Economics of Production and Marketing of Safed Musli (Chlorophytum borivilianum) in Rural Areas of Vindhyan Plateau, Madhya Pradesh, India Vikas Parmar Dr Vijay Kumar Dr Manoj K Singh M. Phil. Scholar Faculty of Forest Resource Economics Research Assistant- Indian Institute of Forest & Management Economics Management, Bhopal Indian Institute of Forest Management Indian Institute of Forest Management

Introduction production depends upon agro-climatic conditions and management practices. Safed musli is a herb found in tropical moist Cultivation of this wonder crop is much more and dry deciduous forests. It is an extremely profitable than any other crop of this season valuable gift of nature to mankind. Under the and provides good returns on investment in a Indian system of medicine, it holds a reputed short gestation period of 7–8 months. The position. local people also cultivate it in their homes for It is a medicinal plant indigenous to central trial purposes and have realized how India and grows naturally in M.P, rewarding it can be. Chhattisgarh, Gujarat and U.P., in tropical and sub tropical climates with altitudes up to WHY THIS STUDY WAS CONDUCTED 1500m. It is only in India that it is treated as a A study of the Safed Musli marketing system is medicinal plant whereas in other countries it is necessary to understand the complexities regarded as just an ornamental plant. involved and identify bottlenecks with a view to Seventeen species of Chlorophytum had been providing efficient services in the transfer of farm reported in India (P. Oudhia, 2001). All differ products and inputs from producers to consumers. in medicinal properties but due to lack of An efficient marketing system minimizes costs correct information, all of them are called and benefits all sections of society. safed musli. It is used as a natural sex The expectations from the system vary from group tonic with great potential to become an to group and generally, the objectives are in alternative to Viagra. conflict. The efficiency and success of the system Marketing channels for safed musli are still depends on how best these conflicting objectives unorganized as it is currently sold through are reconciled. agents, middlemen, traders, pharmaceutical companies and retailers. There are huge Producers margins of profit on the route from Musli producers want the marketing system to collector/producer to consumer. purchase their produce without loss of time and provide a maximum share of the consumer’s Biological Features of Safed Musli rupee. They want the maximum possible price for their surplus produce. Similarly, they want the In Madhya Pradesh, three main species are system to supply them with inputs at the lowest found and all three are under cultivation. In possible cost. Sehore forest division, two species are found, Chlorophytum borivilianum and Chlorophytum Consumers tuberosum. The quality depends upon the Musli consumers are interested in a marketing agro climatic condition of the area, the system that can provide Musli and other items in steepness of the slope, soil, texture, shade the quantity and of the quality required at the and some anthropological factors lowest possible price. However, this objective of Musli is a tuberous plant and propagates only marketing for consumers is contrary to the through the root. Sexual vegetative objective of marketing for producers. reproduction is very rare and takes 18 months to mature. As it is a valuable forestry product, Market Middlemen whoever finds it, just picks it up and sells it to Market middlemen are interested in a marketing a local trader. In its natural condition, system which provides them with a steady and production has been reduced to half in the last increasing income from the purchase and sale of 3 years while in cultivated condition, its Musli. This objective of market middlemen may be achieved by purchasing Musli produce from

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 1 of 15 producers at low prices and selling to consumers Safed Musli crop growers, a list of growers in the at high prices. respective forest divisions was prepared with the help of officials of the State Forest and Agriculture Government Department and then respondents were selected The objectives and expectations of all three randomly. Only those growers were listed who groups of society - producers, consumers and had been in the business of Safed Musli crop market middlemen – conflict with one another. All production and marketing for the last five years. three groups are indispensable to society. The government has to act as watch-dog to safeguard Various official records were used to collect the interests of all. It must try to provide the secondary data, including published and maximum share to the producer in the consumer’s unpublished information/documents on various rupee; food of the required quality to consumers aspects of Safed Musli cultivation by different at the lowest possible price; and enough margin to private farm corporates, the Directorate of market middlemen so that they may remain in the Agriculture, the Government of Madhya Pradesh trade and not think of going out of trade and Bhopal, M.P., Commissioner, Land Record & jeopardizing the whole marketing mechanism. Settlement, Government of Madhya Pradesh, Thus, the government wants the marketing Gwalior, M.P., Directorate of Horticulture, system to be one that will benefit all segments of Government of Madhya Pradesh, Bhopal, M.P., society. Directorate of Economics & Statistics, Government of Madhya Pradesh, Bhopal, M.P. Objectives along with the Department of Forests, Government of Madhya Pradesh, Bhopal, M.P. 1. To analyze the farming system and among others. landownerwise distribution of Safed Musli 2. To analyze production practices in physical Tools of analysis and monetary terms Simple statistical tools (average, mean, median, 3. To analyze the marketing practices and price percentage) were used to analyze the collected spread of Safed Musli primary data. 4. To suggest measures for the improvement and conservation of Safed Musli Reference year The study conducted in Sehore forest division Research Methodology pertains to the primary data collected for the A specific sampling technique was used. This agricultural year 2002-03. was done on the basis of a sampling design of statistical data. Result and Discussion:

Sample design Status of Safed musli A multistage and multiphase sampling technique was used to obtain a representative sample. At a The total area of Sehore forest division is 152600 later stage, a simple stratified random sampling hectares and the area under was used. For respondent sampling, all 60% as Musli in natural condition is per forest official information were interviewed as 18.6% of total forest area. well as cultivators who had gone for commercial Production went down from cultivation. 2000 to 2002. It became just half due to unsustainable Source & Collection of data: - Respondent harvesting practices which Safed Musli crop growers were the source of resulted in scrub distribution and primary data and were interviewed personally. poor regeneration. Primary data collection was done through a pre- tested questionnaire which included open-ended The area under cultivation increased from and close-ended questions to get a clear view of 2000/02. Before this, there was the growers. During the selection of respondent no cultivation, only wild collection from the forest.

