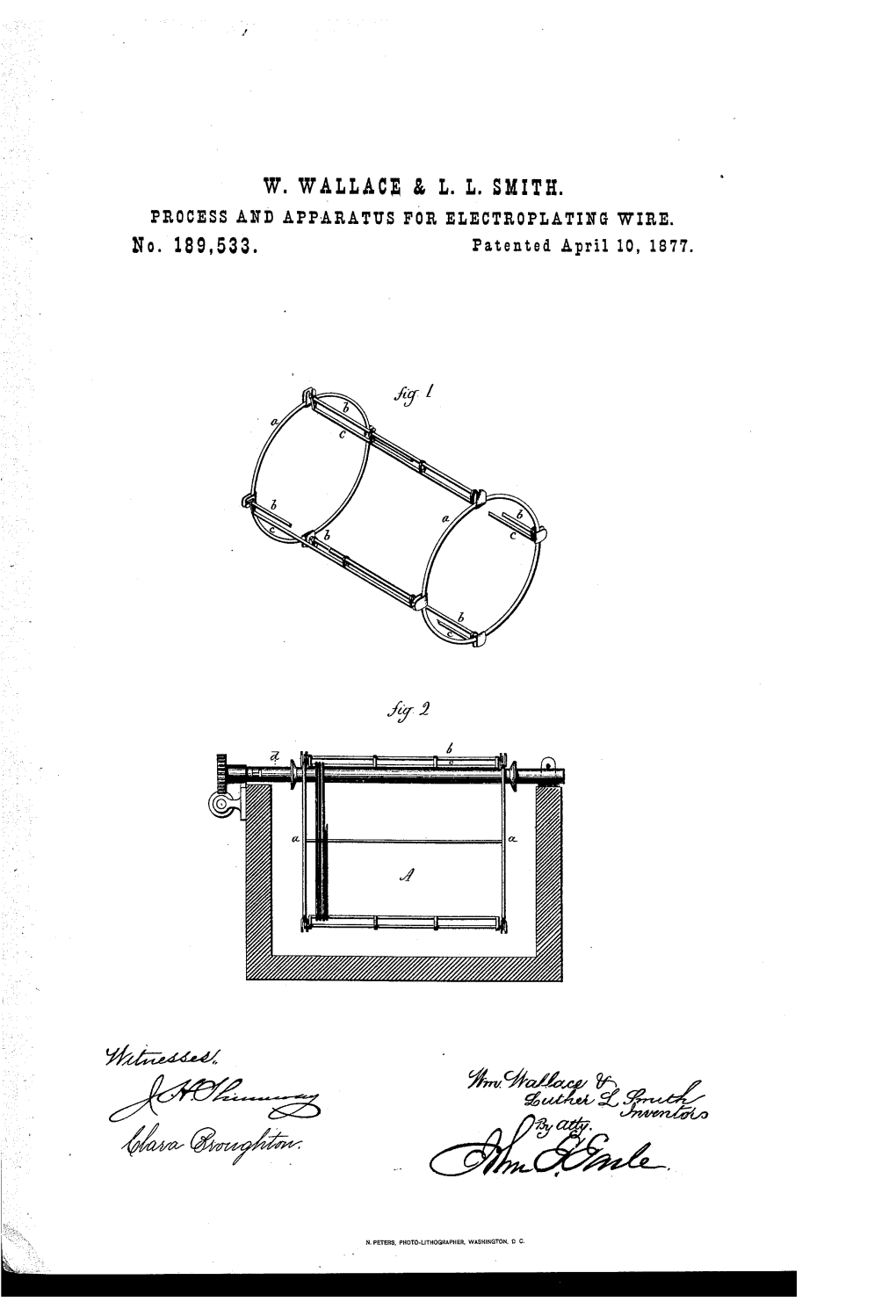

W. Wallace & L. L. Smith

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

February 23, 2021 City Council Agenda

CITY OF GREENFIELD CITY COUNCIL REGULAR MEETING FEBRUARY 23, 2021 @ 6:00 P.M. Attendance and Public Comment Changes Due to COVID-19 The Greenfield City Council will be conducting its regular meeting on February 23, 2021. Given the current Shelter-in-Place Order covering Monterey County and the Social Distance Guidelines issued by Federal, State, and Local Authorities, the City is implementing the following changes for attendance and public comment. The City Council meeting to be held on February 23, 2021 at 6:00 p.m. will only be accessible online. The meeting may be viewed through the following options: Facebook Live: https://www.facebook.com/GreenfieldCA/ Join Zoom Meeting Please click the link below to join the webinar: http://meeting.ci.greenfield.ca.us Meeting ID: 813 9845 6258 Para escuchar en Español marque (520) 420-9593 The City will also provide links to these streaming options on the City’s website and on its Facebook page. Unfortunately, physical attendance by the public cannot be accommodated given the current circumstances and the need to ensure the health and safety of the City Council, City staff, and the public as a whole. If you wish to make a general public comment or public comment on a particular item on the agenda, you can submit your public comments by e-mail to: [email protected] In the subject line of the e-mail, please state your name and the item you are commenting on. If you wish to submit a public comment on more than one agenda item, please send a separate e-email for each item you are commenting on. -

Teen Stabbing Questions Still Unanswered What Motivated 14-Year-Old Boy to Attack Family?

Save $86.25 with coupons in today’s paper Penn State holds The Kirby at 30 off late Honoring the Center’s charge rich history and its to beat Temple impact on the region SPORTS • 1C SPECIAL SECTION Sunday, September 18, 2016 BREAKING NEWS AT TIMESLEADER.COM '365/=[+<</M /88=C6@+83+sǍL Teen stabbing questions still unanswered What motivated 14-year-old boy to attack family? By Bill O’Boyle Sinoracki in the chest, causing Sinoracki’s wife, Bobbi Jo, 36, ,9,9C6/Ľ>37/=6/+./<L-97 his death. and the couple’s 17-year-old Investigators say Hocken- daughter. KINGSTON TWP. — Specu- berry, 14, of 145 S. Lehigh A preliminary hearing lation has been rampant since St. — located adjacent to the for Hockenberry, originally last Sunday when a 14-year-old Sinoracki home — entered 7 scheduled for Sept. 22, has boy entered his neighbors’ Orchard St. and stabbed three been continued at the request house in the middle of the day