United States Patent 0 Ice Patented Aug

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Chemical Name Federal P Code CAS Registry Number Acutely

Acutely / Extremely Hazardous Waste List Federal P CAS Registry Acutely / Extremely Chemical Name Code Number Hazardous 4,7-Methano-1H-indene, 1,4,5,6,7,8,8-heptachloro-3a,4,7,7a-tetrahydro- P059 76-44-8 Acutely Hazardous 6,9-Methano-2,4,3-benzodioxathiepin, 6,7,8,9,10,10- hexachloro-1,5,5a,6,9,9a-hexahydro-, 3-oxide P050 115-29-7 Acutely Hazardous Methanimidamide, N,N-dimethyl-N'-[2-methyl-4-[[(methylamino)carbonyl]oxy]phenyl]- P197 17702-57-7 Acutely Hazardous 1-(o-Chlorophenyl)thiourea P026 5344-82-1 Acutely Hazardous 1-(o-Chlorophenyl)thiourea 5344-82-1 Extremely Hazardous 1,1,1-Trichloro-2, -bis(p-methoxyphenyl)ethane Extremely Hazardous 1,1a,2,2,3,3a,4,5,5,5a,5b,6-Dodecachlorooctahydro-1,3,4-metheno-1H-cyclobuta (cd) pentalene, Dechlorane Extremely Hazardous 1,1a,3,3a,4,5,5,5a,5b,6-Decachloro--octahydro-1,2,4-metheno-2H-cyclobuta (cd) pentalen-2- one, chlorecone Extremely Hazardous 1,1-Dimethylhydrazine 57-14-7 Extremely Hazardous 1,2,3,4,10,10-Hexachloro-6,7-epoxy-1,4,4,4a,5,6,7,8,8a-octahydro-1,4-endo-endo-5,8- dimethanonaph-thalene Extremely Hazardous 1,2,3-Propanetriol, trinitrate P081 55-63-0 Acutely Hazardous 1,2,3-Propanetriol, trinitrate 55-63-0 Extremely Hazardous 1,2,4,5,6,7,8,8-Octachloro-4,7-methano-3a,4,7,7a-tetra- hydro- indane Extremely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]- 51-43-4 Extremely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]-, P042 51-43-4 Acutely Hazardous 1,2-Dibromo-3-chloropropane 96-12-8 Extremely Hazardous 1,2-Propylenimine P067 75-55-8 Acutely Hazardous 1,2-Propylenimine 75-55-8 Extremely Hazardous 1,3,4,5,6,7,8,8-Octachloro-1,3,3a,4,7,7a-hexahydro-4,7-methanoisobenzofuran Extremely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime 26419-73-8 Extremely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime. -