Table 1: Area wise status of Safed Musli in Sehore forest division

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 2 of 15 Sehore forest division Total area under Musli Year Production of Musli under cultivation (in Ha.) Natural condition in quintals

RF PF (Ha.) Total area (Ha.) (in Ha.) 112700 39900 152600 28144.997 2002 114.96 2001 258 2000 422.15

Table 2: Land owner wise status of Safed Musli in Sehore forest division Land owner wise status of cultivation of Safed Musli Year Fouzdar krishi ENBEE Agro Forest Farmer (area Total area % farm(area in Acre) plantation (area in department (area in Acre) in Acre Cultivation Acre) in Acre) 2002 5 Acre ---- 2.25 Acre 1.5 Acre 8.75 .002 2001 1 Acre 2 Acre 3.25 Acre .5 acre 6.75 .0018 2000 1 Acre 2 acre ------2 .00054

Table 3 : Producer wise status of Safed Musli in Sehore Forest Division Name of Year Area Production (in quintal) Price cultivators Fouzdar krishi 2002 5 Acre 9 - 10 (fresh weight) Sale it @ of Rs 800 / kg. farm 2001 1 Acre 8 - 9 (fresh weight) Used as planting material as increase the area of cultivation 2000 1 Acre 5 - 6 (without bed preparation) Used as planting material for next fresh weight. year. Forest 2002 Not harvested. department 2001 1 Acre 0.20 – 0.25 (fresh weight) Not sale equally divided among the through mahila members. sangh 2000 Not cultivated. Farmer 2002 .5 Acre 0.50 – 0.55 (fresh weight) Sale it @ of Rs 800 / kg. 2001 .5 Acre 0.20 – 0.25 (fresh weight) Sale it @ of Rs 500 / kg because Musli cultivated with out bed preparation. 2000 Not cultivated at all. ENBEE Agro . 2002 Not cultivated at all. Farm 2001 2 Acre 8 - 10 (fresh weight) Sale it @ of Rs 1200 - 1300 / kg. 2000 2 Acre 4 - 5 (fresh weight) as cultivated Sale it @of Rs 700 - 800 / kg. with out beds preparation.

Producer wise status of Safed Musli The producer wise status of Safed Musli in Sehore forest division has been described in two difference to the level of production. During terms - physical and monetary. discussion, cultivators also recognized the fact that this crop gives a better return of their Table 3 shows the producer wise status of Safed investment within a short gestation period of 7 – 8 Musli under various categories of land owner. It months as compared to any other crop growing in clearly indicates that the cultivation of Safed Musli this season. This crop makes the farmer tension with and without the preparation of beds makes a free as it does not suffer from any insect/pest huge attacks.

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 3 of 15 PRODUCER WISE PRODUCTION PRACTICES it affects production. If a farmer doesn’t irrigate the Production practices were studied by looking at field or put all other inputs into cultivation then the the soil, drainage systems, field preparation, bed result is a low yield. The farmer follows the single preparation, seeds and planting material, bed system of cultivation which covers a large weeding, irrigation, harvesting practices, drying space but during harvesting it is quite easy to dig and storage practices. out and maintain the quality of tuber as compared to the wide bed system. Table 4 shows the different cultivation practices and clearly indicates that if cultivation is done GAP/ CONSTRAINT ANALYSIS OF SAFED through wide and raised beds, either through the MUSLI farmhouse technique or nursery technique, it hardly makes any difference to production. In the A comparative analysis of different production nursery technique, beds are prepared by mixing a practices was made. These 2:1:1 ratio of alluvial soil: sand: FYM while in the producers were CEDMAP, farm house technique, beds are prepared by first Fouzdar Krishi farm, ENBEE deep tilling, then spreading FYM and again deep agro farm, the forest department tilling. It hardly affects production if all cultivation and farmers. practices are followed sequentially, but if there is difference in the irrigation period or weeding, then

Table 4 : Production practices of Safed Musli in Sehore forest division Activities Fouzdar Krishi ENBEE Agro. Forest Farmer Farm Plantation (nursery department (single bed system) technique) Soil Sehara soil Alluvial soil + sand Sandy loam Sandy loam Drainage system Well Well Well Well Field preparation By tractor By tractor By gathi By gathi Deep tilling 3.75 - 4 trolley 2 - 2.25 trolley 2 trolley ~ 1 trolley Gobar khad by tractor no tilling no tilling no tilling Tilling Bed preparation Up to May end Up to June 1 – 2 weak it June - July July end- Aug. is prepared by mixing 2:1:1ratio of alluvial soil:sand: fym Bed size 3.5 ft wide, 1 –1.5 ft 3.5 ft wide , 10mlong , 1 3.5 ft wide , 10m Single bed system, 1 ft raised ft raised. long , 1 ft raised raised Weights of tuber < 5 gm < 5 gm < 5 gm < 5 gm used for planting material Planting material 3.5 – 4 quintal 2.5 – 3 quintal 3 - 3.5 quintal ~ 4 quintal Pre-treatment Planting material No treatment No treatment Planting material placed in placed in ash and gobar khad and sprit water treatedith for 3-4 days. trichoderma. Spacing 6 * 6 inches 6 * 6inches 9 * 9 inches 9 * 9 inches Plantation By wooden stick By hand By hand By hand Depth of finger 1 inches 1 inches 1 inches 1 inches inside the soil Weeding 3 times 3 times 3 times 3 times Irrigation Every 15 - 20 days Once in a month Once in a month No irrigation Harvesting period March – April Oct. - Nov. Nov. – Dec. Oct. – Nov. Harvesting Iron stick called By gathi and kurphi By gathi By gathi practices Aakri

