are shown in figure 4.1. The 8 bit converter has 28 discrete levels = 256. Each level covers a range of the reference voltage. Vref is 10V in the figure so the range of each level is 10V/256 = 39mV (approx.). The converter will be able to tell that the voltage being measured is between multiples of 39mV but not any closer. If a varying voltage is viewed after passing through this converter it would appear to have steps in it 39mV wide.

If finer steps are required using this converter the only means of doing so is to reduce Vref. If Vref were reduced to 1V the steps would be 3.9mV but the maximum voltage that could be read would be 1V. This technique is used on data acquistion hardware (DAQ) and is often called gain even though it doesn't amplify the signal, only increases the resolution.

The converter on the right has 12 bits and Vref remains at 10V. It can resolve the 10V into 4096 levels, each 2.4mV wide, so can give better resolution and a higher reading range.

Increasing the number of bits a converter has increases the number of components unless the same component can be used to resolve different bits at different times. Flash A/D uses one comparator per bit which work simultaneously. It is quick but expensive. Successive approximation uses fewer comparators, each dealing with more than one bit. The resolution of the signal increases but so does the time required to acquire it. Even so, it is fast enough for collecting 1000's samples/second.

5. Calibration In order to use the transducer the relationship between the measurand - the property being measured - and the voltage the transducer gives needs to be known. If signal conditioning, including A/D conversion, is used the relationship between the measurand and the output of the signal conditioning will be required. The relationship is obtained through calibration. Regardless of the instrument calibration always takes the same format: 1. a means of providing an input to the transducer must be available which is of a greater precision than the measurments required from the transducer in its normal use.

For example if a pressure gauge is intended to measure differences of 0.1Bar it is no use using one that can only be read to 0.5Bar to calibrate it against. 2. the transducer system must be in a known controlled environment while the calibration is carried out

For very precise transducers close environmental control is required. For general purpose somewhere with a reasonably stable temperature close to the service temperature and no darughts or vibrations will suffice

3. the output at both limits of the range of the transducer is set using the precise input

The limits are the transducer's quoted range:e.g. 0 to 50mm or -1 to +1kPa. They can also be a smaller range but the precision of any measuremnt will be limited by the precision of the instrument no matter what is used as a known input.

4. the output for intermediate steps between the limits are set, again, using the precise input

Normally intermediate steps would be in 5% or 10% steps of the range of the instrument, giving 21 and 11 calibration points (including zero) respectively.

5. repeatability of output for given input is established by revisiting each point obtained in a random fashion.

Instead of taking each point in ascending or descending order points are set out of sequence making larger changes but always leaving the transducer to settle before reading the output.

6. a characteristic between the input and the output is established

Figure 5.1. Good and poor curve fitting

A graph of the input against the transducer system's output shows the characteristic*. Ideally error bars will be used which provide an area which the measured point is at the centre of. It will usually have an obvious trend which can generally be defined by a simple mathematical function such as a low order polynomial or exponential fit. Fits such as high order polynomials should not be used to force the line through every point. Figure 5.1 shows a second order polynomial fitted to points in the left graph with a sixth order through the same points on the right. The one on the right is no better than joining the points with straight lines.

7. deviations of the measured points from the established characteristic are calculated as the basis of the expected precision of the transducer system

Errors are often expressed as a percentage of the maximum reading of a transducer which, when that value is calculated equate to a +/-value. All transducers will produce errors due in readings and obtaining the magnitude of these is an important part of the calibration.

* Theoretically all transducers characteristics should follow a mathematical function which the calibration should allow to be reproduced when the fit is made. For various reasons other than the imprecision of the instruments this won't happen. Mathematical functions do not predict exactly what happens in real systems. If they did we we wouldn't need transducers and one of the reasons we do use them is to improve mathematical models. Reasons they do not predict 100% are the assumptions made in deriving the functions. These inevitably simplify the mechanical and electrical complexities to, what is hoped is, an acceptable level. Where the simplification is too great either an empirical correction is made - accepting the best fit the calibration gives - or the assumptions are revised to give a better function.

5.1 Resolution of a transducer system For an A/D converter the resolution is based on the reference voltage and the number of bits it posesses, as discussed in section 4. It means that if a difference in voltage lower than the resolution occurs it will not be detected, or at least not reliably. Analogue devices also have a resolution below which changes in output are undetected, although theoretically their resolution is infinite.

The limit is caused by imperfections in manufacture and electrical hum which cannot be totally eliminated.

