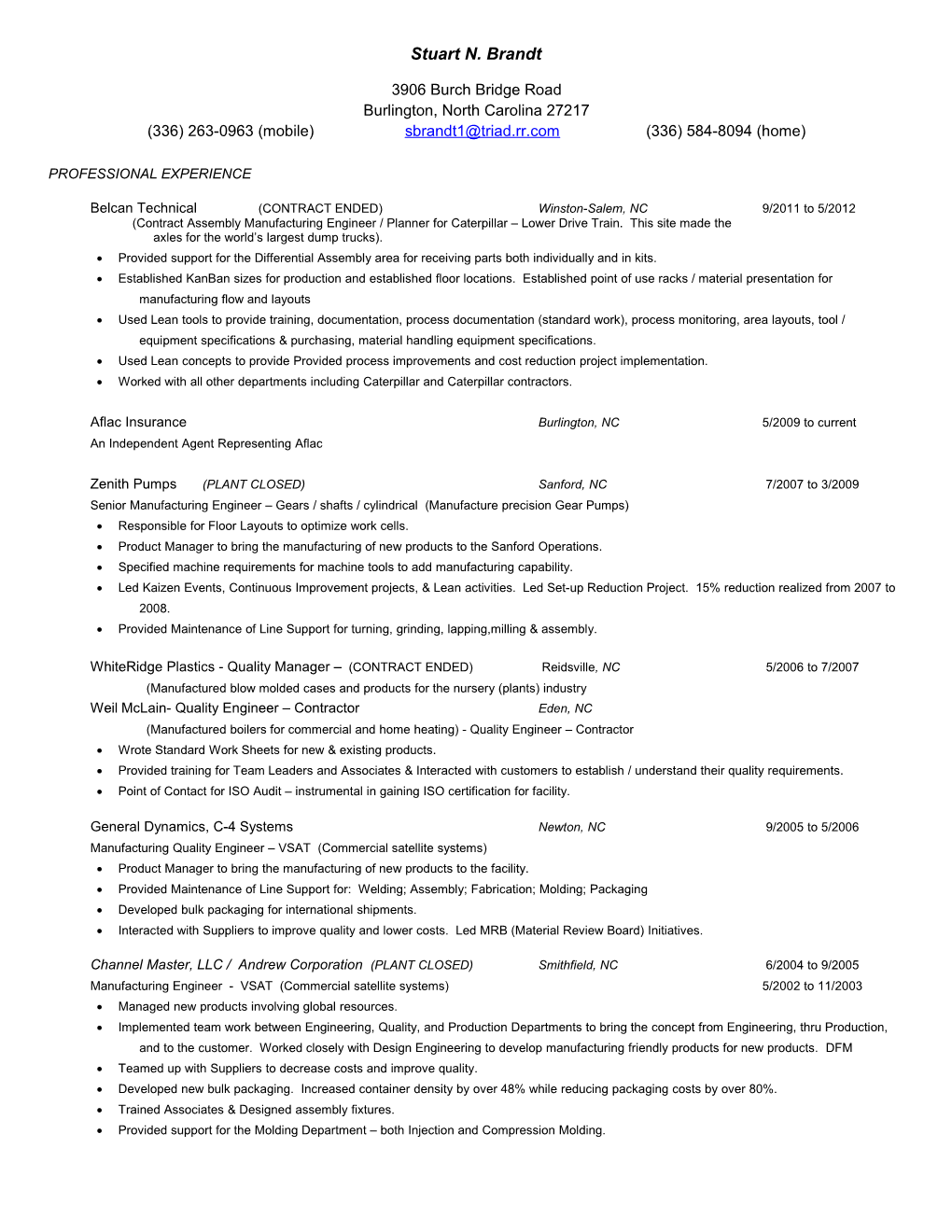

Stuart N. Brandt

3906 Burch Bridge Road Burlington, North Carolina 27217 (336) 263-0963 (mobile) [email protected] (336) 584-8094 (home)

PROFESSIONAL EXPERIENCE

Belcan Technical (CONTRACT ENDED) Winston-Salem, NC 9/2011 to 5/2012 (Contract Assembly Manufacturing Engineer / Planner for Caterpillar – Lower Drive Train. This site made the axles for the world’s largest dump trucks). Provided support for the Differential Assembly area for receiving parts both individually and in kits. Established KanBan sizes for production and established floor locations. Established point of use racks / material presentation for manufacturing flow and layouts Used Lean tools to provide training, documentation, process documentation (standard work), process monitoring, area layouts, tool / equipment specifications & purchasing, material handling equipment specifications. Used Lean concepts to provide Provided process improvements and cost reduction project implementation. Worked with all other departments including Caterpillar and Caterpillar contractors.

Aflac Insurance Burlington, NC 5/2009 to current An Independent Agent Representing Aflac

Zenith Pumps (PLANT CLOSED) Sanford, NC 7/2007 to 3/2009 Senior Manufacturing Engineer – Gears / shafts / cylindrical (Manufacture precision Gear Pumps) Responsible for Floor Layouts to optimize work cells. Product Manager to bring the manufacturing of new products to the Sanford Operations. Specified machine requirements for machine tools to add manufacturing capability. Led Kaizen Events, Continuous Improvement projects, & Lean activities. Led Set-up Reduction Project. 15% reduction realized from 2007 to 2008. Provided Maintenance of Line Support for turning, grinding, lapping,milling & assembly.

