AS the TURBINE TURNS... by Dr

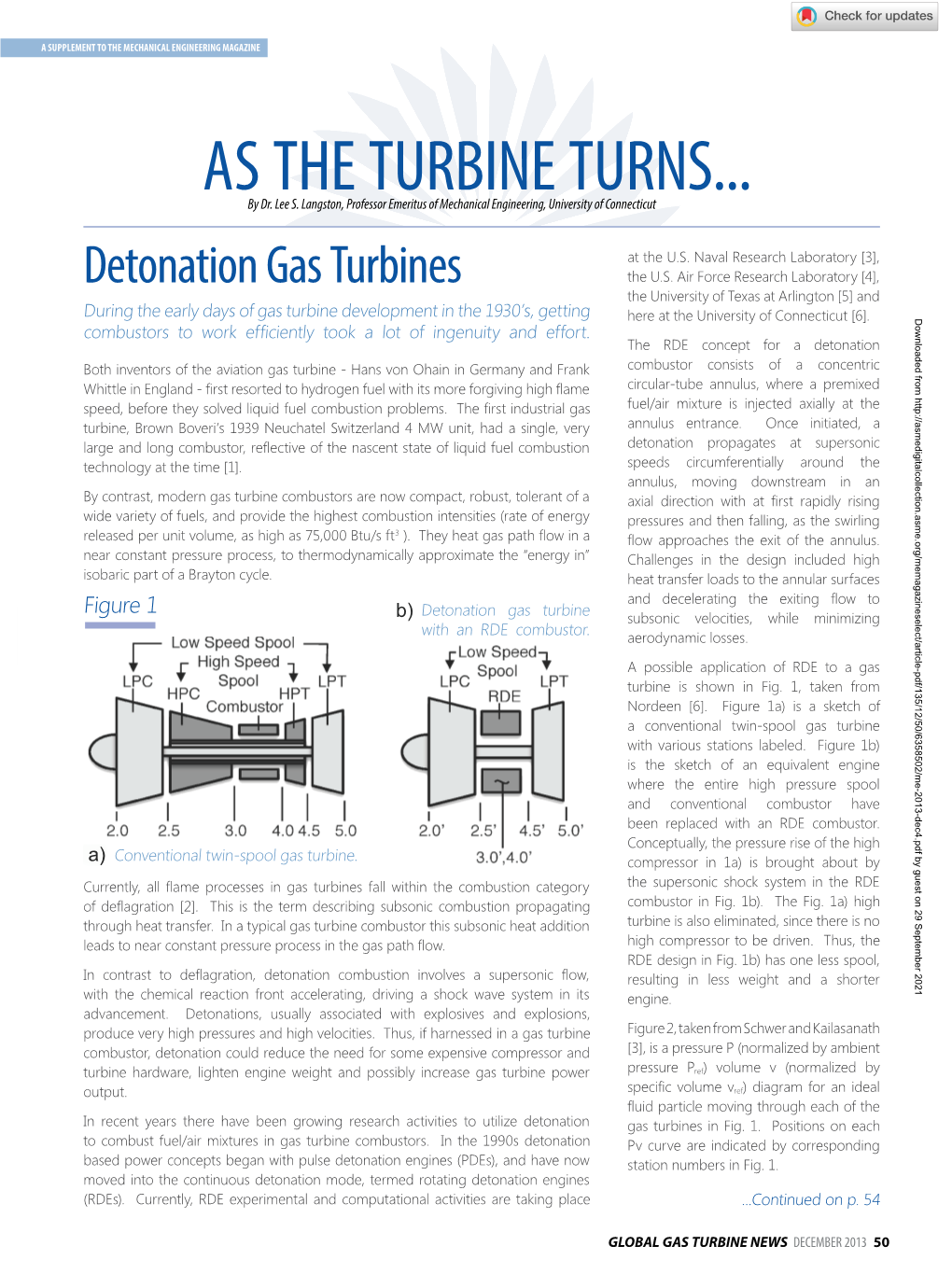

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Investigation of Various Novel Air-Breathing Propulsion Systems

