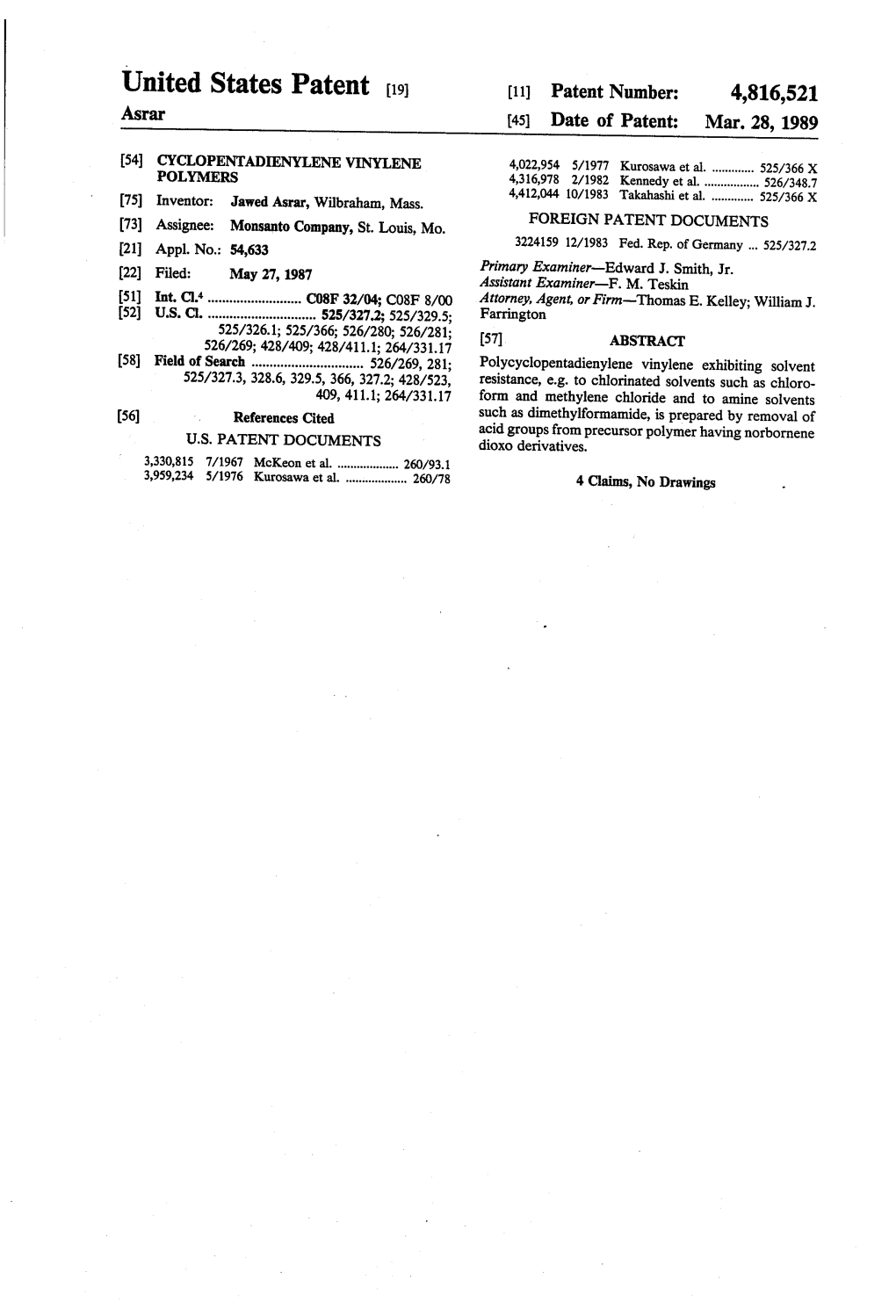

Unlted States Patent [19] [11] Patent Number: 4,816,521 Asrar [45] Date of Patent: Mar

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Transition-Metal Catalyzed Synthesis of Carbonyl Compounds Using Formates Or Formamides As Carbonyl Sources

