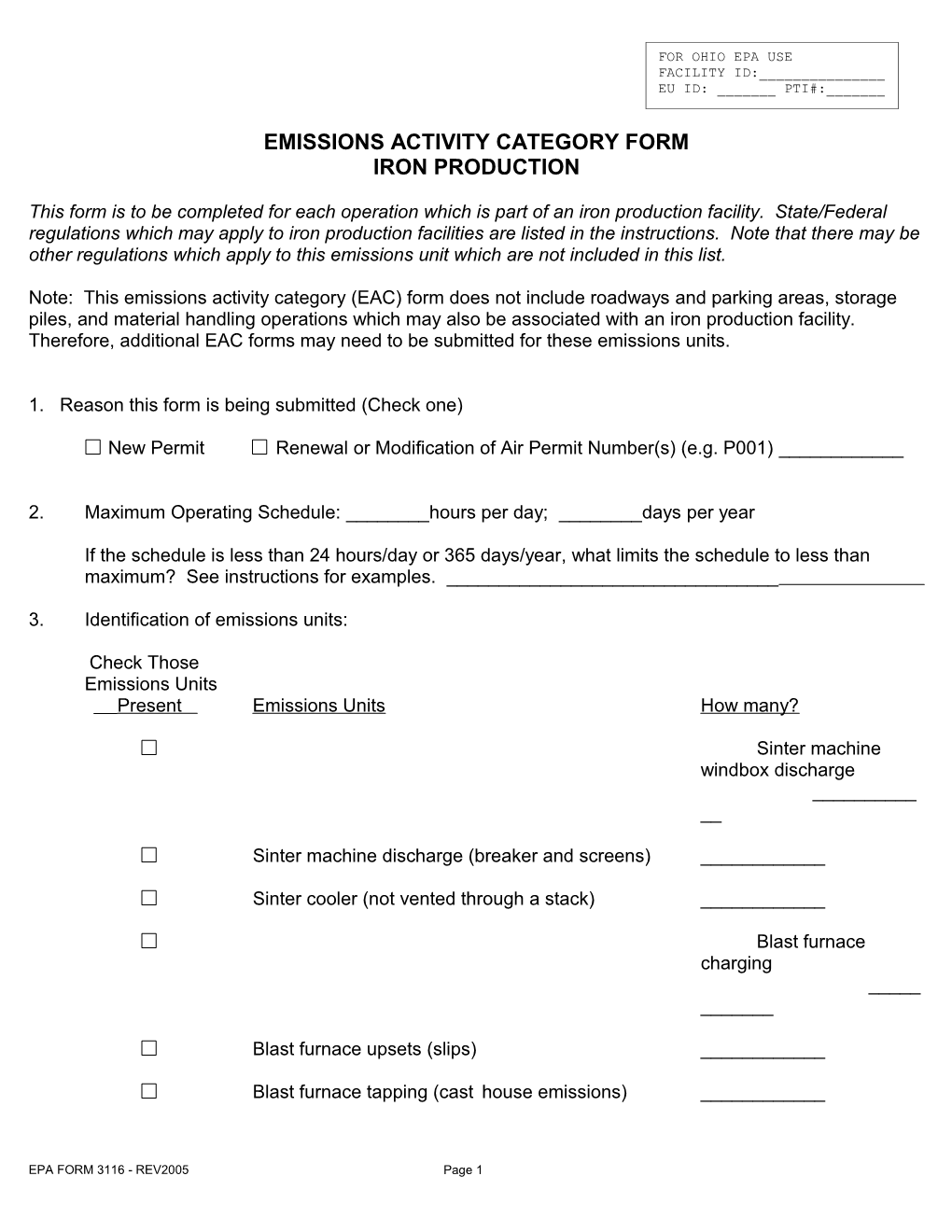

FOR OHIO EPA USE FACILITY ID:______EU ID: ______PTI#:______

EMISSIONS ACTIVITY CATEGORY FORM IRON PRODUCTION

This form is to be completed for each operation which is part of an iron production facility. State/Federal regulations which may apply to iron production facilities are listed in the instructions. Note that there may be other regulations which apply to this emissions unit which are not included in this list.