( Mittal Musli farm ) No. of fingers 5 – 15 5 – 12 5 - 12 3 – 10 Washing and Placed Musli in water Placed Musli in water Leave Musli along with soil for 3 - 4days and peeling and peeled with and peeled with stainless pluck 1 tuber pushed it tail by thumb with finger stainless steel knife. steel knife. on tuber skin if it leave skin than placed in water

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 4 of 15 Activities Fouzdar Krishi ENBEE Agro. Forest Farmer Farm Plantation (nursery department (single bed system) technique) and rub with hand or against stone. Drying 3 - 4 days in bright sunlight on white cloth to maintain quality. Storage practices In a big hall first No storage practices No storage Dig a pit in shady place in spread sand and than practices home and dried it for 5 - 6 placed Musli over it days and than put dried soil no maintenance of than Musli in this way 3 - 4 temperature and layer and than cover it with moisture. soil. Production 9 –10 quintal 8 - 10 quintal 25 - 30 kg 1 - 1.10 quintal (fresh weight) (fresh weight) (fresh weight) (fresh weight ) because only big finger is harvested and huge amount of planting material is left for next year.

Table 5 :Comparison of production practices of Safed Musli in Physical terms in Sehore forest division Scientific method of Fouzdar krishi farm ENBEE Agro. Forest department. Farmer cultivation (according Plantation to CEDMAP ) Sandy loam, well drained , high Sandy loam and well drained Sandy loam and well drained Sandy loam and well Sandy loam and well organic content . soil soil drained soil drained soil Land preparation Deep tilling By gathi Green manure By tractor By tractor By gathi No Decomposed khad(5-10 trolly) No No No 3.75 - 4 trolley 2 – 2.35 trolley 2 trolley (soil +khad) ~ 1 trolley Tilling ------Other khad like Hadi khad , tilling ------soil conditioners ------Bed preparation ( up to 15th June) Up to May end Up to 1 – 2 weak of June June end - July July – Aug. Bed size 3.5 ft wide, 1 – 1.5 ft raised 3.5 ft wide,10m long, 1 ft 3.5 ft wide, 10m long, 1 ft Single bed system 1 ft raised raised raised. Weight of tuber used for planting < 5gm <,5gm < 5 gm < 5gm material (5 – 10 gms ) Planting material 3.5 – 4 quintal 2.5 – 3 quintal 3 - 3.5 quintal ~4 quintal (3 – 6 quintal ) Pretreatment of planting material Planting material placed in No treatment No treatment Planting material placed in a (2 min bovestien solu + 1 hr in cow ash and treat with gobar khad for 3 – 4 days urine ) Trichoderma. and sprit water over it. Spacing (6*6 inches) 6*6 inches 6*6inches 9*9inches 9*9inches Plantation(With the help of wooden With the help of wooden stick By hand By hand By hand stick or kurphi) Fingers placed not more than 1 inch 1 inches 1 Inches 1 inches 1 inches inside the soil Weeding ( 3 times ) 3 times 3 times 3times 3 times

Irrigation ( every 15 – 20 days till 15 – 20 days Once in a month Once in a month No irrigation at all digging ) Harvesting period After Feb. in March and April Oct. - Nov. Nov. – Dec. Oct. - Nov. up to 15th. Harvesting practices ( by kudhali ) Iron stick called Aakri by Gathi and kurphi Gathi Gathi Mittal Musli farm No .of fingers (10- 12 is consider as Mini : 5 – 8 Mini : 5 - 8 Mini : 5 - 8 Mini : 3 – 4 good) Maxi : 10 – 15 Maxi : 10 - 12 Maxi : 10 -12 Maxi : 8 – 10 Washing and peeling( put Musli in Put Musli in water and peeled Put Musli in water and Leave the Musli along with soil for 3 -4 days and take one basket and placed in flowing water with stain less steel knife. peeled with stainless steel finger press the Musli finger with thumb and finger on and washed and peeled with knife. tuber if it leave skin than placed in water and rub with stainless steel knife ) hand or against the stone. Drying: 3 - 5 days in sunlight on Fallow the practices. white cloth for quality maintain. Storage practices In a big hall first spread sand No storage practices No storage practices Dig a pit in a room and By maintaining moisture at 70 – 80 and than placed Musli over it dried for 5-6 days and put % and temperature at 28 – 31 0C. nothing else no need to dried soil over it and than Dig a pit in shady place and dried it maintain temperature and put Musli than soil in such a