Journal of the Japan Petroleum Institute, 61, (1), 1-9 (2018) 1 [Review Paper] Transition-metal Catalyzed Synthesis of Carbonyl Compounds Using Formates or Formamides as Carbonyl Sources Tetsuaki FUJIHARA and Yasushi TSUJI* Dept. of Energy and Hydrocarbon Chemistry, Graduate School of Engineering, Kyoto University, Nishikyo-ku, Kyoto 615-8510, JAPAN (Received August 24, 2017) Various available approaches for catalytic carbonylation reactions using formates and formamides with transi- tion metal catalysts are reviewed. Pd complexes catalyze the hydroesterification or hydrocarbamoylation of alkynes using aryl formates or formamides, respectively, as the carbonyl sources. The esterification of aryl halides with aryl formates proceeds in the presence of a Pd catalyst with suitable ligands. Using a Cu complex with a bulky bidentate phosphine ligand is used as a catalyst, boraformylation and silaformylation of allenes effi- ciently proceeds using alkyl formates as a formyl source. Keywords Formate, Formamide, Homogeneous catalysis, Palladium, Copper 1. Introduction This review describes Pd-catalyzed hydroesterifica- tion and hydrocarbamoylation of alkynes employing Carbon monoxide (CO) is an important C1 unit which formates or formamides as the carbonyl sources, is often used as a carbonyl source to convert various respectively. Esterification of aryl halides with aryl bulk chemicals into functionalized products in large- formates also proceeds in the presence of a Pd catalyst. scale application for industrial syntheses1)~3). Cu-catalyzed bora- and silaformylation of allenes em- However, carbonylation reactions with CO are not typi- ploying an alkyl formate is also possible. The scope cally used in the laboratory-scale synthesis of complex of substrates and plausible reaction mechanisms are dis- organic molecules, probably due to general reluctance cussed. -

Part I: Carbonyl-Olefin Metathesis of Norbornene

Part I: Carbonyl-Olefin Metathesis of Norbornene Part II: Cyclopropenimine-Catalyzed Asymmetric Michael Reactions Zara Maxine Seibel Submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in the Graduate School of Arts and Sciences COLUMBIA UNIVERSITY 2016 1 © 2016 Zara Maxine Seibel All Rights Reserved 2 ABSTRACT Part I: Carbonyl-Olefin Metathesis of Norbornene Part II: Cyclopropenimine-Catalyzed Asymmetric Michael Reactions Zara Maxine Seibel This thesis details progress towards the development of an organocatalytic carbonyl- olefin metathesis of norbornene. This transformation has not previously been done catalytically and has not been done in practical manner with stepwise or stoichiometric processes. Building on the previous work of the Lambert lab on the metathesis of cyclopropene and an aldehyde using a hydrazine catalyst, this work discusses efforts to expand to the less stained norbornene. Computational and experimental studies on the catalytic cycle are discussed, including detailed experimental work on how various factors affect the difficult cycloreversion step. The second portion of this thesis details the use of chiral cyclopropenimine bases as catalysts for asymmetric Michael reactions. The Lambert lab has previously developed chiral cyclopropenimine bases for glycine imine nucleophiles. The scope of these catalysts was expanded to include glycine imine derivatives in which the nitrogen atom was replaced with a carbon atom, and to include imines derived from other amino acids. i Table of Contents List of Abbreviations…………………………………………………………………………..iv Part I: Carbonyl-Olefin Metathesis…………………………………………………………… 1 Chapter 1 – Metathesis Reactions of Double Bonds………………………………………….. 1 Introduction………………………………………………………………………………. 1 Olefin Metathesis………………………………………………………………………… 2 Wittig Reaction…………………………………………………………………………... 6 Tebbe Olefination………………………………………………………………………... 9 Carbonyl-Olefin Metathesis……………………………………………………………. -

S Via Ring-Opening Metathesis Polymerization (ROMP)