Recent Advances in Cyanamide Chemistry: Synthesis and Applications

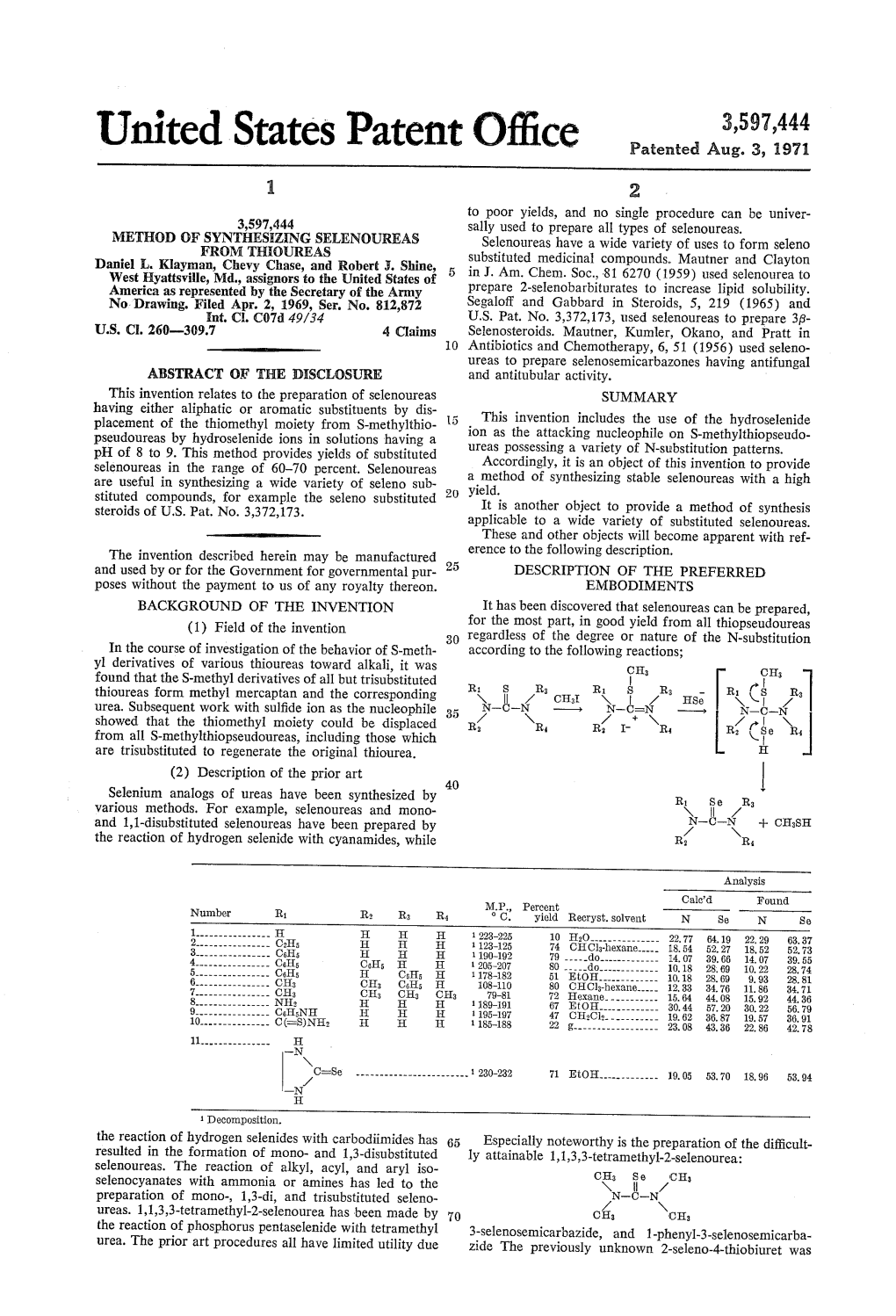

molecules Review Recent Advances in Cyanamide Chemistry: Synthesis and Applications M. R. Ranga Prabhath, Luke Williams, Shreesha V. Bhat and Pallavi Sharma * School of Chemistry, Joseph Banks Laboratories, University of Lincoln, Lincoln LN6 7DL, UK; [email protected] (M.R.R.P.); [email protected] (L.W.); [email protected] (S.V.B.) * Correspondence: [email protected]; Tel.: +44-015-2288-6885 Academic Editor: Margaret A. Brimble Received: 9 March 2017; Accepted: 7 April 2017; Published: 12 April 2017 Abstract: The application of alkyl and aryl substituted cyanamides in synthetic chemistry has diversified multi-fold in recent years. In this review, we discuss recent advances (since 2012) in the chemistry of cyanamides and detail their application in cycloaddition chemistry, aminocyanation reactions, as well as electrophilic cyanide-transfer agents and their unique radical and coordination chemistry. Keywords: cyanamide; synthesis; aminocyanation; cycloaddition; electrophilic cyanation; radical reaction; coordination chemistry 1. Introduction Cyanamide enjoys a rich chemical history, which can be traced to its unique and chemically promiscuous nitrogen-carbon-nitrogen (NCN) connectivity. The chemistry of the nitrile-substituted amino-group of the ‘cyanamide-moiety’ is dominated by an unusual duality of a nucleophilic sp3-amino nitrogen and an electrophilic nitrile unit. The reported use of unsubstituted cyanamide (NH2CN) and metal cyanamides (MNCN, where M = metal) date back as far as the late 19th century, where the likes of calcium cyanamide (CaNCN) was used as a fertilizer, and later as source of ammonia and nitric acid, which fueled the industrial production of metal cyanamides. In contrast, the reported use of the corresponding substituted organic cyanamides (RNHCN or RR’NCN) gathered pace only in more recent years. -

