RESUME

Personal Details Name: Boumediene Hadidi Profession: Reservoir Engineer Date of Birth: 21 April 1973 Nationality: Algerian Qualifications: B.Sc. and Ms. Petroleum Engineering Languages: English, French, Arabic, Berber. Education: . Master degree in Petroleum Engineering , University of Oklahoma, 2001; . Bachelor degree in Production Engineering, INHC, Boumerdes, Algeria, 1998. Email: [email protected]

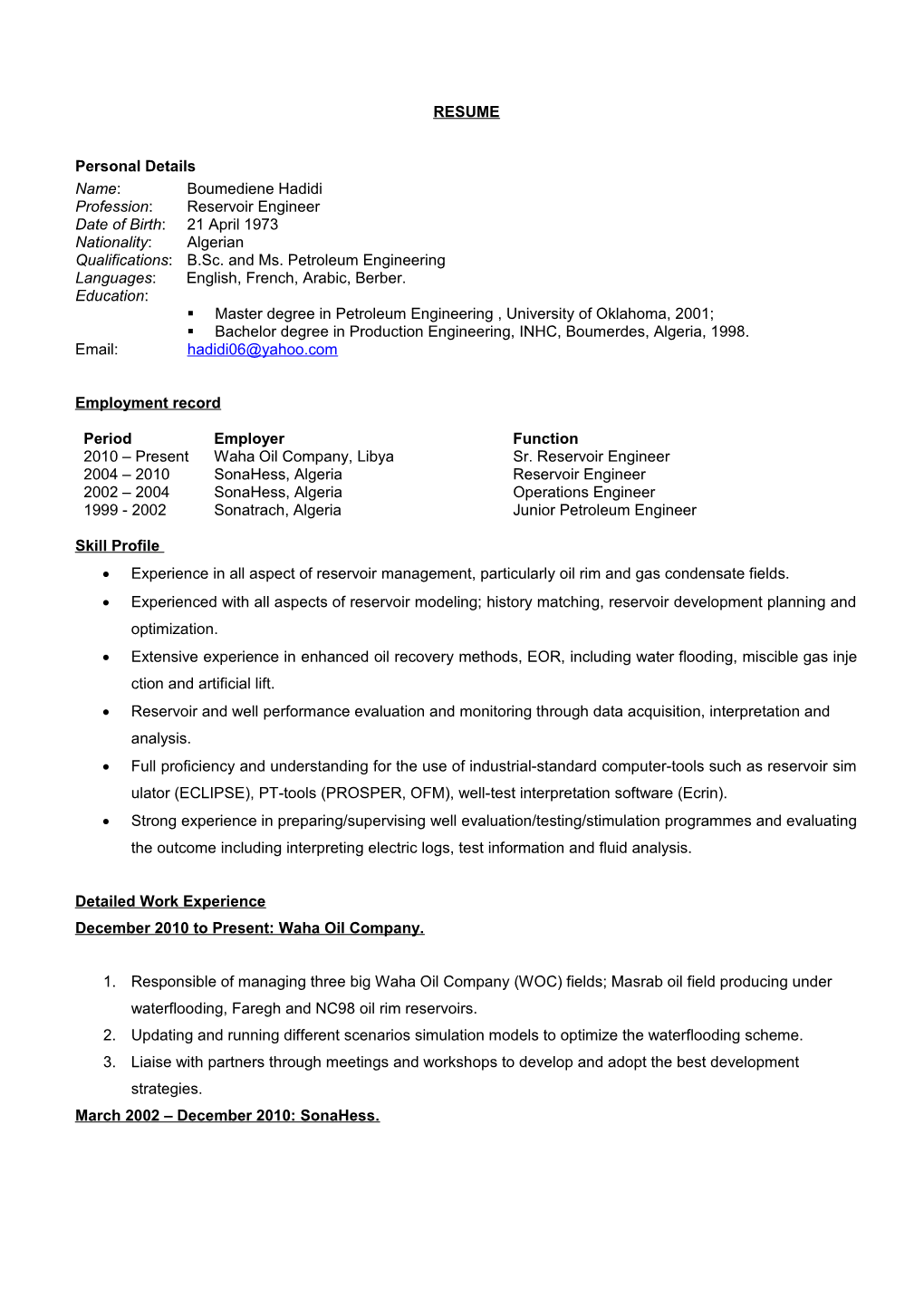

Employment record

Period Employer Function 2010 – Present Waha Oil Company, Libya Sr. Reservoir Engineer 2004 – 2010 SonaHess, Algeria Reservoir Engineer 2002 – 2004 SonaHess, Algeria Operations Engineer 1999 - 2002 Sonatrach, Algeria Junior Petroleum Engineer

Skill Profile Experience in all aspect of reservoir management, particularly oil rim and gas condensate fields. Experienced with all aspects of reservoir modeling; history matching, reservoir development planning and optimization. Extensive experience in enhanced oil recovery methods, EOR, including water flooding, miscible gas inje ction and artificial lift. Reservoir and well performance evaluation and monitoring through data acquisition, interpretation and analysis. Full proficiency and understanding for the use of industrial-standard computer-tools such as reservoir sim ulator (ECLIPSE), PT-tools (PROSPER, OFM), well-test interpretation software (Ecrin). Strong experience in preparing/supervising well evaluation/testing/stimulation programmes and evaluating the outcome including interpreting electric logs, test information and fluid analysis.

