Code of Practice 1. Introduction surfacing is required. It has a minimum plasticity index requirement and may have additional requirement for maximum This Code of Practice describes the process to be permeability when used for heavy duty undertaken when registering any crushed rock unbound pavements. Recycled materials mix (including cement treated crushed rock) for are not permitted for this purpose. use in conjunction with relevant VicRoads Standard Specification for Roadworks and Bridgeworks (including Sections 812, 815 & A high quality pavement base material for 818). unbound flexible pavements in locations where a very high standard of surface A crushed rock is a material composed of Class 2 preparation may not be required. Class 2 graded coarse and fine aggregate components crushed rock does not have a minimum produced by the crushing, scalping and plasticity index or a maximum screening of a raw rock feed source, Newer permeability requirement. Basalt Surface Spalls (NBSS) and/or crushed concrete, and may also be a blend of A high quality upper subbase material for components which includes limited quantities of heavy duty unbound flexible pavements. supplementary materials. It may have a minimum permeability requirement to provide positive drainage A crushed rock mix must be registered for any to the sub-surface drains and overlying crushed rock product supplied to VicRoads unbound pavement layer. Where funded works. This includes Class 1, 2, 3 and 4 specified, Class 3 may be used as base for crushed rock and manufactured Type A Class 3 lightly trafficked pavements provided the material. material produces sufficient cohesive fines The registration of a crushed rock mix will not during compaction. be permitted, where it is intended that different It is also commonly used as a cement source rock types be combined during the treated subbase layer in deep strength primary or secondary crushing processes. asphalt pavements. Registration in accordance with this Code A lower subbase material for heavy duty of Practice does not warrant the unbound and/or bound pavements or a adequacy of the production, delivery, Class 4 subbase for most other types of placement or compaction processes and pavements. It may have a maximum does not guarantee the handling permeability requirement. properties or performance of the crushed rock mix. Submitted mixes must comply with the relevant physical properties in Section 3 and any other specified requirements applicable for that particular class of crushed rock, unless otherwise approved by VicRoads.

