MEM 504: Quality Engineering Assignment # 2 Weight: 5% Due Date: 19/11/2016

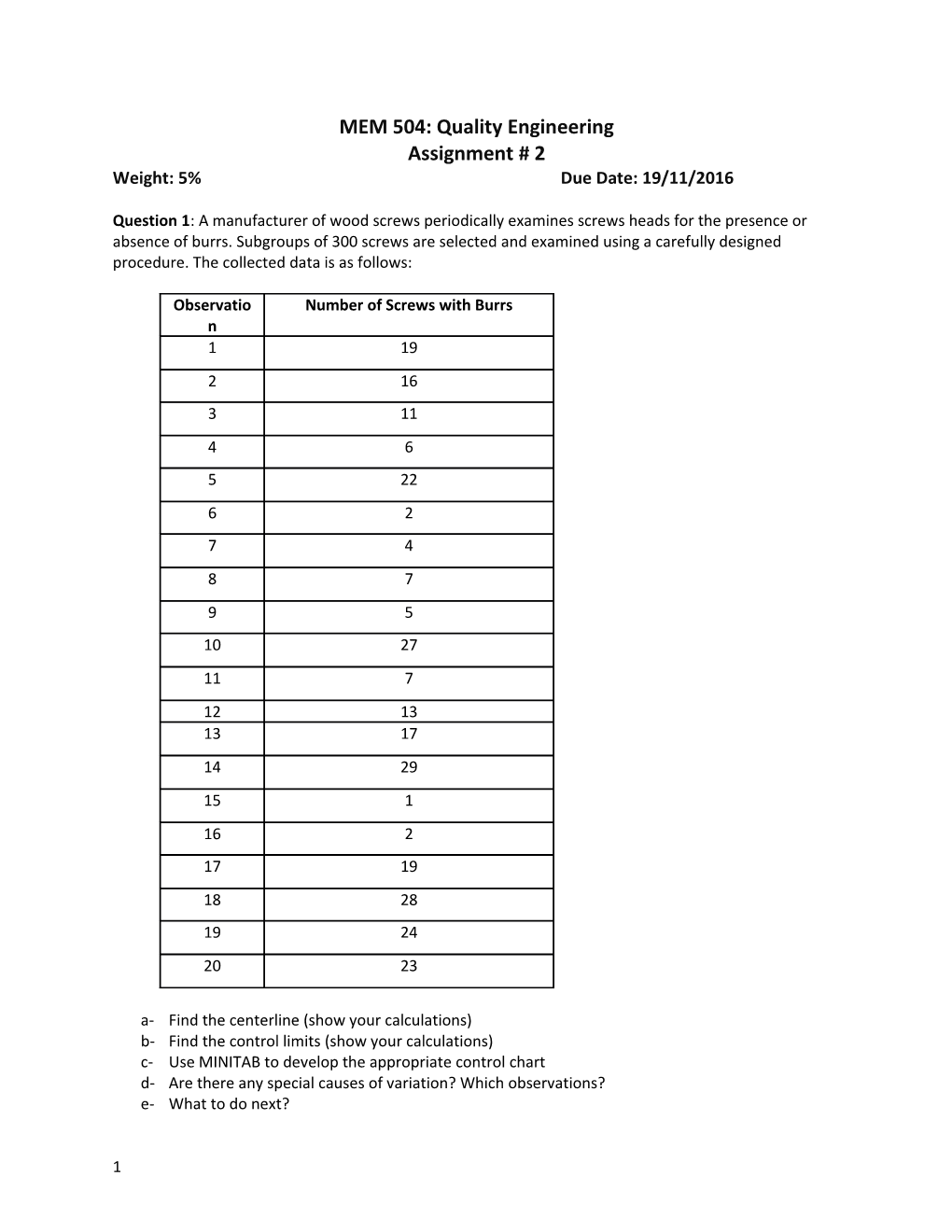

Question 1: A manufacturer of wood screws periodically examines screws heads for the presence or absence of burrs. Subgroups of 300 screws are selected and examined using a carefully designed procedure. The collected data is as follows:

Observatio Number of Screws with Burrs n 1 19 2 16 3 11 4 6 5 22 6 2 7 4 8 7 9 5 10 27 11 7 12 13 13 17 14 29 15 1 16 2 17 19 18 28 19 24 20 23

a- Find the centerline (show your calculations) b- Find the control limits (show your calculations) c- Use MINITAB to develop the appropriate control chart d- Are there any special causes of variation? Which observations? e- What to do next?

