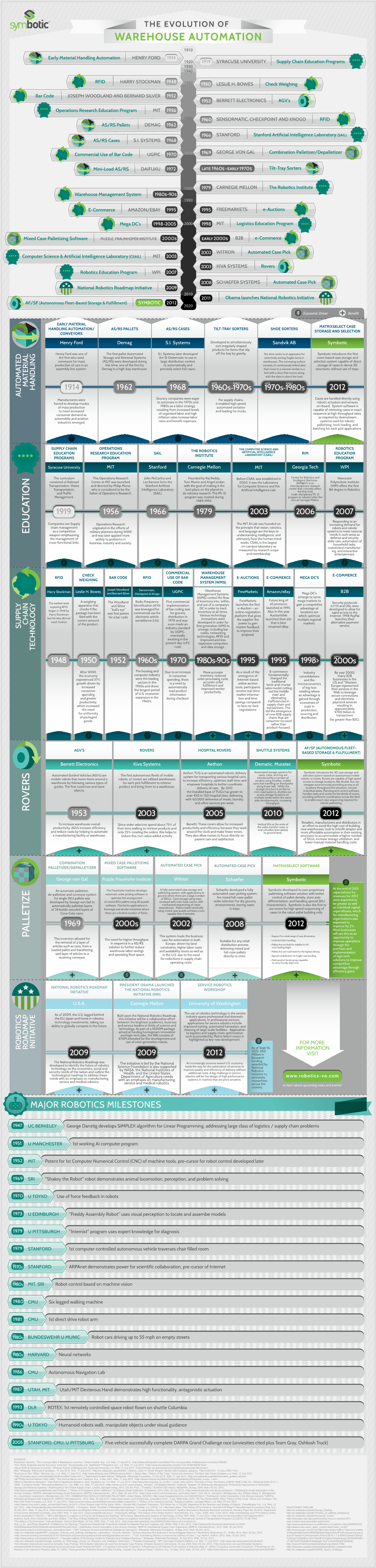

Warehouse Automation

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Warehouse Automation 101

Warehouse Automation 101 More and more warehouses are looking at automation to help achieve greater effiency but, what is warehouse automation and how exactly can it help? We’ve put together this comprehensive guide to outline the many aspects of warehouse automation that you should know – and some best practices for implementing automation successfully. www.scanco.com / -- Table of Contents 1. About This Guide 2. What is Warehouse Automation? 3. Why Should You Automate Your Warehouse? 4. When to Introduce Automation 5. What Processes Can Be Automated? 6. Getting Started with Automation 7. What Automation Solutions Are Available for Sage? 8. Determining the Automation ROI 9. Summary 10. Contact Scanco www.scanco.com / Warehouse Automation 101 | Scanco -- By improving efficiencies and cutting costs, automation technology is one of today’s fastest-growing supply chain innovations. Distributors are facing more challenges than ever before in today's constantly changing world of warehouse management. Emerging trends in retailing and complex global supply chains are putting more pressure on distributors and manufacturers to increase output, cut costs, and reduce inventory cycles. Companies like Amazon have entirely changed the way retailers do business adding even more pressure with customer expectations of "next-day" and even "same-day" shipping. Distributors must find new ways to solve challenges more effectively. Management also has countless responsibilities to worry about as well, such as: Establishing and following best practices for efficiency Driving higher KPI performance and goals Workforce shifting from “Baby Boomers” to “Millennials” Keeping up with technology trends If all of this sounds like a lot, that’s because it is. -