1 Chapter 1 Synthesis of End-Functionalized Polynorbornenes via Ring-Opening Metathesis Polymerization (ROMP) 2 Abstract The synthesis of a variety of polynorbornenes (PNB)s bearing acetoxy, hydroxy, and vinyl end-groups was accomplished. PNBs with an acetoxy group at one terminus and a vinyl group at the other were prepared using norbornene, ruthenium-based olefin metathesis catalyst (PCy3)2Cl2Ru=CHPh, and allyl acetate as a chain transfer agent (CTA). Employing a more active catalyst, (1,3-dimesityl-4,5-dihydroimidazol-2- ylidene)(PCy3)Cl2Ru=CHPh, and 1,4-diacetoxy-2-butene as the CTA afforded telechelic PNBs bearing acetoxy groups at both ends of the polymer chains. Molecular weights were controlled by varying the initial monomer/CTA ratio and were in agreement with their theoretical values. Using a similar procedure, acetoxy end-functionalized PNBs were also obtained by degradation of high molecular weight PNB. Removal of the acetoxy groups afforded the corresponding hydroxy terminated polymers with number averaged functionalities close to two. Mechanisms are proposed for the formation of the end-functionalized polymers. Correction factors for characterizing PNBs by gel- permeation chromatography (GPC) are also suggested. Portions of this chapter have been previously reported, see: Bielawski, C. W.; Benitez, D.; Morita, T.; Grubbs, R. H. Macromolecules 2001, 34, 8610. 3 Introduction Telechelic polymers, or polymers with functional groups selectively positioned at the termini of any given chain, have been extensively employed in a variety of applications including intermediates in the synthesis of block copolymers, use as cross- linking agents, and in the formation of polymeric networks.1-4 Since these applications are often dependent on structural, mechanical, and thermal properties of the telechelic polymer, expanding the range of selectable monomers remains a synthetic goal in polymer chemistry. -

Hydrocarbon Processing Overview

Hydrocarbon Processing Overview Hydrocarbon Processing – The Solutions Start Here Full Spectrum Product Line Other support comes from Praxair R&D, where teams of Today’s hydrocarbon processing industries (HPI) requires scientists are dedicated to the development of specialty high precision measurement, uniform stability, specialty gas products and services. mixes, and reference standards. Praxair’s Spectrum Reliable Production and Distribution products offer a wide range of certified mixes, industry Praxair possesses multiple ISO 9001:2000 certified plants reference standards, and high purity organics. The pro- with 5 specialty gas plants and North America’s largest gas duction of natural gas, liquefied petroleum gas, engine production facility working to provide the highest quality fuels, and ethane are analyzed to meet process feed and products, product availability, and meeting on time delivery salable product specifications. Spectrum gases and liquid requirements. With over 600 US locations, our distribution mixes are formulated to certifiable references and to meet network accompanied by our ability to supply custom standards for your low sulfur fuels and natural gases, vapor delivery solutions for packaged and bulk products allows pressure, LPG standards, and HVOC requirements. Praxair Praxair to offer packaged and bulk options that may help possesses an extensive portfolio of assayed chemicals to you increase your productivity. customize your requirements. A Complete Range of Gas Delivery Equipment Centers of Excellence Praxair’s offers a wide range of essential equipment to meet To effectively service North America, Praxair has three the demands of today’s hydrocarbon processing facility centers of excellence dedicated for hydrocarbons. These laboratories and process feed monitoring instrumentation centers are located in Geismar, Louisiana; Edmonton, gas delivery solutions. -

The Synthetization and Analysis of Dicyclopentadiene and Ethylidene-Norbornene Microcapsule Systems

polymers Article The Synthetization and Analysis of Dicyclopentadiene and Ethylidene-Norbornene Microcapsule Systems Ionut Sebastian Vintila 1,2,*, Horia Iovu 2, Andreea Alcea 1, Andreia Cucuruz 3, Andrei Cristian Mandoc 1 and Bogdan Stefan Vasile 4 1 National Research and Development Institute for Gas Turbines COMOTI, 061126 Bucharest, Romania; [email protected] (A.A.); [email protected] (A.C.M.) 2 Department of Bioresources and Polymer Science, Faculty of Applied Chemistry and Materials Science, University Politehnica of Bucharest, 011061 Bucharest, Romania; [email protected] 3 Department of Science and Engineering of Oxide Materials and Nanomaterials, Faculty of Applied Chemistry and Materials Science, University Politehnica of Bucharest, 011061 Bucharest, Romania; [email protected] 4 National Research Centre for Micro and Nanomaterials, Faculty of Applied Chemistry and Materials Science, University POLITEHNICA of Bucharest, 060042 Bucharest, Romania; [email protected] * Correspondence: [email protected]; Tel.: +40-726998218 Received: 7 April 2020; Accepted: 25 April 2020; Published: 4 May 2020 Abstract: The activities of this paper were focused on an in-situ fabrication process for producing two self-healing systems containing dicyclopentadiene and 5-ethylidene-2-norbornene monomers encapsulated in a urea-formaldehyde shell and integration methods applied in the epoxy matrix to analyse and compare the influences of their integration into the neat epoxy matrix. The self-healing systems were first synthesized according to a literature review, and subsequently, an optimization process was conducted for the fabrication process. Neat epoxy specimens were fabricated as reference specimens and subjected to flexural tests. Several integration methods for incorporating the self-healing systems into the epoxy resin were investigated. -

