Background Statement for SEMI Draft Document 5134 Revision to SEMI C28-0306, Specifications for Hydrofluoric Acid

NOTICE: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this document. NOTICE: Recipients of this document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has issued or has been applied for. In the latter case, only publicly available information on the contents of the patent application is to be provided. Background C28 is due for 5-year review. This process is required for all SEMI Standards and Safety Guidelines. A preliminary review of the document revealed that some minor changes were needed. This ballot makes those changes.

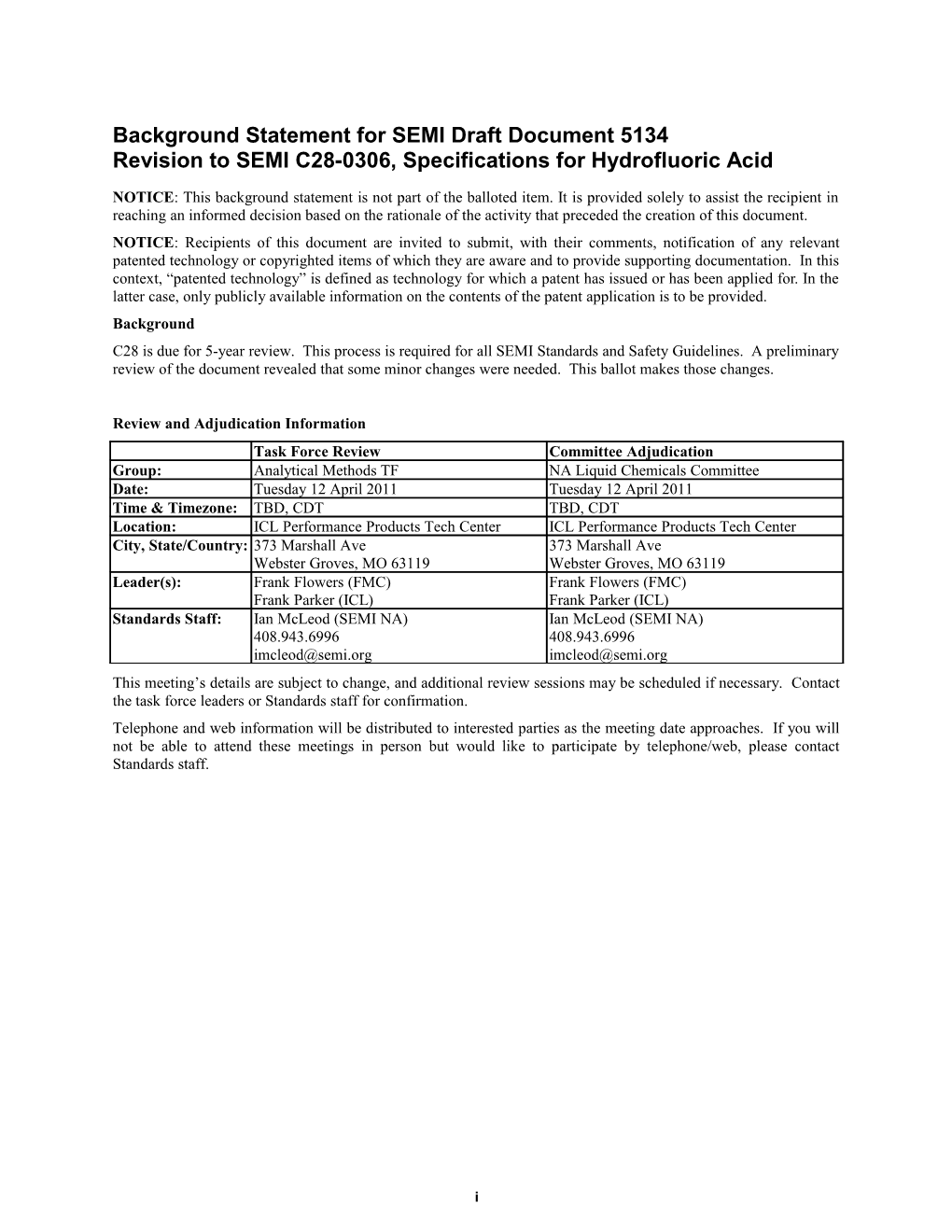

Review and Adjudication Information Task Force Review Committee Adjudication Group: Analytical Methods TF NA Liquid Chemicals Committee Date: Tuesday 12 April 2011 Tuesday 12 April 2011 Time & Timezone: TBD, CDT TBD, CDT Location: ICL Performance Products Tech Center ICL Performance Products Tech Center City, State/Country: 373 Marshall Ave 373 Marshall Ave Webster Groves, MO 63119 Webster Groves, MO 63119 Leader(s): Frank Flowers (FMC) Frank Flowers (FMC) Frank Parker (ICL) Frank Parker (ICL) Standards Staff: Ian McLeod (SEMI NA) Ian McLeod (SEMI NA) 408.943.6996 408.943.6996 [email protected] [email protected] This meeting’s details are subject to change, and additional review sessions may be scheduled if necessary. Contact the task force leaders or Standards staff for confirmation. Telephone and web information will be distributed to interested parties as the meeting date approaches. If you will not be able to attend these meetings in person but would like to participate by telephone/web, please contact Standards staff.

i Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and NOTICE: Hydrofluoric Concentrated Acid Anionsin of Note Trace Technical 45—Determination Dionex 4.3 ElectronicsSemiconductor in WaterIndustry Guide UltraUsed and D5127for the ASTM Pure —Standard 4.2 —Guidethe Analysis ofChemicals SEMI C1 for Liquid 4.1 4 3.1 3 the determine and practices health and safety appropriate other ofprior limitations use.applicability regulatoryor to establish to standard this of users the of responsibility NOTICE: 