Acutely / Extremely Hazardous Waste List

Acutely / Extremely Hazardous Waste List Federal P CAS Registry Acutely / Extremely Chemical Name Code Number Hazardous 4,7-Methano-1H-indene, 1,4,5,6,7,8,8-heptachloro-3a,4,7,7a-tetrahydro- P059 76-44-8 Acutely Hazardous 6,9-Methano-2,4,3-benzodioxathiepin, 6,7,8,9,10,10- hexachloro-1,5,5a,6,9,9a-hexahydro-, 3-oxide P050 115-29-7 Acutely Hazardous Methanimidamide, N,N-dimethyl-N'-[2-methyl-4-[[(methylamino)carbonyl]oxy]phenyl]- P197 17702-57-7 Acutely Hazardous 1-(o-Chlorophenyl)thiourea P026 5344-82-1 Acutely Hazardous 1-(o-Chlorophenyl)thiourea 5344-82-1 Extemely Hazardous 1,1,1-Trichloro-2, -bis(p-methoxyphenyl)ethane Extemely Hazardous 1,1a,2,2,3,3a,4,5,5,5a,5b,6-Dodecachlorooctahydro-1,3,4-metheno-1H-cyclobuta (cd) pentalene, Dechlorane Extemely Hazardous 1,1a,3,3a,4,5,5,5a,5b,6-Decachloro--octahydro-1,2,4-metheno-2H-cyclobuta (cd) pentalen-2- one, chlorecone Extemely Hazardous 1,1-Dimethylhydrazine 57-14-7 Extemely Hazardous 1,2,3,4,10,10-Hexachloro-6,7-epoxy-1,4,4,4a,5,6,7,8,8a-octahydro-1,4-endo-endo-5,8- dimethanonaph-thalene Extemely Hazardous 1,2,3-Propanetriol, trinitrate P081 55-63-0 Acutely Hazardous 1,2,3-Propanetriol, trinitrate 55-63-0 Extemely Hazardous 1,2,4,5,6,7,8,8-Octachloro-4,7-methano-3a,4,7,7a-tetra- hydro- indane Extemely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]- 51-43-4 Extemely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]-, P042 51-43-4 Acutely Hazardous 1,2-Dibromo-3-chloropropane 96-12-8 Extemely Hazardous 1,2-Propylenimine P067 75-55-8 Acutely Hazardous 1,2-Propylenimine 75-55-8 Extemely Hazardous 1,3,4,5,6,7,8,8-Octachloro-1,3,3a,4,7,7a-hexahydro-4,7-methanoisobenzofuran Extemely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime 26419-73-8 Extemely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime. -

Synthesis and Single Crystal Structures of Substituted-1, 3

molecules Article Synthesis and Single Crystal Structures of Substituted-1,3-Selenazol-2-amines † Guoxiong Hua, Junyi Du, Alexandra M. Z. Slawin and J. Derek Woollins * EaStCHEM School of Chemistry, University of St. Andrews, St. Andrews, Fife KY16 9ST, UK; [email protected] (G.H.); [email protected] (J.D.); [email protected] (A.M.Z.S.) * Correspondence: [email protected]; Tel./Fax: +44-1334-463-861 † Dedication: This paper is dedicated to Prof. Eva Marie Hey-Hawkins on the occasion of her 60th birthday. Academic Editors: Claudio Santi and Luana Bagnoli Received: 15 December 2016; Accepted: 26 December 2016; Published: 29 December 2016 Abstract: The synthesis and X-ray single crystal structures of a series of new 4-substituted-1,3- selenazol-2-amines is reported. The efficient preparation of these compounds was carried out by two-component cyclization of the selenoureas with equimolar amounts of α-haloketones. The selenoureas were obtained from the reaction of Woollins’ reagent with cyanamides, followed by hydrolysis with water. All new compounds have been characterized by IR spectroscopy, multi-NMR (1H, 13C, 77Se) spectroscopy, accurate mass measurement and single crystal X-ray structure analysis. Keywords: cyanamides; haloketones; selenazol-2-amines; selenoureas; Woollins’ reagent 1. Introduction Selenazoles have been extensively described as useful synthetic tools [1–4] with biologically significant antibiotic [5] and cancerostatic [6,7] and superoxide anion scavenging activity [8]. A few reports have appeared on the synthesis of selenazoles and thiazoles, including both solid phase [9] and solution phase synthesis [10–12]. Narender et al. -