Investigation of Various Novel Air-Breathing Propulsion Systems A thesis submitted to the Graduate School of the University of Cincinnati in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE in the Department of Aerospace Engineering & Engineering Mechanics of the College of Engineering and Applied Science 2016 by Jarred M. Wilhite B.S. Aerospace Engineering & Engineering Mechanics University of Cincinnati 2016 Committee Chair: Dr. Ephraim Gutmark Committee Members: Dr. Paul Orkwis & Dr. Mark Turner Abstract The current research investigates the operation and performance of various air-breathing propulsion systems, which are capable of utilizing different types of fuel. This study first focuses on a modular RDE configuration, which was mainly studied to determine which conditions yield stable, continuous rotating detonation for an ethylene-air mixture. The performance of this RDE was analyzed by studying various parameters such as mass flow rate, equivalence ratios, wave speed and cell size. For relatively low mass flow rates near stoichiometric conditions, a rotating detonation wave is observed for an ethylene-RDE, but at speeds less than an ideal detonation wave. The current research also involves investigating the newly designed, Twin Oxidizer Injection Capable (TOXIC) RDE. Mixtures of hydrogen and air were utilized for this configuration, resulting in sustained rotating detonation for various mass flow rates and equivalence ratios. A thrust stand was also developed to observe and further measure the performance of the TOXIC RDE. Further analysis was conducted to accurately model and simulate the response of thrust stand during operation of the RDE. Also included in this research are findings and analysis of a propulsion system capable of operating on the Inverse Brayton Cycle. -

Thermodynamic Cycle

INTERNATIONAL JOURNAL OF ENVIRONMENTAL & SCIENCE EDUCATION 2016, VOL. 11, NO. 12, 5009-5019 OPEN ACCESS Detonation Jet Engine. Part 1 – Thermodynamic Cycle Pavel V. Bulata and Konstantin N. Volkovb aSaint Petersburg National Research University of Information Technologies, Mechanics and Optics, Saint Petersburg, RUSSIA; bKingston University, Faculty of Science, Engineering and Computing, London, UK ABSTRACT We present the most relevant works on jet engine design that utilize thermodynamic cycle of detonative combustion. The efficiency advantages of thermodynamic detonative combustion cycle over Humphrey combustion cycle at constant volume and Brayton combustion cycle at constant pressure were demonstrated. An ideal Ficket-Jacobs detonation cycle, and the thermodynamic cycle of real detonation engine that utilizes over compressed detonation were discussed. Main trends in development of detonation engines were described. Relevant for nearest time problems and directions of research were formulated. KEYWORDS ARTICLE HISTORY Detonation, detonation wave, detonation engine, Received 13 April 2016 rotational detonation engine, pulse detonation Revised 17 May 2016 engine Accepted 22 May 2016 Introduction Historically the most important investment into the development of detonative combustion was made by Soviet and then Russian scientists. Ya.B. Zeldovich (1940) was the first who proposed to utilize detonation in engines and energy devices. By examining problem of arbitrary discontinuity breakdown in reacting medium, G.M. Bam-Zelikovich (1949; 1952) has laid the theoretical foundation of pulse detonation engine. He also was the first to give a simple theoretical explanation of pulsation appearance during fuel mixture combustion in cylindrical channel. Later, works were carried out in laboratory of gas- dynamics at Central Institute of Aviation Motors, under the direction of L.I. -

Comprehensive Thermodynamic Analysis of the Humphrey Cycle for Gas Turbines with Pressure Gain Combustion

