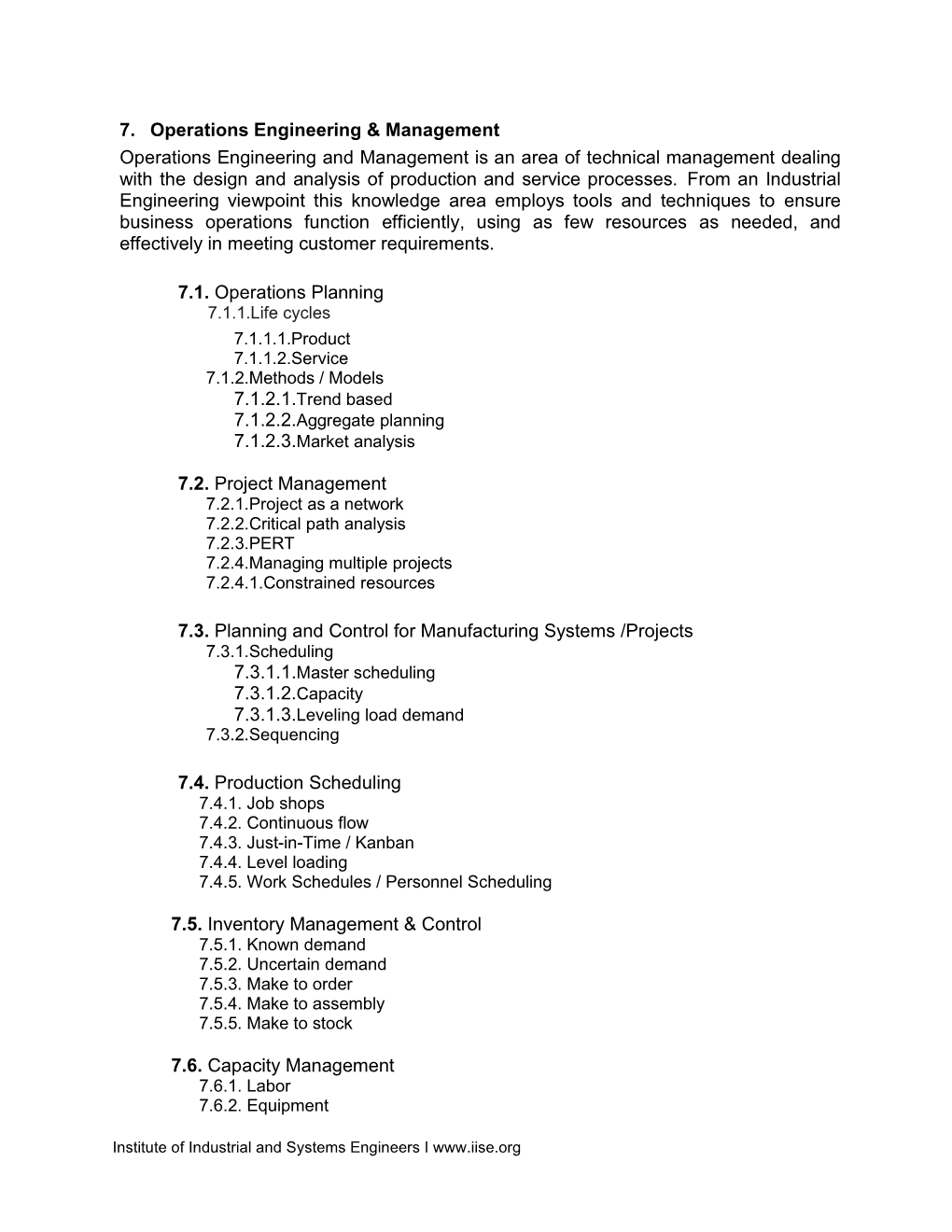

7. Operations Engineering & Management

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Permits-To-Work in the Process Industries

