Technical Description of the Mechanical Pencil

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Pencil Eraser (Edited from Wikipedia)

Pencil Eraser (Edited from Wikipedia) SUMMARY An eraser, (also called a rubber outside America, from the material first used) is an article of stationery that is used for removing writing from paper. Erasers have a rubbery consistency and come in a variety of shapes, sizes and colors. Some pencils have an eraser on one end. Less expensive erasers are made from synthetic rubber and synthetic soy-based gum, but more expensive or specialized erasers are vinyl, plastic, or gum-like materials. Erasers were initially made for pencil markings, but more abrasive ink erasers were later introduced. The term is also used for things that remove writing from chalkboards and whiteboards. HISTORY Before rubber erasers, tablets of wax were used to erase lead or charcoal marks from paper. Bits of rough stone such as sandstone or pumice were used to remove small errors from parchment or papyrus documents written in ink. Crustless bread was used as an eraser in the past; a Meiji-era (1868-1912) Tokyo student said: "Bread erasers were used in place of rubber erasers, and so they would give them to us with no restriction on amount. So we thought nothing of taking these and eating a firm part to at least slightly satisfy our hunger." In 1770 English engineer Edward Nairne is reported to have developed the first widely marketed rubber eraser, for an inventions competition. Until that time the material was known as gum elastic or by its Native American name (via French) caoutchouc. Nairne sold natural rubber erasers for the high price of three shillings per half-inch cube. -

CL4500 - Installation Instructions

Home (/) > Knowledge Base - Home (/knowledgebase/) > KA-01048 Print CL4500 - Installation Instructions Views: 169 Box Contents Check the contents of the box are correct according to the model 4510 4520 1 Front Plate 2 Back Plate 3 Lever Handles 4 Gaskets 5 Sprung Spindle (x1) 6 Spring Spindle (x3) 15/26/60mm (⁄”/ ⁄”/ ⁄”) 7 1.5vAA Batteries (x4) 8 Mortice Latch, Strike and 4 screws 9 Fixing Bolts x 3 incl. spare 10Latch Support Post 11Allen Keys 12Euro profile cylinder escutcheons (x2) 13Double euro profile cylinder & 3 keys 14Cable Connections for REM1 and REM2 15Front Plate Cylinder Keys 16Front Plate Cylinder Cover 17Classroom Function Tailpiece 18Mortice Lock This box should also contain the installation template and getting started guide. Tools Required Power Drill Drill bits CL4510 10mm (⁄”) & 25mm (1”) Drill bits CL4520 10mm (⁄”), 12mm (⁄”), 16mm (⁄”) & 20mm (⁄”) Hammer / mallet Philips screwdriver Chisel 25mm (1") Stanley knife Adhesive tape, pencil, bradawl, tape measure Pliers and hacksaw for cutting bolts Operations Check You should familiarise yourself with the operation of the lock and check that all the parts work properly. Remove the battery cover from the back plate and install the 4 x AA cells supplied. Connect the cables from the front plate and back plate. A BEEP should be heard when you do this. If no BEEP is heard then check that the batteries are correctly installed. Place the long spindle in the front plate socket and using finger grip only, test that the spindle is easily moved 80° in both directions. Leave socket in the centred position. Enter the factory Master Code #12345678. -