List of Lists

United States Office of Solid Waste EPA 550-B-10-001 Environmental Protection and Emergency Response May 2010 Agency www.epa.gov/emergencies LIST OF LISTS Consolidated List of Chemicals Subject to the Emergency Planning and Community Right- To-Know Act (EPCRA), Comprehensive Environmental Response, Compensation and Liability Act (CERCLA) and Section 112(r) of the Clean Air Act • EPCRA Section 302 Extremely Hazardous Substances • CERCLA Hazardous Substances • EPCRA Section 313 Toxic Chemicals • CAA 112(r) Regulated Chemicals For Accidental Release Prevention Office of Emergency Management This page intentionally left blank. TABLE OF CONTENTS Page Introduction................................................................................................................................................ i List of Lists – Conslidated List of Chemicals (by CAS #) Subject to the Emergency Planning and Community Right-to-Know Act (EPCRA), Comprehensive Environmental Response, Compensation and Liability Act (CERCLA) and Section 112(r) of the Clean Air Act ................................................. 1 Appendix A: Alphabetical Listing of Consolidated List ..................................................................... A-1 Appendix B: Radionuclides Listed Under CERCLA .......................................................................... B-1 Appendix C: RCRA Waste Streams and Unlisted Hazardous Wastes................................................ C-1 This page intentionally left blank. LIST OF LISTS Consolidated List of Chemicals -

Speciality Chemicals

Catalog – 2019 (Specialty Chemicals, Reagents, Catalysts) To Place an Order / to Request a Quote Please send e-mail to: [email protected] © Anvia Chemicals Anvia Chemicals Online Catalog Catalog CAS Name Purity Mol. Formula Mol Wt Package Price N-(DIMETHYLAMINOPROPYL)-N'- gm, Kg, 03-2348 25952-53-8 C H N · HCl 191.7 On Request ETHYLCARBO- DIIMIDE HCL 8 17 3 Bulk 3-AMINOQUINUCLIDINE gm, Kg, 02-2389 6530-09-2 98% C H N · 2HCl 199.12 On Request DIHYDROCHLORIDE 7 14 2 Bulk gm, Kg, 02-1286 873-51-8 DICHLOROPHENYLBORANE 97% C H BCl 158.82 On Request 6 5 2 Bulk gm, Kg, 03-1780 5346-90-7 ALPHA-D-CELLOBIOSE OCTAACETATE 98% C H O 678.59 On Request 28 38 19 Bulk gm, Kg, 02-1784 3218-02-8 CYCLOHEXANEMETHYLAMINE 98% C H CH NH 113.2 On Request 6 11 2 2 Bulk gm, Kg, 03-1617 451-46-7 ETHYL 4-FLUOROBENZOATE 99% FC H CO C H 168.16 On Request 6 4 2 2 5 Bulk gm, Kg, 03-1764 2251-50-5 PENTAFLUOROBENZOYL CHLORIDE 99% C F COCl 230.52 On Request 6 5 Bulk gm, Kg, 03-1317 771-61-9 PENTAFLUOROPHENOL 99% C F OH 184.06 On Request 6 5 Bulk gm, Kg, 02-1637 3637-61-4 CYCLOPENTANEMETHANOL 98% C H CH OH 100.16 On Request 5 9 2 Bulk gm, Kg, 03-1405 767-69-1 6-BROMOPURINE 98% C H BrN 199.01 On Request 5 3 4 Bulk gm, Kg, 03-2349 920-66-1 1,1,1,3,3,3-HEXAFLUORO-2-PROPANOL 99% (CF ) CHOH 168.04 On Request 3 2 Bulk gm, Kg, 02-2514 513-31-5 2,3-DIBROMOPROPENE, TECH. -