members of the Sinoracki fam- of his attorney, Frank Nocito. and stabbed three people, kill- According to the office of ing one. ily. Hockenberry is charged Magisterial District Justice Everyone connected to the James Tupper and Kingston case and the general public with homicide, aggravated assault, simple assault, reck- Township Police Chief Michael have been wondering what Moravec, the hearing will be lessly endangering another Photo courtesy of GoFundMe could have motivated the held at 9:30 a.m. Nov. 7 at person and burglary in connec- In this photo taken from the GoFundMe account page set up for the Sinoracki accused, Zachary Hocken- Tupper’s office, 11 Carverton family, David Sinoracki is shown with his wife, Bobbi Jo, and their three children, berry, to walk into a home on tion with the death of David Megan 17; Madison, 14; and David Jr., 11. -

Criminal Procedure, the Police, and the Wire As Dissent

Brooklyn Law School BrooklynWorks Faculty Scholarship 2018 Criminal Procedure, the Police, and The irW e as Dissent I. Bennett aC pers Brooklyn Law School, [email protected] Follow this and additional works at: https://brooklynworks.brooklaw.edu/faculty Part of the Criminal Law Commons, and the Criminal Procedure Commons Recommended Citation 2018 U. Chi. Legal F. 65 (2018) This Article is brought to you for free and open access by BrooklynWorks. It has been accepted for inclusion in Faculty Scholarship by an authorized administrator of BrooklynWorks. Criminal Procedure, the Police, and The Wire as Dissent Bennett Caperst The Wire is rich with metaphors. There is the physical wire in the opening credits, a metaphor for surveillance more generally. There is the metaphor of the wire in the sense of a modern tightrope-another filmic work, Man on a Wire,1 comes to mind-where any minute one can lose one's balance. There is even the metaphor of the wire in the 2 sense that the criminal justice system is all connected or networked. Indeed, thinking about our criminal justice system as a complex net- work allows us to see that many of the perceived flaws in the criminal justice system-racial disparities in charging3 and sentencing,4 and t Visiting Professor of Law, Boston University School of Law (Fall 2017); Stanley A. August Professor of Law, Brooklyn Law School. B.A. Princeton University; J.D. Columbia Law School. Assistant U.S. Attorney, Southern District of New York 1995-2004. E-mail: bennett.capers @brooklaw.edu. ' See generally MAN ON A WIRE (Magnolia Pictures 2008) (documentary about Phillipe Pet- it's successful attempt, on August 7, 1974, to walk on a wire suspended between the towers of the World Trade Center; his act would later be described as the "artistic crime of the century"). -