Pop-Up Supply Chains: Leveraging Network Assets for Dynamic Distribution

Pop-Up Supply Chains: Leveraging Network Assets for Dynamic Distribution Contents 2 Introduction 3 Inflection Points Distribution Center Locations Manufacturing Plant Locations 6 What is a Pop-Up Supply Chain? Temporary DCs? Leveraging All Potential Distribution Points Suppliers Consolidators Stores 10 Conclusion Introduction A ‘perfect storm’ of conditions in recent years has created The more recent phenomenon of channel proliferation new and greater pressures on supply chains than ever is a result of the Internet changing the way consumers before. Laying the foundation was the rise of e-commerce prefer to do business. Retail and direct channels no longer and the Internet in the late 1990s; consumers have become simply co-exist. They now intertwine. This juxtaposition is more educated and more demanding than ever before. more than just buying online and returning at the store. A This demand manifested itself in multiple ways. First, was customer’s store buying habits should be reflected in how SKU proliferation. The ability to research and ultimately the he/she is treated and marketed to online. ability to customize dramatically increased the volume of Early on, this new complexity could be addressed with SKUs supply chains had to manage. Retailers introduced brute force—extra inventory, extra labor and expedited ‘endless aisles’ allowing consumers to buy more products transportation. However, the surge in oil prices that started online or at a kiosk than a retailer could possibly stock. with Katrina and pushed higher with the rise of the BRIC economies ratcheted up financial pressure. Ultimately, the slowdown of western economies is forcing the hands of many supply chain operators. -

Building the World's Best Warehouse 18

PRODUCTIVITY SOLUTIONS FOR DISTRIBUTION, WAREHOUSING AND MANUFACTURING th SARY IVER mmh.com ANN April 2020 READER SURVEY 2020 Warehouse/DC Equipment Survey 26 SPECIAL REPORT Modex in review 36 BEST PRACTICES What does innovation mean to you? 44 Varner: EQUIPMENT REPORT Overhead handling 50 Building the INFORMATION MANAGEMENT Voice system evolution 56 world’s best warehouse 18 Anders Eriksson, the supply chain director for Varner AS MODERN system report Editor’s note: This story on Varner’s automated retail distribution center in Vänersborg, Sweden, is a continuation of our look at global order fulfillment, and our second set in Scandinavia. 18 A PRIL 2 0 2 0 / MODERN MATERIALS HANDLING mmh.com Building the world’s best warehouse That was the goal of Scandinavian retailer Varner. The result is a most highly automated, omni-channel retail distribution center, that is also flexible, cost-effective, ergonomic and sustainable. BY BOB TREBILCOCK, EXECUTIVE EDITOR rom the start of the project, of 10 unique retail chains, each with we declared that we wanted its own go-to-market strategy, along to build the best warehouse with a fast-growing e-commerce busi- in the world.” So says Anders ness. The materials handling systems “FEriksson, the supply chain director address robotic palletizing and depal- for Varner AS, one of Scandinavia’s letizing, automated pallet storage, largest retailers. Eriksson oversaw the automated case storage, automated design and implementation of a new garment-on-hanger (GOH) storage 500,000-square-foot, omni-channel and robotic goods-to-person piece distribution center in Vänersborg, picking. What’s more, it was designed Sweden. -

Supply Chain Packaging Guide

Secondary Packaging Supply Chain Standards July 7, 2021 Business Confidential | ©2021 Walmart Stores, Inc. 177 // 338 Secondary Packaging Supply Chain Standards - Update Summary These standards have included multiple clarifications of what is required and what is NOT ALLOWED. These changes have been updated throughout the published standards to provide clarity to suppliers. The pages have been reorganized to provide a better flow. PAGE 2021 UPDATES Changes to Supply Chain Standards 185 SQEP Phase 2 and Phase 3 Defect Description/Definitions Added 202 General Case Markings Updated for Dates, Unprocessed Meats, and Cylindrical Items 210-213 Updated Pallet Standards 218 Update "Palletized Shipments" to "Unitized Shipments" 227 Add Inbound Appointment Scheduling Standard 228 Update TV Test Standards 235-237 Add Direct Store Delivery (DSD) aka Direct To Store (DTS) Standards 239 Update SIOC Standards 240 Add eCommerce Product Specific Requirement Standards 241-244 Add Drop Ship Vendor (DSV) Standards 268 Add Jewelry Distribution Center Standards 269-271 Add Optical Distribution Center Standards 275 Add Goods Not For Resale (GNFR) Standards 277-278 Update Meat/Poultry/Seafood Case and Pallet Label Standards 284 Add HACCP Pallet Placard for GCC Shipments 311-312 Add Frozen Seafood Carton Marking Requirements Appendix D Update Receiving Pulp Temperature Range Business Confidential | © 2021 Walmart Stores, Inc. The examples shown are for reference only. Supply Chain Standards 178 // 338 Table of Contents Supply Chain Stretch Wrap . 219 Produce Shipments . 280 Contact Information . 179 Trailer Loading . 220 Automated Grocery Handling . 281 Walmart Retail Link Resources . 180 Trailer Measurements. 221 Grocery Import Distribution Center (GIDC) . 282 Walmart Distribution Center Overview . -