WhiteRidge Plastics - Quality Manager – (CONTRACT ENDED) Reidsville, NC 5/2006 to 7/2007 (Manufactured blow molded cases and products for the nursery (plants) industry Weil McLain- Quality Engineer – Contractor Eden, NC (Manufactured boilers for commercial and home heating) - Quality Engineer – Contractor Wrote Standard Work Sheets for new & existing products. Provided training for Team Leaders and Associates & Interacted with customers to establish / understand their quality requirements. Point of Contact for ISO Audit – instrumental in gaining ISO certification for facility.

General Dynamics, C-4 Systems Newton, NC 9/2005 to 5/2006 Manufacturing Quality Engineer – VSAT (Commercial satellite systems) Product Manager to bring the manufacturing of new products to the facility. Provided Maintenance of Line Support for: Welding; Assembly; Fabrication; Molding; Packaging Developed bulk packaging for international shipments. Interacted with Suppliers to improve quality and lower costs. Led MRB (Material Review Board) Initiatives.

Channel Master, LLC / Andrew Corporation (PLANT CLOSED) Smithfield, NC 6/2004 to 9/2005 Manufacturing Engineer - VSAT (Commercial satellite systems) 5/2002 to 11/2003 Managed new products involving global resources. Implemented team work between Engineering, Quality, and Production Departments to bring the concept from Engineering, thru Production, and to the customer. Worked closely with Design Engineering to develop manufacturing friendly products for new products. DFM Teamed up with Suppliers to decrease costs and improve quality. Developed new bulk packaging. Increased container density by over 48% while reducing packaging costs by over 80%. Trained Associates & Designed assembly fixtures. Provided support for the Molding Department – both Injection and Compression Molding. Diebold Corporation (PLANT CLOSED) Danville, VA 11/2003 to 6/2004 Manufacturing Process Engineer - Manufactured / assembled products for the banking industry: Physical Security Products (night drop boxes / teller drawers) & Electro-mechanical modules for ATMs Implemented team work between Engineering, Quality, and Production Departments in multiple sites. Trained & Coached Associates as well as provided Maintenance of Line Support. Worked closely with Design Engineering to develop manufacturing friendly products. Implemented batch sizes of one – reducing wait times and improving productivity.

GKN Automotive, Inc. (LAY OFF) Mebane, NC 6/1998 to 2/2001 Manufacturing Engineer - (Manufactured components for front wheel drive vehicles – Ford & Toyota) Decreased tool usage by over 25%. ($62K savings) Increased machine up-time by 17.5%. Decreased scrap costs more than 50%, and increased the lathe capability from less than 1.0 to greater than 2.0. Developed Poka – Yoke to stop non-conforming material from moving up the line. Programmed and supported the MotoMan Robots. Assisted with gaining QS 9000 certification for GKN - Alamance Facility. Worked with the Tool Room & Maintenance groups to overcome obstacles and to be ready for Production during shut down activities.

Dialight Corporation, Roxboro, NC 6/1996 to 6/1998 Manufacturing Engineer - (Manufactured LED assemblies for commercial vehicles as well as traffic signals) Provided leadership, supervision, and training to the technical support staff. Developed a wave solder process for the successful use of Hewlett Packard LEDs. Implemented new environmentally friendlier packaging. Saving over $750,000 in packaging costs per year. Programmed Cencorp TR1000 Depaneling machine for all PCBs to separate the assembled circuit boards. Designed fixtures and test systems. Implemented capital project for heat staking PC Boards – improving the process & product quality. Utilized 5 Whys to focus on solution. Changed from ultrasonic staking to heat staking. Virtually eliminated costs for set-up tooling costs for securing the circuit board to the housing. Justified the purchase and supervised the installation of essential production equipment. Performed layouts to optimize production flow and into Work Cells. Line balancing.

Mettler - Toledo, Inc., (PLANT CLOSED) Inman, SC 1/1987 to 6/1996 Senior Manufacturing Engineer (Manufactured transducers, scales, & weighing equipment) Championed Continuous Improvement Projects, Cost Reductions, Quality Improvements, Decreased Warranty Returns, Increased Sales. Managed and led the transducer and retail scale assembly technical support teams. Supervised, directed, trained, and coached ICE (Initial Career Experience) Engineers, Coop students, Engineers, Technicians, and Associates. Streamlined Retail Scale Focused Factory to require 70% less floor space with a 50% increase in efficiency. Completed the Project Approval Request (PAR), obtained approval, and completed the purchase and successful installation of the Nd:YAG laser welder with two workstations. Programmed CNC Plasma Arc Welders and YAG Laser welders. Developed fixtures to increase through put and to reduce ergonomic problems. Reduced gaging cycle time by more than 50%. Programmed and supported the ADEPT gaging robots. Instructed floor personnel and helped prepare process procedures to receive ISO 9002 Certification. Coordinated all testing required eliminating CFCs from the manufacturing process. At the time of implementation, a yearly cost savings of over $250,000 was realized. Developed & expanded the Kan-Ban System.

EDUCATION Bachelor of Science, Engineering Technology - Mechanical Specialty 5/1983 College of Engineering, Clemson University, Clemson, South Carolina.

COMMUNITY SERVICE Eagle Scout w/ palms, Boy Scouts of America Scout Leader – Alamance District, Old North State Council