The Wire the Complete Guide

The Wire The Complete Guide PDF generated using the open source mwlib toolkit. See http://code.pediapress.com/ for more information. PDF generated at: Tue, 29 Jan 2013 02:03:03 UTC Contents Articles Overview 1 The Wire 1 David Simon 24 Writers and directors 36 Awards and nominations 38 Seasons and episodes 42 List of The Wire episodes 42 Season 1 46 Season 2 54 Season 3 61 Season 4 70 Season 5 79 Characters 86 List of The Wire characters 86 Police 95 Police of The Wire 95 Jimmy McNulty 118 Kima Greggs 124 Bunk Moreland 128 Lester Freamon 131 Herc Hauk 135 Roland Pryzbylewski 138 Ellis Carver 141 Leander Sydnor 145 Beadie Russell 147 Cedric Daniels 150 William Rawls 156 Ervin Burrell 160 Stanislaus Valchek 165 Jay Landsman 168 Law enforcement 172 Law enforcement characters of The Wire 172 Rhonda Pearlman 178 Maurice Levy 181 Street-level characters 184 Street-level characters of The Wire 184 Omar Little 190 Bubbles 196 Dennis "Cutty" Wise 199 Stringer Bell 202 Avon Barksdale 206 Marlo Stanfield 212 Proposition Joe 218 Spiros Vondas 222 The Greek 224 Chris Partlow 226 Snoop (The Wire) 230 Wee-Bey Brice 232 Bodie Broadus 235 Poot Carr 239 D'Angelo Barksdale 242 Cheese Wagstaff 245 Wallace 247 Docks 249 Characters from the docks of The Wire 249 Frank Sobotka 254 Nick Sobotka 256 Ziggy Sobotka 258 Sergei Malatov 261 Politicians 263 Politicians of The Wire 263 Tommy Carcetti 271 Clarence Royce 275 Clay Davis 279 Norman Wilson 282 School 284 School system of The Wire 284 Howard "Bunny" Colvin 290 Michael Lee 293 Duquan "Dukie" Weems 296 Namond Brice 298 Randy Wagstaff 301 Journalists 304 Journalists of The Wire 304 Augustus Haynes 309 Scott Templeton 312 Alma Gutierrez 315 Miscellany 317 And All the Pieces Matter — Five Years of Music from The Wire 317 References Article Sources and Contributors 320 Image Sources, Licenses and Contributors 324 Article Licenses License 325 1 Overview The Wire The Wire Second season intertitle Genre Crime drama Format Serial drama Created by David Simon Starring Dominic West John Doman Idris Elba Frankie Faison Larry Gilliard, Jr. -

Schooling, Standardization, and Inequality Through the Lens of the Wire

“No one wins. One side just loses more slowly:” Schooling, Standardization, and Inequality through the Lens of The Wire An honors thesis for the Program in American Studies Benjamin R. Phelps Tufts University, 2011 ACKNOWLEDGEMENTS “Thanks for bein’ straight on this.” — Nick Sobotka First and foremost, I would like to thank Steve Cohen for the guidance he has provided me as my first reader on this project and as my academic advisor here at Tufts. Steve’s course, ED 01, which I took freshman year, guided me to American Studies, and I could not be happier that it did. Our weekly meetings this year were a great opportunity to talk about my thesis progress, educational issues, and our shared enthusiasm for The Wire, and I cannot see my final product, or my Tufts experience, being nearly as successful without his presence. Sarah Sobieraj has also been a tireless reader this year on both this thesis and my Communications and Media Studies senior project. Just as this project allowed me to marry my interests in education and television, it also allowed me to work with a media-focused sociologist who I may otherwise have only known from our brief time together in SOC 40, and I am extremely grateful that it did. Tom Chen and the support of the American Studies senior seminar have been invaluable. As something of a procrastinator, I was kept on track by Tom’s deadlines, and even though he did not work with me as closely as my two advisors, it never hurt to have another set of eyes to read over my progress. -