energies Article Comprehensive Thermodynamic Analysis of the Humphrey Cycle for Gas Turbines with Pressure Gain Combustion Panagiotis Stathopoulos Chair of Unsteady Thermodynamics in Gas Turbine Processes, Hermann Föttinger Institute, Technische Universität Berlin, Müller Breslau Str. 8, 10623 Berlin, Germany; [email protected]; Tel.: +49-30-314-29361 Received: 20 November 2018; Accepted: 11 December 2018; Published: 18 December 2018 Abstract: Conventional gas turbines are approaching their efficiency limits and performance gains are becoming increasingly difficult to achieve. Pressure Gain Combustion (PGC) has emerged as a very promising technology in this respect, due to the higher thermal efficiency of the respective ideal gas turbine thermodynamic cycles. Up to date, only very simplified models of open cycle gas turbines with pressure gain combustion have been considered. However, the integration of a fundamentally different combustion technology will be inherently connected with additional losses. Entropy generation in the combustion process, combustor inlet pressure loss (a central issue for pressure gain combustors), and the impact of PGC on the secondary air system (especially blade cooling) are all very important parameters that have been neglected. The current work uses the Humphrey cycle in an attempt to address all these issues in order to provide gas turbine component designers with benchmark efficiency values for individual components of gas turbines with PGC. The analysis concludes with some recommendations for the best strategy to integrate turbine expanders with PGC combustors. This is done from a purely thermodynamic point of view, again with the goal to deliver design benchmark values for a more realistic interpretation of the cycle. Keywords: pressure gain combustion; gas turbine; Humphrey cycle; thermodynamic analysis; turbine cooling; turbine integration 1. -

An Alternative Architecture of the Humphrey Cycle and the Effect of Fuel Type on Its Efficiency

Received: 24 January 2020 | Revised: 9 June 2020 | Accepted: 10 June 2020 DOI: 10.1002/ese3.776 RESEARCH ARTICLE An alternative architecture of the Humphrey cycle and the effect of fuel type on its efficiency Panagiotis Stathopoulos Chair of Unsteady Thermodynamics in Gas Turbine Processes, Technische Universität Abstract Berlin, Berlin, Germany Conventional gas turbines are a very mature technology, and performance improve- ments are becoming increasingly difficult and costly to achieve. Pressure-gain com- Correspondence Panagiotis Stathopoulos, Chair of Unsteady bustion (PGC) has emerged as a promising technology in this respect, due to the Thermodynamics in Gas Turbine Processes, higher thermal efficiency of the respective ideal gas turbine cycles. The current work Technische Universität Berlin, Müller analyzes two layouts of the Humphrey cycle for gas turbines with pressure-gain com- Breslau Str. 8, 10623 Berlin, Germany. Email: [email protected] bustion. One layout replicates the classical layout of gas turbine cycles, whereas an alternative one optimizes the use of pressure-gain combustion by ensuring the opera- Funding information tion of the combustor at stoichiometric conditions. In parallel, both cycle layouts are Deutsche Forschungsgemeinschaft, Grant/ Award Number: SFB 1028 - Turbin studied with two different fuels—hydrogen and dimethyl ether—to account for dif- ferences in combustion specific heat addition and its effect on cycle efficiency. The current work concludes with an attempt to benchmark the maximum losses of a ple- num to achieve efficiency parity with the Joule cycle, for a given pressure gain over a PGC combustor. It is found that the cycle layout with stoichiometric combustion results in an increase in thermal efficiency of up to 7 percentage points, compared to the classic cycle architecture. -

Cranfield University Matthew Moxon Thermodynamic Analysis of The

Cranfield University Matthew Moxon Thermodynamic analysis of the Brayton-cycle gas- turbine under equilibrium chemistry assumptions School of Engineering PhD Academic year: 2010/2011 Supervisor: Professor Riti Singh July 2011 © Cranfield University, 2011. All rights reserved. No part of this publication may be reproduced without the written permission of the copyright holder. ii ABSTRACT A design-point thermodynamic model of the Brayton-cycle gas-turbine under assumptions of perfect chemical equilibrium is described. This approach is novel to the best knowledge of the author. The model uniquely derives an optimum work balance between power turbine and nozzle as a function of flight conditions and propulsor efficiency. The model may easily be expanded to allow analysis and comparison of arbitrary cycles using any combination of fuel and oxidizer. The model allows the consideration of engines under a variety of conditions, from sea level/static to >20 km altitude and flight Mach numbers greater than 4. Isentropic or polytropic turbomachinery component efficiency standards may be used independently for compressor, gas generator turbine and power turbine. With a methodology based on the paper by M.V. Casey, “Accounting for losses” (2007), and using Bridgman’s partial differentials , the model uniquely describes the properties of a gas turbine solely by reference to the properties of the gas mixture passing through the engine. Turbine cooling is modelled using a method put forward by Kurzke. Turboshaft, turboprop, separate exhaust turbofan and turbojet engines may be modelled. Where applicable, optimisation of the power turbine and exhaust nozzle work split for flight conditions and component performances is automatically undertaken. -

