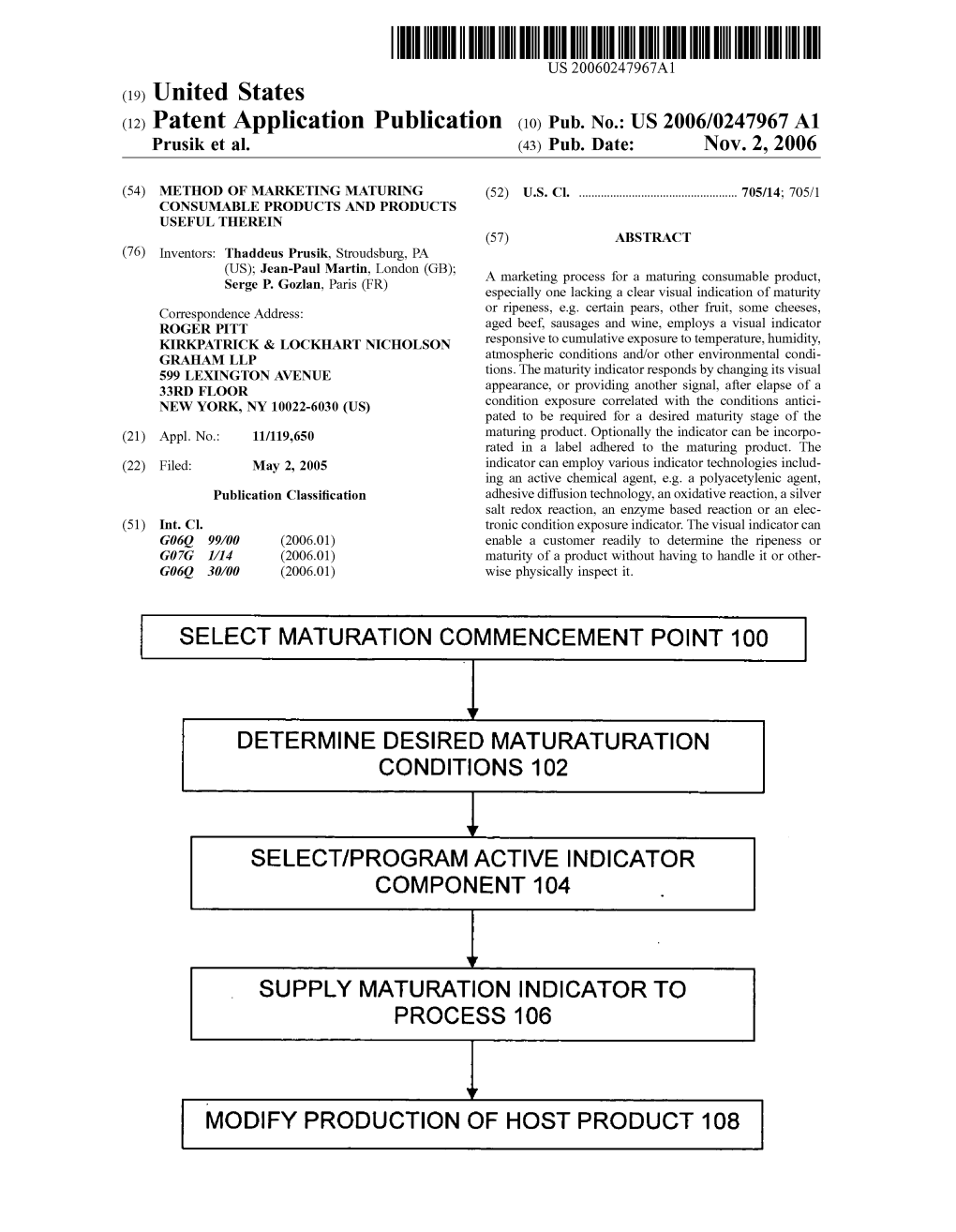

MODIFY PRODUCTION of HOST PRODUCT 108 Patent Application Publication Nov

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Chemistry of Beef Flavor - Executive Summary Prepared for the National Cattlemen’S Beef Association M