2. Definitions

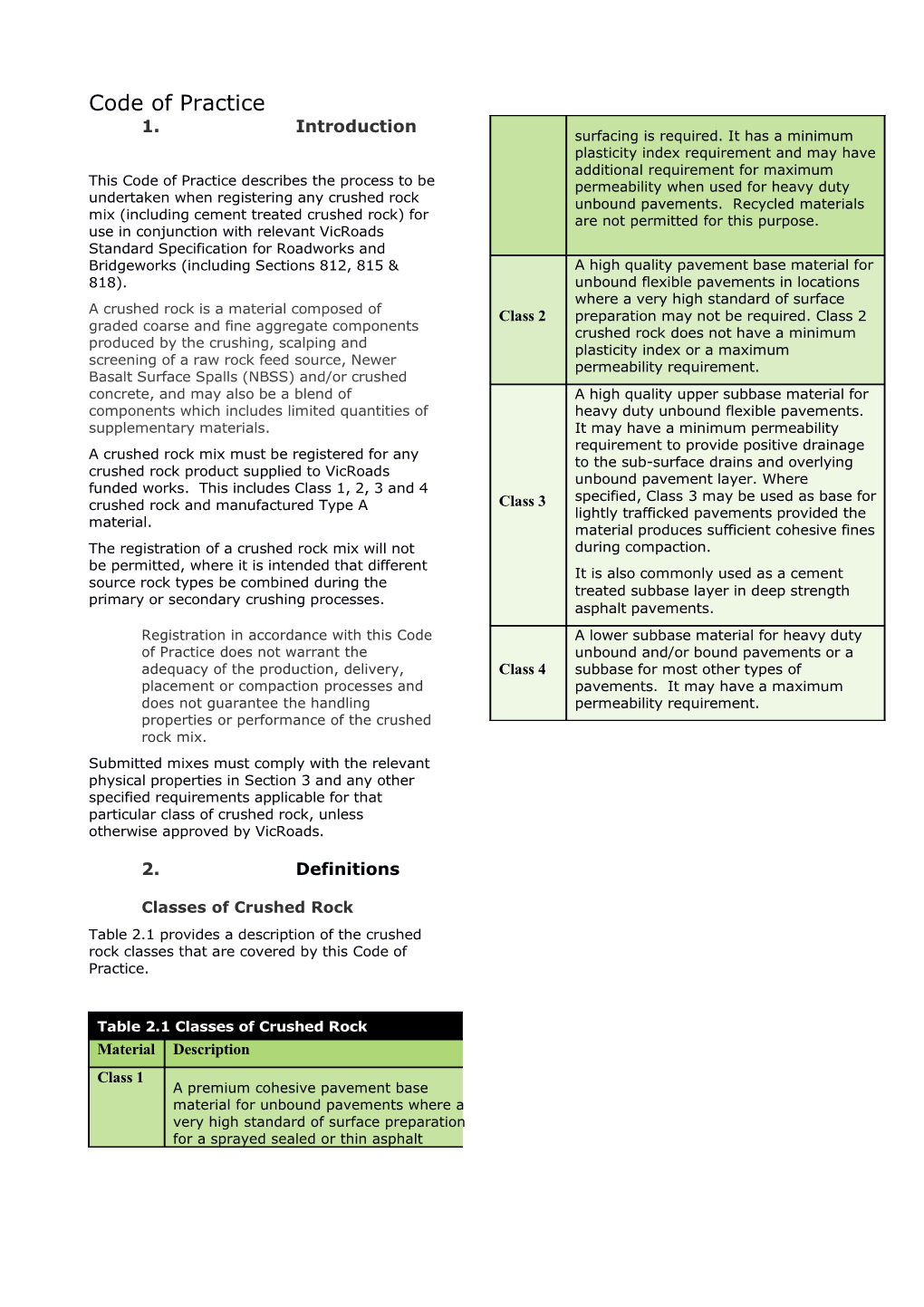

Classes of Crushed Rock Table 2.1 provides a description of the crushed rock classes that are covered by this Code of Practice.

Table 2.1 Classes of Crushed Rock Material Description Class 1 A premium cohesive pavement base material for unbound pavements where a very high standard of surface preparation for a sprayed sealed or thin asphalt

RC 500.02 March 2015 Version: 13 Page 1 of 9 Code of Practice Other Definitions VicRoads funded projects shall be registered and current prior to the commencement of the Assigned Los Angeles Value supply to any works. The assigned Los Angeles Value (LAV) is a hardness rating derived from Los Angeles Value Sources used in crushed rock mixes must test results on representative crushed rock conform to the applicable requirements in products during VicRoads accreditation process. Standard Section 801 - Source Requirements for The value is assigned to each source by the Production of Crushed Rock and Aggregates. VicRoads on an annual basis. Crushed rock mixes submitted for registration Cement Treated Crushed Rock must comply with the applicable requirements of this Code (refer Section 3) and where relevant, Cement treated crushed rock (CTCR) is a any other requirements contained in VicRoads registered mixture of crushed rock, cement and Standard Sections 801, 812, 815, 304 and 204, water produced at a controlled mixing plant to unless otherwise approved by VicRoads. close tolerances of grading, moisture content and binder content. Crushed rock mixes submitted using accredited quarry sources will be registered for all classes Coarse & Fine Aggregates of crushed rock. Those mixes which contain For the purposes of this Code, fine aggregate appreciable recycled material components shall be the portion of the crushed rock mixture (including NBSS) will generally be registered for passing the 4.75 mm AS sieve, and coarse Class 3 crushed rock or lesser products and aggregates shall be the portion of the crushed conditions may apply. rock mixture retained on the 4.75 mm AS sieve. Class 2 crushed rock containing recycled materials (>10% in total) will be generally Supplementary Material registered for light duty pavements only (<3500 AADT and <10% heavy vehicles). A durable material added to a crushed rock to improve its workability and physical properties. Any component of a crushed rock mix which is imported from either a different source or Crushed Brick location within a quarry/recycling facility, or Crushed brick is a crushed material which manufactured from a different sources to that of principally consists of crushed fired brick, but the primary coarse aggregate source will be may also contain crushed concrete, aggregate regarded as a supplementary material. and concrete paste. Mud brick or non fired brick Crushed rock products may contain crushed or shall not be used. appropriately processed supplementary Glass Fines materials (such as concrete, brick, recycled glass, slag, clayey sand, clay filler, etc) provided Glass fines are recycled glass cullet crushed to a the permitted maximum percentage (by mass) cubic shape and passing the 4.75 mm AS sieve. of supplementary material for that class of Light Duty Base Pavement crushed rock and that registered mix is adhered to. Light duty base pavement is the layer directly beneath the bituminous surfacing on lightly Components of crushed rock blends must trafficked roads (i.e. roads carrying <3500 individually comply with the relevant AADT and <10% heavy vehicles). requirements of Section 3, prior to Plant Mixed Wet Mix Crushed Rock blending, unless otherwise approved by VicRoads. Plant mixed wet mix crushed rock (PMWMCR) is a mixture of crushed rock and water, produced All testing associated with crushed rock mixes, at a controlled mixing plant to close tolerances crushed rock products and crushed rock of moisture content based on the modified components shall be undertaken in accordance Optimum Moisture Content (OMC) of the with relevant VicRoads Codes of Practice material. (including RC 500.16 - Selection of Test Methods for the Testing of Materials and Work), 3. Crushed Rock and any referenced VicRoads Standard Specification Sections and Test Methods as Mix specified in VicRoads Standard Section 175 at Crushed rock mixes nominated for use on the time of contract award.