Environmental Protection Agency § 302.4

Environmental Protection Agency § 302.4 State, municipality, commission, polit- ern Marianas, and any other territory ical subdivision of a State, or any or possession over which the United interstate body; States has jurisdiction; and Release means any spilling, leaking, Vessel means every description of pumping, pouring, emitting, emptying, watercraft or other artificial contriv- discharging, injecting, escaping, leach- ance used, or capable of being used, as ing, dumping, or disposing into the en- a means of transportation on water. vironment (including the abandonment or discarding of barrels, containers, [50 FR 13474, Apr. 4, 1985, as amended at 67 FR 45321, July 9, 2002] and other closed receptacles containing any hazardous substance or pollutant § 302.4 Designation of hazardous sub- or contaminant), but excludes: stances. (1) Any release which results in expo- (a) Listed hazardous substances. The sure to persons solely within a work- place, with respect to a claim which elements and compounds and haz- such persons may assert against the ardous wastes appearing in table 302.4 employer of such persons; are designated as hazardous substances (2) Emissions from the engine ex- under section 102(a) of the Act. haust of a motor vehicle, rolling stock, (b) Unlisted hazardous substances. A aircraft, vessel, or pipeline pumping solid waste, as defined in 40 CFR 261.2, station engine; which is not excluded from regulation (3) Release of source, byproduct, or as a hazardous waste under 40 CFR special nuclear material from a nuclear 261.4(b), is a hazardous substance under incident, as those terms are defined in section 101(14) of the Act if it exhibits the Atomic Energy Act of 1954, if such any of the characteristics identified in release is subject to requirements with 40 CFR 261.20 through 261.24. -

"Protocol for Conducting Environmental Compliance Audits

United States Enforcement and EPA-305-B-98-006 Environmental Protection Compliance Assurance December 1998 Agency (2224A) Protocol for Conducting Environmental Compliance Audits of Treatment, Storage and Disposal Facilities under the Resource Conservation and Recovery Act EPA Office of Compliance Protocol for Conducting Environmental Compliance Audits of TSDFs under RCRA Notice This document has been developed to assist in conducting environmental audits. The use of this document should be restricted to environmental audits only. For example, areas such as safety, transportation, occupational health, and fire protection are mentioned solely for clarification purposes. It is a summary of environmental regulations under RCRA but it is not a substitute for a comprehensive knowledge of the regulations themselves. Any variation between applicable regulations and the summaries contained in this guidance document are unintentional, and, in the case of such variations, the requirements of the regulations govern. This document is intended solely as guidance to explain performance objectives for environmental auditors. Following the steps set forth in this guidance generally should result in compliance with those aspects of the regulations that it covers. The U.S. Environmental Protection Agency (EPA) does not make any guarantee or assume any liability with respect to the use of any information or recommendations contained in this document. Regulated entities requiring additional information or advice should consult a qualified professional. This guidance does not constitute rulemaking by the EPA and may not be relied on to create a substantive or procedural right or benefit enforceable, at law or in equity, by any person. EPA may take action at variance with this guidance and its internal procedures. -

Novel Urea, Thiourea and Selenourea Derivatives of Diselenides: Synthesis and Leishmanicidal Activity