® Funded by the Beef Checkoff The Chemistry of Beef Flavor - Executive Summary Prepared for the National Cattlemen’s Beef Association M. Susan Brewer, Ph.D., Department of Food Science and Human Nutrition, University of Illinois, December, 2006 The beef industry is continually working to satisfy consumer expectations for dependable, high quality beef products at a reasonable cost to producer, packer, processor and retailer. Flavor and tenderness are the sensory traits that affect consumer acceptance of beef the most; therefore, it is vital that both traditional and new beef systems assure consistently tender products with acceptable flavor. — Kerth et al., 1995 between some of the more common volatiles in beef and “Flavor” results from the combination their respective flavors is shown in Table 1. Beef flavor, which of basic tastes (sweet, sour, bitter, salt and umami) derived develops when heat is applied, depends on the amounts from water-soluble compounds and odor derived from a and proportions of precursor compounds present. Meat is myriad of substances present in the food product from the composed of water, proteins, lipids, carbohydrates, minerals onset or derived via various reactions. The flavors and aromas and vitamins. Of these, proteins, lipids and carbohydrates associated with beef are generally those that develop during play primary roles in flavor development because they include heating. When water-soluble substances derived from precursor numerous compounds which are capable of developing into compounds dissolve in the saliva, they bind to the taste buds important flavor precursors when heated (Spanier and Miller, and stimulate a response that is perceived in the brain. -

Beef Tenderness Find out Why Black Canyon

WHAT MAKES BEEF TENDER? Quality beef starts with high-quality All cattle are grass-fed but research cattle, time and good management. shows that grain-finished cattle produce Black Angus is a breed known for its more marbling (or more flecks of fat superior flavor and tenderness. within the lean), which means more flavorful, tender beef. Black Canyon Angus Beef is a USDA certified program with strict specifications. LOOK FOR MARBLING BEEF AGING All beef is inspected but Black Canyon is Beef aging (both wet and dry) after also graded to identify and sort beef by harvesting increases tenderness. The palatability – tenderness, juiciness and aging process allows natural enzymes flavor of cooked beef. in beef to break down specific USDA Choice is more tender and proteins. Not only is the meat flavorful than USDA Select. Marbling, naturally tenderized, but flavor is the flecks of fat within the lean, is directly improved. Aging is done under strict related to the flavor and juiciness of controls and is not something to be cooked beef. done in a home kitchen. COOKING METHOD COUNTS Match the correct cooking method to the beef cut. Tender beef cuts can be cooked using dry-heat methods – grill, broil, roast, skillet, stir-fry. Less tender beef cuts can be cooked using moist heat methods – braise, pot roast, stew, slow-cooker. DONENESS IS IMPORTANT Overcooking can undo all of the factors. • Use a meat thermometer for perfectly cooked tender steaks and roasts – KNOW THE LOCATION 145°F medium rare, 160°F medium. Large roasts need to be pulled 5 to 10 degrees below because the temperature rises during the standing time. -

Final Report Safety Implications of the Manufacture of Minced Meat from Aged Meat FRPERC REF NO

Final report Safety implications of the manufacture of minced meat from aged meat FRPERC REF NO. 2006141 Report Finalised: 31.12.2006 By Christian James, Raquel Machado Pinho and Stephen J. James Produced by: Food Refrigeration and Process Engineering Research Centre (FRPERC) University of Bristol Churchill Building, Langford, North Somerset, BS40 5DU, UK Tel: ++44 (0)117 928 9239 Fax: ++44 (0)117 928 9314 e-mail: [email protected] Web: http://www.frperc.bris.ac.uk 1. Summary The aim of this review was to critically look at the available scientific evidence that would support the newly imposed hygiene legislation regarding the regulatory limit on the age restriction of meat at time of mincing. The following new requirements apply to the production of minced meat and meat preparations. (a) Unless the competent authority authorises boning immediately before mincing, frozen or deep-frozen meat used for the preparation of minced meat or meat preparations must be boned before freezing. It may be stored only for a limited period. (b) When prepared from chilled meat, minced meat must be prepared: (i) in the case of poultry, within no more than three days of their slaughter; (ii) in the case of animal other than poultry, within no more than six days of their slaughter; or within no more than 15 days from the slaughter of the animals in the case of boned, vacuum-packed beef and veal. These requirements apply to establishments approved under Regulation (EC) No. 853/2004 that produce minced meat that is not sold directly to the final consumer. -