RC 500.02 March 2015 Version: 13 Page 2 of 9 Code of Practice The registration of a crushed rock mix may only with the requirements of Tables 3.13 and all apply to a specific project or pavement other sources with LAV≥26 shall comply with construction application due to the application of Table 3.14. special or different requirements in some specifications (e.g. permeability requirements). Table 3.13 – Grading Limits for 20 mm Class 3 CR for sources with a LAV ≤ 25 A crushed rock mix can be registered with or without submitting permeability values. However, where a crushed rock mix is proposed for use on a VicRoads contract with specified permeability requirements; the Supplier will be required to submit test reports with conforming permeability values.

3.1 Grading of Uncompacted Class 1, 2, 3 & 4 Crushed Rock & PMWMCR Table 3.14 – Grading Limits for 20 mm After completion of production, but before Class 3 CR for sources with a LAV ≥ 26 compaction, Class 1, 2, 3 and 4 crushed rock products and PMWMCR must comply with the relevant grading requirements of Tables 3.11, 3.12, 3.13, 3.14 and 3.15 corresponding to the assigned LAV of the material source. The grading of 40 mm Class 3 crushed rock with an assigned Los Angeles Value ≤25 shall comply The grading of the crushed rock product shall with the requirements of Tables 3.15 and all not extend from the coarse limit on one sieve to other sources with a LAV ≥26 shall comply with the fine limit on the following sieve or vice Table 3.16. versa.

The target grading of the submitted crushed Table 3.15 – Grading Limits for 40 mm rock mix shall be at or near the centre of the Class 3 CR for sources with a LAV ≤ 25 specified grading envelope. The target grading may be varied from time to time to achieve the specified post-compaction grading outcome. The specified grading limits shall remain unchanged regardless of the target grading.

Class 1 and 2 Crushed Rock The grading of 20 mm Class 1 or 2 crushed rock with an assigned Los Angeles Value ≤25 shall comply with the requirements of Tables 3.11 and all other sources with LAV≥26 shall comply with Table 3.12.

Table 3.11 – Grading Limits for 20 mm Table 3.16 – Grading Limits for 40 mm Class 1 or 2 CR for sources with a LAV ≤ Class 3 CR for sources with a LAV ≥ 26 25

Grading of Uncompacted Class 4 Crushed Rock & PMWMCR Class 4 crushed rock of nominal size differing from that specified may be accepted for Table 3.12 – Grading Limits for 20 mm registration provided it meets the grading Class 1 or 2 CR for sources with a LAV ≥ requirements of Table 3.17 corresponding to a 26 nominal size adjacent to that specified.

Class 3 Crushed Rock The grading of 20 mm Class 3 crushed rock with an assigned Los Angeles Value ≤25 shall comply

RC 500.02 March 2015 Version: 13 Page 3 of 9 Code of Practice

Table 3.17 – Grading Limits for Class 4 CR 3.2 Physical Property Requirements of Class 1, 2, 3 & 4 Crushed Rock

The registered crushed rock mix will comply with the physical property requirements listed in Tables 3.18, 3.19, 3.20 and 3.21, where applicable, for that class of crushed rock.

Note, Standard Section 812 also requires that any crushed rock product in stockpile (prior to compaction) be tested at the frequency specified in Table 812.101 to demonstrate that these specified physical properties of the registered crushed rock mix are consistently met.

Additional testing of the crushed rock mix may also be specified as part of the conditions for registration of the submitted crushed rock mix.