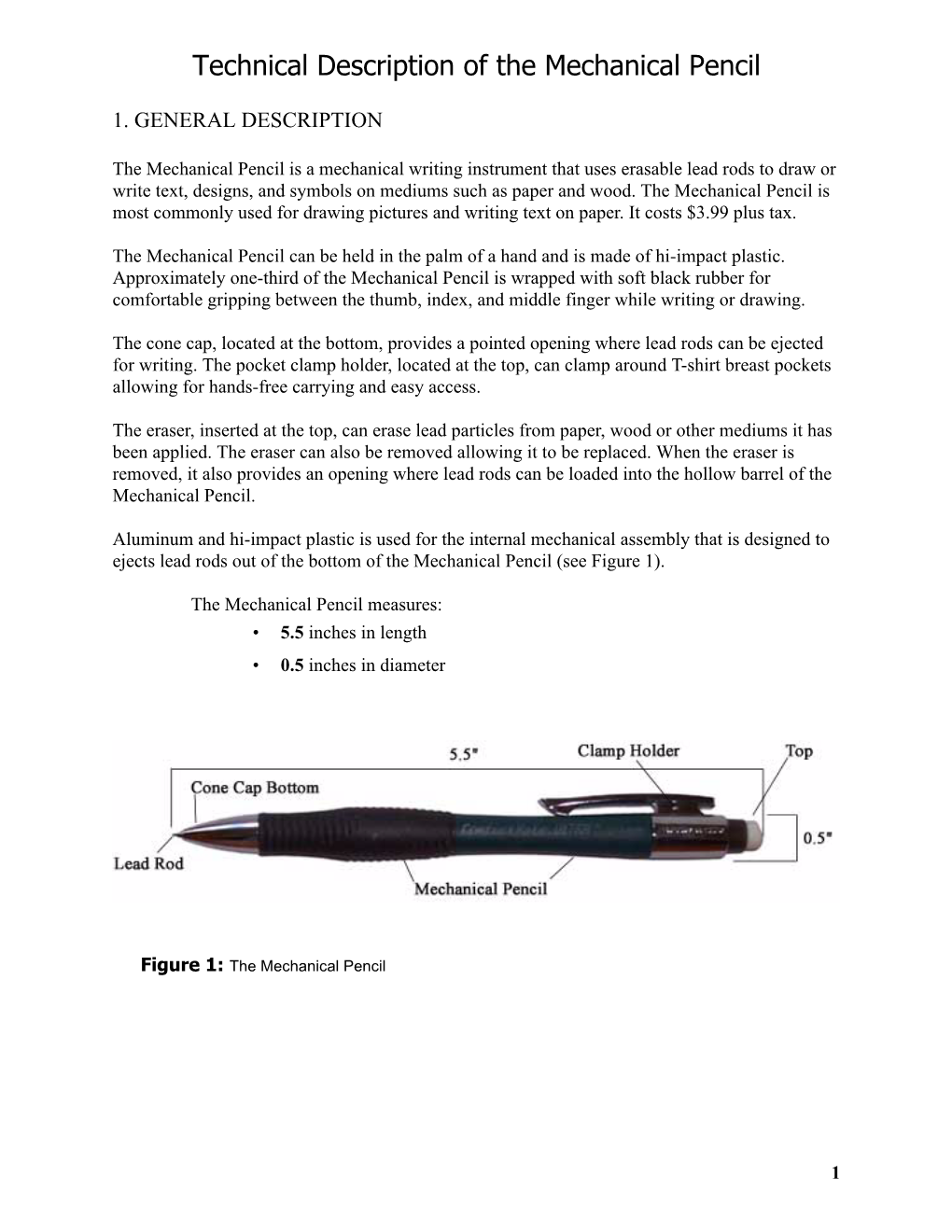

Technical Description Mechanical Pencil Portfolio

The Mechanical Pencil A Technical Description The mechanical pencil is a reusable wri�ng instrument that uses a lead-advance mechanism to extend rods of graphite lead forward. The mechanical pencil is most commonly used for drawing pictures, designs or symbols, and wri�ng text on paper. Tombow Pencil Co. is recognized for high-quality mechanical pencils, and mul�farious erasers. This document uses the Tombow Mono Graph pencil (as a model) to describe the features and components of a mechanical pencil. Features The mechanical pencil is a precision wri�ng instrument more commonly used for drawing than wooden pencils and uses either dra�ing lead or thin leads. Graphic art, technical drawing, and wri�ng professionals use the mechanical pencil to create a line of constant thickness. (see fig. 1) • Life�me reusable holder • Individual replacemtn of graphite lead rods • Pencil never decreases in size or need to be sharpened • Rubber gripping prevents callus buildup under the middle finger joint The mechanical pencil combines the features of a wooden pencil and a ballpoint pen. It can be held in the palm of a hand and is made of hi-impact plas�c or metal. Approximately one-third of the mechanical pencil is wrapped with so� black rubber for gripping between the thumb, index, and middle finger while wri�ng or drawing. The clamp holder (or clip), located at the top, can slide into a T-shirt breast pocket allowing for hands-free carrying and easy access. Types There are three basic types of mechanisms used to extend the graphite lead in the mechanical pencil. -