United Natural Foods (UNFI)

United Natural Foods Annual Report 2019 Form 10-K (NYSE:UNFI) Published: October 1st, 2019 PDF generated by stocklight.com UNITED STATES SECURITIES AND EXCHANGE COMMISSION Washington, D.C. 20549 FORM 10-K x ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the fiscal year ended August 3, 2019 or ¨ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the transition period from _______ to _______ Commission File Number: 001-15723 UNITED NATURAL FOODS, INC. (Exact name of registrant as specified in its charter) Delaware 05-0376157 (State or other jurisdiction of (I.R.S. Employer incorporation or organization) Identification No.) 313 Iron Horse Way, Providence, RI 02908 (Address of principal executive offices) (Zip Code) Registrant’s telephone number, including area code: (401) 528-8634 Securities registered pursuant to Section 12(b) of the Act: Name of each exchange on which Title of each class Trading Symbol registered Common Stock, par value $0.01 per share UNFI New York Stock Exchange Securities registered pursuant to Section 12(g) of the Act: None Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No x Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. -

United Natural Foods, Inc. (UNFI) Q1 2019 Earnings Call

Corrected Transcript 06-Dec-2018 United Natural Foods, Inc. (UNFI) Q1 2019 Earnings Call Total Pages: 26 1-877-FACTSET www.callstreet.com Copyright © 2001-2018 FactSet CallStreet, LLC United Natural Foods, Inc. (UNFI) Corrected Transcript Q1 2019 Earnings Call 06-Dec-2018 CORPORATE PARTICIPANTS Steven J. Bloomquist Sean F. Griffin Vice President-Investor Relations, United Natural Foods, Inc. Chief Operating Officer & Chief Executive Officer of SUPERVALU, United Natural Foods, Inc. Steven L. Spinner Chairman, President & Chief Executive Officer, United Natural Foods, Michael Paul Zechmeister Inc. Chief Financial Officer, United Natural Foods, Inc. ...................................................................................................................................................................................................................................................... OTHER PARTICIPANTS John Heinbockel Paul Kearney Analyst, Guggenheim Securities LLC Analyst, Wolfe Research LLC Edward J. Kelly Kelly Ann Bania Analyst, Wells Fargo Securities LLC Analyst, BMO Capital Markets (United States) Christopher Mandeville Eric J. Larson Analyst, Jefferies LLC Analyst, The Buckingham Research Group, Inc. Vincent J. Sinisi Analyst, Morgan Stanley & Co. LLC ...................................................................................................................................................................................................................................................... MANAGEMENT DISCUSSION SECTION -