Beef Grading by Daryl Tatum, Ph.D., Department of Animal Science, Colorado State University Ft

Beef Grading By Daryl Tatum, Ph.D., Department of Animal Science, Colorado State University Ft. Collins, Colorado he grade of a beef cut sold at retail can be an important selection factor for many consumers. Likewise, the grade of a beef carcass is critical to the beef producer, since the dollar value received is Tdirectly dependent upon the grade. Yet consumers and producers alike often are confused as to what grades mean, and how they are determined. Purpose of Beef Grading The U.S. Department of Agriculture (USDA) has established Standards for Grades of Slaughter Cattle and Standards for Grades of Carcass Beef (USDA, 1996), which are designed to facilitate beef marketing by separating a highly variable population of live cattle and/or beef carcasses into groups which are more uniform in quality and composition. Beef carcass grading is a voluntary service of the USDA, and the user (the packer) is charged a fee for the service. Grades are determined by an employee of the USDA, working independently of both the producer and packer. The USDA Standards include two separate grade designations – Quality Grades and Yield Grades – and are designated by the stamps shown in Figure 1. A carcass may be either Quality graded, or Yield graded, or both Quality and Yield graded at the same time. Figure 1: Qualily and Yield Grade Stamps for Beef Carcasses Quality Grading Beef quality refers to the expected eating characteristics (tenderness, juiciness and flavor) of the cooked product. USDA Quality Grades are used to reflect differences in expected eating quality among slaughter cattle and their carcasses. -

Industry Guide for Beef Aging

INDUSTRY GUIDE FOR BEEF AGING INDUSTRY GUIDE FOR BEEF AGING 1 BACKGROUND Postmortem aging is a critical management practice that can improve the consistency of beef tenderness (Tatum et al., 1999); however, the two most recent National Beef Tenderness Surveys revealed variability in length of post- mortem aging time of beef cuts (Morgan et al., 1991; Brooks et al., 2000). Previous studies have characterized improvements in tenderness associated with aging a variety of beef subprimals (Smith et al., 1978; Eilers et al., 1996). Researchers at Texas A&M University (Lorenzen et al., 1998), on behalf of the Texas Beef Council, developed an “aging index” that could be used by retailers for purposes of managing postmortem aging time of beef subprimal cuts to maximize beef palatability. That study recommended that ribeyes and shortloins be aged for at least 13 days; chuck rolls should be aged for at least 12 days; and bottom and top rounds should be aged at least 12 and 16 days, respectively. Researchers at Colorado State University (Mies et al., 1998), on behalf of the National Cattlemen’s Beef Association (NCBA) and the Cattlemen’s Beef Board, prepared a comprehensive review of scientific literature addressing the influence of postmortem aging time on beef tender- ness for a number of different beef subprimals. They concluded that steaks from the rib be aged between 11 and 15 days; the chuck roll and clod for a minimum of 12 and 11 days, respectively; striploin and top sirloin cuts for at least 14 and 21 days, respectively; and top and bottom round cuts for a minimum of 16 and 12 days, respectively (Mies et al., 1998). -