Discovering Moral Imagination Along the Wire. (2014)

SOLÉR, MICHELLE LOWE, Ph.D. All the Pieces Matter: Discovering Moral Imagination Along The Wire. (2014). Directed by Dr. Svi Shapiro. 304 pp. This dissertation is an investigation into the tool of moral imagination in the service of social justice. Supported by the philosophies of David Purpel, Maxine Greene, and John Dewey, this analysis is engaged through six themes examined through the text of David Simon’s series, The Wire. These themes supply a foundation for how we might more thoroughly engage with moral imagination on a daily basis because there is a crisis in our culture around how we value the lives of all people. Themes presented in this discussion are: (1) The idea that everybody matters; (2) A changing notion of truth; (3) Thoughtlessness and banality; (4) Wide-awakeness and not taking things for granted; (5) Asking critical questions; and lastly, (6) People claiming responsibility. Applying these themes to specific textual examples excerpted from a dramatized television serial creates a space to discuss prophetic in- betweenness to interrogate and examine situations of systemic dysfunction and economic injustice outside of a fictional space. ALL THE PIECES MATTER: DISCOVERING MORAL IMAGINATION ALONG THE WIRE by Michelle Lowe Solér A Dissertation Submitted to the Faculty of The Graduate School at The University of North Carolina at Greensboro in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy Greensboro 2014 Approved by ____________________________ Committee Chair 2014 Michelle Lowe Solér APPROVAL PAGE This dissertation written by Michelle Lowe Solér has been approved by the following committee of the Faculty of the Graduate School at The University of North Carolina at Greensboro. -

Why Every Show Needs to Be More Like the WIRE

Why Every Show Needs to Be More Like THE WIRE (“Not Just the Facts, Ma’am.”) The Wire upends the traditional police procedural by moving past basic plot points and “twists” in the case, diving deep into the lives of both the cops and the criminals they pursue. We see this immediately in the teaser of the pilot. Detective Jimmy McNulty (Dominic West) is at the scene of a shooting, questioning a Witness (Kamal Bostic-Smith) on the murder of a boy from “round the way nicknamed “Snot Boogie.” McNulty and the Witness go back and forth on the origin of “Snot Boogie’s” nickname at first. Until the Witness explains what happened: MCNULTY So who shot Snot? WITNESS I ain’t going to no court. Motherfucker ain’t have to put no cap in him though. MCNULTY Definitely not. WITNESS He could’ve just whipped his ass, like we always whip his ass. MCNULTY I agree with you. !1 WITNESS He gonna kill Snot. Snot been doing the same shit since I don’t know how long. Kill a man over some bullshit. I’m saying, every Friday night in the alley behind the cut-rate, we rolling bones, you know? All the boys from around the way, we roll till late. MCNULTY Alley crap game, right? WITNESS And like every time, Snot, he’d fade a few shooters. Play it out till the pot’s deep. Then he’d snatch and run. MCNULTY --Every time? WITNESS —Couldn’t help hisself. MCNULTY Let me understand you. Every Friday night, you and your boys would shoot crap, right? And every Friday night, your pal Snotboogie he’d wait till there was cash on the ground, then grab the money and run away?--You let him do that? WITNESS --We catch him and beat his ass. -