GENSETS Program Overview

GENSETS Program Overview B. PROGRAM OVERVIEW 1. SUMMARY The GENSETS Program – GENerators for Small Electrical and Thermal Systems – seeks to fund the development of potentially disruptive generator technologies that will enable widespread deployment of residential Combined Heat and Power (CHP) systems. Here, CHP is defined as the distributed generation of electricity from piped-in natural gas fuel at a residence or a commercial site complemented by use of exhaust heat for local heating and cooling. If adopted widely by U.S. residential and commercial sectors, GENSETS CHP systems could lead to annual primary energy savings of more than 5 quadrillion BTU (quads). GENSETS systems could also provide annual CO2 emissions reductions of more than 200 million metric tons, which is roughly 10% of the CO2 produced annually from U.S. electricity generation and 4% of total U.S. annual CO2 emissions. The GENSETS Program seeks transformative generators/engines with 1 kW of electrical output (kWe) that have high efficiency (40% fuel to electricity), long life (10 years), low cost ($3,000 per system), and low emissions. Heat engines and generators capable of achieving these targets may include internal and external combustion engines, turbines, and solid state devices such as thermophotovoltaics, thermionic emitters, and thermoelectrics. It is anticipated that the same technologies developed for 1-kWe engines in GENSETS could be adapted to build larger engines with even higher efficiencies for various commercial sectors of the U.S. 2. BACKGROUND AND MOTIVATION 2.1 Opportunity and Impact of CHP In 2013, U.S. central-station power plants consumed 38.2 quads of primary energy to generate 12.4 quads of electricity with an average electricity generation efficiency of 33% when aggregated over all primary energy sources, including coal, natural gas, nuclear, hydro, and wind1. -

Pulse Powered Turbine Engine Concept – Numerical Analysis of Influence of Different Valve Timing Concepts on Thermodynamic Performance

BULLETIN OF THE POLISH ACADEMY OF SCIENCES TECHNICAL SCIENCES, Vol. 66, No. 3, 2018 DOI: 10.24425/123444 Pulse powered turbine engine concept – numerical analysis of influence of different valve timing concepts on thermodynamic performance P. TARNAWSKI* and W. OSTAPSKI Institute of Machine Design Fundamentals, Warsaw University of Technology, 84 Narbutta St., 02-524 Warsaw, Poland Abstract. The present work is an attempt to create the concept of an engine that will combine the benefits of a pulse powered piston engine and continuously powered turbine engine. The paper focuses on the subject of pressure gain combustion (PGC). A turbine engine concept with stationary constant volume combustors, working according the Humphrey cycle, is presented. Its work has to be controlled by valve timing system. Four different valve timing concepts were analyzed. Their influence on thermodynamic performance of engine was evaluated. Different valve constructions were researched by means of 3D numerical computational fluid dynamics (CFD) simulation. Key words: pressure gain combustion (PGC), constant volume combustion (CVC), turbine engine, CFD analysis, valve timing. 1. Introduction over a continuously powered one, with beneficial influence on overall engine efficiency. Internal combustion engines utilized as power supply can be A continuously powered turbine engine has significant ad- divided into the continuous powered and the pulse powered. vantage over a pulse powered piston engine regarding the ratio A classical turbine engine is powered continuously, while of engine power to engine mass. In the case of aviation, this a piston engine is an example of a pulse powered unit. Apart is an important aspect which contributes to reducing fuel con- from different conversion of mechanical work, the process of sumption. -