Effects of Grilling Temperature on Tenderness, Juiciness, And

EFFECTS OF GRILLING TEMPERATURE ON TENDERNESS, JUICINESS, AND FLAVOR OF RIBEYE, STRIP LOIN, AND TOP SIRLOIN STEAKS A Thesis by KAYLEY RHIAN WALL Submitted to the Office of Graduate and Professional Studies of Texas A&M University in partial fulfillment of the requirements for the degree of MASTERS OF SCIENCE Chair of Committee, Chris R. Kerth Committee Members, Rhonda K. Miller Christine Alvarado Head of Department, Cliff Lamb August 2017 Major Subject: Animal Science Copyright 2017 Kayley Rhian Wall ABSTRACT The objective of this study was to characterize the impact of grilling temperature on ribeye, top loin and top sirloin steaks. Boneless ribeye rolls, top loin and top sirloin butt subprimals (n = 16 each, 48 total) were purchased from a local meat supplier. After aging 21 d post-processing, 2.54-cm-thick steaks were hand cut and randomly assigned a grilling temperature treatment (177°C, 205°C, or 232°C), vacuum-packaged, and frozen at -10°C until testing. Steaks were grilled to an internal temperature of 71°C on a commercial flat top grill set at 177° C, 205° C, or 232° C. Consumers (n = 80) were served nine samples and prompted to rate their liking of overall, tenderness, juiciness, appearance, and flavor on a 9-point hedonic scale. Steaks cooked for Warner-Bratzler shear force were held over night at 4° C before removing six cores 1.3 cm in diameter from each steak. Steaks were also cooked and served to a sensory panel trained on flavor and texture attributes. Samples from the steaks used for trained sensory panel analysis were quick-frozen in liquid nitrogen and stored at -80° C for GC/MS – olfactory analysis. -

September 2018

SEPTEMBER 2018 RITUAL 602 Studewood Houston 77007 832.203.5180 ritualhouston.com Located in the busy little bar-restaurant district across from Fitzgerald’s at the intersection with White Oak, Ritual is a large, warm, and inviting restaurant with a menu that is perfectly tailored for Houstonians. The décor is natural wood and brick, with an outside patio and a very cool craft beer panel on the wall which is made with a former European style airport flight announcement board. A glassed-in butcher shop allows the diner to see large sides of beef aging on hooks. An energetic and enthusiastic staff provide great service.Small Plates: Sourdough hush puppies, jalapeno jelly; Boudin corn dogs, sorghum-ipa mustard, pickled okra, & celery salad; Jumbo lump crab cake, remoulade, charred lemon, blackened butter; Chicken lollipops, collard green mop sauce, citrus butter, parmesan. Entrees: Palacios redfish, lump crab & fried oyster, stewed okra, smoked tomato, house mustard butter sauce, cilantro rice; Chicken fried steak, skirt steak, kielbasa cream gravy, whlpped mashers, green beans; Death by gumbo, quail, pork belly, skirt steak, shrimp, sausage, king crab, boudin, friend pickled okra, cornbread; Potlicker pork chop; Market lamb chops; Rancher’s meatloaf; Roasted magret duck breast; Smoked short ribs; Smoked chicken pot pie; Red beans & rice. Soups & greens: Gulf seafood gravy, gulf crab & shrimp, fish, tomato-red pepper bisque, white rice, grilled sourdough; Buffalo pork belly wedge, Buffalo sauce, Danish blue cheese, red onion, mini iceberg, pickled celery, carrot. From the Butcher Room: Bone in strip; Bone in ribeye; Porterhouse; T-bone; Cast iron ribeye; Special filet; toppings: pit onion/marrow glaze; A2 steak sauce; House Worcestershire; Deep Ellum blue fondue. -

Consumer Sensory Acceptance and Value of Wet-Aged and Dry-Aged Beef Steaks" (2006)

University of Nebraska - Lincoln DigitalCommons@University of Nebraska - Lincoln Faculty Papers and Publications in Animal Science Animal Science Department 2006 Consumer Sensory Acceptance and Value of Wet-Aged and Dry- Aged Beef Steaks B. M. Sitz University of Nebraska-Lincoln Chris R. Calkins University of Nebraska-Lincoln, [email protected] D. M. Feuz University of Nebraska-Lincoln W. J. Umberger University of Nebraska-Lincoln Kent M. Eskridge University of Nebraska-Lincoln, [email protected] Follow this and additional works at: https://digitalcommons.unl.edu/animalscifacpub Part of the Animal Sciences Commons Sitz, B. M.; Calkins, Chris R.; Feuz, D. M.; Umberger, W. J.; and Eskridge, Kent M., "Consumer Sensory Acceptance and Value of Wet-Aged and Dry-Aged Beef Steaks" (2006). Faculty Papers and Publications in Animal Science. 580. https://digitalcommons.unl.edu/animalscifacpub/580 This Article is brought to you for free and open access by the Animal Science Department at DigitalCommons@University of Nebraska - Lincoln. It has been accepted for inclusion in Faculty Papers and Publications in Animal Science by an authorized administrator of DigitalCommons@University of Nebraska - Lincoln. Consumer sensory acceptance and value of wet-aged and dry-aged beef steaks1 B. M. Sitz, C. R. Calkins,2 D. M. Feuz, W. J. Umberger, and K. M. Eskridge Animal Science Department, University of Nebraska, Lincoln 68583-0908 ABSTRACT: To determine sensory preference and Choice samples were numerically superior for all sen- value of fresh beef steak differing in aging technique, sory traits, consumers placed similar bid values (P = strip steaks were evaluated by consumers in Denver 0.12) on wet- and dry-aged Choice samples ($3.82 per (n = 132 consumers) and Chicago (n = 141 consumers). -