Note: This emissions activity category (EAC) form does not include roadways and parking areas, storage piles, and material handling operations which may also be associated with an iron production facility. Therefore, additional EAC forms may need to be submitted for these emissions units.

1. Reason this form is being submitted (Check one)

New Permit Renewal or Modification of Air Permit Number(s) (e.g. P001) ______

2. Maximum Operating Schedule: ______hours per day; ______days per year

If the schedule is less than 24 hours/day or 365 days/year, what limits the schedule to less than maximum? See instructions for examples. ______

3. Identification of emissions units:

Check Those Emissions Units Present Emissions Units How many?

Sinter machine windbox discharge ______

Sinter machine discharge (breaker and screens) ______

Sinter cooler (not vented through a stack) ______

Blast furnace charging ______

Blast furnace upsets (slips) ______

Blast furnace tapping (cast house emissions) ______

EPA FORM 3116 - REV2005 Page 1 Slag crushing

______

Other (describe):______

4. General blast furnace data:

Emissions Number of Manufacturer Blown-in Maximum Maximum Unit ID(s) identical Capacity Pig Iron Pig Iron furnaces (tons/hour) Production Production (tons/hour) (tons/year)

5. Sinter machine process data:

Emissions Number of Manufacturer Maximum Maximum Maximum Unit ID(s) identical Design Hourly Annual machines Production Sinter Sinter Capacity Production Production (tons/hour) (tons/hour) (tons/year)

6. Blast furnace charging process data:

Emissions Number of Type of Type of Maximum Maximum Maximum Unit ID(s) Identical Charging Charge Design Hourly Annual Machines Capacity Production Production (tons/hour) (tons/hour) (tons/year)

pellets sinter ore other: ______pellets sinter ore

EPA FORM 3116 - REV2005 Page 2 other: ______

pellets sinter ore other: ______

7. Blast furnace upsets (slips) process data:

Emissions Unit ID(s) Maximum Maximum Number of Number of Slips Slips Per Hour Per Year

8. Blast furnace tapping (cast house emissions) process data:

Emissions Number Maximum Maximum Maximum Slag Tapped Slag Average Unit ID(s) of Tap Number of Number of Number From or Discharged Length of Holes Taps Per Taps Per of Taps Removed Into Tapping Hour Day Per Year Through Period (minutes) separate adjacent notch slag pit iron notch slag thimble

separate adjacent notch slag pit iron notch slag thimble

separate adjacent notch slag pit iron notch slag thimble

9. Slag crushing process data:

Emissions Number of Manufacturer Maximum Maximum Maximum Unit ID(s) Identical Design Input Hourly Annual Processes Capacity Throughput Throughput

EPA FORM 3116 - REV2005 Page 3 (tons/hour) (tons/hour) (tons/year)

EPA FORM 3116 - REV2005 Page 4 10. Control methods to be used for emissions from iron production:

Capture Method Capture Control Method Control Efficiency Efficiency Blast Furnace Enclosure Vent to fabric filter Other (describe): ______Sinter Machine Windbox Water spray Discharge Enclosure Vent to fabric filter Precautionary operating practices (describe): ______Other (describe): ______Sinter Machine Discharge Enclosure (breaker and screens) Vent to fabric filter Other (describe): ______Sinter Cooler Enclosure (not vented through a stack) Vent to fabric filter Other (describe): ______

Blast Furnace Charging Blast Furnace Upsets (slips) Operating practices and control of raw materials (describe): ______Vent bleeder to valve to water well Baffled enclosure of bleeder valve Other (describe): ______Blast Furnace Tapping Hooding tap holes and troughs to Vent to fabric filter (cast house emissions) skimmers Other (describe): ______Hooding tap holes to runners ______Building evacuation Other (describe): ______Slag Crushing Watering Chemical suppression Vent to fabric filter Other (describe): ______Other (describe):

EPA FORM 3116 - REV2005 Page 5 11. Details for wet suppression systems:

Activity Material Used Application Point(s) Application Rate (wetting agent) (gal./ton processed) Sinter Machine Windbox Discharge Slag Crushing

Other Activity (describe):

EPA FORM 3116 - REV2005 Page 6