Police Violence in the Wire

University of Chicago Legal Forum Volume 2018 Article 7 2019 Police Violence in The irW e Jonathan Masur Richard H. McAdams Follow this and additional works at: https://chicagounbound.uchicago.edu/uclf Recommended Citation Masur, Jonathan and McAdams, Richard H. (2019) "Police Violence in The irW e," University of Chicago Legal Forum: Vol. 2018 , Article 7. Available at: https://chicagounbound.uchicago.edu/uclf/vol2018/iss1/7 This Article is brought to you for free and open access by Chicago Unbound. It has been accepted for inclusion in University of Chicago Legal Forum by an authorized editor of Chicago Unbound. For more information, please contact [email protected]. Police Violence in The Wire Jonathan Masur† and Richard H. McAdams†† INTRODUCTION Police brutality—the unsanctioned, unlawful use of force by police against unarmed (and often defenseless) civilians—is one of the recur- ring motifs of The Wire.1 The violence occurs in a variety of settings: occasionally the victim of the police brutality has done something to precipitate it (though the brutality is never justified), but more often the violence is unprovoked and senseless.2 Some police are one-time wrongdoers; others are repeat offenders. Some officers participate in the actual beatings, while others only cover up for the actions of their fellow officers. But in sum, the violence is regular and recurring, if not omnipresent. In this respect, The Wire is not dissimilar from other filmic depictions of police, such as NYPD Blue. What is different is the cast of police officers who are involved in police brutality throughout the show. -

Discipline and Policing: HBO's the Wire As A

THE POPULAR CULTURE STUDIES JOURNAL VOLUME 2 NUMBERS 1 & 2 2014 Editor BOB BATCHELOR Thiel College Associate Editor NORMA JONES Kent State University Associate Editor KATHLEEN TURNER Aurora University Book Review Editor JENNIFER C. DUNN Dominican University Assistant Editor MYC WIATROWSKI Indiana University Assistant Editor MAJA BAJAC-CARTER Kent State University Please visit the PCSJ at: http://mpcaaca.org/the-popular-culture-studies-journal/ The Popular Culture Studies Journal is the official journal of the Midwest Popular and American Culture Association. Copyright © 2014 Midwest Popular and American Culture Association. All rights reserved. Cover photo credits Cover Artwork “Living Popular Culture” by Brent Jones © 2014 “Selfie for Peace” by Savannah Jones © 2014 “Party People” by Roob9 licensed by PhotoDune iPhone frame: Creative Commons “iPhone 5S” by Karlis Dambrans is licensed under CC BY 2.0 EDITORIAL ADVISORY BOARD ANTHONY ADAH JUSTIN GARCIA Minnesota State University, Moorhead Millersville University AARON BARLOW ART HERBIG New York City College of Technology (CUNY) Indiana University - Faculty Editor, Academe, the magazine of the AAUP Purdue University, Fort Wayne JOSEF BENSON ANDREW F. HERRMANN University of Wisconsin Parkside East Tennessee State University PAUL BOOTH JARED JOHNSON DePaul University Thiel College GARY BURNS JESSE KAVADLO Northern Illinois University Maryville University of St. Louis KELLI S. BURNS KATHLEEN A. KENNEDY University of South Florida Missouri State University ANNE M. CANAVAN WILLIAM KIST Emporia State University Kent State University ERIN MAE CLARK LARRY Z. LESLIE Saint Mary’s University of Minnesota University of South Florida BRIAN COGAN MATTHEW MIHALKA Molloy College University of Arkansas - Fayetteville ASHLEY M. DONNELLY LAURIE MOROCO Ball State University Thiel College LEIGH H. -

Critical Response I Wired

Critical Response I Wired Patrick Jagoda In the fourth season of HBO’s television show The Wire, a major may- oral debate unfolds shortly before the Baltimore city election. The debate comes through in a series of fragments, in audio sound bites addressing Baltimore’s crime epidemic and views of the three candidates—incum- bent Clarence Royce, challenger Tony Gray, and the eventual winner Tommy Carcetti—campaigning on different television screens. The visual focus of this sequence, however, is not on the debate itself but on the massive ensemble of characters that is either watching or not watching this episode of political theater. To a few of Baltimore’s citizens it is a central event, but to most this contest is entirely peripheral. During a series of short scenes that takes the debate as its nexus, members of the Royce and Carcetti camps scrutinize the television coverage. Meanwhile, detectives in the homicide unit watch with distant interest, listening selectively for is- sues that pertain to their daily criminal investigations. Ex-con Dennis “Cutty” Wise, in another vignette, notices the debate on his screen before immediately switching the channel to a football game. Even further at the edges, Namond Brice, a young aspiring drug dealer, turns off the debate as if it were televisual static and begins to play Halo 2, a first-person shooter videogame.1 In this series of shots, plotting is subordinated to the detailed mapping of Baltimore’s intersecting social and political worlds. Rather than com- 1. See David Simon, “Soft Eyes,” dir. Christine Moore, 2006, The Wire: The Complete Series, DVD, 23 discs (2002–8), season 4, episode 2. -