UC Berkeley Previously Published Works

UC Berkeley UC Berkeley Previously Published Works Title Building the Second Mind, 1961-1980: From the Ascendancy of ARPA-IPTO to the Advent of Commercial Expert Systems Permalink https://escholarship.org/uc/item/7ck3q4f0 ISBN 978-0-989453-4-6 Author Skinner, Rebecca Elizabeth Publication Date 2013-12-31 eScholarship.org Powered by the California Digital Library University of California Building the Second Mind, 1961-1980: From the Ascendancy of ARPA to the Advent of Commercial Expert Systems copyright 2013 Rebecca E. Skinner ISBN 978 09894543-4-6 Forward Part I. Introduction Preface Chapter 1. Introduction: The Status Quo of AI in 1961 Part II. Twin Bolts of Lightning Chapter 2. The Integrated Circuit Chapter 3. The Advanced Research Projects Agency and the Foundation of the IPTO Chapter 4. Hardware, Systems and Applications in the 1960s Part II. The Belle Epoque of the 1960s Chapter 5. MIT: Work in AI in the Early and Mid-1960s Chapter 6. CMU: From the General Problem Solver to the Physical Symbol System and Production Systems Chapter 7. Stanford University and SRI Part III. The Challenges of 1970 Chapter 8. The Mansfield Amendment, “The Heilmeier Era”, and the Crisis in Research Funding Chapter 9. The AI Culture Wars: the War Inside AI and Academia Chapter 10. The AI Culture Wars: Popular Culture Part IV. Big Ideas and Hardware Improvements in the 1970s invert these and put the hardware chapter first Chapter 11. AI at MIT in the 1970s: The Semantic Fallout of NLR and Vision Chapter 12. Hardware, Software, and Applications in the 1970s Chapter 13. -

Distribution Center

Distribution Center Deployment Environment Guide INTERMEC CONFIDENTIAL Contents Preface.......................................................................................................................................... 2 Environment Overview.................................................................................................................. 3 The Warehouse Management System...................................................................................... 4 DC Metrics................................................................................................................................. 4 Detailed Environment Description................................................................................................ 5 Key Applications Common to Warehouse/DC Operations:....................................................... 5 Receiving............................................................................................................................... 5 Put-Away............................................................................................................................... 6 Picking................................................................................................................................... 7 Why Intermec?.............................................................................................................................. 13 Positioning and Differentiating Intermec................................................................................. 13 Intermec’s -

Strategic Latency: Red, White, and Blue Managing the National and International Security Consequences of Disruptive Technologies Zachary S

Strategic Latency: Red, White, and Blue Managing the National and International Security Consequences of Disruptive Technologies Zachary S. Davis and Michael Nacht, editors Center for Global Security Research Lawrence Livermore National Laboratory February 2018 Disclaimer: This document was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor Lawrence Livermore National Security, LLC, nor any of their employees makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or Lawrence Livermore National Security, LLC. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or Lawrence Livermore National Security, LLC, and shall not be used for advertising or product endorsement purposes. LLNL-BOOK-746803 Strategic Latency: Red, White, and Blue: Managing the National and International Security Consequences of Disruptive Technologies Zachary S. Davis and Michael Nacht, editors Center for Global Security Research Lawrence Livermore National Laboratory February -

DARPA Grand Challenge - Wikipedia 1 of 11

DARPA Grand Challenge - Wikipedia 1 of 11 DARPA Grand Challenge The DARPA Grand Challenge is a prize competition for American autonomous vehicles, funded by the Defense Advanced Research Projects Agency, the most prominent research organization of the United States Department of Defense. Congress has authorized DARPA to award cash prizes to further DARPA's mission to sponsor revolutionary, high- payoff research that bridges the gap between fundamental discoveries and military use. The initial DARPA Grand Challenge was created to spur the development of technologies needed to create the first fully autonomous ground vehicles capable of completing a substantial off-road course within a limited time. The third event, the DARPA Urban Challenge extended the initial Challenge to The site of the DARPA Grand Challenge on race autonomous operation in a mock urban environment. day, fronted by the Team Case vehicle, DEXTER The most recent Challenge, the 2012 DARPA Robotics Challenge, focused on autonomous emergency- maintenance robots. The first competition of the DARPA Grand Challenge was held on March 13, 2004 in the Mojave Desert region of the United States, along a 150-mile (240 km) route that follows along the path of Interstate 15 from just before Barstow, California to just past the California–Nevada border in Primm. None of the robot vehicles finished the route. Carnegie Mellon University's Red Team and car Sandstorm (a converted Humvee) traveled the farthest distance, completing 11.78 km (7.32 mi) of the course before getting hung up on a rock after making a switchback turn. No winner was declared, and the cash prize was not given. -