15. Pneumatic Tools

PNEUMATIC TOOLS Innovation is our mission! GD_KP_$KT-K14-$KP-DRUCKLUFT_#SALL_#APR_#V1.indb 484 14.04.2014 14:35:48 1 PAGE 2 REVERSIBLE RATCHET 488 3 DIE & ANGLE DRILLING MACHINES 489 4 SPOT WELD DRILLING MACHINES 490 PIN & DIE GRINDERS 490 - 491 5 ANGLE DIE GRINDER 491 - 492 6 BURNISHER 492 7 GRINDING MACHINES 493 BELT SANDER 493 8 ROUGH GRINDERS 494 9 RANDOM ORBIT SANDERS 494 10 MULTIGRINDER 495 ERASER 495 11 CHISEL HAMMER 495 - 496 12 NEEDLE SCALER 496 13 NIBBLERS 496 SAWING 497 14 LONG-DISC CUTTER 497 - 498 15 METAL SHEARS 498 16 IMPACT WRENCHES 498 - 500 IMPACT WRENCH SETS 500 17 RIVETING TOOLS PISTOL 501 18 OSCILLATING CUTTER 501 19 VIBRO EXTRACTOR 501 AXLE BOOTS ASSEMBLY DEVICES 502 20 OILS & GREASES 502 21 GREASE GUN 502 22 WHEEL FILLING GAUGE 502 - 503 SPRAY GUNS 503 23 AIR BLOW OUT TOOLS 503 - 504 24 VACUUMS 504 25 COMPRESSED AIR HOSE 504 AIR SERVICE UNIT 505 26 PNEUMATIC ADAPTERS & COUPLINGS 505 - 506 27 i GD_KP_$KT-K14-$KP-DRUCKLUFT_#SALL_#APR_#V1.indb 485 14.04.2014 14:35:48 PNEUMATIC TOOLS Advantages Extremely versatile Extremely strong • For hard to reach places • Particularly low air consumption • Particularly low air consumption • Low vibration • Low vibration • Cold insulated handle • Long service life • Long service life • Easy operation • Easy operation • Supplied incl. coupling connector • Supplied incl. coupling connector Composition Cold insolation Adjusting screw for air supply handle adjusts speed and performance Angular transmission with lubrication nipple Compressed air connection with rotating exhaust Collet -