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 5 of 15 Scientific method of Fouzdar krishi farm ENBEE Agro. Forest department. Farmer cultivation (according Plantation to CEDMAP ) and put Musli and cover it with soil. moisture. way 3 – 4 layer and at last cover with soil. No washing leave Musli along with soil and stored it . Production: According to CEDMAP 9 – 10 quintal (fresh weight) 8 – 10 quintal and no 25 - 30 kg (fresh weight) 1 - 1.10 quintal (fresh if planting material from reputed and no planting material is planting material is left. and good amount of weight) no planting material farm house than production will be left. planting material is left for is left for next year. 17 quintal fresh weight + planting next year because only big material for next year and if planting finger is harvested and material is taken from forest than other huge number of finger production is 2 quintal fresh weight is remaining in the field. + planting material for next year. Table 5 shows that none of the cultivators follow practices are followed in a timely way, as in case standard production/cultivation practices. They do of the ENBEE agro plantation and Fouzdar Krishi not use green manure or bone meal, there is a farm. However, with farmers who did not follow difference in the timing of bed preparation, the timely management practices, the ultimate result quantity of planting material, pretreatment of was low production. The forest department planting material and a difference in the irrigation production was also low but they get a better period. Harvesting practices also differ but quantity of planting material for the next year and production was similar to that in standard save money in that way. cultivation practices, if all the management

Table 6: Comparison of production practices of Safed Musli in monetary terms Activities CEDMAP Fouzdar ENBEE Agro Forest Dept. Farmer Krishi Farm Plantation Cost of 30,000 14,000 6,000 7,000 6,000 planting material Decomposed 2500 1200 600 600 400 Khad Expenditure 1000 1000 1200 3000 500 on land preparation (tilling twice) Bed 2000 1000 2700 500 500 preparation Expenditure 2000 ------on green manure/ mulching Weeding twice 1500 1500 1500 500 300 Plantation cost 2000 500 600 500 300 Harvesting 2500 1000 1000 2000 300 and washing Expenditure 20,000 10,000 10,000 250 500 on drying and peeling Others 2000 ------

Total 65,500 30,200 23,600 14,350 8800 Expenditure

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 6 of 15 Income from crop By selling dry 100,000 180,000 240,000 6000 20,000 Musli Earn as 75,000 No planting No planting 8000 No planting planting material material material material Total Earnings 17,500 180,000 240,000 6000 20,000 Total 65,000 30,200 23,600 14,350 8800 Expenditure Net Profit 90,000 149,800 216,400 No profit 11,200

