UNITED STATE S PATENT OFFICE

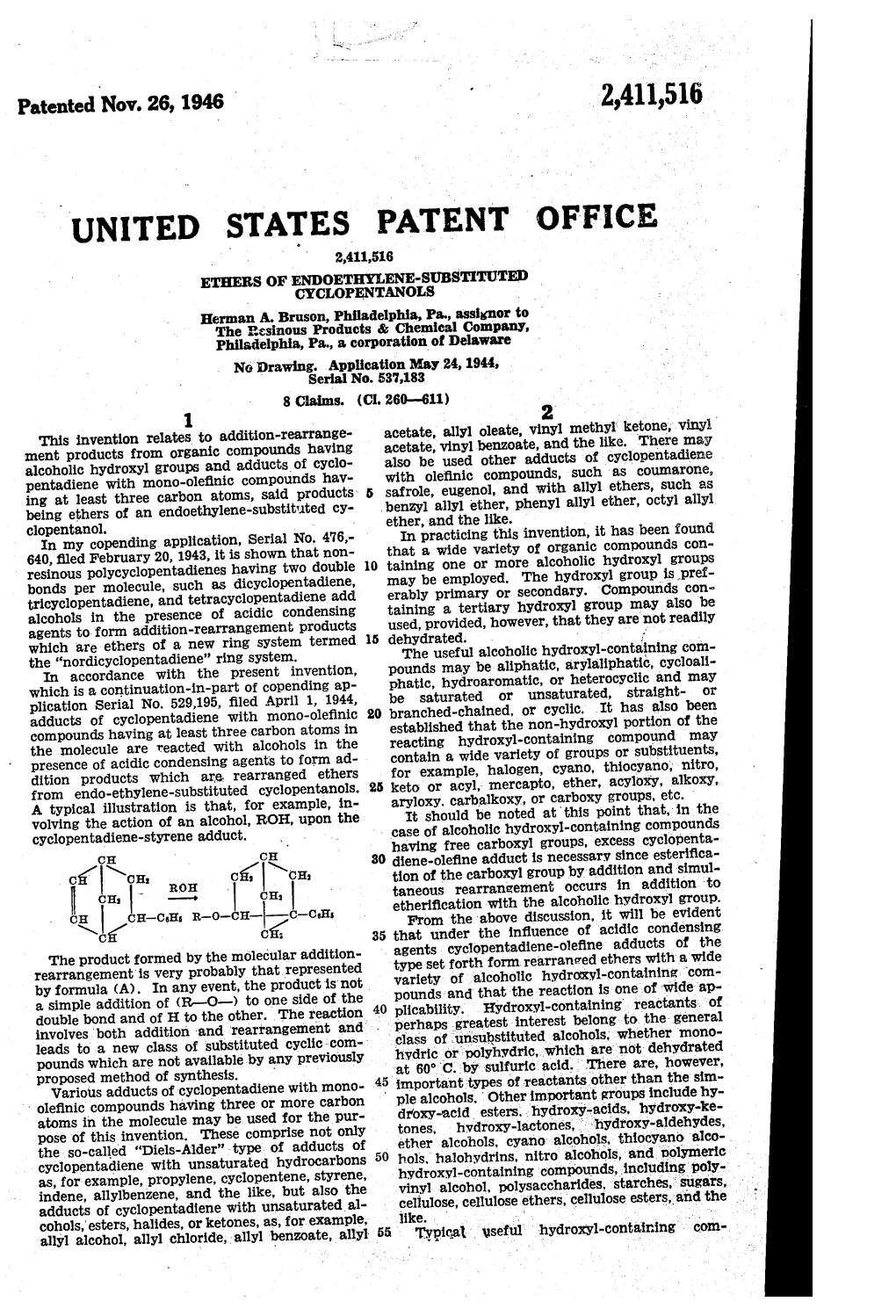

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Gc Applications

gc applications Alcohols C1-C7 Alcohols C1-C6 Alcohols 1007 1255 1. Methanol 1. Methanol 4. 2-Methyl-2- 6. 2-Butanol 2. 2-Propanol 2. Ethanol propanol 7. 2-Methyl-1-propanol 3. 1-Propanol 3. 2-Propanol 5. 1-Propanol 8. 2-Methyl-2-butanol 4. 2-Butanol 9. 1-Butanol 5. 2-Methyl-1-propanol 10. 2,2-Dimethyl-1-propanol 6. 1-Butanol 11. 3-Methyl-2-butanol 7. 3-Methyl-1-butanol 12. 2-Pentanol + 3-Pentanol 8. 1-Pentanol 13. 3-Methyl-1-butanol 9. 2-Ethyl-1-butanol 14. 2-Methyl-1-butanol 10. 1-Hexanol 15. 4-Methyl-2-pentanol 11. Cyclohexanol 16. 1-Pentanol 12. 3-Methylcyclohexanol 17. 1-Hexanol 13. 1-Heptanol 18. Cyclohexanol å-IN Column: Econo-Cap™ EC™-1, 30m x 0.32mm x 0.25µm Column: Heliflex® AT™-1, 30m x 0.53mm x 5.00µm (Part No. 19651) (Part No. 16843) Temp: 40°C to 120°C at 10°C/min Temp: 35°C to 100°C at 5°C/min Carrier Gas: Helium at 1.09mL/min (26.7cm/sec) Carrier Gas: Helium at 3mL/min Detector: FID Detector: FID C1-C6 Alcohols Aromatic Alcohols 2596 1249 1. Methanol 1. A,A-Dimethylbenzyl Alcohol 2. Ethanol 2. DL-A-Methylbenzyl Alcohol 3. 1-Propanol 3. Benzyl Alcohol 4. 2-Methyl-1-propanol 4. 2-Phenylethyl Alcohol 5. 1-Butanol 5. 3-Phenyl-1-propanol 6. 4-Methyl-2-pentanol 6. Cinnamyl Alcohol 7. 1-Pentanol 7. Phenyl-1,2-ethanediol 8. 2-Ethyl-1-butanol 8. -

A Practical and Stereoselective Synthesis of Cinnamyl Alcohols Bearing A-Cyano Or A-Ester Functional Group from Baylis-Hillman Adducts

Notes Bull. Korean Chem. Soc. 2004, Vol. 25, No. 3 413 A Practical and Stereoselective Synthesis of Cinnamyl Alcohols Bearing a-Cyano or a-Ester Functional Group from Baylis-Hillman Adducts Ka Young Lee, Saravanan GowriSankar, and Jae Nyoung Kim Department of Chemistry and Institute of Basic Science, Chonnam National University, Gwangju 500-757, Korea Received December 18, 2003 Key Words : Cinnamyl alcohols, Baylis-Hillman adducts, Sulfuric acid, Acetic anhydride Cinnamyl alcohols bearing ester, acid, or nitrile functional Hillman alcohol into the primary acetate or eventually to group at the 2-position are very useful synthons for the primary alcohol (Scheme 1 and Table 1). synthesis of various biologically important compounds.1 The reaction of Baylis-Hillman adducts with acetic Synthesis of cinnamyl alcohol derivatives from the Baylis- anhydride (1.5 equiv.) in the presence of sulfuric acid (10 Hillman adducts has been reported