Bartholdi-Hackman.Pdf

T WAREHOUSE & DISTRIBUTION SCIENCE Release 0.1.2 http://www.warehouse-science.com John J. Bartholdi, III 1 Steven T. Hackman May 22, 1998; revised May 24, 2002 1 Copyright c 1998–2002 John J. Bartholdi, III and Steven T. Hackman. All rights reserved. This material may be freely copied for educational purposes, but not for resale, as long as the authors’s names and the copyright notice appear clearly on the copies. The authors may be con- tacted at [email protected] or [email protected]. edu. DRAF 2 DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT Contents Preface i 0.1 Why this book . ........................... i 0.2 Organization ............................... i 0.3 Resources . ............................... ii 0.4 But first. ............................... ii 1 Introduction 1 2 Material flow 5 2.1 The warehouse as a queueing system . ................ 6 2.1.1 Extensions ........................... 8 2.2 Questions . ............................... 9 3 Warehouse operations 11 3.1 Receiving . ............................... 12 3.2 Put-away . ............................... 12 3.3 Process customer orders . ....................... 13 3.4 Order-picking . ........................... 13 3.4.1 Sharing the work of order-picking . ............ 14 3.5 Checking and packing . ....................... 16 3.6 Shipping . ............................... 16 3.7 Summary . ............................... 16 3.8 More . ............................... 17 3.9 Questions . ............................... 18 4 Storage and handling equipment 19 4.1 Storage equipment ........................... 19 4.1.1 Pallet storage . ....................... 20 4.1.2 Bin-shelving or static rack . ................ 23 4.1.3 Gravity flow rack . ....................... 23 4.1.4 Carousels . ........................... 26 4.2 Conveyors . ............................... 27 4.3 Sortation equipment ........................... 27 4.4 Summary . ............................... 27 3 DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT 4 CONTENTS 4.5 On the lighter side ........................... -

Unlocking Hidden Cost in the Distribution Center

Unlocking Hidden Cost in the Distribution Center A Research Report by Intermec Technologies Corporation RESEARCH PAPER EXECUTIVE SUMMARY RESEARCH METHODOLOGY The “Unlocking Hidden Cost in the Distribution The research, commissioned by Intermec and carried Center” research examines current views out by research company Vanson Bourne, surveyed on distribution center trends and challenges 250 senior supply chain and distribution center from senior supply chain and distribution managers at organisations with over 500 employees center managers within the UK, France, in the UK, France, Germany and North America. Germany and Northern America. The interviews were conducted by telephone with respondents spanning industries including retail, With many businesses still feeling the effects manufacturing, distribution, transport, chemicals, of the recession, facing increased competition logistics, pharmaceuticals, wholesale and FMCG. and being forced to operate on smaller and smaller profit margins, distribution managers 50 interviews were conducted in each European are increasingly tasked with the seemingly country with 100 interviews taking place in impossible job of finding cost savings from North America during October 2012. existing operations. To do this, managers are learning that they have to leave no stone unturned in order to effectively evaluate SIZE current processes and technology to help identify areas for efficiency improvements. 28% 36% Key Findings From The Intermec Research Are: • Managers are seeking to improve operational efficiency by gaining back mere seconds from each workflow to improve the overall 36% time and cost savings. Having workers take fewer steps over the course of a day, eliminating battery changes mid-shift or 501-1000 employees using one device for multiple purposes are all areas managers identified as key 1001-3000 employees components to increase efficiency.