SYMPOSIUM SERIES NO. 151 # 2006 IChemE PERMITS-TO-WORK IN THE PROCESS INDUSTRIES John Gould Environmental Resources Management, Suite 8.01, 8 Exchange Quay, Manchester M5 3EJ; [email protected] The paper presents the collective results from a number of Safety Management System audits. The audit protocol is based on the Health and Safety Executive pub- lication ‘Successful health and safety management’ and takes into account formal (written) and informal procedures as well as their implementation. Focused on permit-to-work systems, these have shown a number of common failings. The most common failure in implementing a permit-to-work system is the issue of too many permits. However, the audit protocol considers the whole risk control system. The failure to ‘close’ the management loop with an effective regular review process is the largest obstacle to an effective permit system. INTRODUCTION ‘Permits save lives – give them proper attention’. This is a startling statement made by the Health and Safety Executive (HSE) in its free leaflet IND(G) 98 (Rev 3) PTW systems. The leaflet goes on to state that two thirds of all accidents in the chemical industry are main- tenance related, with the permit-to-work (PTW) failures being the largest single cause. Given these facts, it comes as no surprise that PTW systems are a key part in the provision of a safe working environment. Over the past four years Environmental Resources Management (ERM) has been auditing PTW systems as part of its key risk control systems audits. Numerous systems have been evaluated from a wide rage of industries, covering personal care products man- ufacturing to refinery operations. -

Organizational Culture and Knowledge Management Success at Project and Organizational Levels in Contracting Firms

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by PolyU Institutional Repository This is the Pre-Published Version. Organizational Culture and Knowledge Management Success at Project and Organizational Levels in Contracting Firms Patrick S.W. Fong1 and Cecilia W.C. Kwok2 ABSTRACT This research focuses on contracting firms within the construction sector. It characterizes and evaluates the composition of organizational culture using four culture types (Clan, Adhocracy, Market, and Hierarchy), the strategic approach for knowledge flow, and the success of KM systems at different hierarchical levels of contracting organizations (project and parent organization level). Responses from managers of local or overseas contracting firms operating in Hong Kong were collected using a carefully constructed questionnaire survey that was distributed through electronic mail. The organizational value is analyzed in terms of the four cultural models. Clan culture is found to be the most popular at both project and organization levels, which means that the culture of contracting firms very much depends on honest communication, respect for people, trust, and cohesive relationships. On the other hand, Hierarchy 1 Associate Professor, Department of Building & Real Estate, The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong (corresponding author). T: +(852) 2766 5801 F: +(852) 2764 5131 E-mail: [email protected] 2 Department of Building & Real Estate, The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong. 1 culture, which focuses on stability and continuity, and analysis and control, seems to be the least favored at both levels. Another significant finding was that the two main KM strategies for knowledge flow, Codification and Personalization, were employed at both project and organization levels in equal proportion. -

Collaborative Engineering for Research and Development

NASA/TM—2004-212965 Collaborative Engineering for Research and Development José M. Davis Glenn Research Center, Cleveland, Ohio L. Ken Keys and Injazz J. Chen Cleveland State University, Cleveland, Ohio February 2004 The NASA STI Program Office . in Profile Since its founding, NASA has been dedicated to ∑ CONFERENCE PUBLICATION. Collected the advancement of aeronautics and space papers from scientific and technical science. The NASA Scientific and Technical conferences, symposia, seminars, or other Information (STI) Program Office plays a key part meetings sponsored or cosponsored by in helping NASA maintain this important role. NASA. The NASA STI Program Office is operated by ∑ SPECIAL PUBLICATION. Scientific, Langley Research Center, the Lead Center for technical, or historical information from NASA’s scientific and technical information. The NASA programs, projects, and missions, NASA STI Program Office provides access to the often concerned with subjects having NASA STI Database, the largest collection of substantial public interest. aeronautical and space science STI in the world. The Program Office is also NASA’s institutional ∑ TECHNICAL TRANSLATION. English- mechanism for disseminating the results of its language translations of foreign scientific research and development activities. These results and technical material pertinent to NASA’s are published by NASA in the NASA STI Report mission. Series, which includes the following report types: Specialized services that complement the STI ∑ TECHNICAL PUBLICATION. Reports of Program Office’s diverse offerings include completed research or a major significant creating custom thesauri, building customized phase of research that present the results of databases, organizing and publishing research NASA programs and include extensive data results . even providing videos. -

Managing Design and Construction Using Systems Engineering for Use with DOE O 413.3A

NOT MEASUREMENT SENSITIVE DOE G 413.3-1 9-23-08 Managing Design and Construction Using Systems Engineering for Use with DOE O 413.3A [This Guide describes suggested nonmandatory approaches for meeting requirements. Guides are not requirements documents and are not construed as requirements in any audit or appraisal for compliance with the parent Policy, Order, Notice, or Manual.] U.S. Department of Energy Washington, D.C. 20585 AVAILABLE ONLINE AT: INITIATED BY: www.directives.doe.gov National Nuclear Security Administration DOE G 413.3-1 i 9-23-08 TABLE OF CONTENTS 1.0 INTRODUCTION ........................................................................................................... 1 1.1. Goal .................................................................................................................................. 1 1.2. Applicability. .................................................................................................................... 2 1.3. What is Systems Engineering? ......................................................................................... 2 1.4. Links with Other Directives ............................................................................................. 2 1.5. Overlapping Systems Engineering and Safety Principles and Practices .......................... 4 1.6. Differences in Terminology ............................................................................................. 5 1.7. How this Guide is Structured .......................................................................................... -

