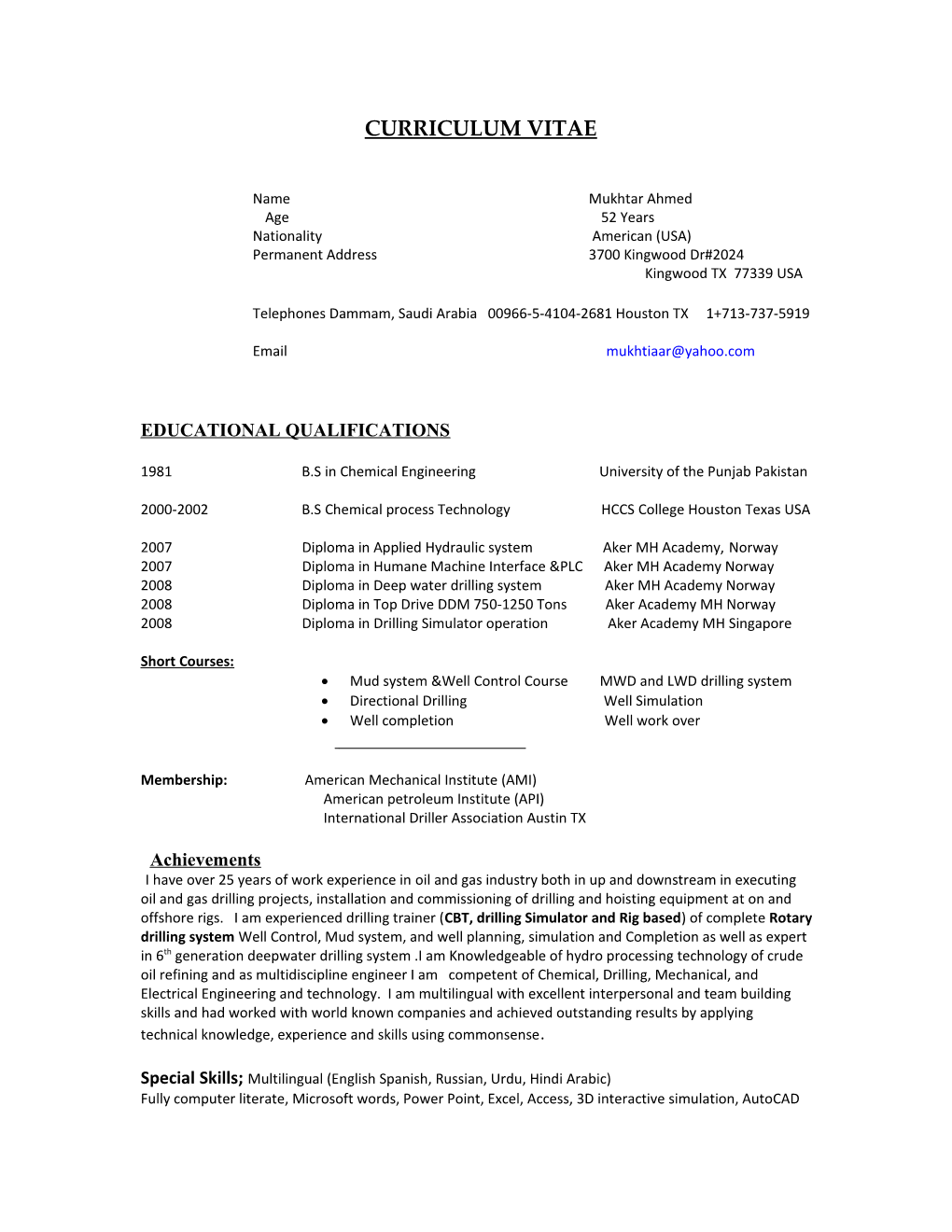

CURRICULUM VITAE

Name Mukhtar Ahmed Age 52 Years Nationality American (USA) Permanent Address 3700 Kingwood Dr#2024 Kingwood TX 77339 USA

Telephones Dammam, Saudi Arabia 00966-5-4104-2681 Houston TX 1+713-737-5919

Email [email protected]

EDUCATIONAL QUALIFICATIONS

1981 B.S in Chemical Engineering University of the Punjab Pakistan

2000-2002 B.S Chemical process Technology HCCS College Houston Texas USA

2007 Diploma in Applied Hydraulic system Aker MH Academy, Norway 2007 Diploma in Humane Machine Interface &PLC Aker MH Academy Norway 2008 Diploma in Deep water drilling system Aker MH Academy Norway 2008 Diploma in Top Drive DDM 750-1250 Tons Aker Academy MH Norway 2008 Diploma in Drilling Simulator operation Aker Academy MH Singapore

Short Courses: Mud system &Well Control Course MWD and LWD drilling system Directional Drilling Well Simulation Well completion Well work over

Membership: American Mechanical Institute (AMI) American petroleum Institute (API) International Driller Association Austin TX

Achievements I have over 25 years of work experience in oil and gas industry both in up and downstream in executing oil and gas drilling projects, installation and commissioning of drilling and hoisting equipment at on and offshore rigs. I am experienced drilling trainer (CBT, drilling Simulator and Rig based) of complete Rotary drilling system Well Control, Mud system, and well planning, simulation and Completion as well as expert in 6th generation deepwater drilling system .I am Knowledgeable of hydro processing technology of crude oil refining and as multidiscipline engineer I am competent of Chemical, Drilling, Mechanical, and Electrical Engineering and technology. I am multilingual with excellent interpersonal and team building skills and had worked with world known companies and achieved outstanding results by applying technical knowledge, experience and skills using commonsense.

