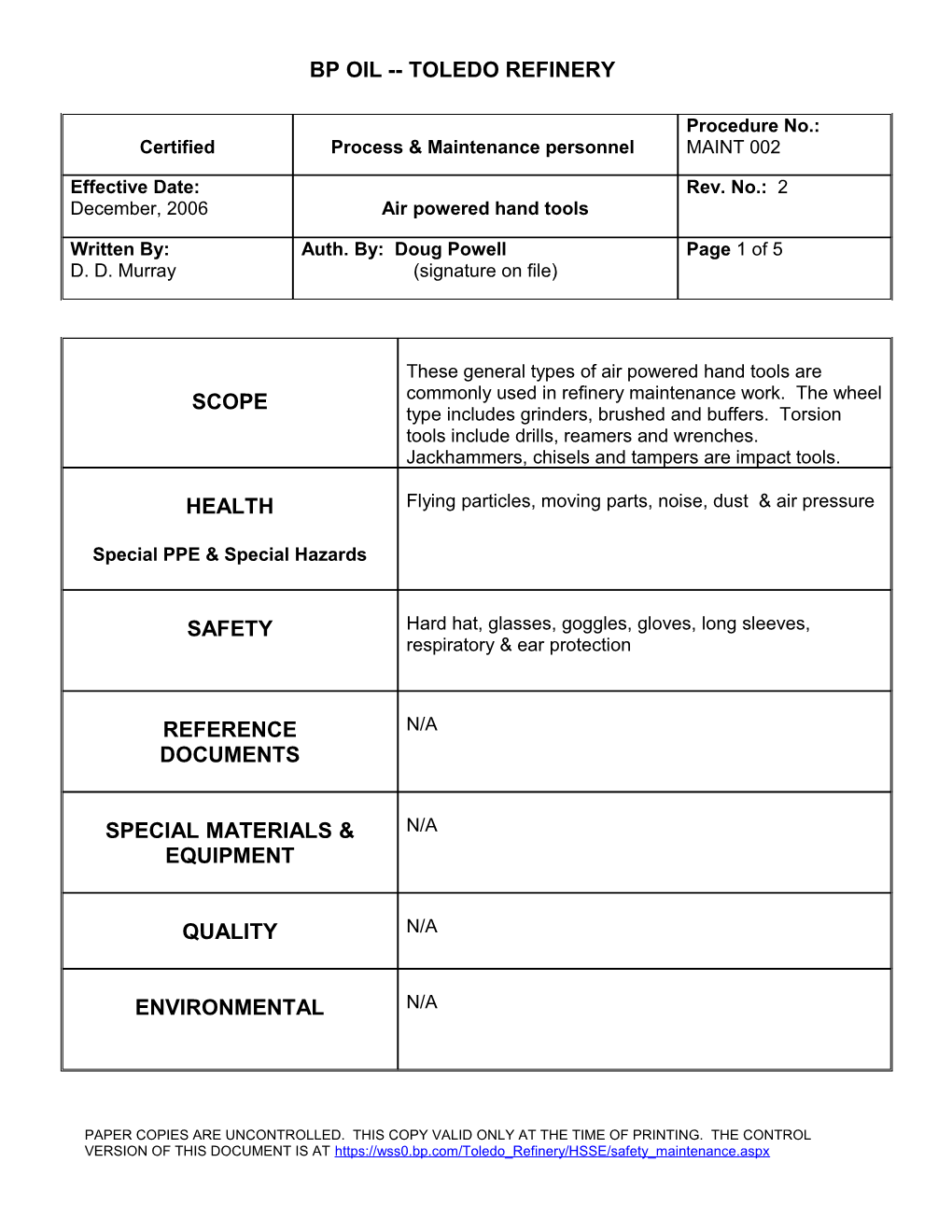

BP OIL -- TOLEDO REFINERY

Procedure No.: Certified Process & Maintenance personnel MAINT 002

Effective Date: Rev. No.: 2 December, 2006 Air powered hand tools

Written By: Auth. By: Doug Powell Page 1 of 5 D. D. Murray (signature on file)

These general types of air powered hand tools are SCOPE commonly used in refinery maintenance work. The wheel type includes grinders, brushed and buffers. Torsion tools include drills, reamers and wrenches. Jackhammers, chisels and tampers are impact tools.

