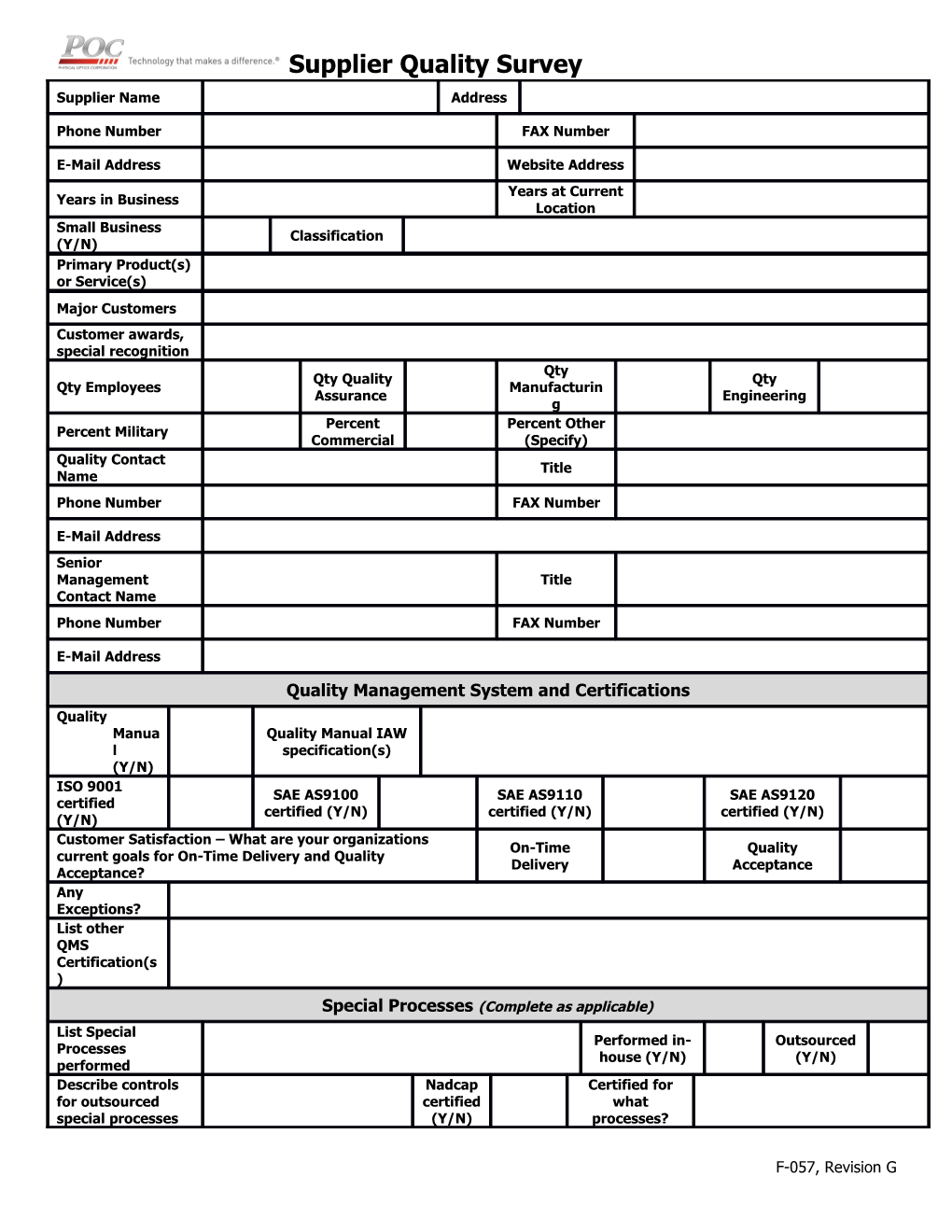

Supplier Quality Survey Supplier Name Address

Phone Number FAX Number

E-Mail Address Website Address Years at Current Years in Business Location Small Business Classification (Y/N) Primary Product(s) or Service(s) Major Customers Customer awards, special recognition Qty Qty Quality Qty Qty Employees Manufacturin Assurance Engineering g Percent Percent Other Percent Military Commercial (Specify) Quality Contact Title Name Phone Number FAX Number

E-Mail Address Senior Management Title Contact Name Phone Number FAX Number

E-Mail Address

Quality Management System and Certifications Quality Manua Quality Manual IAW l specification(s) (Y/N) ISO 9001 SAE AS9100 SAE AS9110 SAE AS9120 certified certified (Y/N) certified (Y/N) certified (Y/N) (Y/N) Customer Satisfaction – What are your organizations On-Time Quality current goals for On-Time Delivery and Quality Delivery Acceptance Acceptance? Any Exceptions? List other QMS Certification(s ) Special Processes (Complete as applicable) List Special Performed in- Outsourced Processes house (Y/N) (Y/N) performed Describe controls Nadcap Certified for for outsourced certified what special processes (Y/N) processes?

F-057, Revision G Supplier Quality Survey List SP specifications you are able to certify to Soldering & Workmanship (Complete as applicable) IPC - J-Std- WH Class(es IPC-A-610 001 Class(es) MA- ) (Y/N) (Y/N) 620 (Y/ N) Other

Quality Processes Describe your system for material traceability Is a First Article Inspection process in place? Per what industry specification(s) Does your organization outsource assembly or testing? If so, please describe controls that are utilized. Describe your records retention process Does your organization flow down customer requirements to your suppliers as applicable? Does your organization have a counterfeit parts detection and mitigation program? Per what industry specification(s)? Does your organization have a Foreign Object Detection (FOD) program? Per what industry specification(s)? Summarize inspection / process / test equipment Calibrated per what standard(s)?

Describe training program Summarize proactive tools utilized such as Statistical Process Control (SPC), Failure Modes and Effects Analysis (FMEA), Process Control Plans, etc. Other important information or comments as warranted Questionnaire Title Date completed By To Submit, please: 1) Include electronic copies of current certifications, plus attachments as necessary in support of responses. 2) Return MS Word file, do not send PDF file. 3) Submit to [email protected], or as otherwise directed. POC Review SCOPE OF Approve Not Date Received APPROVA d approved L

F-057, Revision G Supplier Quality Survey Further Actions Business Risk Required Rating Subcontractor Contract No., (Y/N) SOW No., Part No. Reviewed by Title Date Addition Date entered Supplier al into AVL Level comment s

F-057, Revision G