Designing Polymers for Advanced Battery Chemistries

REVIEWS Designing polymers for advanced battery chemistries Jeffrey Lopez 1, David G. Mackanic 1, Yi Cui 2,3 and Zhenan Bao 1* Abstract | Electrochemical energy storage devices are becoming increasingly important to our global society , and polymer materials are key components of these devices. As the demand for high- energy density devices increases, innovative new materials that build on the fundamental understanding of physical phenomena and structure–property relationships will be required to enable high-capacity next-generation battery chemistries. In this Review , we discuss core polymer science principles that are used to facilitate progress in battery materials development. Specifically , we discuss the design of polymeric materials for desired mechanical properties, increased ionic and electronic conductivity and specific chemical interactions. We also discuss how polymer materials have been designed to create stable artificial interfaces and improve battery safety. The focus is on these design principles applied to advanced silicon, lithium-metal and sulfur battery chemistries. The development of new electrochemical energy storage of existing materials or to enable the application of new technologies has been instrumental to the proliferation battery chemistries. In this Review, we summarize the of portable electronic devices and the increasing adop- fundamental polymer science and engineering con- tion of electric vehicles. Intermittent electricity genera- cepts related to the development of polymers for next- tion (for example, from wind and solar power sources) generation battery applications (Table 1). We specifically has further intensified the demand for high-energy den- discuss how these core concepts drive the design of new sity, high- power and low-cost energy storage devices1,2. -

Revised Group Additivity Values for Enthalpies of Formation (At 298 K) of Carbon– Hydrogen and Carbon–Hydrogen–Oxygen Compounds

Revised Group Additivity Values for Enthalpies of Formation (at 298 K) of Carbon– Hydrogen and Carbon–Hydrogen–Oxygen Compounds Cite as: Journal of Physical and Chemical Reference Data 25, 1411 (1996); https://doi.org/10.1063/1.555988 Submitted: 17 January 1996 . Published Online: 15 October 2009 N. Cohen ARTICLES YOU MAY BE INTERESTED IN Additivity Rules for the Estimation of Molecular Properties. Thermodynamic Properties The Journal of Chemical Physics 29, 546 (1958); https://doi.org/10.1063/1.1744539 Critical Evaluation of Thermochemical Properties of C1–C4 Species: Updated Group- Contributions to Estimate Thermochemical Properties Journal of Physical and Chemical Reference Data 44, 013101 (2015); https:// doi.org/10.1063/1.4902535 Estimation of the Thermodynamic Properties of Hydrocarbons at 298.15 K Journal of Physical and Chemical Reference Data 17, 1637 (1988); https:// doi.org/10.1063/1.555814 Journal of Physical and Chemical Reference Data 25, 1411 (1996); https://doi.org/10.1063/1.555988 25, 1411 © 1996 American Institute of Physics for the National Institute of Standards and Technology. Revised Group Additivity Values for Enthalpies of Formation (at 298 K) of Carbon-Hydrogen and Carbon-Hydrogen-Oxygen Compounds N. Cohen Thermochemical Kinetics Research, 6507 SE 31st Avenue, Portland, Oregon 97202-8627 Received January 17, 1996; revised manuscript received September 4, 1996 A program has been undertaken for the evaluation and revision of group additivity values (GAVs) necessary for predicting, by means of Benson's group additivity method, thermochemical properties of organic molecules. This review reports on the portion of that program dealing with GAVs for enthalpies of formation at 298.15 K (hereinafter abbreviated as 298 K) for carbon-hydrogen and carbon-hydrogen-oxygen compounds. -