HEALTH Flying particles, moving parts, noise, dust & air pressure

Special PPE & Special Hazards

SAFETY Hard hat, glasses, goggles, gloves, long sleeves, respiratory & ear protection

REFERENCE N/A DOCUMENTS

SPECIAL MATERIALS & N/A EQUIPMENT

QUALITY N/A

ENVIRONMENTAL N/A

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx Procedure No. MAINT 002 Rev. No. 1

OVERVIEW

Since air powered hand tools are mobile and difficult to guard, their use often involves hazards to tool users and other people. The power medium, high pressure air, can cause serious injuries if it is allowed to get out of control. The tools themselves are usually heavy and often awkward to handle, so dropping is always a potential hazard. Other, equally serious hazards can be created by mishandling, improper usage, tool breakage, inadequate maintenance or poor design.

1.0 Personal Protective 1.1 Most tools create eye hazards from flying particles, dust and compressed air itself. Impact goggles worn over safety glasses are required for tool users and other people at the work site. Face shields should be worn where chipping or wire brushing produces many flying particles.

__1.2 Safety shoes are needed to protect toes against deflected impact tool blows or tool droppage.

__1.3 Suitable gloves are required for air powered tool work. Turbining operations often require the use of insulated gloves to protect hands against tool and air hose heat.

__1.4 Some air tools produce high noise levels that increase the risk of hearing loss. A recent survey showed that hearing protection is required to turbine furnace tubes. Further surveys are likely to disclose other air tool operations requiring hearing protection.

__1.5 Wear clothing which protects against high velocity or hot flying particles produced by some air tool work Do not wear loose, ragged clothing and neckties, unbuttoned shirt sleeves or shirt tails exposed outside the trousers.

__1.6 Breathing protection is required where air tool operations produce dusts of concrete, coke, sand, metal, abrasives, etc. Approved dust masks are the minimum required protection against such dusts produced by hand tool work.

2.0 General air tool 2.1 Use only hoses approved for air tool service. Before using, check precautions hoses for cracks, cuts, blisters or other defects that might cause hose rupture, and replace damaged hoses.

__2.2 Air hoses in traffic areas are prone to damage and create tripping hazards. Wherever possible, “bridge” hoses with boards or suspend them overhead.

__2.3 Check hose “quick-connects” for insecure locking and for proper clamps--not “makeshifts”. To prevent accidental parting of connections at the air tool housing, secure the hose coupler to the housing with a chain or wire. Where feasible, hose couplers should be fitted with automatic shut-off valves.

Page 2 of 5

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx Procedure No. MAINT 002 Rev. No. 1

__2.4 Before connecting hoses to air supply outlets, open line valves sufficiently to bleed water from the line. Use a steam hose to thaw a frozen air line - never use direct flame.

__2.5 Air supply line outlets should be positioned away from users to protect them in case hoses blow off during coupling or uncoupling. Outlets fitted with valved tee vents are desirable to provide pressure relief before uncoupling hoses.

__2.6 Before opening the air supply line valve, make sure the tool’s operating trigger or valve is closed. When through using tool and uncoupling hoses, first close the air supply line valve then open the tool’s operating trigger or valve to release residual pressure.

__2.7 To protect against accidental starting, air tools with operating triggers located inside the handles should be used. If such tools are not available, controls located outside handles should be guarded by suitable devices that still permit quick release. Tools with unguarded triggers must be handled carefully to avoid accidental starting.