Engineering Management - M.S

Engineering Management - M.S. Leading and managing projects in a technical environment needs qualied MGMT6340 Lean Production and Quality Control professionals who possess a blend of analytical and project management Total Credits 30-33 credits skills combined with an understanding of engineering processes and product * Students without evidence of coursework in programming from at least a bachelor's degree development. level program will need to take this course prior to taking core courses. The online Engineering Management Master of Science degree program ** Students can choose any combination of three courses that they have prerequisites for from is an interdisciplinary program that integrates the elds of engineering, the listing of Data Analytics, Finance, or Operations and Supply Chain Management courses, technology and business. It is designed for engineering and other STEM to earn the MS Engineering Management degree. (Science, Technology, Engineering and Math) related bachelor’s degree recipients as well as professionals in the eld with bachelor’s degrees in business who are seeking to take on leadership and management roles in a technology environment. The program includes core courses in statistical analysis, nance, decision making, leadership and innovation, new product development, and project management principles for the engineering and technology industry. In this program, students gain the theoretical, quantitative and analytical skills and tools they will need to be an effective leader of an engineering management team. The Engineering Management Master of Science degree program emphasizes management and leadership skills specically for the engineering and technology industry. Students use electives to tailor their degree to their interest. Electives can also be chosen to create a focus area in either Data Analytics, Finance or Operations & Supply Chain Management. -

Operational Formality for Department of Energy Nuclear Facilities and Activities

DNFSDrrECII-l~ OPERATIONAL FORMALITY FOR DEPARTMENT OF ENERGY NUCLEAR FACILITIES AND ACTIVITIES Defense Nuclear Facilities Safety Board Technical Report March 1997 OPERATIONAL FORMALITY FOR DEPARTMENT OF ENERGY NUCLEAR FACILITIES AND ACTIVITIES This technical report was prepared for the Defense Nuclear Facilities Safety Board by the following staff members: Steve Krahn Matthew Moury with assistance from: Wayne Andrews Dan Burnfield Don Owen and outside expert John Drain FOREWORD The Board has emphasized that when performing work involving hazardous materials, it is important to plan the work carefully, and to develop the controls and implementing procedures necessary to provide reasonable assurance that the work will be conducted safely. While the exact nature ofthese practices will valY depending on the work being performed, certain operational practices have evolved that have been effective. These operational practices are treated in this report as a composite forming what is termed "formality ofoperations." John T. Conway Chairman III EXECUTIVE SUMMARY Commercial manufacturing organizations ofall sizes have developed policies and practices, termed "formality ofoperations," to be followed by employees to ensure safety in the workplace, establish norms ofperformance, and promote work practices fostering efficiency and uniform product quality. For small companies, these "good engineering (or shop) practices" are often passed on by example and by word ofmouth from journeyman to apprentice. Larger organizations usually codify these concepts in policies, requirements, and procedural documents to achieve desired practices on the shop floor, and such practices become an integral part ofnew employee training. When these policies and procedures are reinforced by all managers, fi'om upper-level management to first-line supervisors, formality ofoperations becomes second nature. -

Engineering Management Graduate Program

More Information ENGINEERING MANAGEMENT STUDENT ADVISER Denise Engebrecht [email protected] Engineering Management (208) 364-6123 Graduate Program INTEGRATING ENGINEERING & BUSINESS INTEGRATING ENGINEERING & BUSINESS www.uidaho.edu/engr/engineeringmanagement Program Why an Engineering Management Program Delivery Advising Outcomes Graduate Degree? Faculty and instructors teach courses at U of I locations in Moscow, Idaho You will work with the student adviser to build a unique study • To expand and reinforce your Falls, and Boise. Courses may be delivered live, online via the web, or produced Bridging the Gap between Engineering and Business plan around a set of core courses existing engineering skill set for online delivery by Engineering Outreach (EO). EO courses are accessible that allows you to meet your Engineering Management is a multidisciplinary field that involves the within 2 hours of production. If you want the flexibility to watch classes at your career objectives. • To thoroughly examine the convenience, this program can meet your needs. roles and responsibilities of an application of engineering methods and technologies with business engineering manager approaches to solve today’s complex and challenging problems. This program bridges the gap between engineering and business by equipping engineers with Engineering Management Degree Good Career • To provide you with a solid the expertise and leadership skills needed to advance their career in today’s Opportunities foundation in engineering Requirements fast-paced world. Students will expand their breadth of knowledge beyond a Engineering managers are #6 on management and business The Engineering Management master’s degree requires 30 credits; a minimum the top 20 list of best paying jobs approaches, tools and practices specific technical field into management and business. -