AAC Accepted Manuscript Posted Online 19 February 2019 Antimicrob. Agents Chemother. doi:10.1128/AAC.02200-18 Copyright © 2019 American Society for Microbiology. All Rights Reserved. 1 NOVEL UREA, THIOUREA AND SELENOUREA DERIVATIVES 2 OF DISELENIDES: SYNTHESIS AND LEISHMANICIDAL 3 ACTIVITY a,b c a,b,d 4 Marta Díaz, Héctor de Lucio, Esther Moreno, Socorro Downloaded from a,b,d a,b,d c 5 Espuelas, Carlos Aydillo, Antonio Jiménez-Ruiz, Miguel c c e 6 Ángel Toro, Killian Jesús Gutiérrez, Victor Martínez-Merino, e a,b,d a,b,d,* 7 Alfonso Cornejo, Juan Antonio Palop, Carmen Sanmartín, a,b,d http://aac.asm.org/ 8 Daniel Plano 9 Departamento de Tecnología y Química Farmacéuticasa and Instituto de Salud 10 Tropical,b University of Navarra, Pamplona, Spain; Departamento de Biología 11 de Sistemas, Universidad de Alcalá, Madrid, Spain;c Instituto de 12 Investigaciones Sanitarias de Navarra (IdiSNA), Pamplona, Spain;d on February 20, 2019 by guest 13 Departamento de Química Aplicada, Universidad Pública de Navarra, 14 Pamplona, Spaine 15 16 17 * Prof. Carmen Sanmartín 18 Department of Organic and Pharmaceutical Chemistry 19 University of Navarra 20 Irunlarrea, 1, E-31008 Pamplona 21 SPAIN 22 +34 948 425 600 (Telephone) 23 +34 948 425 649 (Fax) 24 e-mail: [email protected] 25 Abstract 26 A novel series of thirty-one N-substituted urea, thiourea and selenourea 27 derivatives containing diphenyldiselenide entity were synthesized, fully 28 characterized by spectroscopic and analytical methods, and screened for their 29 in vitro leishmanicidal activities. The cytotoxic activity of these derivatives was Downloaded from 30 tested against Leishmania infantum axenic amastigotes, and selectivity was 31 assessed in human THP-1 cells. -

Synthesis and Catalytic Investigations

materials Article Novel Selenoureas Based on Cinchona Alkaloid Skeleton: Synthesis and Catalytic Investigations Mariola Zieli ´nska-Błajet 1,* and Joanna Najdek 2 1 Faculty of Chemistry, Wrocław University of Science and Technology, Wybrzeze˙ Wyspia´nskiego27, 50-370 Wrocław, Poland 2 Institute of Chemistry and Biochemistry, Freie Universität Berlin, Takustr. 3, 14195 Berlin, Germany; [email protected] * Correspondence: [email protected]; Tel.: +48-71-3202128 Abstract: An efficient approach to the synthesis of chiral selenoureas consisting of Cinchona alkaloid scaffolds was described. The new selenoureas were assessed as bifunctional organocatalysts in the asymmetric Michael addition reactions under mild conditions. The best results were obtained for selenoureas bearing the 4-fluorophenyl group. These catalysts promoted the reactions with enantioselectivities of up to 96% ee. Additionally, the catalytic performance of the thiourea and selenourea counterpart was compared. Keywords: Cinchona alkaloids; selenoureas; isoselenocyanates; organocatalysis; Michael addition; asymmetric synthesis 1. Introduction In recent years, growing attention has been focused on the synthesis and applications Citation: Zieli´nska-Błajet,M.; of selenourea derivatives. The structures of selenoureas are closely related to those of Najdek, J. Novel Selenoureas Based analogs of oxygen and sulfur compounds [1–3], but the presence of larger, more polarizable on Cinchona Alkaloid Skeleton: selenium results in a change of significant properties. They possess various biological Synthesis and Catalytic properties, such as antioxidant [4,5], antibacterial and antifungal [6], antileishmanial [7], Investigations. Materials 2021, 14, 600. pesticidal [8], and anti-urease activity [9]. Selenoureas also demonstrate enzyme inhibition, https://doi.org/10.3390/ma14030600 free-radical scavenging, and anticancer activity [10,11]. -

Cooperativity Between Hydrogen- and Halogen Bonds: the Case of Selenourea

Cooperativity Between Hydrogen- and Halogen Bonds: the Case of Selenourea Gianluca Ciancaleoni* Università degli Studi di Pisa, Dipartimento di Chimica e Chimica Industriale, via Giuseppe Moruzzi, 13 - 56124 Pisa, Italy. *Email: [email protected], ORCID: 0000-0001-5113-2351 Abstract A combined experimental/computational study of cooperativity between halogen- (XB) and hydrogen bonding (HB) is presented. The selenourea (SeU) has been chosen for its ability to act at the same time as XB acceptor toward I(CF2)5CF3 (I1) through the two lone pairs on the selenium atom, and HB donor to the benzoate anion through its two amino moieties. All the equilibrium constants have been estimated using either diffusion NMR and NMR titrations techniques. Experimental results … … demonstrate that the -NH2 anion interaction strongly enhances the Se I one of about one order of magnitude (in terms of formation constant of the adduct), whereas DFT results rationalize such results revealing that the presence of a HB between the benzoate and SeU strongly polarizes the latter, enhancing the negative partial charge on the selenium and, consequently, its Lewis basicity and its XB acceptor properties. Introduction The halogen bond (XB),1,2 which can be defined as the interaction between a Lewis base and a polarized halogen atom, has recently become a powerful tool in many fields of chemistry, from catalysis3,4 to biochemistry,5 but it plays a special role in the crystal engineering.6,7 Indeed, we can say that the “halogen bond adventure” officially started with the analysis of inter-molecular Br…O 8 distance in Br2/dioxane co-crystal, in which this distance was less than the sum of the van der Waals radii. -