__2.8 Wherever it is possible for air tools to accidentally contact electricity circuits, use hoses having built-in ground wires and attach the air supply end to a suitable electrical ground.

__2.9 Compressed air is a deadly weapon in the hands of a jokester.

__2.10 “Playful” use of air will not be tolerated. Do not use an air hose to blow dust from clothing or any part of the body--to do so, can cause serious injuries.

3.0 Wheel type air tools 3.1 Grinders are high speed tools which required careful matching of wheels and tools to avoid accidents. Grinders must be clearly marked to show the maximum allowable wheel size and operating speed. If data is not clearly legible, attach a stamped metal tag showing wheel size and r.p.m.

__3.2 Use the size grinding wheel shown on the tool--never use a larger wheel. To do so, can result in a surface speed high enough to destroy the wheel. Check the maximum speed shown on the wheel. This speed should be equal to or more than the tool’s spindle speed. Never use a wheel having a marked speed less than the tool’s spindle speed,

__3.3 Wheel type tools are designed to operate within definite air pressure ranges. Too high a pressure may be dangerous. Too low a pressure may create flat spots on grinding wheels which can lead to breakage. Air line pressure should be checked from time to time to reveal pressure problems.

Page 3 of 5

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx Procedure No. MAINT 002 Rev. No. 1

__3.4 The breaking grinding wheels, inspect them carefully for cracks, chips, flat ware or other flaws. Wheels should be free of oil or water which can throw them out of balance.

__3.5 Follow air tool manufacturer’s recommendations to mount grinding wheels. Make sure the wheel’s inside diameter matches the size of the tool spindle. Shock absorbing washers should be installed next to wheel blotters to help prevent vibration and breakage. Both wheel flanges must have the same hole and outside diameter.

In using cone and plug wheels, the length of wheel must be suited to the length of the spindle--neither too short nor too long. In bolting wheels, heighten spindle nuts just tight enough to provide a good grip--overtightening can damage wheels.

__3.6 Wheel guards should cover at least 180o of the periphery and be easily adjustable. In operations where guards are not feasible, extreme care must be used to avoid body contracts.

__3.7 Grinding should not be done with a newly mounted wheel until one minute after it reaches maximum speed. During this test, the user should stand aside inn case the wheel breaks.

__3.8 If grinding is done with the side of a straight wheel, use care to avoid cramping due to high side pressure.

__3.9 Wire wheels and buffers must be handled with care to avoid body contact and flying particles. Direct work movement away from the body.

__3.10 Tool wear can cause valve and governor damage that leads to excessive speeds. Spindle speeds should be checked with a tachometer after each 40 hours of tool use.

__3.11 Grinding produces highly heated particles (sparks) which might cause ignition of flammable gases. Therefore, a hot work permit is required to grind where a flammable atmosphere could exist.

4.0 Torsion type air tools 4.1 Torsion tools develop high speed power that can cause injuries through contacts, tool breakage or flying chips. Tool guards are usually impractical so alert handling is required to avoid injury.

__4.2 Drills should have chuck guards to help keep clothing from being caught. Drills should be no longer than needed to do the job. Sleeves that fit over drills serve as limit stops and protect against injury due to breakage.

Page 4 of 5

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx Procedure No. MAINT 002 Rev. No. 1

__4.3 When drilling holes deeper than the drill flutes, keep chips cleaned out to prevent breaking or jamming. Small or dull drills are the ones most likely to break while large drills tend to heat up, causing them to jam or break. To avoid jamming, drills must have both cutting lips of equal length and angle. Feed drills slowly and keep them perpendicular to the drilling surface.

THIS IS THE LAST PAGE

Page 5 of 5

PAPER COPIES ARE UNCONTROLLED. THIS COPY VALID ONLY AT THE TIME OF PRINTING. THE CONTROL VERSION OF THIS DOCUMENT IS AT https://wss0.bp.com/Toledo_Refinery/HSSE/safety_maintenance.aspx