Special Skills; Multilingual (English Spanish, Russian, Urdu, Hindi Arabic) Fully computer literate, Microsoft words, Power Point, Excel, Access, 3D interactive simulation, AutoCAD Employment History Saudi Petroleum Services Polytechnic Dammam, Saudi Arabia ongoing Senior Drilling Instructor. Develop Drilling Curriculum and conduct CBT and Rig based training for students from Aramco and other oil and gas sponsored companies. Manage and Conduct Rigman, assistant driller and driller training program including Rotary drilling system, Hoisting system, casing and cementing, Mud Circulation system, well control system, completion and work over, as well as Rig safety and HSE program. Conduct classroom and performance test at Rig, workshop based equipment evaluation. Arrange field trips to operational Rig visit for student in cooperation with Rig Contractor and supervise drilling operations.

Larsen Oil and Gas (Semi submersible DP) www.larsenoilandgas.com Technical support (Drilling) Semisubmersible DP Petrorig1 Singapore 2009-2010 . Advised in real time drilling operations based on daily drilling plan at drilling simulator in Stand building, Conductor Casing and cementing, Worked with Subsea Engineer in Marine Riser and BOP landing, Drilling Operation, Bit and BHA Selection, Mud Circulatory system and well control system. . Planed and managed preventive maintenance of rig machines and equipment. . Conducted CBT based training for deep water drilling, MWD/LWD for Drilling crew. . Developed and implemented drilling procedures and provided engineering support. . Conducted HSE and rig safety meeting and conducted weekly fire and emergency safety drills.

Aker Solutions MH Houston TX www.akersolutions.com Technical Instructor (drilling) 2006-2009 Participated in Top drive Design, developed drilling curriculum of Aker MH (Complete drilling Package) including Drilling system equipment Top drive (DDM), Hoisting System Drawwork, Iron Roughneck, Hoisting Crane and conducted training at Norway and Houston. Conducted real time drilling operation training at drilling simulator including, Cyber Drilling Smart zone management system, Drill view system, Drilling data analysis and Well Control Conducted Aker MH standards drilling courses like Drilling system, Hoisting system, Casing and cementing, Complete Well Control System, Mud Circulatory system and MWD/LWD using drilling simulator, animation, Videos, and pictures. Conducted Aker MH technical courses of (DDM) or Top Drive (500, 650, 750, 1000, and 1250) Ton, Auto Iron Roughneck, Stand Building Crane, Knuckle Boom crane Hydraulic System, Human Machine Interface, PLC and Preventive Maintenance. Developed and conducted technical drilling courses at offshore floating drilling unit Semi Submersible rigs of clients like Thunderhorse (Bp), Seadrill, Maersk, Petrorig of Larsen oil and gas, Petrobras and more, pride International, Transocean, Diamond offshore and more..

Shell Scotford Refinery Edmonton Alberta Canada

Senior Process Engineer 2004-2006 Supervised two phase Hydro- process unit for naphtha treatment and production of 100,000 bbl synthetic oil (Gasoline, jet fuel, diesel, propane, butane) per day Designed process logs, conduct process analysis and control, and supervised shift engineers and worked with production department to meet supply. Provided technical, engineering and Training support to refinery technical staff for new employees and conducted safety meeting in accordance with company rules.

TODCO oil and gas Houston, TX www.todco.com Project Engineer (Offshore Drilling) 1997-2004 . Executed offshore oil and gas projects for Top drive Design, installation, commissioning, testing, operation and Rotary Drilling Training in accordance with contract and documents, standards and regulations. Read the project document, prepared assignment and implemented within stipulated timeframe. . Developed and changed equipment design, implemented at workshop, ordered components and materials. Made all purchases orders and maintain inventory. . Provided Technical/ operation/training support under the project agreement for mechanical/ hydraulic /pneumatic and control system problems. . Developed equipment operation and training material, safety manuals and conducted Health Safety and environment (HSE) and preventive maintenance training at the premises.

Design Development Fabrication Company www.ddfc.com Business Development Manager (Technical) 1990-1997 Responsible of process equipment and piping installation and testing at refinery and natural gas pipeline. Performed equipment design fabrication, installation and commissioning of water treatment plant and utility boilers. Lead team for installation and commissioning of desalter, Catalytic reformer Hydrotreater reactor along with complete piping system. Prepared most of project document, design, drawings, plans, schedules and worked as a single point of contact in executing the project. Developed training and safety material and manual s and conducted training for the equipment. Al-Shauiba Refinery Kuwait www.knpc.com 1983-1990 Process Engineer (Hydrogen Plant) Worked as Process engineer at Hydro- processing unit, controlled hydro- treating unit to treat naphtha by hydrogen, monitored processing and operation phases

Shift Supervisor for hydrogen production plant (Natural Gas based) with optimum efficiency, participated in several design changes to safe energy

Maintained refinery utility system like water treatment plant, boiler, heat Exchangers and re-boiler Prepared PFD and P&IDs programs in process and production, prepared logs, conducted mass and energy balance used HYSYS simulation for design changes. All References are available on request