by us and other groups.1-4 mol%) gave the corresponding rearranged cinnamyl acetates The conversion can be carried out directly by using 20% quantitatively in dichloromethane at room temperature aqueous sulfuric acid (for the Baylis-Hillman adducts within 30 min (Actually, the cinnamyl acetate derivatives derived from acrylonitrile)2 or trifluoroacetic acid (for the could be isolated in 92-95% yields.). In order to obtain the Baylis-Hillman adducts derived from acrylates).3 Recently, corresponding cinnamyl alcohols in a one-pot we tried some Basavaiah and coworkers have reported the two-step, one- reaction conditions for the next partial hydrolysis. Addition pot conversion method: TMSOTf-assisted conversion of of water to the reaction mixture (two-phase system) afforded Baylis-Hillman alcohol into the corresponding primary the hydrolyzed cinnamyl alcohols in trace amounts. -

Food and Drug Administration, HHS § 172.515

Food and Drug Administration, HHS § 172.515 Common name Scientific name Limitations Tolu ................................................................ Myroxylon balsamum (L.) Harms. Turpentine ...................................................... Pinus palustris Mill. and other Pinus spp. which yield terpene oils exclusively. Valerian rhizome and roots ............................ Valeriana officinalis L. Veronica ......................................................... Veronica officinalis L .................................................. Do. Vervain, European ......................................... Verbena officinalis L ................................................... Do. Vetiver ............................................................ Vetiveria zizanioides Stapf ......................................... Do. Violet, Swiss ................................................... Viola calcarata L. Walnut husks (hulls), leaves, and green nuts Juglans nigra L. or J. regia L. Woodruff, sweet ............................................. Asperula odorata L ..................................................... In alcoholic beverages only Yarrow ............................................................ Achillea millefolium L .................................................. In beverages only; fin- ished beverage thujone free1 Yerba santa .................................................... Eriodictyon californicum (Hook, et Arn.) Torr. Yucca, Joshua-tree ........................................ Yucca brevifolia Engelm. Yucca, -