And All the Pieces Matter: Thoughts on the Wire and the Criminal Justice System

DePaul University Via Sapientiae College of Law Faculty College of Law 2011 And All the Pieces Matter: Thoughts on the Wire and the Criminal Justice System Susan Bandes DePaul College of Law Follow this and additional works at: https://via.library.depaul.edu/lawfacpubs Part of the Law Commons Recommended Citation Susan A. Bandes, And All the Pieces Matter: Thoughts on the Wire and the Criminal Justice System, 8 Ohio St. J. Crim. L. 435 (2011). This Article is brought to you for free and open access by the College of Law at Via Sapientiae. It has been accepted for inclusion in College of Law Faculty by an authorized administrator of Via Sapientiae. For more information, please contact [email protected]. Content downloaded/printed from HeinOnline Wed Sep 18 10:31:41 2019 Citations: Bluebook 20th ed. Susan A. Bandes, And All the Pieces Matter: Thoughts on the Wire and the Criminal Justice System, 8 Ohio St. J. Crim. L. 435 (2011). APA 6th ed. Bandes, S. A. (2011). And all the pieces matter: Thoughts on the wire and the criminal justice system. Ohio State Journal of Criminal Law, 8(2), 435-446. ALWD Bandes, S. A. (2011). And all the pieces matter: Thoughts on the wire and the criminal justice system. Ohio St. J. Crim. L., 8(2), 435-446. Chicago 7th ed. Susan A. Bandes, "And All the Pieces Matter: Thoughts on the Wire and the Criminal Justice System," Ohio State Journal of Criminal Law 8, no. 2 (Spring 2011): 435-446 McGill Guide 9th ed. Susan A Bandes, "And All the Pieces Matter: Thoughts on the Wire and the Criminal Justice System" (2011) 8:2 Ohio State J of Crim L 435. -

SEC Complaint: Rodney E. Wallace, Joe B. Dorman and John A. Blank

Case 3:10-cv-00440-F Document 1 Filed 03/03/2010 Page 1 of 14 UNITED STATES DISTRICT COURT NORTHERN DISTRICT OF TEXAS DALLAS DIVISION : SECURITIES AND EXCHANGE COMMISSION, : : Plaintiff, : vs. : : RODNEY E. WALLACE, JOE B. DORMAN and : JOHN A. BLANK, : Civil Action No. 3:10-cv-440 : Defendants. : : COMPLAINT Plaintiff Securities and Exchange Commission (“SEC” or “Commission”) alleges as follows: JURISDICTION AND VENUE 1. This Court has jurisdiction over this action pursuant to Section 27 of the Securities Exchange Act of 1934 (the “Exchange Act”) [15 U.S.C. § 78aa]. Defendants have, directly and indirectly, made use of the means or instrumentalities of interstate commerce and/or the mails in connection with the transactions described in this Complaint. 2. Venue lies in this Court pursuant to Section 27 of the Exchange Act [15 U.S.C. § 78aa], because certain of the acts and transactions described herein took place in the Northern District of Texas. DEFENDANTS 3. Rodney E. Wallace is an individual residing in Texas. He was employed as the Director of Operations for North American Technologies Group, Inc. (“NATG” or COMPLAINT Page 1 SEC v. Rodney E. Wallace, et al. Case 3:10-cv-00440-F Document 1 Filed 03/03/2010 Page 2 of 14 the “company”) from January 2007 until he became NATG’s Chief Executive Officer (“CEO”) in March 2008. NATG fired Wallace on February 26, 2009. Wallace’s last known address of 1365 S. Hubbard St., Alvord, Texas 76225-7330. 4. Joe B. Dorman is an individual residing in Texas. He has been NATG’s general counsel since 2005 and served as NATG’s acting CFO from January 2008 to February 2009.