Cycloolefin Copolymers: Processing, Properties Application

Cycloolefin copolymers: Processing, Properties Application Petr Mlejnek Bachelor Thesis 2007 ABSTRACT The main object of this bachelor thesis is to compile the complex review of preparation, chemical structure, morphology, properties, processing and applica- tion of cyclic olefin copolymers. Recently, these modern materials have attracted the attention of the researchers as well as plastic processors. Cyclic olefin co- polymers are prepared by copolymerization of cyclic and linear olefins. By varying the structure, they can be tailored for specific applications. Generally, they are characterized by almost amorphous structure, high glass transition temperature, high transparency and low density. Presently, they are successfully applied in packaging and pharmaceutics ANOTACE Hlavním úelem této bakaláské práce je sestavit pehlednou literární re- šerši týkající se výroby, chemické struktury, morfologie, vlastností, zpracování a aplikací cyklických olefinických kopolymer. V poslední dob jsou tyto moderní materiály pedmtem zájmu jak výzkumných tým, tak pedevším zpracovatel plast. Cyklické olefinické kopolymery se vyrábjí kopolymerací cyklických a line- árních olefin. Zmnou struktury lze vyrábt tzv. materiály na míru pro specifické aplikace. Obecn jsou charakterizovány tém zcela amorfní strukturou, vysokou teplotou skelného pechodu, vysokou prhledností a nízkou hustotou. V souasné dob se s úspchem využívají pro výrobu obal a farmaceutických pomcek. ACKNOWLEDGEMENTS I would like to thank my supervisor Jana Výchopová for her professional help, -

Forcing Single-Chain Nanoparticle Collapse Through Hydrophobic Solvent Interactions in Comb Copolymers

Polymer Chemistry View Article Online COMMUNICATION View Journal | View Issue Forcing single-chain nanoparticle collapse through hydrophobic solvent interactions in Cite this: Polym. Chem., 2020, 11, 292 comb copolymers† Received 16th August 2019, Accepted 4th October 2019 Cheyenne H. Liu, ‡ Logan D. Dugas,‡ Jared I. Bowman, Tamuka Chidanguro, DOI: 10.1039/c9py01235d Robson F. Storey and Yoan C. Simon * rsc.li/polymers We introduce a novel synthetic strategy in which high molecular crosslinks are reminiscent of disulfide bridges, and the intro- weight comb copolymers with aliphatic side chains can collapse duction of catalytic sites is comparable to active enzymatic into single-chain nanoparticles (SNCPs) via photodimerization of pockets.6,17,18 Consequently, the scientific pursuit of SCNPs – anthracene under ultraviolet (UV) irradiation. By deliberately has grown unabated in areas such as catalysis,17,19 21 – – selecting hydrophobic comonomers with disparate solvency, we sensing,22 24 and site-specific drug delivery.25 27 demonstrated that we could control chain collapse. We attribute To realize the full potential of SCNPs, one must understand these results to the formation of pseudo-unimicellar structures, the parameters governing chain collapse. Seminal work by whereby polyisobutylene (PIB) side chains are preferentially sol- Pomposo and coworkers laid the theoretical framework for the vated, thereby compressing anthracene moieties to form a denser understanding of how solvent selection affects the ultimate – crosslinked core. The control of hydrophobic interactions is a size and structure of SCNPs.28 31 They meticulously explored common occurrence in proteins and we believe that our approach through computational modeling whether SCNPs can form – can be further extended to achieve multi-compartment SCNPs true globular structures.28,29,31 33 Namely, they showed that whereby each section is responsible for a given function. -

Molecular Encapsulation in Kinetically Trapped, Hydrogen-Bonded Pyrogallolarene Hexamers

University of Denver Digital Commons @ DU Electronic Theses and Dissertations Graduate Studies 6-1-2014 Molecular Encapsulation in Kinetically Trapped, Hydrogen-Bonded Pyrogallolarene Hexamers Jennifer Christine Chapin Lake University of Denver Follow this and additional works at: https://digitalcommons.du.edu/etd Part of the Organic Chemistry Commons Recommended Citation Chapin Lake, Jennifer Christine, "Molecular Encapsulation in Kinetically Trapped, Hydrogen-Bonded Pyrogallolarene Hexamers" (2014). Electronic Theses and Dissertations. 120. https://digitalcommons.du.edu/etd/120 This Dissertation is brought to you for free and open access by the Graduate Studies at Digital Commons @ DU. It has been accepted for inclusion in Electronic Theses and Dissertations by an authorized administrator of Digital Commons @ DU. For more information, please contact [email protected],[email protected]. MOLECULAR ENCAPSULATION IN KINETICALLY TRAPPED, HYDROGEN-BONDED PYROGALLOLARENE HEXAMERS __________ A Dissertation Presented to the Faculty of Natural Sciences and Mathematics University of Denver __________ In Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy __________ by Jennifer Christine Chapin Lake June 2014 Advisor: Byron W. Purse ©Copyright by Jennifer Christine Chapin Lake 2014 All Rights Reserved Author: Jennifer Christine Chapin Lake Title: MOLECULAR ENCAPSULATION IN KINETICALLY TRAPPED, HYDROGEN-BONDED PYROGALLOLARENE HEXAMERS Advisor: Byron W. Purse Degree Date: June 2014 Abstract Pyrogallolarene and resorcinarene hexamers are hydrogen-bonded capsules that self-assemble in the solid state and can be studied in gaseous and solution phases. Guest loading within pyrogallolarene hexamers in solution has primarily been comprised of solvent molecules with some tertiary amines. A novel solvent-free method for loading guests into the interior of the hexamer has been shown to be effective for encapsulation of a variety of molecules. -