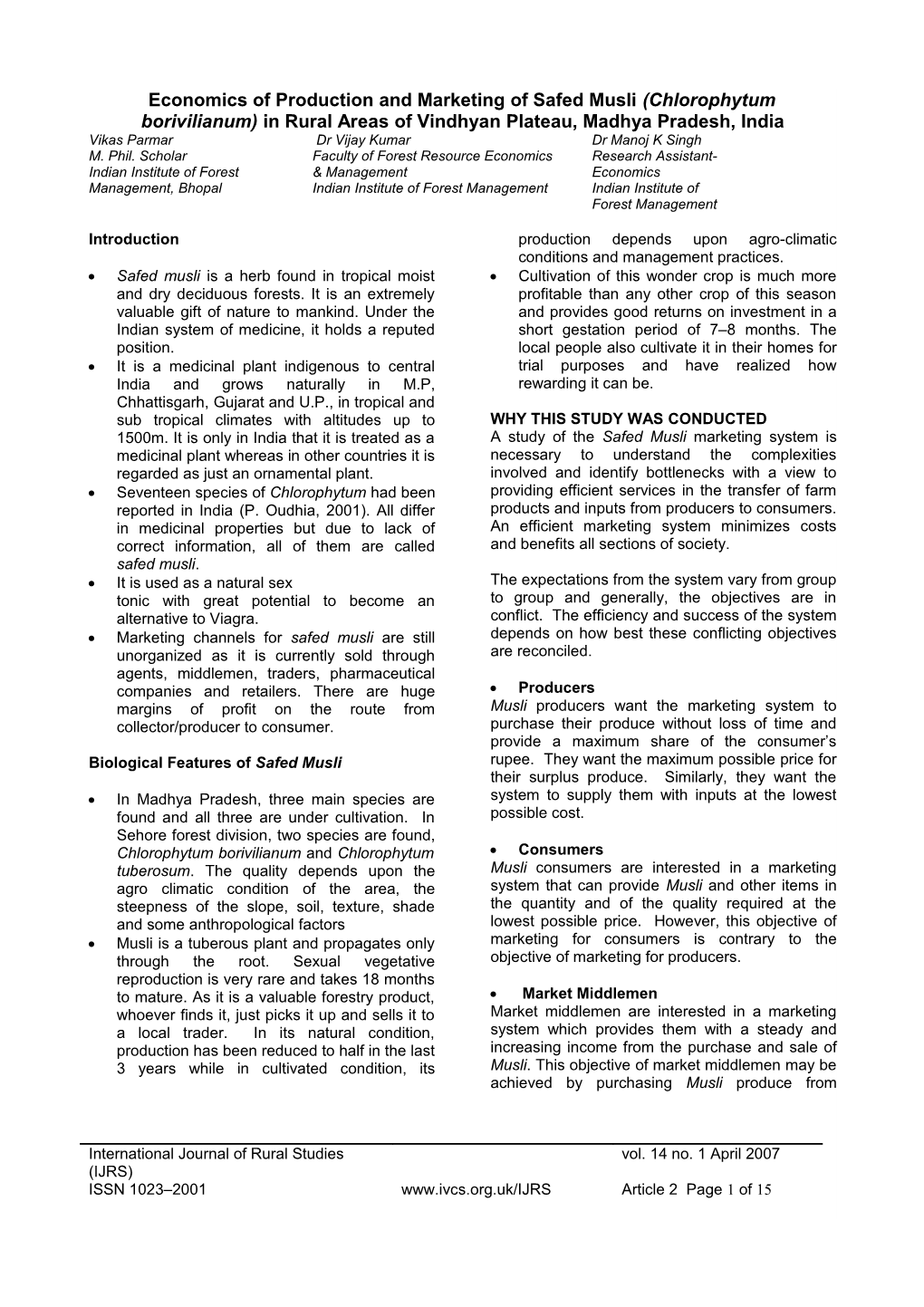

Table 6 shows that the total expenditure in at all, from collector level to consumer level. At cultivation of this wonder crop is quite small in collector level, the price was Rs 35/40 per kg in comparison to net earnings and there is a huge the beginning, increasing to a final price of Rs 60 difference in the economy of Safed Musli -80 per kg. At agent level, the price increases by published by CEDMAP and that actually in the Rs 5 –10 per kg, middlemen made a margin of Rs field. The Fouzdar Krishi Farm invested Rs 30,200 10 - 20 per kg and the consumer paid Rs 80 – per acre and earned Rs149,800 while ENBEE 100 per kg for the same quantity of product. Agro plantation invested Rs 23,600 per acre and earned Rs 21,600 from this crop. Farmers earned The second graph shows the price spread of the least profits but even so, more than they did processed Musli where the collector got only Rs for any other crop growing in this season. 800-900 per kg while for the same quantity, the final consumer paid Rs 3000 per kg although no Price Spread and Associated Issues value addition took place except grading and 1 – 2 The first graph shows the price spread/ marketing days drying. channel of wet Musli where no value was added

Price spread of wet/unprocessed S a f e d M u s l i 90 80 70

e 60 c

i 50 r 40 P 30 20 10 0 r r t n e to n e m c e m u le g e s l A l n o d o c id c l M a in F Person

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 7 of 15 Price spread of dried/processed Safed Musli

12000 10000 8000 e c i

r 6000 p 4000 2000 0

r r r r r o e e le e m t d d i m r c a a a u fo le tr tr t s t l l re n c o l ig u c a b co d m ro s person p

collector vs consumers shares

23%

collector consumer

77%

The third graph shows the gatherer’s contribution village level traders who collect to the final consumer share as the gatherer got wet Musli @ Rs 30 – 80 per kg, only 23% of the total money that the consumer dry it in bright sunlight for 1 –2 actually paid and the consumer paid 77% more weeks and store it for 2- 3 than the actual cost. All this is due to the months, make a margin of Rs unorganized market. 200- 400 per kg. The agent collects the Musli unprocessed from the collector and sells it to Price spread and value addition of Safed Musli the next level in the same form without processing. For this, Table 7 clearly shows the price spread at various they make a margin of Rs 5–10 levels from agent to big trader per kg. Their job is simply to and pharmaceutical company transport the Musli up the road. with value added at each level. The next person in this series is In the marketing of Safed Musli, the village level middleman who

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 8 of 15 collects the Musli from the agent material and sell it to other parties, making a and sells it to a big plantation margin of at least Rs 500 per kg. For this work company. No other value they have agents whose margin money is 1-2 %. addition is done at this level yet If they purchase 1 kg of Musli @ of Rs 1400 per they make a margin of Rs 15 – kg and sell it @ Rs 2200 per kg they get at least 20 per kg. Rs70 – 80 per kg. Small traders take only processed Musli, dry it for 1-3 days and grade it, for which they make the margin of at least Rs150 – 300 per kg the big traders just contac small traders, purchase their

Table 7: Price spread and value addition to Safed Musli at agent and trader levels Agent / Species Year Purchasing price Selling price Turn over Value addition traders (in Rs/ kg) (in Rs / kg) (in Wet Dry Musli Wet Dry Musli quintal) Musli Musli Village Chlorophytum 2002 30 – 80 ------800 - 1000 1 - 1.5 Dried and level borivilianum stored it. trader Agent Chlorophytum 2002 30 – 50 ------40- 60 ------~ 50 No value borivilianum addition except transport to road. 2001 25 – 35 ------30 -40 ------~60 No value addition 2000 15 – 25 ------20 30 ------80 - 90 No value addition. Middle- Chlorophytum 2002 40 – 60 ------80 ------40 - 50 No value men borivilianum addition 2001 40 -45 ------60- 65 ------50 - 60 No value addition City Chlorophytum 2002 ----- Grade1 : ----- 1100 – 1300 1 – 1.25 Graded and level borivilianum 350 – 400 dried it. traders Grade 2 : 800 – 950 2001 ------500- 600 ------700 – 800 4 – 5 Graded and dried it. 2000 ------200 – 250 ------400 – 500 7 – 8 Graded and dried it. Big Chlorophytum 2002 ------1300 – ------2100 – 2200 30 – 35 No value traders borivilianum 1400 addition. 2001 ------1200 – ------2000 – 2100 40 – 45 No value 1300 addition. Pharma Chlorophytum 2002 ------2100 – ------2400 – ~5 Powdered and ceutical borivilianum 2200 10000 capsule form. firm