Chemical Hygiene Plan

University Individuals. /1ispired. ~ CHEMICAL HYGIENE PLAN Version 02.06.16 1 ALFRED UNIVERSITY CHEMICAL HYGIENE PLAN TABLE OF CONTENTS PART I Scope, Application, and Compliance 1.1 SCOPE 1.2 APPLICATION 1.3 COMPLIANCE 1.3.1 REQUIREMENTS 1.3.2 AU COMPLIANCE POLICIES 1.3.2.1 STANDARD OPERATING PROCEDURES 1.3.2.2 CONTROLS TO REDUCE EMPLOYEE EXPOSURE TO HAZARDOUS CHEMICALS 1.3.2.3 EMPLOYEE INFORMATION AND TRAINING 1.3.2.3.1 OSHA Lab Standard Training 1.3.2.3.2 Site-Specific Training 1.3.2.3.3 Other Types of Training 1.3.2.4 OPERATIONS, PROCEDURES, ACTIVITIES REQUIRING PRIOR APPROVAL 1.3.2.5 PROVISIONS FOR MEDICAL CONSULTATION AND EXAMS 1.3.2.6 CHEMICAL HYGIENE RESPONSIBILITIES 1.3.2.6.1 President of Alfred University 1.3.2.6.2 Vice President for Business and Finance 1.3.2.6.3 Provost, Deans, Directors, and Chairpersons 1.3.2.6.4 Office of Environmental Health and Safety (EH&S) 1.3.2.6.5 Chemical Hygiene Committee 1.3.2.6.6 Laboratory Supervisors, Faculty and Principal Investigators 1.3.2.6.7 Laboratory Employees 1.3.2.7 PROCEDURES AND PRECAUTIONS FOR WORKING WITH PARTICULARLY HAZARDOUS SUBSTANCES 1.3.2.8 EXPOSURE MONITORING 1.3.2.9 HAZARD IDENTIFICATION WITH RESPECT TO LABELS AND SAFETY DATA SHEETS 1.3.2.10 PROVISIONS THAT SHALL APPLY TO CHEMICAL SUBSTANCES DEVELOPED IN THE LABORATORY 1.3.2.11 RECORDKEEPING 1.3.2.12 EMERGENCY RESPONSE 1.3.2.13 WASTE MANAGEMENT PART II General Standard Operating Procedures 2.0 INTRODUCTION 2.1 SAFE WORK PRACTICES - EMPLOYEE RESPONSIBILITIES 2.2 EMERGENCY PROCEDURES 2.2.1 EMERGENCY NUMBERS 2 2.2.2 EMERGENCY EXIT ROUTES 2.2.3 FIRE EMERGENCY 2.2.4 ACCIDENTS 2.2.5 CHEMICAL SPILLS 2.2.6 USING EMERGENCY EYEWASHES 2.2.7 USING EMERGENCY SHOWERS 2.2.8 EMERGENCY SHUTDOWN AND EVACUATION PROCEDURES 2.3 CONTROL MEASURES 2.3.1 ENGINEERING CONTROLS 2.3.2 EYEWASHES AND SAFETY SHOWERS 2.3.3 ADMINISTRATIVE CONTROLS 2.3.3.1 Prior Approval (Appendix A) 2.3.3.2 Working Alone 2.3.3.3 Unattended Operations (Appendix T) 2.3.3.4 Laboratory Housekeeping 2.3.3.5 Personal Dress, Hygiene and Lab Behavior, Eating, Drinking, Etc.