These typical physical properties include Liquid Limit, Plasticity Index, California Bearing Ratio (CBR), Flakiness Index, and Los Angeles Value as per Table 3.18.

3.

RC 500.02 March 2015 Version: 13 Page 4 of 9 Code of Practice

3.3 Unsound Rock & Foreign Materials Table 3.18 shall apply, unless otherwise Content of Class 1, 2, 3 & 4 CR approved by VicRoads.

In addition to the requirements of Table With respect to clayey sands and clay 3.18, crushed rock shall be tested (as filler, the supplementary materials added applicable) for Unsound Rock Content must comply with the requirements of and Foreign Materials as per Table 3.19 Table 3.21 below. and Table 3.20. Table 3.21 – Grading & Other Unsound rock and marginal rock in that Requirements for Clayey Sand and Clay fraction of the crushed rock product Filler retained on a 4.75 mm AS sieve shall not exceed the percentages specified in Table 3.19. The amount of any clay filler added must Table 3.19 - Unsound and Marginal Rock not exceed 1.5% of the total dry mass of Content the crushed rock product.

Recycled crushed products which contain higher percentages of crushed brick and glass than those specified in Table 3.20 Foreign materials in that fraction of the shall have a wet strength not less than crushed concrete product retained on a 100 kN and a wet/dry strength variation 4.75 mm sieve shall not exceed the not greater than 45 when tested in percentages by mass specified in accordance with AS 1141.22. Table 3.20.

Table 3.20 – Foreign Material (Max Allowable %)

(1) Higher percentages of crushed brick & glass may be permitted as a supplementary material in a registered crushed rock mix.

Where a Crushed Rock is a blend of crushed rock and crushed concrete, both of the above tests shall be undertaken on the individual components prior to blending.

Where a registered mix allows a higher percentage of crushed brick or glass fines to be used; the percentage of unsound rock or foreign materials is to be determined on the total dry mass of the test sample.

3.4 Supplementary Materials

Supplementary materials may be included into a crushed rock mix to improve its workability and physical properties. Supplementary materials must be durable and not subject to appreciable breakdown.

Where supplementary materials are included as a component in a crushed rock mix, the maximum limits set out in

RC 500.02 March 2015 Version: 13 Page 5 of 9 Code of Practice 3.5 Cement Treated Crushed Rock performance and immediately advise the Contractor of action taken. Registration of cement treated crushed rock mixes will require the applicable requirements of the Code to be met prior to the addition of any binder. The submission of cement treated crushed rock containing supplementary materials such as crushed brick and glass fines will be initially limited to light duty pavements only (<3500 5. Mix Status AADT and <10% Heavy Vehicles). All crushed rock mixes registered with VicRoads are issued a status according to compliance as: 4. Mix Registration General A crushed rock mix which fully complies with the Applications to register a crushed rock mix shall requirements of this Code of Practice. be submitted by the Supplier to VicRoads (Technical Services, 12 Lakeside Drive Burwood Conditional East) at least two weeks prior to the proposed A crushed rock mix which does not comply in all date for the commencement of supply of the respects with the requirements of this Code of mix and shall be accompanied by the Practice, but is considered appropriate for use information listed in Clause 6 - Submission of subject to conditions attached to the Mix for Registration. registration. The Supplier shall nominate a mix identification Expired number for each mix and this number shall be A crushed rock mix that has passed its expiry used to identify the mix for all future job records date or a mix that has not been re-registered. and communications. Withdrawn Registered crushed rock mixes nominated for A crushed rock mix that has been withdrawn use on VicRoads funded projects shall appear on from use due to unsatisfactory field the VicRoads Crushed Rock Mixes database performance, but whose details are retained for current at the time of the commencement of the record purposes. supply of the mix to the project. The registration of the crushed rock mix shall 6. Submission of remain current for a period of two years subject Mix for Registration to there being no changes to the source or grading of the aggregate components or the source or nature of the additive. Registration Information Required can be extended beyond two years with the The following information shall be submitted for agreement of VicRoads and the Superintendent each new crushed rock mix (The Supplier may of the project on which the crushed rock mix is use Appendix A to provide a guide to the to be used. information to be submitted): New crushed rock mixes shall be submitted 7. Supplier Identification; for registration where it is proposed to change the source, grading or nature of the 8. Crushed Rock Class; components; and current registered 9. Supplier’s crushed rock mix number; crushed rock mixes are more than two years old. 10. Proposed date of commencement of supply if applicable; The Supplier will be advised in writing of the 11. Components proposed and source of result of the application to register a crushed each component including additives; rock mix and any conditions attached to the registration. 12. Assigned Los Angeles Value (Hardness) of source rocks from which components If a registered mix has unsatisfactory handling are to be supplied; or field performance, the Supplier or Contractor using the product may request VicRoads to 13. Proportion of each component in the mix; withdraw the mix. Alternatively, VicRoads may withdraw the mix pending a review of its field RC 500.02 March 2015 Version: 13 Page 6 of 9 Code of Practice 14. Unsound and marginal rock content Compliance Requirements and/or foreign materials content of the coarse aggregate components; All components of the crushed rock mix shall comply with the relevant requirements of the 15. Grading and Plasticity Index of the Code and where applicable the requirements combined mix; VicRoads Standard Specification Sections. 16. CBR values for the proposed mix where Section 801 - Source Requirements for applicable. Crushed Rock and Aggregates. 17. Binder type, target binder content and Section 812 - Production of Crushed Rock for Unconfined Compressive Strength results Pavement Base and Subbase. for cement treated crushed rock mixes. Section 815 - Production of Cementitious 18. Flakiness Index of coarse aggregate Treated Crushed Rock for fraction of 10mm and above; Pavement Subbase. 19. For crushed river gravels, the proportion Section 818 - Crushed Scoria for Pavement of crushed particles in coarse aggregate; Base and Subbase. 20. Degradation Factor and Plasticity Index The required tests and the testing frequency for for crusher fines components; supplementary materials incorporated in any crushed rock mix shall be as 21. Grading and Plasticity Index of any specified in the individual registered supplementary material component; crushed rock mix. 22. Where specified, the permeability of the mix; 23. Maximum Dry Density and Optimum Moisture Content of crushed rock product using the combined mix and modified compactive effort; and 24. Post compaction grading and PI results, if applicable. All test results shall be current (not more than 3 months old) at the time of submission of the crushed rock mix.