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 9 of 15 Table 8 : Mode of Advance Payment for Safed Musli Sub Range Beat Time of Type of advance payment division advance Kind payment Cash Budhni Budhni Khatpura ------Bhimkothi June-July Rs 100-200 Samnapur May- July Wheat, rice and other household grocery Hoda May – July Wheat, rice and other household grocery. Dungariya ------Raeti Salkanpur ------Khanpura June - July Rs 100-300 Semri ------Ratanpur ------Khajuri ------Dhaba ------Larkui Sewaniya ------Bilakhara June-July Rs 100-200 Mograkhara ------Bhoorakhara June-July Rs 100-200 Piplani ------Donglapani ------Sehore Birpura Lohapahar ------Saras ------Kathotia ------Baweriyakha ------Table 8 shows the time and mode of advances advances, a certain quantity and price is prefixed which are given in both cash and kind in the but when the supply of the quantity at a prefixed summer before Musli collection. The collector only price is in excess, then it becomes a free market receives Rs 100-300 in cash, depending on the price. The advances given in kind are generally quantity. The trader gives cash to the head/chief cereals/grains and other items of consumption of the area who distributes it to the collector and valued at minimum existing market prices. collects the Musli. At the time of extending

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 10 of 15 Flow Chart 1: Marketing ChannelsTribal and collectors Margin in the trade of Safed Musli Rs 30 - 80 per kg for wet Musli Dried Musli: Rs 500 - 700 per kg

Agents Rs 5 -10 kg margin for wet Musli No margin for dry Musli

Local village level traders Wet Musli: Rs 40 - 80 per kg Dry Musli: Rs 500 - 700 per kg

Small traders Dry Musli : Rs 800 - 1000 per kg

Big traders Dry Musli: Rs 1200 - 1400 per kg

International Journal of Rural Studies Retailersvol. 14 no. 1 April 2007 (IJRS) Rs 2100 - 2200 per kg ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 11 of 15

Consumers Rs 3000 per kg Pharmaceutical companies Rs 2100 - 2200 per kg

The above figure shows the marketing channel of grows naturally in the forest, it is spread over Safed Musli from collector to consumer level. The 18.6% of the total forest land area in Sehore collector invests 10 – 12 hr/day to collect Safed forest division and this has been the case for Musli and gets Rs 30 – 80 per kg for unprocessed many years. However, production under natural Musli if they sell it directly to the trader but if they conditions is continuously decreasing due to sell it through an agent, then it makes a difference complete uprooting of the plant. Under cultivated of Rs 5–10 per kg from the market price and Rs condition, its area is continuously increasing. 500 – 700 per kg for processed Musli which is sold directly to traders; agents do not purchase it. Regarding different cultivation practices (i.e. The local village level trader collects both farmhouse technique, nursery technique, single processed and unprocessed Musli and sells only bed technique), it hardly makes any difference in processed Musli to small traders @ Rs 800 – yield level if all cultivation practices are followed in 1000 per kg. These traders dry and grade it and time. Weeding has an adverse effect on sell it to big traders @ of Rs 1200 – 1400 per kg. production as compared to irrigation. If weeding They sell it to pharmaceutical companies and is not done at all, then the Musli dies under the retailers @ Rs 2100 – 2200 per kg. Finally, the soil but if irrigation is not done, the same amount consumer pays Rs 3000 for the same quantity of of Musli is still produced. Musli although the price varies widely depending upon the quality. Cultivators did not follow all stages of standard cultivation practices as they did not grow green manure nor apply bone meal nor make any time CONCLUSION difference in planting or quantity of planting Sehore forest division is most suited for both the material, pretreatment of planting material, cultivation and natural growth of Safed Musli due irrigation period, harvesting time or harvesting to its agro-climatic conditions. Under natural period. Despite this, their production was still conditions, it is found in both steep and less steep similar to the standard one. A detailed economic areas, and on sandy loam and mooram soil. It is study on resource use efficiency would be useful. rarely found in the plains. This study concludes that there is a huge difference in quality and Regarding distribution and marketing practices, production of Safed Musli between two there is a huge difference in the price of Safed subdivisions as well as in the different ranges of Musli among ranges of the same subdivision. In the same subdivision. A better quality of musli is Budhni, range collectors get only Rs 30–40 per kg available in Budhni subdivision and within the while in Larkui collectors get Rs 60-80 per kg. subdivision, in Budhni range in comparison to Raethi and Larkui Forest Range. Marketing channels for Safed Musli are informal and unorganized. Intermediaries and traders Cultivation practices show that people are keenly have a strong grip over the market and take interested in the cultivation of Musli. Where it