Calligraphy Tools Visual Reference Notes Supplies Ll Resources

CALLIGRAPHY TOOLS VISUAL REFERENCE NOTES SUPPLIES LL RESOURCES It’s technically hand lettering because you’re drawing the letters! Learn about the Monoline Pen Sample Pack Faux Real Calligraphy (free online course) difference: Hand Lettering vs. Calligraphy (video) How to Hold Brush Pens (video) Our Custom Brush Pen Use brush pens for brush Collection Brush Pen Warmup Worksheet (PDF) calligraphy, other types of brush script, or hand lettering. Beginner Brush Pen Brush Pen Comparison (notes and videos) Supplies (pens and paper) Brush Lettering Bootcamp (online course) Dip pens are dipped into real ink. Pointed Pen Supply Guide A pointed nib comes to a sharp point at the tip. Copperplate Guide Sheet Intro to Pointed Pen Workshop (video) (55° slant) Styles created with pointed pen: Calligraphy On Point (online course) - Copperplate (seen in image) Spencerian Guide Sheet - Spencerian (52° slant) Broad edge nibs are flat, and used Fun fact: This was the first style we in these calligraphy styles: learned! But we don’t teach it. Check Broad Edge Supply Guide by - Italic out: Jake Rainis - Blackletter Intro to Uncial Calligraphy (video) BROAD EDGE NIB. - Uncial Blackletter Intro (video) You’ll need an iPad, the Free iPad Facebook group Create the look of any lettering Procreate App, and tool with digital brushes (brush preferably an Apple Pencil. Intro to iPad Lettering Workshop (video) pen, paint, chalk, pencil, etc.) and use amazing effects. Here’s the exact iPad and Procreate Lettering Projects (online Apple Pencil we use course) COPYRIGHT LOVELEIGH LOOPS 2019 | LOVELEIGHLOOPS.COM 1 LETTERING STYLES (use any calligraphy tool from p.1) VISUAL REFERENCE NOTES LL RESOURCES How to do Bounce Lettering (video) A popular style of calligraphy that looks flowy and effortless. -

Stefa O. Öl Blau (Englisch)

Date of Printing: 02/07/2009 No. 15012e edition 03 from 15.06.2009 page 1 of 5 Safety Data Sheet according to 1907/2006/EC Plastic Eraser Pelikan Vertriebsgesellschaft mbH & Co. KG Squeezy, Black & White _______________________________________________________________________________ 1. Identification of the substance/preparation and the company Trade name: Plastic Eraser Squeezy, Black & White Application of the product: Eraser for pencil Manufacturer/Supplier: Pelikan Vertriebsgesellschaft mbH & Co. KG Street/PO. Box: Postfach 11 07 55 Nat. Code/Location: D-30102 Hannover Tel.: +49-(0)-511-6969-0 Further information obtainable from: - Chemisches Labor Tel.: +49-(0)-5171-299-0 Fax: +49-(0)-5171-299-249 - Institut für Umwelttechnik Dr. Kühnemann und Partner GmbH Tel.: +49-(0)-511-12194-0 Fax: +49-(0)-511-12194-23 E-Mail: [email protected] Information in case of emergency: Tel.:+49-(0)-511-12194-0 (Monday – Friday 9 am till 5 pm) ______________________________________________________________________________________ 2. Hazards identification Hazard description: No dangerous preparation according to 1999/45/EC No hazards if used for intended purpose Additional Information concerning particular hazards for human and environment: Ingestion of eraser may cause asphyxia and inner injuries in the digestive system due to hardening May cause sensitisation by skin contact ______________________________________________________________________________________ 3. Composition / information on ingredients Chemical characterization: Preparation of calcium carbonate, polyvinyl chloride, phthalates (DINP) and pigments Dangerous components according to 1999/45/EC: Classification CAS -No. EG-No. Name % Symbol R-phrases ( Pkt. 16) 120-78-5 204-424-9 DIBENZOTHIAZIL DISULFIDE N, Xi 31, 50/53, 43 < 0,2 ______________________________________________________________________________________ 4. First aid measures After inhalation: n.a. -

How to Make 'Condor Tails'

How to Make ‘Condor Tails’ BY JAMEEL ABRAHAM An ingenious way to combine routers, a band saw and hand tools for big dovetails. know what you’re thinking: “Another opinion on how to cut I dovetails.” I hear you. But this one’s different. I promise. No back and forth over pins or tails first. No Rob Cosman vs. Frank Klausz. Well, actually a little Klausz. When I built my first serious workbench in the 1990s I practically memorized Scott Landis’ “The Work- bench Book” (Taunton) and like many woodworkers I was attracted to Frank Klausz’s beautiful bench, especially the large, crisp dovetails that joined the parts of the tail vise. Klausz told us what tools he used to cut the joints, but didn’t elaborate much on technique. I suppose with a lifetime of skill at your command, you just pick up the tools and the joint emerges. I wanted the crisp look of Klausz’s joints without waiting 20 years to develop the skill. After build- ing several large benches over the past few years, this technique emerged. Best of Both Worlds I’m a big believer in making dovetail Enormous perfection. Cutting large-scale dovetails, such as for this workbench, can be a challenge. joints that fit right off the saw. That’s a This technique makes it straightforward. skill that’s easy to learn with some prac- tice. But not so with the beefy members of a workbench, or large-scale furni- railing just to get the thing vertical so where they excel. This is truly blended ture. -