The Photochemistry of Some Substituted 2-Cyclohexenones and the Excited States Involved

PHOTOCHEMISTRY OF SUBSTITUTi':D 2... CYCLOHE:XE;NONES THE PHOTOCHEMISTRY OF S0~1E SUBSTITUTED 2~CYCLOHEXENONES AND THE EXCITED STATES INVOLVED By FLOlTI FP~ERICK SNYDER, B.Sce .A Thesis Submitted to the Faculty of Graduate Studies in Partial Fulfilment of the Requirements for the Degree Master of Science McMaster University October 1969 To MOM and DAD on Your 25th Anniversary MASTER OF SCIENCE (1969) McMASTER UNIVERSITY (Ghemi stry) Hamilton, Ontario. TITLE: The Photochemistry of some Substituted 2-Cyclohexenones and the Excited States Involved AUTHOR: Floyd Frederick Snyder, B.Sc. '(University of Alberta) SUPERVISOR: Dr. J. J. McCullough NUMBER OF PAGES: viii, 87 SCOPE AND CONTENTS: The photoadditions of 3~phenyl-2-cyclohexenone to bicyclo [2.2.1] hepta-2,5-diene, bicyclo [2.2.1] hept-2mene and cyclopentene have been studied. In all cases £.!1! fused cyclobutane products were obtained. Quenching and sensitization experiments indicated a singlet excited state to be active in photocycloaddition. Phosphorescence and fluorescence emission were observed from 3-phenyl-2-cyclohexenoneo Energy transfer to the lo~.rest triplet of 3-phenyl-2-cyclohexenone was evident from the quenching of Michler's ketone phosphorescence. Two norbornene dimers were detected in the photolysis of 3-phenyl-2-cyclo hexenone and norbornene giving evidence for a higher triplet excited state of the enone. The photoaddition of 3-methyl-2-cyclohexenone to cyclopentene l.ras studied for comparison and both .£!..! and !.r..!.U! fused adducts l-Tere obtained. In photolyses with bicyclo [2e2el] hepta-2,5 diene or cyclopentene, 2-phenyl... 2-cyclohexenone lvas unreactive. iii ACKNOWLEDGEMENTS It is a pleasure to express my gratitude to Dr. -

Photocontrolled Self-Assembly of a Fluorescent Anthracene at Nano- and Microscales Christiaan J.F

Photocontrolled self-assembly of a fluorescent anthracene at nano- and microscales Christiaan J.F. de Vet To cite this version: Christiaan J.F. de Vet. Photocontrolled self-assembly of a fluorescent anthracene at nano- and mi- croscales. Organic chemistry. Université de Bordeaux, 2016. English. NNT : 2016BORD0333. tel-02003479 HAL Id: tel-02003479 https://tel.archives-ouvertes.fr/tel-02003479 Submitted on 1 Feb 2019 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. THÈSE PRÉSENTÉE POUR OBTENIR LE GRADE DE DOCTEUR DE L’UNIVERSITÉ DE BORDEAUX ÉCOLE DOCTORALE DES SCIENCES CHIMIQUES SPÉCIALITÉ CHIMIE ORGANIQUE Christiaan J.F. de Vet Auto-assemblage d'un anthracène fluorescent aux échelles nano- et micrométriques par photoréaction contrôlée Photocontrolled self-assembly of a fluorescent anthracene at nano- and microscales Sous la direction de: Prof. André DEL GUERZO Soutenue le 9 Décembre 2016 Membres du jury : Mme. ISHOW, Elena Professeur, Univ. de Nantes Rapporteur M. SOPPERA, Olivier Directeur de recherche, Univ. de Haute Alsace Rapporteur M. BARTHELEMY, Philippe Professeur, Univ. de Bordeaux Président M. DEL GUERZO, André Professeur, Univ. de Bordeaux Directeur Voor ome Ad… Remerciements These three years have been an interesting experience which did not only consist of dealing with the challenges of scientific research, but also a change of culture and language.