The main limiting factor in most transducer systems will be the instrument used to read the voltages, the resolution of which will be much less than any other component of the system. Even if it is capable of high resolution the scale most likely not be. Analogue scales can be read to about a quarter of the smallest division marked on them, although the thickness of the needle will have a bearing on this. Digital instruments are always +/- 0.5 of the last digit and fluctuating digits can be very awkward to read. Instruments supplied with a transducer system will be matched to the resolution the system is capable of or expected to meet in service. When building your own system these limits should be taken into consideration.

Computer systems can display data to as many decimal places as asked in a similar manner to a calculator. As with a calculator only sufficient significant figures should be displayed or recorded to suit the resolution of the instrument.

A good indication of the resolution of a system is if an analogue meter or a reqiured digit on a digital display is not steady during calibration..

6. System and transducer interactions All transducers have inertia which prevents them from reacting infinitely quickly to changes in the phenomenon they measure. There will be some time lag as the energy of the phenomenon is stored in the materials of the transducer before being converted to electrical energy. Often this is not a problem but if the transducer's signal is used as feedback of an automatic control system, warnings need to be given if limits are exceeded, or if the phenomenon being measured is simply changing very rapidly a transducer needs to be selected that can respond rapidly enough.

A transducer can also affect the system it is introduced to by providing extra mass to a system measuring accelerations or blockage in a system where the flow rate is required. Such things are not always obvious and must be guarded against or allowed for.

6.1 Transducer response time Thermometers are a good example of a transducer that may be required to respond rapidly, as a sudden increase in temperature is often an indication that something is going wrong in a machine, but don't necessarily do so.

A common type of electrical thermometer is a thermocouple. It is described on the web site for the course. It is made from two wires of disimilar metals which generate a small voltage that is proportional to temperature. Like most thermometers a thermocouple measures its own temperature and in order to measure the temperature of another object it must be in contact with the object so it can be at the same temperature as it is. If it is put onto the object or immersed in a liquid of a different temperature it will take some time to reach that temperature.

If it is mounted on an object with a higher thermal inertia than its own (more mass and Cp) then it will be able to follow changes in temerature accurately If it is mounted on an object or immersed in a fluid with a similar thermal inertia to its own it will not follow changes in temperature and may also affect the thermal properties of what is being measured.

It is important, particularly with contact devices, to choose a transducer that will suit the measurments being made. Thermocouples come in two main styles: bare wire or in a protective case. The protective case keeps the thermocouple safe from damage but won't allow heat through rapidly because of its extra mass. A bare bead will respond more quickly but is open to attack from aggressive media it is immersed in or simply mechanically breaking. Bead thermocouples are made in different wire gauges. The smaller ones can have wires down to 0.025mm diameter with time constants in the order of 0.01s. They are also quite fragile.

6.2 Effects of the transducer on the system The addition of a sensor to a system will affect how it works. These are examples with specific transducers but could easily apply to others. flow meters: orifice plate / turbine flow meter / Pitot static tube Any device added to a flowing fluid will affect it by changing the area it has to flow in or by introducing drag. Te system's flow rate can be reduced by the meter or make pumps and fans work harder (and cost more to run) to maintain a required rate.

accelerometer How a body accelerates depends on its mass. Accelerometers have mass and are attached to the body and thus changing the phenomenon being measured.

thermometer Thermometers add to the thermal mass of a system, making it slower to respond. They also provide a route for heat to escape from, changing the dynamics of the system in a different manner.

load cells Load cells measure forces in structures using strain gauge bridges. The cell itself will alter the stiffness of a structure and its dynamic behaviour.

ammeter / voltmeter The ideal voltmeter has an infinitely high electrical resistance while an ideal ammeter's would be infinitely low. Real voltmeters will increase the current in an electrical system and reduce the voltage drop across the device being measured. Real ammeters will decrease the current and the voltage.

From this list of examples it can be seen the general rule is to make the transducer small with respect to the system it is measuring so its effects are negligible. If this is not possible the effects must be taken account of. If this is not possible a non contact means of measuring must be employed.Often transducers using emitted beams of light can be used as alternatives. Light is non invasive to most systems and responds rapidly to changes. Thermometers can use 'light' emitted from a hot object to read it's temperature*. Accelerations can be obtained using a device similar to a light beam ruler to measure displacement over time and differentiating the signal twice to get acceleration.

* 'heat' is radiation emitted in the infra red which we can feel through our skin, even from a distance. There is a wavelength at which most radiation is emitted but the band all the wavelength covers is fairly broad. As the object gets hotter the wavelengths it emits at get shorter but the band covered is still as wide. If the object gets hot enough the shorter wavelengths it emits cross into our visual range and we see it as red. As it gets hotter still wavelengths we see as orange and yellow are emitted. Once it gets hot enough for greens to appear there are so many wavelengths present our eyes can detect we see the object as white.