2021 Premium Business Gifts Advertise with Lamy

2021 Premium Business Gifts Advertise with Lamy Fountain pens Ballpoint pens Rollerball pens Mechanical pencils Multisystem pens Notebooks Set offers Lamy’s wide range of promotional articles is available solely to commercial enterprises, businesses and Contents freelancers. Private sale is not possible. Sending a lasting message ................... 3 LAMY AL-star EMR ......................... 44 Taking responsibility – shaping the future ....... 4 LAMY twin pen ............................. 46 From Heidelberg into the world ............... 8 LAMY tri pen ............................... 48 LAMY safari . 10 Notebook assortment from Lamy ............. 50 LAMY AL-star .............................. 12 Sets ....................................... 54 LAMY xevo ................................ 14 Cases ..................................... 55 LAMY noto ................................ 16 LAMY ideos ............................... 56 LAMY logo ................................ 18 LAMY studio ............................... 58 LAMY tipo ................................. 28 LAMY scala. 60 LAMY econ ................................ 30 LAMY 2000 ................................ 62 LAMY pur .................................. 32 LAMY 2000 M ............................. 64 LAMY swift ................................ 34 LAMY dialog cc ............................ 66 LAMY cp1 ................................. 36 LAMY dialog .............................. 68 LAMY pico ................................ 38 LAMY imporium ............................ 70 LAMY -

Pencil Size and Their Impact on Penmanship Legibility

5 Pencil Size and their Impact on Penmanship Legibility Becky Sinclair Texas A&M University-Commerce Susan Szabo Texas A&M University-Commerce Abstract Legible penmanship is important. However, young students have difficulty producing legible handwriting (Marr, Windsor, & Cermak, 2001). As legible handwriting is a benefit for both the students and the teachers in the classroom setting, this study examined if pencil size had an impact on preschool and kindergarten students’ handwriting. The students used four different pencil sizes over a two-week period. The data showed pencil size did not impact handwriting legibility but there was a pencil size preference difference between preschool and kindergarten students, which may impact the yearly student supply lists. This action research study began after several second-year teachers attended a mandated professional development workshop on the importance of teaching handwriting. During the workshop they learned that writing promotes thinking, builds communication skills, enhances learning and reading, and builds fine motor skills. In addition, they examined the writing Texas Essential Knowledge and Skills (TEKS) and found that kindergarten students should be able to form upper and lower-case letters using the basic conventions of print (left to right and top-to- bottom). The teachers were curious to know if pencil size had an impacted preschoolers and kindergarten students’ handwriting legibility. However, they were not interested in writing an article, so they gave us the data to do so. Theoretical Framework There are several theories that can be connected to penmanship: 1) connection theory; and 2) motor learning theory. First, the connection theory looks at the idea that handwriting legibility is related to fluency of writing and reading skills (Rose, 2004). -