Detailed Work Experience December 2010 to Present: Waha Oil Company.

1. Responsible of managing three big Waha Oil Company (WOC) fields; Masrab oil field producing under waterflooding, Faregh and NC98 oil rim reservoirs. 2. Updating and running different scenarios simulation models to optimize the waterflooding scheme. 3. Liaise with partners through meetings and workshops to develop and adopt the best development strategies. March 2002 – December 2010: SonaHess. I worked on multiple projects during my career in GEA fields: 1. Viability and feasibility of the early miscible gas injection pilot project. My main tasks were: Fine grid sector reservoir model definition and simulation; Chemical tracer technology implementation to determine the path of the injection gas; Reservoir management and data gathering; 2. Full Field Miscible Gas Cycling and Recompression (GCR) of El Gassi field to maximize production and maintain the reservoir pressure. A project worth 550 millions $ was signed and currently injecting 110 MMscfd. My main contributions consisted on: Reservoir modeling study, history match (over 40 year’s history); Infill drilling and conversion of oil producer wells to gas injector wells; Reservoir management and data gathering; Daily monitoring of wells performance and gas sampling strategy for tracer breakthrough; 3. Full Field Waterflooding Simulation of El Agreb Field: the project was about evaluating the potential for production improvement and incremental development. Main contributions to the project included: Definition of reservoir model and the identification of zones of possibly by-passed oil; Re-conciliation of past well- and field production performance using Eclipse; Came out with production improvement measures, such as side-tracking of wells, stimulation, shut-off of high water cut zones. 4. Design and implement reservoir surveillance procedures to acquire reservoir information for purpose of reservoir management in a timely fashion. Evaluate and analyze those data and results by retrieving data and interpreting them using Ecrin software (Kappa Engineering Package). Incorporated all the existing welltests in Eclipse update the simulation model. 5. Evaluate incremental oil recovery potential via WAG in miscible reservoirs in Zotti field. Investigated WAG performance and parameters for maximum recovery. Optimized fluid injection; type, amount, timing, combination and distribution. 6. Worked on disposal water wells project. My main contributions were: Simulating the impact of re-injecting the produced water in the reservoir. Injection performance monitoring on a daily basis to keep good injectivity. Control of the water quality through a thorough follow up of the performance of the filtering system. 7. Liaise with Service Company and Operations Department for tracer technology implementation. Take part in technical evaluation of tenders from service companies, select the best service provider. Coordinate the implementation of the chemical tracers and supervise the job execution. Preparation of the sampling schedule and coordinate the shipment of the samples through the M&L. 8. Worked closely with our partner (Hess) to finalize approval for the field development plan (FDP). Active member of joint team responsible for getting all the approvals from ALNAFT (Algerian National Agency for Revalorization and Regularization of Hydrocarbon) representing the government interest. Meet on a monthly basis to evaluate the progress and conformance with the FDP document.

9. Management and interpersonal skills: Participate in weekly and monthly meetings prior for any reservoir management action for OPEC curtailment (production quota). Currently team leader of a multi-disciplined team (geologists, petrophysicists, and reservoir engineers). Meet on a weekly basis. Ensured the team was progressing according to the strategy adopted by the department and make sure everybody adheres to it. Provide help and guidance to junior engineers and ensure their full integration to the department objectives. April 1999 – March 2002: Sonatrach. Experience with remedial plans for reservoir damage caused by Salt, scale, sediment, water blockage and Asphaltene depositions. Identify production enhancing opportunities in existing wells through periodic well reviews. Stimulation in various environments, oil producer wells, gas injectors and producer water wells. Experience with field supervision of Coiled tubing operations ,Nitrogen kick-offs, perforating, electric wireline, downhole camera, fish recovering and Hydraulic fracturing. Very good understanding of Production optimization by Nodal Analysis and artificial lift design ( Gas-lift , ESP pumps) using WEM, Prosper.

Papers 2007: Boumediene Hadidi, SonaHess, Jonathan Ovens, Improved Recovery Consulting. “Modeling and e arly monitoring of miscible gas injection in the tight El Gassi Field, Algeria”. SPE 107155, EAGE, London 2007. Softwares Used . Eclipse 100 & 300 . WEM ; Well Evaluation Model . Prosper ; Nodal Analysis . GAP; Multiphase System optimization . OFM ; Oil Field Manager . Ecrin ; well test Analysis . Maximo, purchase requisition database Trainings

2010: PVT Properties of Reservoir Fluids Course, NeXT, Hassi Messaoud, October 2010 2009: Advanced Reservoir Simulation Course HOT Engineering, Austria, August 2009 2009: Advanced OFM Course SIS Schlumberger, Hassi Messaoud, July 2009 2009: Advanced Eclipse Course SIS Schlumberger, Hassi Messaoud, May 2009 2008: SimOpt SIS Schlumberger, Hassi Messaoud, December 2008 2008: PVTi SIS Schlumberger, Hassi Messaoud, January 2008 2007: Eclipse E300 Schlumberger, Hassi Messaoud, Algeria, December 2007 2007: Saphir software Kappa Engineering, Antipolis, Nice, France 2007 2005: Petrophysics for production optimisation Petroskills, London June 2005

2005: First aid Algeria, March 2005 2004: Production Operation Petroskills, Houston, USA November 2004 2003: Eclipse Schlumberger, London, August 2003 1999: TOEFL Language solution, London, July 1999