Download Paper

Proceedings of the 1st Global Power and Propulsion Forum GPPF 2017 Jan 16-18, 2017, Zurich, Switzerland www.pps.global GPPF-2017-0006 PRESSURE GAIN COMBUSTION ADVANTAGE IN LAND-BASED ELECTRIC POWER GENERATION S. Can Gülen Bechtel Infrastructure & Power Inc. [email protected] Reston, VA, USA ABSTRACT available units (i.e., GT 24/26 gas turbines with “sequential” or reheat combustion). The latter, which is the subject of this This paper evaluates the improvement in gas turbine paper, has been on the draft-board for more than half century combined cycle power plant efficiency and output via pressure for aircraft propulsion (pulsed detonation combustion, PDC) gain combustion (PGC). Ideal and real cycle calculations are [3]. The generic name for the practical devices approximating provided for a rigorous assessment of PGC variants (e.g., constant volume heat addition is “pressure gain combustor”. detonation and deflagration) in a realistic power plant The closest practical implementation of the process is the framework with advanced heavy-duty industrial gas explosive combustion inside the cylinder of a reciprocating turbines. It is shown that PGC is the single-most potent knob internal combustion engine (ICE). available to the designers for a quantum leap in combined The tremendous performance improvement potential of cycle performance. pressure gain combustion within the context of land-based gas INTRODUCTION turbines for electric power generation is investigated herein. Gas turbine combined cycle (GTCC) power plant is the Fundamental considerations and detailed heat and mass most efficient and least-polluting fossil fuel-based electric balances show that 65+% net thermal efficiency is readily power generation technology. -

Main Performances of the Unsteady Constant Volume Combustion Thermodynamic Cycle

DOI: 10.13009/EUCASS2019-776 Main Performances of the Unsteady Constant Volume Combustion Thermodynamic Cycle Roberto Andriani* and Antonella Ingenito** *Politecnico di Milano, Department of Energy, Via Lambruschini, 4, 20156 Milan, Italy **Università “La Sapienza”, Scuola di Ingegneria Aerospaziale, Via Salaria, 851, 00138 Rome, Italy Abstract Common gas turbine engine work following the constant pressure combustion Brayton thermodynamic cycle. In the Humphrey cycle, heat is instead introduced at constant volume, allowing the pressure rise without the need of the compressor. The reduction of the compressor work can rise the thermal efficiency, however the process unsteadiness can mitigate these benefits. By means of a thermodynamic numerical program, a comparison of the main features of the two cycle, in particular specific output work and thermal efficiency, is done, focusing on the main effects that the unsteady combustion and expansion can have on the performance, and on the problems that can arise when joining steady and unsteady intermittent flow components. Nomenclature T: temperature Qin : heat for unity of mass introduced at constant volume in the combustion chamber cp: constant pressure specific heat γ: specific heat ratio L: turbine work Lc: compressor work Lnet : output work m: mass ηth : cycle thermal efficiency τ: temperature ratio (T 3/T 1) βc: compressor pressure ratio CVC: Constant Volume Combustion 1. Introduction The continuous research of high efficiency and low emission gas turbine engines has brought the engineers to consider novel approaches for next future engines. In the years, the engine efficiency has been enhanced mainly rising the maximum DOI: 10.13009/EUCASS2019-776 R. Andriani and A. -

Detonation Confinement in a Radial Rotating Detonation Engine

Air Force Institute of Technology AFIT Scholar Theses and Dissertations Student Graduate Works 3-2020 Detonation Confinement in a Radial Rotating Detonation Engine Kavi Muraleetharan Follow this and additional works at: https://scholar.afit.edu/etd Part of the Heat Transfer, Combustion Commons, and the Propulsion and Power Commons Recommended Citation Muraleetharan, Kavi, "Detonation Confinement in a Radial Rotating Detonation Engine" (2020). Theses and Dissertations. 3218. https://scholar.afit.edu/etd/3218 This Thesis is brought to you for free and open access by the Student Graduate Works at AFIT Scholar. It has been accepted for inclusion in Theses and Dissertations by an authorized administrator of AFIT Scholar. For more information, please contact [email protected]. DETONATION CONFINEMENT IN A RADIAL ROTATING DETONATION ENGINE THESIS Kavi Muraleetharan, Second Lieutenant, USAF AFIT-ENY-MS-20-M-273 DEPARTMENT OF THE AIR FORCE AIR UNIVERSITY AIR FORCE INSTITUTE OF TECHNOLOGY Wright-Patterson Air Force Base, Ohio DISTRIBUTION STATEMENT A APPROVED FOR PUBLIC RELEASE; DISTRIBUTION UNLIMITED. The views expressed in this document are those of the author and do not reflect the official policy or position of the United States Air Force, the United States Department of Defense or the United States Government. This material is declared a work of the U.S. Government and is not subject to copyright protection in the United States. AFIT-ENY-MS-20-M-273 DETONATION CONFINEMENT IN A RADIAL ROTATING DETONATION ENGINE THESIS Presented to the Faculty Department of Aeronautics and Astronautics Graduate School of Engineering and Management Air Force Institute of Technology Air University Air Education and Training Command in Partial Fulfillment of the Requirements for the Degree of Master of Science in Aeronautical Engineering Kavi Muraleetharan, B.S. -