2.1 2 results. valid statistically give to shown been have methods Test standards. those support to procedures testing and industry 1.1 1 NOTICE toSEMIC28-0306, Revision Specifications Hydrofluoric for Acid Draft Document SEMI 5134 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 610.832.9555.Website: www.astm.org610.832.9585, Fax: 1 8.1.1 the of stopper the (loosen sample the phenolphthalein add of mL 0.1 vessel, 1N solution, sodium a and to indicator standardized slight, titratehydroxide Add with color. pink sample). plastic the with stopper a the and in container the both water add and of bottle, polyethylene mL 50 To reweigh. and immediately, 8.1 1: NOTE 8 7.1 7 6 5.1 5

American Society for Testing and Materials,Drive, 100 Barr forHarbor West Society Pennsylvania and Conshohocken, Testing USA. Telephone: American 19428-2959, Referenced Standards Referenced Documents and Limitations Scope Purpose Grade 1 Grade1 Procedures Requirements PropertyPhysical(for only) information Terminology Other ASTM SEMI None. of is scope this The document semiconductor the in used acid hydrofluoric for requirements standardize to is document this of purpose The Assay 1. listed hydrofluoricTable Gradesin for 1,2,3and requirements for 4are The acid None. Alternately, potentiometric end pointcanused. potentiometric end detection be Alternately,

Each laboratory responsible verifying is validity forthe the of method its operation.within own : : by marked Additions are

cuaey wih 1415 m f sml n plehln egig btl, sml, stopper sample, bottle, weighing polyethylene in sample of mL 1.4–1.5 weigh Accurately — Density at Density 25

Unless otherwise indicated, all documents cited shall be theversions. latestpublished otherwise documents all cited be shall Unless indicated, Standards the is It use. its with associated any, if issues, safety address to purport not does standard This Documents Standards 1 C all underline grades of hydrofluoric acid used in hydrofluoricacid industry. used the gradesof semiconductor %Assay 1.15 1.15 g/mL , deletions are marked by , deletionsaremarked mL Weight of sample Page N

of 2 NaOH 2.001 g jn l jn strikethrough . Document Document 5134 Number: Doc. 5134 Doc. 5134 Date: 2011/02/17Date: DRAFT SEMI

LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 8.6.1.1 8.6.1 as long as used be may methods be can demonstrated SEMI C1 according to validation method alternate other Any ¶9.2. in described is method alternate An (Zn). zinc and (V) lithium (Pb), lead vanadium (Ti), (Fe), titanium (Sn), tin (Na), iron sodium (K), potassium (Ni), nickel (Cu), (Mn), manganese (Mg), magnesium (Li), copper (Cr), chromium (Ca), calcium (Cd), cadmium, (B), boron (Ba), barium (As), arsenic (Sb), antimony (Al), aluminum metals: trace following the of each for specified value the at impurities 8.6 2: NOTE and solutions. chloridestandard the sample to the barium adding after minutes 10 Compare test. the in used reagents of quantities the containing solution of volume equal an (SO ion sulfate of mg 0.1 by produced that exceed not should turbidity Any solution. reagent chloride barium of Neutralize mL 2 solution. and 19) + (1 acid hydrochloric dilute of mL 2 addindicator and mL, 20 to water with dilute phenolphthalein hydroxide, ammonium with of mL 0.01 add and water, of mL 15 about with dilute mL, 1 about a in to bath Evaporate acid. perchloric steam of mL 3 a add and water, on of volume small a dryness with dish the to of sides the down Evaporate wash hood, peroxide. hydrogen 30 of mL 1 and carbonate sodium of mg 10 about 8.5 0.01mg phosphate thanproducedwhen (PO that beion should of nogreater blue color Any temperature. room at hours 2 for stand to Allow solution. reagent sulfate p-(methylamino)phenol of mL 1 and solution reagent molybdate ammonium of mL 1 Add acid. sulfuric N 0.5 of mL 25 in residue the Dissolve hood. a 8.4 solution. the standard in that than greater no be should solution sample the in color yellow The minutes. 10 for stand to Allow acid. sulfuric of mL 20 stirring with add cautiously and solution reagent sulfate brucine of mL 2.5 add solution, each To mL. per (NOnitrate ofmg 0.01 solution containing nitratestandard of 1 mL and water of 6.5 mL add beaker, plastic mL 50 8.3 greater no be should produced turbidity Any solution. as when(Cl)the issample. ion of 0.01mg chloride treated than produced that reagent nitrate silver of mL 1 and acid nitric of mL 1 Add 8.2 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 9.1 4: NOTE 9 by ICP-MS. preferably 8.6.3.1 8.6.3 to minutes several warm carefully a Run reagent volume. blank. dilution to volume, maintaining and rinsing for acid While nitric 2% using flask acid. volumetric mL 50 a nitric to quantitatively Transfer Cool. 70% residue. any dissolve pure, ultra of mL 1 Add Cool. 3: NOTE of spattering2mL liquid until remains. ofor approximately loss avoiding sample by effervescence 8.6.2.1 8.6.2 ASTM E1.1in Type D5127. 8.6.1.2 Grade 2 Grade2 Procedures Trace Metal Analysis Metal Trace SO (as Sulfite and Sulfate Phosphate Nitrate Chloride Non-Metal ImpuritiesNon-Metal Phosphate, and Nitrate, Chloride, Assay, Special Analysis Sample Using the acid sample and reagent blank, analyze all specified elements by plasma emission spectroscopy or spectroscopy emission plasma by elements specified all analyze blank, reagent and sample acid the Using plate, hot a on evaporate Slowly dish. evaporating PTFE a in sample of g 250 place environment, clean a In — Solution Acid Nitric 2% Acid, UltraNitric Pure

Each laboratory responsible verifying is validity forthe the of method its operation.within own Evaporation typically 2 to hours.requires 1/2 4 For determination,alternateanion method based ion used,may upon chromatographybe ¶10.2. see — Weigh 3.3 g of sample in a white plastic 50 mL beaker and dilute with 4.5 mL of water. To another To water. of mL 4.5 with dilute and beaker mL 50 plastic white a in sample of g 3.3 Weigh — — Add 1.7 mL (2.0 g) of sample to 45 mL of water. Filter, if necessary, through a chloride-free filter. chloride-free a through necessary, if Filter, water. of mL 45 to sample of g) (2.0 mL 1.7 Add —