Now You See Me… a History of Erasing

Now You See Me, Now You Don’t A History of Erasing or as long as there has been writing there have been errors and the need to erase them. Logically, the erasure of writing can be done in one of three ways: namely the removal of the writing from the page, the hiding of the Fwords on the page, and lastly the covering of the words on the page. The first writing implements and surfaces were made for mistakes, as the wet clay used in tablets could simply be smoothed over and new letters formed with the stylus. It is likely that the complexity of the glyphs used in the first written languages seen in Egypt and Sumer (now in southern Iraq) resulted in many mistakes being made as each glyph would be formed individually. It is estimated that Sumerian cuneiform had approximately 1000 different glyphs in its infancy with its instruction being the main focus of lessons in the very first schools that began in Sumer. Cuneiform script The Sumerians established tablet houses that were located in the courtyard of the city temple and its pupils were boys from the wealthiest families. These educational establishments were so named because of the clay tablets upon which lessons were carefully copied from one half to the other by pupils. The learning and recitation of these texts was the primary focus of the school day and upon completion of their education, pupils were employed as scribes. Editing on Papyrus The transition from clay tablets to papyrus is significant not only in terms of its transportability, but also its cost and availability, both of which had implications for the writer’s ability to make and correct errors. -

Installation Guide Detailed Diagram of CT-670/ CS-1670 Components

CT-670/ CS-1670 Centec Frameless sliding Door Installation Guide Detailed diagram of CT-670/ CS-1670 components 7 4 8 16 4 10 12 8 5 5 7 15 11 9 9 # Part Name Qty 1 Door track 1 2 Wall jambs 2 3 Track guide 1 4 Rubber bumpers 6 5 Glass door 2 6 2 Header 1 3 7 Plastic wall anchors 6 8 1-1/4” wall mount screws 6 9 Tower bar kit 2 10 Header 1 11 Sidelight glass panel 1 1 4 12 Transition channel upright 1 13 Threshold 1 2 14 Thick vinyl shims 2 15 Wall channel upright 1 14 13 16 #8 x 1/4” panhead screws 3 Tools required Tape Measure Level Hacksaw Safety glasses Drill bits (2) (#32 metal bit, Masking tape Scissors 3/16” carbide masonry bit) Glazing block/ Rubber mallet Piece of carpet/ padding Drill Flat head and Pencil/Marker Caulking gun piece of wood Phillips head (2”x 4”) Screwdriver Windex WARNINGS **Before starting, please read instructions carefully and thoroughly; then proceed step by step. **Please wear safety glasses and safety gloves whenever drilling or cutting tile or handling metal/glass parts. **When drilling through tile, carefully break through glazed surface only with sharp tool and then drill slowly. **Wall uprights must be installed level and plumb. Do not follow grout lines. **To insure complete customer satisfaction Century Bathworks recommends installation by a professional. **Risk of injury or product damage. Two people should perform this installation. **Do not cut the top and bottom track the same length for this installation. -

Study Guide: Hand Tools

STUDY GUIDE: HAND TOOLS Learning Objectives: • The features and benefits of the products you sell. • How to answer your customers’ product-related questions. • How to help your customer choose the right products. • How to increase transaction sizes by learning more about add-on sales and upselling techniques. Chapter 1: Fastening Tools Module 1: Hammers Product Knowledge: Claw Hammer • Use for general carpentry, household chores and nail pulling. • Curved claw offers leverage in removing nails. • Use only with non-hardened, common or finishing nails. • You can choose 16 or 20 oz. weights for general carpentry. For fine cabinetry or light- duty driving, choose 7, 10 and 13 oz. nail weights. • Available with a smooth face for finishing jobs, or a waffled face for more control when hammering large nails into lumber. Framing (Rip) Hammer • Use for ripping apart wooden components and demolition work. • Use only with non-hardened, common or finishing nails. • Choose weights from 20 to 32 oz. for framing and ripping. • Available with milled or waffled faces to grip the nail head and reduce the effect of glancing blows and flying nails. Ball Peen (Ball Pein) Hammer • Use with cold chisels for riveting, center punching and forming unhardened metal work. • Striking face diameter should be about 3/8” larger than the diameter of the head of the object being struck. • Popular sizes are 12 and 16 oz. • Variations include a cross-peen hammer (with a horizontal wedge-shaped face) and a straight-peen hammer (with a vertical wedge-shaped face). Sledgehammer • Use for jobs that require great force, such as breaking up concrete or driving heavy spikes.