Nomination Background: Methyl Trans

' 7/?1 Methyl styryl ketone 122-57-6 NTP NOMINATION HISTORY AND REVIEW A. Nomination History 1. Nomination Source: NCI 2. Recommendations: -Comparative toxicity studies with methyl vinyl ketone -Metabolism -Carcinogenicity 3. Rationale/Remarks: -Potential for widespread human exposure -Nominated as a result of a class study of a,~-unsaturated ketones -Flavoring and fragrance additive -Natural product -Environmental pollutant -Mutagenic in Salmonella 4. Priority: -High for toxicity studies -Moderate for carcinogenicity s. Date of Nomination: July 1994 B. Interagency Committee for Chemical Evaluation and Coordination Review 1. Date of Review: 2. Recommendations: 3. Priority: 4. NTP Chemical Selection Principles: 5. Rationale/Remarks: 122-57-6 Methyl styryl ketone SUMMARY OF DATA FOR CHEMICAL SELECTION CHEMICAL IDENTIFICATION CAS Registry Number: 122-57-6 Chemical Abstracts Name: 3-Buten-2-one, 4-phenyl- (SCI, 9CI) Svnonvms and Trade Names: Acetocinnamone; benzalacetone; benzylideneacetone; methyl 2 phenylvinyl ketone; methyl styryl ketone; methyl ~-styryl ketone; 4 phenylbutenone; 4-phenyl-3-butene-2-one; 2-phenylvinyl methyl ketone; styryl methyl ketone; MSK FEMA Number: 2881 Related isomers CAS Registry Number: 937-53-1 Chemica] Abstracts Name: 3-Buten-2-one, 4-phenyl-, (Z)- (SCI, 9CI) Synonvms and Trade Names: cis -4-Phenyl-3-buten-2-one; cis -benzalacetone; cis benzylideneacetone; cis-methyl styryl ketone CAS Registry Number: 1896-62-4 Chemical Abstracts Name: 3-Buten-2-one, 4-phenyl-, (E)- (SCI, 9CI) Synonyms and Trade Names: trans-4-Phenyl-3-buten-2-one; trans-benzalacetone; trans benzylideneacetone; trans-methyl styryl ketone; TPBO Structure. Molecular Formula. and Molecular WeiKbt 0 II H•CHCCH3 Mol. wt.: 146.19 Chemical and Phvsical Properties (from Aldrich Chemical Co., 1993, 1994; Budavari, 1989) Description: White to yellow solid with a sweet, pungent, creamy, floral odor Prepared for NCI by Technical Resources, Inc. -

Functional Expression of a Novel Methanol-Stable Esterase From

Cai et al. BMC Biotechnology (2020) 20:36 https://doi.org/10.1186/s12896-020-00622-1 RESEARCH ARTICLE Open Access Functional expression of a novel methanol- stable esterase from Geobacillus subterraneus DSM13552 for biocatalytic synthesis of cinnamyl acetate in a solvent- free system Xianghai Cai1†, Lin Lin2,3†, Yaling Shen1, Wei Wei1* and Dong-zhi Wei1 Abstract Background: Esterases are widely distributed in nature and have important applications in medical, industrial and physiological. Recently, the increased demand for flavor esters has prompted the search of catalysts like lipases and esterases. Esterases from thermophiles also show thermal stability at elevated temperatures and have become enzymes of special interest in biotechnological applications. Although most of esterases catalyzed reactions are carried out in toxic and inflammable organic solvents, the solvent-free system owning many advantages such as low cost and easy downstream processing. Results: The gene estGSU753 from Geobacillus subterraneus DSM13552 was cloned, sequenced and overexpressed into Escherichia coli BL21 (DE3). The novel gene has an open reading frame of 753 bp and encodes 250-amino-acid esterase (EstGSU753). The sequence analysis showed that the protein contains a catalytic triad formed by Ser97, Asp196 and His226, and the Ser of the active site is located in the conserved motif Gly95-X-Ser97-X-Gly99 included in most esterases and lipases. The protein catalyzed the hydrolysis of pNP-esters of different acyl chain lengths, and the enzyme specific activity was 70 U/mg with the optimum substrate pNP-caprylate. The optimum pH and temperature of the recombinant enzyme were 8.0 and 60 °C respectively. -