Strategic Plan for Industrial and Management Systems Engineering

University of Nebraska - Lincoln DigitalCommons@University of Nebraska - Lincoln Industrial and Management Systems Industrial and Management Systems Engineering -- Reports Engineering 8-2008 Strategic Plan For Industrial and Management Systems Engineering Paul Savory University of Nebraska at Lincoln, [email protected] Follow this and additional works at: https://digitalcommons.unl.edu/imsereports Part of the Industrial Engineering Commons Savory, Paul, "Strategic Plan For Industrial and Management Systems Engineering" (2008). Industrial and Management Systems Engineering -- Reports. 2. https://digitalcommons.unl.edu/imsereports/2 This Article is brought to you for free and open access by the Industrial and Management Systems Engineering at DigitalCommons@University of Nebraska - Lincoln. It has been accepted for inclusion in Industrial and Management Systems Engineering -- Reports by an authorized administrator of DigitalCommons@University of Nebraska - Lincoln. STRATEGIC PLAN INDUSTRIAL and MANAGEMENT SYSTEMS ENGINEERING ROLE OF THIS PLAN The role of this strategic plan is to map out a range of department goals, offer objectives for achieving each goal, and list potential strategies for meeting an objective. It also lists performance metrics for measuring progress for each goal. Each year, a subset of goals and objectives will be identified by the IMSE department as a priority for the coming year. Detailed metrics for measuring improvement for the department’s priorities areas will then be defined. DEPARTMENT MISSION The mission of the department is to advance the frontiers of industrial engineering, to educate qualified individuals in the discipline, and to disseminate knowledge both within and beyond the university for applying industrial engineering concepts and principles to technical and societal challenges. -

Collaboration Engineering: Foundations And

CORE Metadata, citation and similar papers at core.ac.uk Provided by AIS Electronic Library (AISeL) Special Issue Collaboration Engineering: Foundations and stems stems y Opportunities: Editorial to the Special Issue on the Journal of the Association of Information Systems Gert-Jan de Vreede Anne P. Massey Center for Collaboration Science Indiana University University of Nebraska at Omaha [email protected] and Delft University of Technology [email protected] Robert O. Briggs Center for Collaboration Science University of Nebraska at Omaha [email protected] Abstract Collaboration is a critical phenomenon in organizational life. Collaboration is necessary yet many organizations struggle to make it work. The field of IS has devoted much effort to understanding how technologies can improve the productivity of collaborative work. Over the past decade, the field of Collaboration Engineering has emerged as a focal point for research on designing and deploying collaboration processes that are recurring in nature and that are executed by practitioners in organizations rather than collaboration professionals. In Collaboration Engineering, researchers do not study a collaboration technology in isolation. Rather, they study collaborative work practices that can be supported on different technological platforms. In this editorial, we discuss the field of Collaboration Engineering in terms of its foundations, its approach to designing and deploying collaboration processes, and its modeling techniques. We conclude with a Collaboration Engineering research agenda for the coming decade. Journal of the Association for Information S Journal of the Association Volume 10, Special Issue, pp. 121-137, March 2009 Volume 10 Special Issue Article 2 Collaboration Engineering: Foundations and Opportunities 1. -