Preparation Reagents — Evaporate 9 mL (10 sample 9mL dryness g) suitabledish to orsteam bath of ain other in platinum —Evaporate ona — See §8, which contains procedures for the following for contains procedures —Seethe tests: §8,which — The following method has given satisfactory results in determining trace metal trace determining in results satisfactory given has method following The — 4 ) — Use nitric acid specified for ultra content. for lowmetalion —Usespecified nitricacid — To 18 mL (20 g) of sample in a platinum or other suitable evaporating dish, add dish, evaporating suitable other or platinum a in sample of g) (20 mL 18 To — Dilute 20 mL of ultra pure nitric acid to 1 L using water meeting the criteria for criteria the meeting water using L 1 to acid nitric pure ultra of mL 20 Dilute Page 3 . jn l jn 4 ) is treated like the sample. is the) like sample. treated Document Document 5134 Number: Doc. 5134 Doc. 5134 Date: 2011/02/17Date: DRAFT SEMI 4 ) in ) 3 )

LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 10 plasmacoupled mass cones spectrometry, platinum should considered be as when alternative performing analysis.this 6: NOTE inductively for mass coupled spectrometry.plasma These are systems available suppliers.most from instrument 5: NOTE solution acid theof standardfinal20ng/g that theconcentrationis indium. indium hydrofluoric internal such and 4.9% the with up made are standards the calibration, For (ICP/MS). spectrometry mass 9.2.4.1 9.2.4 blank. 20 Add g. 20.0 of weight final a to water E1.1 Type with 9.2.3 indium the appropriatesolution. concentrated standard from 9.2.2.4 toanalysis. in Type D5127regard cation ASTM for in E1.1 9.2.2.3 forASTM E1.1in Type the D5127. criteria 9.2.2.2 9.2.2.1 9.2.2 (Zn). zinc and (V), vanadium (Ti), titanium be used can demonstrated. asSEMIC1 asaccording be to long validation method (Sn), can method Alternate tin (Na), sodium (K), potassium (Ni), nickel (Mn), manganese (Mg), magnesium (Li), lithium (Pb), lead (Fe), iron (Cu), copper (Cr), boron chromium (Ca), calcium (Ba), (Cd), cadmium barium (B), (As), arsenic (Sb), antimony (Al), aluminum metals: trace following the of each for specified 9.2.1 9.2 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This Solution 3% 100gwith Nitric Acid of the ¶10.3.1.2. 10.3.2.1 10.3.2 cation in E1.2into analysis. Type D5127 regard criteria for ASTM 10.3.1.3 to FEPDilute final weight bottle. ofwater¶10.3.1.3. 500ml ultrapure clean a 500gusing tared 10.3.1.2 be can C1 SEMI 10.3.1.1 to according validation method as 10.3.1 long as used be can method demonstrated. Alternate (Zn). zinc and (V), vanadium (Ti), titanium (Sn), tin (Na), sodium (K), potassium (Ni), nickel (Mn), manganese (Mg), magnesium (Li),(Pb), lithium lead iron (Fe), (Cu), copper chromium (Cr), (Ca), (Cd), calcium cadmium (B), boron (Ba), barium (As),(Sb),antimony arsenic (Al), aluminummetals: tracefollowing the of each for specified value the at impurities 10.3 be can demonstrated.C1 SEMI to according validation method as long as used be can method Alternate addition. standard of method the by an using when obtained are done preferably is results Calibration TN45. the in Better recommended ICE-AS6 IonPac the of instead column ICE-AS1 IonPac 45. Note Technical Dionex example for see procedure, detailed a approach. For dimensional two a using chromatography ion by determined be can anions mentioned above The 10.2.1 10.2 10.1 Grade Procedures 3 Trace Metals Trace Sulfate and (as Sulfite Sulfate SO Nitrate, SulfateChloride, Assay Analysis — Preparation Sample Special value the at impurities metal trace determining in results satisfactory given has method following The rc ea nlss—— Analysis Metal Trace Special Sample Using the prepared solutions and blanks, analyze all the specified elements by inductively coupled plasma coupled inductively by elements specified the all analyze blanks, and solutions prepared the Using Standard Internal Indium Water Solution Acid Hydrofluoric 4.9% UltraHydrofluoric Pure Acid,