Proceedings of the Indiana Academy of Science

The Reactions of Silicomolybdic Acid with Organic Compounds 1 John H. Billman, Donald B. Borders, and John A. Buehler, Indiana University, Hondo AFB, Texas, and Anderson College For many years the analytical and inorganic chemists have been seeking specific reagents to identify metallic ions. At the same time, the organic chemist has been interested in finding compounds that would be useful for spotting different types of functional groups commonly en- countered in organic compounds. A typical example of such a reagent is ferric chloride, which has found wide use with phenols. For several years we have been testing various compounds in an effort to find reagents that would be specific for metallic ions as well as organic functional groups. In the course of our investigation it was found that silicomolybdic acid (1), H 4 SiMo 12 O 40 .xH 2 O, would produce a dark blue mixture in the presence of aliphatic aldehydes, but would not give the same test with aromatic aldehydes. Further investigation indi- cated that only aldehydes that contain a hydrogen atom on the alpha carbon atom would give a positive test. On the basis of this work a more thorough study was undertaken of the reaction of silicomolybdic acid with various organic compounds containing different functional groups. Altogether the reagent has been tried with a one-hundred and forty-five organic compounds. Table 1 shows the aldehydes that have been tested. TABLE I Aldehydes — Formaldehyde — Benzaldehyde + Acetaldehyde — m-Nitrobenzaldehyde -f Phenylacetaldehyde — p-Nitrobenzaldehyde -

Alcohol Dehydrogenase and Cinnamoyl-Coa Reductase (Monolignol͞genetic Modification͞antisense Rna͞coniferyl Alcohol͞feruloyl-Coa)

Proc. Natl. Acad. Sci. USA Vol. 95, pp. 12803–12808, October 1998 Biochemistry NMR characterization of altered lignins extracted from tobacco plants down-regulated for lignification enzymes cinnamyl- alcohol dehydrogenase and cinnamoyl-CoA reductase (monolignolygenetic modificationyantisense RNAyconiferyl alcoholyferuloyl-CoA) JOHN RALPH*†‡,RONALD D. HATFIELD*, JOE¨L PIQUEMAL§,NABILA YAHIAOUI§,MICHEL PEAN¶, i CATHERINE LAPIERRE , AND ALAIN M. BOUDET§ *United States Dairy Forage Research Center, United States Department of Agriculture, Agricultural Research Service, Madison, WI 53706-1108; †Department of Forestry, University of Wisconsin, Madison, WI 53706-1598; §Unite´Mixte de Recherche, Centre National de la Recherche Scientifique 5546, Centre de Biologie et Physiologie Ve´ge´tale, Universite´Paul Sabatier Baˆt.4R1, 118 route de Narbonne, F-31062 Toulouse Cedex, France; ¶Commissariat a`l’Energie Atomique, De´partementd’Ecophysiologie Ve´ge´tale et Microbiologie, Cadarache, Baˆt.177, F-13108 Saint Paul lez Durance Cedex, France; and iInstitut National de la Recherche Agronomique, Laboratoire de Chimie Biologique, F-78850 Thiverval-Grignon, France Communicated by Ron Sederoff, North Carolina State University, Raleigh, NC, July 29, 1998 (received for review May 13, 1998) OHO OS OH OH ABSTRACT Homologous antisense constructs were CoA used to down-regulate tobacco cinnamyl-alcohol dehydro- CCL' CCR' CAD' p-Coumaryl genase (CAD; EC 1.1.1.195) and cinnamoyl-CoA reductase alcohol (CCR; EC 1.2.1.44) activities in the lignin monomer biosyn- OH OH OH OH 1) HYD1' 1) HYD2' 1) HYD3' 1) HYD4' thetic pathway. CCR converts activated cinnamic acids 2) OMT1' 2) OMT2' 2) OMT3' 2) OMT4' OHO OS OH OH (hydroxycinnamoyl–SCoAs) to cinnamaldehydes; cinnama- CoA CCR CAD ldehydes are then reduced to cinnamyl alcohols by CAD. -