1 Question 2: A given model of large radar dish represents the area of opportunity in which nonconformities may occur. Results of quality check for 25 radar assemblies are as follows:

Radar Assembly Number Number of Nonconformities 1 25 2 60 3 28 4 65 5 91 6 56 7 40 8 54 9 90 10 44 11 62 12 81 13 70 14 75 15 24 16 50 17 70 18 56 19 21 20 88 21 34 22 82 23 53 24 102 25 64

a- Determine the centerline (show your calculations) b- Determine the control limits (show your calculations) c- Use MINITAB to develop the appropriate control chart d- Are there any indications of lack of control? e- What to do next?

2 Question 3: Workers at a packaging operation shovels a granular product from a large pile into sacks that are then sealed and placed on pallets for shipping. A sequence of 25 subgroups each consisting of the weights of 5 sacks has been recorded as follows:

Observations Subgroup # Sack 1 Sack 2 Sack 3 Sack 4 Sack 5 1 35.4 35.6 34.8 34.7 34.8 2 36 35.6 34.9 34.8 35.9 3 35.2 35 35 35.4 35.1 4 34.8 35.8 35.2 35 34.9 5 34.2 35 36.1 34.9 35.1 6 36 35 35.2 34.8 34.9 7 36.1 34.9 34.5 35 35.1 8 35.1 35 35.6 34.9 36.2 9 35 35.6 36.1 34.8 35.6 10 35.4 35.8 36 34.2 36 11 35.2 35.3 35.2 35.9 34.8 12 35.9 36 35.1 35.1 35.6 13 35.2 35.6 35 34.9 35 14 35.2 35.6 35.8 35 35.1 15 34.9 34.8 35 35.2 34.9 16 35.2 35.3 35.2 35.6 35.1 17 35.6 35.8 35.2 35.4 34.9 18 35.2 35.6 35.4 35.6 35.2 19 34.7 34.9 35.6 35.2 35 20 35 35.1 35.6 35 35.1 21 35.6 35 35.8 35.2 34.6 22 34.9 35.1 35.6 35 35.2 23 35.9 36 35.2 36 35.2 24 35.2 35.1 35.4 34.9 35.1 25 35.2 35.2 35.1 35.6 34.9

a- What is the appropriate control chart that can be used by the quality engineer in this case? b- Determine the control limits (show your calculations) c- Construct the appropriate control chart for the data above using MINITAB. d- Is the process in-control? If not, when does the out-of-control behavior occur? e- If the process is found to be out of control, drop the out-of-control points and use MINITAB to re-construct the control chart. f- Is the process now in-control? If not, what to do next?

3 Question 4: Viscosity is one of the important quality characteristics of paste ink used in printing presses. A viscosity measure is taken at the end of production of each batch of ink. Viscosity measures for 50 consecutive batches have been recorded as follows:

Sample Viscosity Sample Viscosity 1 305 26 291 2 274 27 301 3 290 28 290 4 314 29 290 5 291 30 308 6 315 31 306 7 301 32 292 8 298 33 279 9 306 34 276 10 305 35 285 11 270 36 296 12 296 37 275 13 307 38 299 14 284 39 301 15 280 40 294 16 264 41 312 17 299 42 289 18 270 43 278 19 275 44 288 20 276 45 299 21 294 46 270 22 313 47 308 23 304 48 298 24 310 49 294 25 271 50 306

a- What is the appropriate control chart that can be used by the quality engineer in this case? b- Determine the control limits (show your calculations) c- Construct the appropriate control chart for the data above using MINITAB. d- Is the process in-control? If not, when does the out-of-control behavior occur? e- If the process is found to be out of control, drop the out-of-control points and use MINITAB to re-construct the control chart. f- Is the process now in-control? If not, what to do next?

4