Water Solution Acid Nitric % 3 Acid, UltraNitric Pure In a clean environment, place 20 g of sample into a tared clean 120 ml FEP bottle. Dilute to a final weight final a to Dilute bottle. FEP ml 120 clean tared a into sample of g 20 place environment, clean a In Analysis of dilute hydrofluoric acid requires the use of special hydrofluoric acid resistant sample introduction systems introduction sample resistant acid hydrofluoric special of use the requires acid hydrofluoric dilute of Analysis Analysis of dilute hydrofluoric acid can produce rapid corrosion of nickel cones commonly used in inductively in used commonly cones nickel of corrosion rapid produce can acid hydrofluoric dilute of Analysis

—See ¶8.1

— The water used for all the dilution,standardsthe minimum criteria calibration for meet —Theand should at a the waterused all Reagents

Preparation the minimum a at meet should standards and calibrations dilutions, the all for used water The — Reagents

Analysis

In a clean environment, place 2.00 g of sample into a tared FEP bottle (30 mL), dilute mL), (30 bottle FEP tared a into sample of g 2.00 place environment, clean a In 4 , ). Phosphate — Use nitric acid specified for ultra content. for lowmetalion —Usespecified nitricacid The following method has given satisfactory results in determining trace metal trace determining in results satisfactory given has method following The — Make up a internal standard solution to a concentration of 20 20 of concentration a to solution standard internal a up Make — — In a clean environment, place 15 g of Ultra Pure Nitric Acid ¶10.3.1.1 Acid Nitric Pure Ultra of g 15 place environment, clean a In — — Use hydrofluoric acid specified for lowmetalion —Use for specified hydrofluoric content. acid — Dilute 20 g of ultrapure hydrofluoric acid to 200 g using water meeting water using g 200 to acid hydrofluoric ultrapure of g 20 Dilute — Page L of the indium internal standard solution. Run a reagent a Run solution. standard internal indium the of L 4 jn l jn Document Document 5134 Number: Doc. 5134 Doc. 5134 Date: 2011/02/17Date: g/mL (ppm) g/mL DRAFT

SEMI into a into

LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 16.1 16 15.1 15 14.1 14 13.1 13 12.1 12 11.3 11.2 11.1 11 instrument canOther typebe as as used long method according SEMI canvalidation to C1 be demonstrated. 9: NOTE plasmacoupled mass cones spectrometry, platinum should considered be as when alternative performing analysis.this 8: NOTE inductively for mass coupled spectrometry.plasma These are systems available suppliers.most from instrument Solution Acid Nitric % 7: NOTE 3 the with up made are standards ¶10.3.1.2. and blank calibration, For (ICP-MS). spectrometry 10.3.3.1 10.3.3 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This Table 1 TierDProcedures TierCProcedures TierBProcedures TierAProcedures Grade Procedures 5 Grade Procedures 4 Previous ReferenceSEMI # Sulfate Sulfate Sulfite SO and (as This section does not apply to not chemical. section this This does apply to not chemical. section this This does apply to not chemical. section this This does apply to not chemical. section this This does apply to not chemical. section this This does apply Metal Analysis Trace Nitrate, Phosphate Sulfate, Chloride, Assay Analysis