Electrophilic Agents James A

part 1 . PART 1 concordance between cancer in humans and in experimental CHAPTER 1 animals chapter 1. Electrophilic agents James A. Bond and Ronald L. Melnick Introduction or mice and, except for ethylene chloride), the lung (sulfur mustard), oxide, sufficient evidence of carci- the lymphohaematopoietic system In this chapter, electrophilic agents nogenicity from studies of exposed (benzene, 1,3-butadiene, and eth- include direct-acting electrophilic humans. For ethylene oxide, there ylene oxide), nasal tissue (formal- chemicals and chemicals that are was limited evidence of carcinogen- dehyde), and the kidney (TCE). For metabolized to reactive electro- icity in humans, but the classification bis(chloromethyl)ether (BCME), the philes. All of the chemicals discussed of this chemical was raised to carci- lung and the nasal cavity were iden- here are IARC Group 1 agents and nogenic to humans (Group 1) based tified as target organs in humans as such can be characterized as on strong mechanistic evidence and rats, respectively. In addition, carcinogenic to humans. Relevant of mutagenicity and clastogenici- angiosarcomas of the liver, which carcinogens discussed in this chap- ty, including the induction of sister are rare tumours, were identified in ter do not include pharmaceutical chromatid exchange (SCE), chro- humans, rats, and mice exposed to drugs classified in Group 1, which mosomal aberrations (CA), and mi- vinyl chloride. otherwise typically include alkylating cronuclei (MN) in workers exposed In several instances, tumour sites cytotoxic agents. to ethylene oxide. identified in animals were not de- Tumour sites identified in previous Among this group of chemicals, tected in epidemiological studies of IARC evaluations of the carcinogen- there is remarkable concordance in exposed workers. -

Chemical Compatibility Guide

45678 Chemical Compatibility Guide Guide Chemical Compatibility Elastomeric Compounds Chemical Compatibility Guide HIGH-PERFORMANCE MATERIALS APPLYING THE COMPATIBILITY GUIDE Greene, Tweed offers customized-engineered components that optimize The ratings contained in this guide (see chart on the next pages) the total system. We have 100 years of experience developing high- are based on existing published data, laboratory soak tests and performance materials for a range of industries, from medical, informed decisions on the part of Greene, Tweed personnel. Most aerospace and defense, to fluid handling, oilfield and semiconductor. ratings are based on ambient temperature, low pressure and 100 We currently manufacture more than 300 unique elastomeric percent concentrations. Exposure conditions differing from stated compounds and over 300 plastic production compounds from eight conditions could affect these ratings. distinct plastic families. It is important to recognize real world differences when applying Greene, Tweed formulates a variety of compounds to meet specific laboratory and empirical information to actual field situations. Soak characteristics such as durometer, modulus, compression set, tests usually employ full immersion of the test sample, in a pure temperature, fluid compatibility, etc. Because we believe in fluid, at room temperature, without pressure or other stresses. In collaborating with customers to match the specific needs of their actual service, however, the seal is likely to experience a mixture of applications, we can customize one of our many compounds to fluids, be exposed only on one edge, be compressed in a sealing extend the performance of any process. Our engineers work side by gland and/or be subjected to process pressure, elevated tempera- side with customers to design the best solution for each individual tures and possibly abrasive particles. -

X-ADH Is the Sole Alcohol Dehydrogenase Isozyme of Mammalian Brains: Implications and Inferences (Class III Alcohol Dehydrogenase/Tissue-Specific Enzyme) THOMAS B

Proc. Natl. Acad. Sci. USA Vol. 82, pp. 8369-8373, December 1985 Biochemistry X-ADH is the sole alcohol dehydrogenase isozyme of mammalian brains: Implications and inferences (class III alcohol dehydrogenase/tissue-specific enzyme) THOMAS B. BEISSWENGER, BARTON HOLMQUIST, AND BERT L. VALLEE* Center for Biochemical and Biophysical Sciences and Medicine, Harvard Medical School, 250 Longwood Avenue, Boston, MA 02115 Contributed by Bert L. Vallee, August 14, 1985 ABSTRACT Class m (X) is the only alcohol dehydrog- occurrence and function of ADH in that tissue has always enase (ADH) in human, equine, bovine, simian, canine, and been of particular interest, but efforts to uncover facts rodent brain and is the first to be identified, purified, and relevant to ethanol have been singularly disappointing. Most characterized from the brain of humans or other vertebrates. of those studies antedate the awareness of the remarkable Like the corresponding isozymes from human placenta and number and diversity of structure and specificity of ADH liver, the X-ADH isozymes purified from mammalian brain are isozymes (4), first noted much earlier (5). neither inhibited by nor do they bind to immobilized pyrazole, Experimental work failed to reveal any significant ADH and they oxidize ethanol only very poorly (Km > 2.5 M). activity in brain (6). The level ofethanol oxidation in rat brain Indeed, it would be incorrect to classify them as "ethanol is so vanishingly low that only assays of exceptionally high dehydrogenases." They contain 4 g.atom of zinc/mol, bind 2 sensitivity could detect it (7). A number of contemporaneous moles of NAD, and readily oxidize long-chain aliphatic and studies employing [14C]ethanol concluded that the perfused aromatic primary alcohols. -