Postmortem Aging of Beef with a Special Reference to the Dry Aging

Korean J. Food Sci. An. Vol. 36, No. 2, pp. 159~169 (2016) DOI http://dx.doi.org/10.5851/kosfa.2016.36.2.159 © 2016 Korean Society for Food Science of Animal Resources ISSN 1225-8563 eISSN 2234-246X ARTICLE Postmortem Aging of Beef with a Special Reference to the Dry Aging Muhammad I. Khan1,2, Samooel Jung3, Ki Chang Nam4, and Cheorun Jo1* 1Department of Agricultural Biotechnology, Center for Food and Bioconvergence, Research Institute of Agriculture and Life Science, Seoul National University, Seoul 08826, Korea 2National Institute of Food Science and Technology, University of Agriculture, Faisalabad 38040, Pakistan 3Department of Animal Science and Biotechnology, Chungnam National University, Daejeon 34134, Korea 4Department of Animal Science and Technology, Sunchon National University, Suncheon 57922, Korea Abstract Animal muscles are stored for specific period (aging) at refrigerated temperatures, during and after which the living muscles start to convert into meat and thus, attain certain superior properties in the final product. Proteolysis, lipolysis, and oxidation are the major bio- chemical processes involved during the postmortem aging of meat that affect the tenderness, juiciness, and flavor, as well as sometimes may introduce certain undesirable traits. This review analyzes the role of pre- and post-mortem factors that are important for aging and their effect on the chemical and physical changes in the “dry- and wet-aged meat.” Thus, if the meat processing manufacturers optimize the effects of aging for specific muscles, the palatability, color, and the shelf life of the aged meat products could be significantly enhanced. Keywords: meat, aging, pre- and post-slaughter factors, tenderness, flavor Received June 2, 2015; Revised November 3, 2015; Accepted December 4, 2015 Introduction beef (Irurueta et al., 2008). -

Ranking of Beef Muscles for Tenderness by Chris R

Ranking of Beef Muscles for Tenderness By Chris R. Calkins, Ph.D. and Gary Sullivan, University of Nebraska The Significance of Tenderness Tenderness and flavor are the most important palatability characteristics relating to consumer satisfaction with beef. Research has repeatedly shown consumers are willing to pay a premium for beef that can be guaranteed tender. Considerable resources have been expended to understand factors influencing tenderness and to develop technology capable of predicting tender cuts. Recently, the Muscle Profiling research conducted by the University of Nebraska and the University of Florida, funded by The Beef Checkoff, brought attention to the potential use of under-utilized muscles for value-added products. That study evaluated 39 different muscles from the beef chuck and round for many traits, including Warner-Bratzler shear (WBS) force and sensory characteristics, such as tenderness and juiciness. One of the most successful results has been the Flat Iron steak. Muscle Profiling research demonstrated the exceptional tenderness of the infraspinatus, which is the muscle of the Flat Iron steak. In 2006, more than 92 million pounds of Flat Iron steaks were sold in the U.S. indicating there is great value in knowing which muscles produce tender steaks. Features of Muscle Structure Influencing Tenderness Beef tenderness is a complex trait. Structural elements of muscle have profound effects on the perception of tenderness. Savell and Cross (1988) reiterated the commonly used categorization of factors influencing meat tenderness - an actomyosin effect, a background effect, and a bulk density or lubrication effect. Actomyosin effect This term refers to aspects of meat tenderness influenced by the condition of the sarcomeres in the muscle fibers. -