Impurity Limits and Other Requirements for Hydrofluoric AcidImpurity LimitsandOtherRequirementsforHydrofluoric Using the prepared solutions, analyze all the specified elements by inductively coupled plasma mass plasma coupled inductively by elements specified the all analyze solutions, prepared the Using Analysis of dilute hydrofluoric acid requires the use of special hydrofluoric acid resistant sample introduction systems introduction sample resistant acid hydrofluoric special of use the requires acid hydrofluoric dilute of Analysis The analytical methodology described in ¶10.3 has been validated using a “Reaction / Collision cell” type ICP-MS. type cell” Collision / “Reaction a using validated been has ¶10.3 in described methodology analytical The Phosphate (PO Analysis of dilute hydrofluoric acid can produce rapid corrosion of nickel cones commonly used in inductively in used commonly cones nickel of corrosion rapid produce can acid hydrofluoric dilute of Analysis Aluminum (Al) Aluminum (see NOTE (see 10) Antimony (Sb) Antimony Nitrate (NO Nitrate Chloride (Cl) Chloride Sulfate (SO Sulfate Arsenic (As) Arsenic —See ¶8.1. Barium (Ba) Barium Assay Assay (HF) Appearance 4 3 ) ) 4 ) —See ¶10.3. 4 ) Clear colorlessand (Specification) 48.8–49.2% or 48.8–49.2% 0.03ppm max 0.03ppm max 0.05ppm max 49.8−50.2% 5 maxppm 1 maxppm 3 maxppm 5 maxppm Grade 1 Grade C1.8-95 —See ¶10.2. -- -- Page Clear colorlessand (Specification) 48.8–49.2% or 48.8–49.2% 5000 maxppb 1000 maxppb 3000 maxppb 5000 maxppb 10.ppb max 10.ppb max 49.8−50.2% 15 maxppb 15 maxppb Grade 2 Grade 5 C7.3-93 -- jn l jn Clear colorlessand (Specification) 48.8–49.2% or 48.8–49.2% 200 maxppb 100 maxppb 100 maxppb 200 maxppb 49.8−50.2% 1 maxppb 1 maxppb 1 maxppb 1 maxppb Grade 3 Grade C8.3-96 -- Document Document 5134 Number: Clear colorlessand Doc. 5134 Doc. 5134 Date: 2011/02/17Date: (Specification) 48.8–49.2% or 48.8–49.2% 100 maxppb 100 maxppb 100 maxppb 100 maxppb 100 maxppt 100 maxppt 100 maxppt 100 maxppt 49.8−50.2% Grade 4 Grade - DRAFT SEMI

LETTER BALLOT Informational (Blue) Ballot1000AInformational (Blue) Ballot Ballot1000AInformational (Blue) (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and Calibration and Measurement Method for Particles Measurement in Liquids for Method and Calibration #1 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This own such responsibility. infringementareentirely rights their the of risk of this in mentioned item any with connection in rights any copyrights, areexpressly such determinationandasserted standard that ofpatent or Users this standard. advised copyrights or rights position patent no any of takes validity (SEMI) the International respecting Materials and Equipment Semiconductor standard, this of publication By other and notice.without change to sheets, subject are data standards These product herein. labels, mentioned equipment product or materials instructions, any respecting manufacturer’s literature relevant to refer to cautioned are Users user. the of responsibility the solely is standard(s) the of suitability the of determination The application. particular any NOTICE: 10: For relatedNOTE reason mainly transportation to regulations, the assay typical range different US Europe.is between and Due to the limitations of current particle counters, particle size and number are to be agreed upon between supplier and user. See SEMI C1, SEMI See user. and supplier between upon agreed be to are number and size particle counters, particle current of limitations the to Due Previous ReferenceSEMI # Particles bottles in Magnesium (Mg)Magnesium Manganese(Mn) Chromium (Cr) Chromium Cadmium (Cd) Cadmium Vanadium (V) Vanadium SEMI makes no warranties or representations as to the suitability of the standard(s) set forth herein for herein forth set standard(s) the of suitability the to as representations or warranties no makes SEMI Potassium (K) Titanium (Ti) Titanium Calcium (Ca) Sodium (Na) Copper (Cu) Copper Lithium (Li)Lithium (size, (size, #/mL) Nickel (Ni) Nickel Boron (B) Lead (Pb) Zinc Zinc (Zn) Iron (Fe) Iron Tin (Sn) Tin

(Specification) 0.05ppm max 0.01ppm max 0.05ppm max 1.0 1.0 0.3 max0.3 ppm max0.3 ppm max0.3 ppm max0.3 ppm max0.3 ppm max0.1 ppm max0.2 ppm max0.2 ppm max0.1 ppm max0.2 ppm max0.3 ppm Grade 1 Grade C1.8-95 m, maxm, 25 #1 ------Page

(Specification) 0.5 0.5 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 10.ppb max 5. max5. ppb Grade 2 Grade 6 C7.3-93 m, maxm, 25 #1 jn l jn (Specification)

0.2 0.5 0.5 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb 1 maxppb Grade 3 Grade C8.3-96 #1 m, maxm, 5 m,TBD Document Document 5134 Number: Doc. 5134 Doc. 5134 Date: 2011/02/17Date: (Specification) 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt 100 maxppt Grade 4 Grade TBD #1 - DRAFT SEMI

LETTER BALLOT