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 12 of 15 advantage of this situation. There is no parameter REFERENCES: for pricing in the study area. As produce moves Ambasta, S.P (1986). The useful plants of India. published by from collector to big trader, the value addition publication and information directorate CSIR , New Delhi. portion goes down and marketing margins per kg Page 121. increase. The agent gets Rs 5–10 per kg and the Arora, A.K and Anjula Pandey (1996). Wild edible plants of big trader Rs 500–700 per kg, a surprising and India diversity, conservation and use. Page 12 , 13 , 42. unbalanced situation but due to the increase in Bhatnagar Pratibha (2002) Conservation and trade of the number of intermediaries from collector to medicinal herbs: a study of Safed Musli (Chlorophytum consumer. The collector who works 10–12 hours borivilianum spp.) in M.P. sustainable forestry , May – Dec. per day gets at most a 23% share of the price 2002. Vol. 7 (2 and 3). Page 11 – 14. actually paid by the consumer. The remaining Bhatnagar Vishnu (2001). A community based marketing 77% goes to intermediaries, agents and traders. information system for non wood forest products in M.P. This situation should be rectified by providing sustainable forestry, Jan.- June 2001. Vol. 6(1):1. Page 11 – 13. training to various intermediaries and agents in processing, grading, packaging etc. At the same Bhatnagar Pratibha (1997 ). Need for conservation of time, these intermediaries should be minimized to medicinal plants in M.P.. sustainable forestry. Vol. 2 (4). Page no. 3 – 8. a justifiable limit of their existence in the business system. Bhattacharya , P.(2000)A village level workshop on community based sustainable management of medicinal plant in M.P.IIFM newsletter . vol.(l), March.2000. This crop can probably only be harvested for the next two years as the species is disappearing. It Bhattacharya A.K and Regina Hansda (2003). Exsitu is threatened locally because of the huge amount conservation of medicinal and aromatic plants in India with special reference to Madhya Pradesh. The Indian forester. of wild, unsustainable and premature harvesting Vol. 129 . Jan. 2003. Page 93 – 101. from the forest. An equal quantity of re-planting does not take place to compensate for that loss. Chopra , R.N , I.C.chopra and S.L.Nayer (1969) . Glossory of Once the plant is harvested, reseeding never Indian medicinal plants. Page 62 occurs because Musli is a tuberous plant which Colonel , H , K.R. Kirtikar , F.L.S., I.M.S. (Retired). Major germinates by tuber only; sexual reproduction B.D.Basu , M.R.C.S.(Eng.), I.M.S. ( Retired) and Ani.C.S. (Retired)(1996). Indian medicinal plants. Sec. Edi. , vol. 2. through seed is very rare in this plant. Page 2449 – 2502.

Dr. Suman, Ravish M.D (ll). and Prof. M. Sharma. Safed Musli Various observations were made about – A wonder herb with global opportunity. National Institute of unsustainable and unscientific harvesting Ayurveda Jaipur(Rajesthan ) . practices in all four ranges. The most prominent Dymock William , C.J.H. Warder and David Hoopen . reasons were: an increase in competition among Pharmacographia indica – A history of the principle drugs of collectors to collect more and more as this plant is vegetable origin. Vol. 1. Page 451- 452. a cash crop; informal and unorganized market Garial , G.S (2000 ). Aushydhi Ayum Sungandhiya poudha . channels where traders have a strong grip over cedmap publication (June 2000).Sec. Edi. Page 39 – 48 the market because they provide quick credit for the collector’s product and demand for the next; Garial , G.S (2000 ). Aushydhi Ayum Sungandhiya Poudha . cedmap publication (Dec. 2000).Sec. Edi. Page.39 – 48 they also give advances before the season starts; collectors have a readymade market for the trader Gautam , P.L , B.M Singh and Neelam Sharma comes to him to purchase the product. (1998 ).Bioprespecting and conservation of non timber forest product vis – vis Medicinal and aromatic plants : some approaches of forest management, International journal of To maintain future availability of Safed Musli, the center of minor forest products(1998 ). Dehradun India. Page plant must be nurtured and protected. There must 143 – 150. be immediate checks on present harvesting Geetha K.A. and Satyabrata Maiti ( 2002) Variability in roots practices; the plant should only be collected when of Safed Musli. ICAR news A science and technology it is mature; the entire plant should not be pulled Newsletter . Jan. – March 2002. Page 15 – 16 out; only big Musli should be harvested; Gera, Mohit, N.S. Bishat and A. K Rana.(2003). Market cultivators should be encouraged to cultivate it at Information system for sustainable management of medicinal home in their kitchen gardens; training on plants. The Indian forester .vol. 129. Jan.2003.page 102 -,108. scientific production should be given so that they are processing-oriented rather then harvesting- Guhabakshi , D.N , P. Sensarma and D.C. Pal ( 1999). A oriented. lexicon of medicinal plants in India. Page 428. Kaushik Purshotam and Anil Kumar Dhaman (2000). Medicinal plant and raw drug of India, Page 568,571.

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 13 of 15 Patnaik, Suprava (1998). Conservation assessment and Kaushik Purshotam . Indigenous medicinal plants ( include management planing workshop for NTFP in M.P. 16 – 18 microbes and fungi ).Page 175. June1998.Indian Institute of Forest Management, Bhopal.

Kumar Ashok (2001).Botany in forestry and environment. Page Prajapati Narayandas (2002). Jari – butioo ki sarel khati. 371 , 599. Rajesthan Agroforestry Corporation , Jodhpur (2002) . Page 86 – 91. Lanska Dagmar( 1992). The illustrated guide to edible plants. Page 10 , 11, 17. Prasad, R, P.C.Kotwal and Manish Mishra (2000). Draft report on standardizing methodology for sustainable harvesting of Maheshwari , J.K (2000). Ethnobotany and medicinal plants of some important NTFP species in M.P. Indian institute of forest Indian subcontinent. Page 259- 263. management, Bhopal.

Mittal , G.D. (1999 ). Safed Musli – The much sought after Prasad , Ram (2001) . Unsustainable extraction of bio diversity medicinal crop. Science tech. and entrepreneur vol.7 (2). raised question on future of Indian system of medicine. IIFM Page 19 – 22. newsletter. Vol.(lll).Sept.2000.