Pressure Gain Combustion Advantage in Land-Based Electric Power Generation

JOURNAL OF THE GLOBAL POWER AND PROPULSION SOCIETY journal.gpps.global/jgpps Pressure gain combustion advantage in land-based electric power generation Seyfettin C. Gülen1,* Original article 1 Bechtel Infrastructure & Power Inc., 12011 Sunset Hills Road, 20190 Article history: Reston, USA Accepted: 13 January 2017 Published: 8 December 2017 This paper is the updated version of a paper originally presented at the 1st Global Abstract Power and Propulsion Forum, GPPF 2017, This article evaluates the improvement in gas turbine combined in Zurich, Jan 16-18 2017 cycle power plant efficiency and output via pressure gain combustion (PGC). Ideal and real cycle calculations are provided for a rigorous assessment of PGC variants (e.g., detonation and deflagration) in a realistic power plant framework with advanced *Correspondence: heavy-duty industrial gas turbines. It is shown that PGC is the SCG: [email protected] single-most potent knob available to the designers for a quan- tum leap in combined cycle performance. Peer review: Single blind Introduction Copyright: © 2017 Gülen. c This is an open access Gas turbine combined cycle (GTCC) power plant is the most article distributed under the Creative efficient and least-polluting fossil fuel-based electric power ‑ Commons Attribution License (CC BY 4.0), generation technology. Largely driven by turbine inlet tem- which permits unrestricted use, distribution, perature (TIT) and pressure ratio, the Brayton cycle based and reproduction in any medium, provided “J class” heavy-duty industrial gas turbines with more than the original work is properly cited and its ffi authors credited. 40% net thermal e ciency have been the foundation of combined cycle power plants with field-proven 60+% net Keywords: thermal efficiency. -

An Overview of Propulsion Systems for Flying Vehicles

FOI-R--1563--SE June 2005 ISSN 1650-1942 Technical report Anders Hasselrot, Björn Montgomerie An Overview of Propulsion Systems for Flying Vehicles Source: Kanda and Kudo (2002) Systems Technology SE-172 90 STOCKHOLM SWEDISH DEFENCE RESEARCH AGENCY FOI-R--1563--SE Systems Technology June 2005 SE-172 90 Stockholm ISSN 1650-1942 Technical report Anders Hasselrot, Björn Montgomerie An Overview of Propulsion Systems for Flying Vehicles Issuing organization Report number, ISRN Report type FOI – Swedish Defence Research Agency FOI-R--1563--SE Technical report Systems Technology Research area code SE-172 90 Stockholm 7. Vehicles Month year Project no. June 2005 E83 0058 Customers code 5. Contracted Research Sub area code 73 Aeronautical Research Author/s (editor/s) Project manager Anders Hasselrot Fredrik Haglind Björn Montgomerie Approved by Monica Dahlén Sponsoring agency FMV Scientifically and technically responsible Anders Hasselrot, Björn Montgomerie Report title An Overview of Propulsion Systems for Flying Vehicles Abstract This report presents an overview of propulsion systems for flying vehicles, based on literature studies on current and future technologies. This effort is motivated by the need of this kind of information for the studies of vehicle concepts, being pursued in order to evaluate their performance merits. General information on inlets and outlets are also presented, as these influence the geometry and performance of the vehicles. The overview of inlet types is given with respect to the requirements at various Mach number regimes that govern the design. The stealth aspects are also viewed. In the report the available propulsion principles are presented category-wise, where most are based on combustion according to the Brayton cycle (heat addition under constant-pressure) and the other are based on combustion according to the Humphrey cycle (heat addition under constant-volume).