Decision Making in Engineering Management

Decision Making in Engineering Management John Murdoch, University of York Antony Powell, YorkMetrics 24th June 2009 PSM 2010/ Julyyp 08 Workshop Performance Information Enterprise Project Needs Objective Integrated Fact-Based Management Data Analysis Decisions Actions Measurement Application Decision Environment • Capable Information Process • Decision “Freedom” • Viable Measurement Constructs • Decision - Change Implementation • Both Measurement and Risk Data • Performance Tradeoff Decisions • Performance Analysis • Measureable Performance Feedback • Decision Alternatives • Integrated Context - Portfolio Mgt. • Unfettered Communication • Revised Strategies and Objectives Source: PSM Project Decision Makers SUPPLIERS SUPPLIER MANAGERS REGULATORS SUPPLY CHAIN MANAGEMENT ACQUISITION CERTIFICATION MANAGER AND COMPLIANCE PROJECT DESIGN MANAGER AUTHORITY COMPLIANCE MANAGEMENT CHIEF ENGINEER FUNDERS ENTERPRISE PROJECT MANAGERS DECISION CONFIG MAKING CONTROL COMMERCIAL ENTERPRISE MANAGERS ASSURANCE MANAGEMENT ENGINEERING MANAGER SYSTEMS ENGINEERS SPECIALTY CUSTOMERS ENGINEERS SOFTWARE COMPONENT ENGINEERS ENGINEERS 309 00 ENGINEERING END USERS 0102 MANAGEMENT Source: SSEI Motivation and Objectives ■ Complex defense projects often perform poorly from external perspectives ■ Engineering perspective: strive to develop and support products that are fit for purpose and that use resources as efficiently as possible ■ Hypothesis: better su pport and promotion of the en gineerin g view, integrated through supply chains and through the lifecycle, will -

The Effect of the Harmony Between Organizational Culture and Values on Job Satisfaction

International Business Research; Vol. 10, No. 5; 2017 ISSN 1913-9004 E-ISSN 1913-9012 Published by Canadian Center of Science and Education The Effect of the Harmony between Organizational Culture and Values on Job Satisfaction Erkan Taşkıran1, Canan Çetin2, Ata Özdemirci2, Baki Aksu 3, Meri İstoriti4 1School of Tourism Administration and Hotel Management, Düzce University, Düzce, Turkey 2Faculty of Business Administration, Marmara University, Istanbul, Turkey 3Vocational School of Logistics, Beykoz University, Istanbul, Turkey 4Liv Hospital, Istanbul, Turkey Correspondence: Erkan Taşkıran, School of Tourism Administration and Hotel Management, Düzce University, Osmaniye Mahallesi, Atatürk Caddesi, No.221 Akçakoca, 81650, Düzce, Turkey. Received: March 13, 2017 Accepted: April 19, 2017 Online Published: April 24, 2017 doi:10.5539/ibr.v10n5p133 URL: https://doi.org/10.5539/ibr.v10n5p133 Abstract In this study, the effect of the harmony between organizational culture and values on job satisfaction is examined. Hierarchical regression analysis was applied to the data, which was obtained from the study conducted on 181 employees working in a private hospital in Istanbul. The result of the analysis shows that value-culture variation in which employees will have the highest job satisfaction is the traditionalist/conservative values-clan culture. The second most successful value-culture variation on job satisfaction is the impulsive/hedonistic values-adhocracy culture. In other words, it is predicted that job satisfaction will be high when an employee with traditionalist/conservative values works in an organization where clan culture is important, and an employee with impulsive/hedonistic values works in an organization where adhocracy culture is important. The most negative impacts on job satisfaction are impulsive/hedonistic values-clan culture and precautionary values-market culture. -

Collaboration Engineering: Foundations and Opportunities

Special Issue Collaboration Engineering: Foundations and stems stems y Opportunities: Editorial to the Special Issue on the Journal of the Association of Information Systems Gert-Jan de Vreede Anne P. Massey Center for Collaboration Science Indiana University University of Nebraska at Omaha [email protected] and Delft University of Technology [email protected] Robert O. Briggs Center for Collaboration Science University of Nebraska at Omaha [email protected] Abstract Collaboration is a critical phenomenon in organizational life. Collaboration is necessary yet many organizations struggle to make it work. The field of IS has devoted much effort to understanding how technologies can improve the productivity of collaborative work. Over the past decade, the field of Collaboration Engineering has emerged as a focal point for research on designing and deploying collaboration processes that are recurring in nature and that are executed by practitioners in organizations rather than collaboration professionals. In Collaboration Engineering, researchers do not study a collaboration technology in isolation. Rather, they study collaborative work practices that can be supported on different technological platforms. In this editorial, we discuss the field of Collaboration Engineering in terms of its foundations, its approach to designing and deploying collaboration processes, and its modeling techniques. We conclude with a Collaboration Engineering research agenda for the coming decade. Journal of the Association for Information S Journal of the Association Volume 10, Special Issue, pp. 121-137, March 2009 Volume 10 Special Issue Article 2 Collaboration Engineering: Foundations and Opportunities 1. Introduction In the knowledge economy, organizations frequently face problems of such complexity that no single individual has sufficient expertise, influence, or resources to solve the problem alone.