Muraleedharan , P.K , N Sasidharan and K.K Seethalakshmi Prasad ram and Pratibha Bhatnagar (1991).Socioeconomic (1997 ).Biodiversity in tropical moist forest: Study of potential of minor forest produce in M.P. Bulletin no.26.State sustainable use of non wood forest product in western ghat of forest research institute ,Jabalpur. Kerla. Kerla forest research institute , Peechi , Kerla. Prasad Ram and Manish Mishra . Documentation of Nadkani , K.M ( 1976). Indian meteria medica . vol . l. page unpublished literature / reports on non timber forest products 399. ( 1989 – 2000 ). IIFM , Bhopal.

Nautiyal , A.R , M.C. Nautiyal and A.N. Purohit (1997) . Pullaiah ,T(2002). Medicinal plant in India . vol . l .Regency Harvesting herbs – 2000 medicinal and aromatic plants an publication, New Delhi. Page 152 – 154 . action plan for Uttaranchal. Page 32. Ram Prasad. 2000. Unsustainable extraction of Bio- diversity Nayer , M.P, K.ramomurthy and V.S Agarwal(1989). Economic raises question on future of Indian system of medicines. IIFM plants of India. vol.1 New latter Vol. III (3), September 2000.

Oudhia , P (2000a ) Can we save the endangered medicinal Rastogi Ram Prasad and B.M. Mehrotra (1993). Compendium plant Safed Musli (Chlorophytum borivilianum ) in Indian of Indian medicinal plants. Vol.3.published by central drug forests ? http:/ www.herb.com / poudl.html, July – Aug, 2000. research Institute , Lucknow and publication and information directorate, New Delhi(1993). Page 165. Oudhia , Pankaj (2002, 2003). Aphrodisiac of chattisgarh traditional medicinal knowledge about common herb used as Roy, B , A.C.halder and D.C.Pal ( 1998). Plants for human sex tonic in chattisgarh , India.(wwwbotanical.com). consumption in India. Page 46. Oudhia , Pankaj (2002, 2003). Harvesting processing and trading of wonder crop Musli (Chlorophytum borivilianum) my Sarni Y.K. (2003). Medicinal plant raw material for Indian drug research and experience, Chhatisgarh,India . and pharmaceutical Industry- An appraisal of resources. The (wwwbotanical.com) Indian forester. Vol. 129. Jan.2003.

Oudhia , Pankaj (2001a). My experiences with wonder crop Seminar proceeding on harvesting of non wood forest Safed Musli. In : souvenir. International seminar on medicinal products, Menemen – izimir , Turkey 2 – 8 Oct. 2000. plants and quality standardization , VHERDS . Chennai , India, 9 – 10 June. Sharma , P.K and P.M. Patel. Safed Musli – A valuable herb. BAIF development research foundation. Oudhia, Pankaj (2001b).Problem perceived by Safed Musli ( Chlorophytum borivilianum) grower of Chattisgarh( India ) Sharma Ravindra .Agro. technique of medicinal and aromatic region : A study. Journal of medicinal and aromatic plant plants . Page 215 – 218. sciences 22/4A and 23/1A Page 396 – 399. Singh , S. P., H.P. lhungdim , Dr. Manish Mishra and B.R. Oudhia , Pankaj (2002, 2003 ). My experience and experiment Phukan.(2000) utilisation pattern of medicinal plants amongthe with wonder crop Safed Musli ( Chlorophytum Bhariyas of patalkot and their sustainablity. IIFM newsletter. borivilianum ).Chattisgarh, India.(www.celestine-india.com). vol. .(lll).Dec.2000.

Oudhia , Pankaj (2002, 2003). Interaction with the traditional Singh, V.K and Zaheer Anwer Ali. Herbal drugs of Himalaya healers and natives of Bhopalpatam region Chattisgarh , (medicinal plants of Garhwal and Kumaon region of India). India .(www.botanical.com). Page 37.

Oudhia Pankaj (2002,2003). Traditional medicinal knowledge Singh Umrao (Genetics Division IARI , New delhi ) , A.M. about common herb used in woman care after delivery ( post Wadhwani (1983). (Publication Division, ICAR, New Delhi ) natal ) in Chattisgarh .(www.celestine-india.com). and B.M. Jorhi (Dept. of Botany , University of Delhi, Delhi). Dictionary of economic plants in India. Page 49. Pandey R.K and S.K. Sahni . Parthenium : threat to biological diversity of natural forest ecosystem in M.P – A case study in Sinha, Rajiv Kumar (1996) . Ethnobotany the Ranaissance of people protected area of baiga chak , Dindori forest division. traditional herbal medicine. Page 70 , 141 – 145 , 211. State forest research institute , Jabalpur. Wong , J.L.G , K. Thornberg and M. Baker (2001 ). Resource assessment of non wood forest product : Experience and

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 14 of 15 Biometrics principle. Food and Agriculture Organisation Rome , Italy. http://www.baif.com http://www.herb.com http://www.ikisan.com http://www.indiaagronet.com http://www.indiainfoline.com http://www.kgnherbal.com http://www.omendrugs.com http://www.sandhyapharma.com http://www.vedicherbal.com

International Journal of Rural Studies vol. 14 no. 1 April 2007 (IJRS) ISSN 1023–2001 www.ivcs.org.uk/IJRS Article 2 Page 15 of 15