Influence of Cut, Cooking Method, and Post-Mortem Aging on Beef

INFLUENCE OF CUT, COOKING METHOD, AND POST-MORTEM AGING ON BEEF PALATABILITY A Dissertation Submitted to the Graduate Faculty of the North Dakota State University of Agriculture and Applied Science By Ashley Nicole Lepper In Partial Fulfillment for the Degree of DOCTOR OF PHILOSOPHY Major Department: Animal Sciences April 2013 Fargo, North Dakota North Dakota State University Graduate School Title Influence of cut, cooking method, and post-mortem aging on beef palatability By Ashley Nicole Lepper The Supervisory Committee certifies that this disquisition complies with North Dakota State University’s regulations and meets the accepted standards for the degree of DOCTOR OF PHILOSOPHY SUPERVISORY COMMITTEE: Dr. Eric Berg Chair Dr. Kasey Maddock-Carlin Dr. Robert Maddock Dr. Julie Garden-Robinson Approved: 05/06/2013 Dr. Greg Lardy Date Department Chair ABSTRACT The objectives of these studies were to determine the effects of cut, cooking method, and postmortem aging on improving consumers’ perception of beef. Consumers evaluated bottom round, top sirloin, ribeye, and a value cut samples for overall like, tenderness, juiciness, and flavor to understand how different cuts influence consumers’ perception of beef characteristics. Consumers’ rated the ribeye and value cut similar for overall like, tenderness, juiciness, and flavor. Bottom round steaks were rated the lowest for overall like and the toughest. Correlation and regression coefficients showed flavor was the largest influencing factor for overall like for the ribeye, value cut, and top sirloin. The value cut is comparable to the ribeye. Study two evaluated how different cooking methods (open-pan, oven bag, vacuum bag) influence the formation of warmed-over flavor (WOF) in reheated and fresh beef clod roasts (small, medium, large) utilizing a trained panel and thiobarbituric acid reactive substances (TBARS). -

Influence of Cut, Cooking Method, and Post-Mortem Aging on Beef

CORE Metadata, citation and similar papers at core.ac.uk Provided by NDSU Libraries Institutional Repository INFLUENCE OF CUT, COOKING METHOD, AND POST-MORTEM AGING ON BEEF PALATABILITY A Dissertation Submitted to the Graduate Faculty of the North Dakota State University of Agriculture and Applied Science By Ashley Nicole Lepper In Partial Fulfillment for the Degree of DOCTOR OF PHILOSOPHY Major Department: Animal Sciences April 2013 Fargo, North Dakota North Dakota State University Graduate School Title Influence of cut, cooking method, and post-mortem aging on beef palatability By Ashley Nicole Lepper The Supervisory Committee certifies that this disquisition complies with North Dakota State University’s regulations and meets the accepted standards for the degree of DOCTOR OF PHILOSOPHY SUPERVISORY COMMITTEE: Dr. Eric Berg Chair Dr. Kasey Maddock-Carlin Dr. Robert Maddock Dr. Julie Garden-Robinson Approved: 05/06/2013 Dr. Greg Lardy Date Department Chair ABSTRACT The objectives of these studies were to determine the effects of cut, cooking method, and postmortem aging on improving consumers’ perception of beef. Consumers evaluated bottom round, top sirloin, ribeye, and a value cut samples for overall like, tenderness, juiciness, and flavor to understand how different cuts influence consumers’ perception of beef characteristics. Consumers’ rated the ribeye and value cut similar for overall like, tenderness, juiciness, and flavor. Bottom round steaks were rated the lowest for overall like and the toughest. Correlation and regression coefficients showed flavor was the largest influencing factor for overall like for the ribeye, value cut, and top sirloin. The value cut is comparable to the ribeye. Study two evaluated how different cooking methods (open-pan, oven bag, vacuum bag) influence the formation of warmed-over flavor (WOF) in reheated and fresh beef clod roasts (small, medium, large) utilizing a trained panel and thiobarbituric acid reactive substances (TBARS).