.

Code of Practice – Revision Summary

RC 500.02 Registration of Crushed Rock Mixes

RC 500.02 March 2015 Version: 13 Page 7 of 9 Code of Practice Date Clause Number Description of Revision Authorised by

Principal Advisor - Sept 2012 Full document Re-styled with minor corrections made Pavements and Materials

Revision of various sections on basis of internal March 2015 Full Document comments received

Appendix A - Crushed Rock Mix Registration Form (informative) CRUSHED ROCK MIX REGISTRATION FORM Complete one form sheet for every product to be registered SUPPLIER DETAILS Supplier Name & Date Submitted (e.g. XY Resources P/L)

Quarry / Site Location

Product to be Registered (e.g. 20mm Cl3 CR) Crushed Rock Mix Number (your reference number to identify this product)

Name of Person Completing Form

Contact Phone No.

Contact Email Address

CRUSHED ROCK DETAILS# Optimum Moisture Content & Test Report Attached? Maximum Dry Density Yes No Test Reports Attached? Proposed Target Grading* Yes No Test Reports Attached? Proposed Target Plasticity Index (PI)* Yes No Test Report Attached? Degradation Factor Crusher Fines (if applicable) Yes No Test Report Attached? Class 1 / Class 2 Flakiness Index Yes No Unsound and Marginal Rock Content and/ or Test Reports Attached? Foreign Materials* as applicable. Yes No CBR Strength Values Test Report Attached? (if specified / applicable) Yes No Permeability Test Report Attached? (if specified / applicable) Yes No Proposed Binder Type and Binder Content for Test Report Attached? CTCR Yes No (if specified / applicable) Unconfined Compressive Strength @ 7days (if Test Report Attached? specified / applicable) Yes No SUPPLEMENTARY MATERIALS

RC 500.02 March 2015 Version: 13 Page 8 of 9 Code of Practice Are any supplementary materials added? Yes No

If yes, please supply proposed percentage and description of any supplementary materials Test Report Attached? Supplementary Material Grading Yes No Test Report Attached? Supplementary Material PI Yes No Wet & Dry Strength Variation on Final Product Test Report Attached? (if applicable) Yes No *These should be realistic targets for production. Attach available test reports as supporting evidence. # Test results must be less than 3 months old at the time of submission

RC 500.02 March 2015 Version: 13 Page 9 of 9