UNITED STATES PATENT of FICE

Patented Dec. 27, 1949 2,492,266 UNITED STATES PATENT of FICE 2,492,266 TETRAHYDRODICYCLOPENTADENE ETHER COMPOUNDS AND INSECTC DES THERE OF George Allen Buntin, Wilmington, Del, assignor to Hercules Powder Company, Wilmington, Del, a corporation of Delaware No Drawing. Application October 15, 1947, Serial No. 780,102 11. Claims. (C. 16-30) 2 This invention relates to new polychloro ethers g-chloroethoxytetrahydrodicyclopentadienes were and, more particularly, to chlorinated ethers of tested for their insecticidal activity against house hydroxydihydrodicyclopentadiene and to insecti flies. In this and the following examples, the test cidal compositions containing these new products for insecticidal activity against houseflies was as the toxic ingredient. made in the following manner and is referred to It is known that ethers of hydroxydihydrodicy in this Specification as the bell jar method. clopentadiene may be obtained by the addition of Approximately 100 five-day old flies (Musca an alcohol to one of the double bonds of dicyclo domestica) were placed in a bell jar and a prede pentadiene in the presence of an acidic catalyst. termined quantity of the insecticide to be tested The remaining double bond of the dicyclopenta 10 was atomized into the bell jar. The quantity of diene ring will undergo further addition reactions, insecticide used was equal to the amount of the as with halogen, etc. These dihalo ethers, such Official Test Insecticide which was necessary to as the dichloro ether, have many valuable prop give a 30%-55% kill and must be within the lim erties but lack any insecticidal activity. its of 0.4–0.6 ml. -

RIFM Fragrance Ingredient Safety Assessment, Α-Amylcinnamyl Alcohol, CAS T Registry Number 101-85-9 A.M

Food and Chemical Toxicology 134 (2019) 110712 Contents lists available at ScienceDirect Food and Chemical Toxicology journal homepage: www.elsevier.com/locate/foodchemtox Short review RIFM fragrance ingredient safety assessment, α-amylcinnamyl alcohol, CAS T Registry Number 101-85-9 A.M. Apia, D. Belsitob, S. Bisertaa, D. Botelhoa, M. Bruzec, G.A. Burton Jr.d, J. Buschmanne, M.A. Cancellieria, M.L. Daglif, M. Datea, W. Dekantg, C. Deodhara, A.D. Fryerh, S. Gadhiaa, L. Jonesa, K. Joshia, A. Lapczynskia, M. Lavellea, D.C. Liebleri, M. Naa, D. O'Briena, A. Patela, T.M. Penningj, G. Ritaccoa, F. Rodriguez-Roperoa, J. Rominea, N. Sadekara, D. Salvitoa, ∗ T.W. Schultzk, F. Siddiqia, I.G. Sipesl, G. Sullivana, , Y. Thakkara, Y. Tokuram, S. Tsanga a Research Institute for Fragrance Materials, Inc, 50 Tice Boulevard, Woodcliff Lake, NJ, 07677, USA b Member Expert Panel, Columbia University Medical Center, Department of Dermatology, 161 Fort Washington Ave, New York, NY, 10032, USA c Member Expert Panel, Malmo University Hospital, Department of Occupational & Environmental Dermatology, Sodra Forstadsgatan 101, Entrance 47, Malmo SE, 20502, Sweden d Member Expert Panel, School of Natural Resources & Environment, University of Michigan, Dana Building G110, 440 Church St, Ann Arbor, MI, 58109, USA e Member Expert Panel, Fraunhofer Institute for Toxicology and Experimental Medicine, Nikolai-Fuchs-Strasse 1, 30625, Hannover, Germany f Member Expert Panel, University of Sao Paulo, School of Veterinary Medicine and Animal Science, Department of Pathology, Av. Prof. dr. Orlando Marques de Paiva, 87, Sao Paulo, CEP 05508-900, Brazil g Member Expert Panel, University of Wuerzburg, Department of Toxicology, Versbacher Str.