Top Gun Flex ~

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Overview of Evaluations & Competitions

EVALUATIONS & COMPETITIONS EVALUATIONS TEAM DANCE MOCK EVALUATION • Valuable feedback from the Staff prior to final evaluation TEAM DANCE FINAL EVALUATION • Approximately 20 sec. of each style: pom, jazz, and hip hop • Each team will receive written feedback and a rating of Outstanding, Excellent or Superior GAME DAY PRACTICE RUN • Time allotted for teams participating in the Game Day Bid Evaluation to practice on the floor prior to the competition GAME DAY BID EVALUATION • Participation is Optional • Teams learn a Band Chant routine by video link prior to camp along with their own fight song and perform in the Game Day Run Off on Day One • Approximately 1 minute routine COMPETITIONS ALL competitions are completely optional. Note: No crossover participation by individuals is allowed. • Team Dance (Each team within a division will receive a placement; 1st-3rd place receive a trophy) • Game Day Run-Off (All teams compete in division one day 1, Division Winners compete again on Final Day; Winner receives Gold Paid Bid) TOP GUN Each team is allowed up to 2 participants for each Top Gun Competition. This does not have to be the same 2 dancers for each category. Selection of participants for each team is up to the discretion of the Coach. TOP GUN LEAPS & JUMPS • Minimum of five leaps and jumps • Variety of Advanced/Elite leaps and jumps with excellent technique TOP GUN TURNS • Variety of Advanced/Elite turns with excellent technique TOP GUN HIP HOP • Maximum 30 sec. hip hop improvisation • NDA will provide music, dancers will perform in groups DANCE ALL-AMERICAN MINIMUM REQUIREMENTS • Dancers will be nominated by the NDA Staff based on leadership, performance and technical skills • Nominees will perform Team Dance for their audition *Las Vegas Camp will have separate choreography for All-American Audition NATIONALS BIDS SEE REQUIREMENTS AND DISTRIBUTION PROCESS. -

UPC Platform Publisher Title Price Available 730865001347

UPC Platform Publisher Title Price Available 730865001347 PlayStation 3 Atlus 3D Dot Game Heroes PS3 $16.00 52 722674110402 PlayStation 3 Namco Bandai Ace Combat: Assault Horizon PS3 $21.00 2 Other 853490002678 PlayStation 3 Air Conflicts: Secret Wars PS3 $14.00 37 Publishers 014633098587 PlayStation 3 Electronic Arts Alice: Madness Returns PS3 $16.50 60 Aliens Colonial Marines 010086690682 PlayStation 3 Sega $47.50 100+ (Portuguese) PS3 Aliens Colonial Marines (Spanish) 010086690675 PlayStation 3 Sega $47.50 100+ PS3 Aliens Colonial Marines Collector's 010086690637 PlayStation 3 Sega $76.00 9 Edition PS3 010086690170 PlayStation 3 Sega Aliens Colonial Marines PS3 $50.00 92 010086690194 PlayStation 3 Sega Alpha Protocol PS3 $14.00 14 047875843479 PlayStation 3 Activision Amazing Spider-Man PS3 $39.00 100+ 010086690545 PlayStation 3 Sega Anarchy Reigns PS3 $24.00 100+ 722674110525 PlayStation 3 Namco Bandai Armored Core V PS3 $23.00 100+ 014633157147 PlayStation 3 Electronic Arts Army of Two: The 40th Day PS3 $16.00 61 008888345343 PlayStation 3 Ubisoft Assassin's Creed II PS3 $15.00 100+ Assassin's Creed III Limited Edition 008888397717 PlayStation 3 Ubisoft $116.00 4 PS3 008888347231 PlayStation 3 Ubisoft Assassin's Creed III PS3 $47.50 100+ 008888343394 PlayStation 3 Ubisoft Assassin's Creed PS3 $14.00 100+ 008888346258 PlayStation 3 Ubisoft Assassin's Creed: Brotherhood PS3 $16.00 100+ 008888356844 PlayStation 3 Ubisoft Assassin's Creed: Revelations PS3 $22.50 100+ 013388340446 PlayStation 3 Capcom Asura's Wrath PS3 $16.00 55 008888345435 -

Scoreboard: City of Aventura 2020 Winter Adult Softball League

Scoreboard: City of Aventura 2020 Winter Adult Softball League Date Team Opponent Score Game At Game Highlights 1/5/2020 Los Titanes vs Minyan 9-8 Minyan 8:15a Minyan comes from behind to beat Los Titanes in their league debut 1/5/2020 Ely-M vs Aventura's Finest 14-0 Finest 9:30a Finest absolutely hammers Ely-M with stellar defense and some solid hitting 1/5/2020 Team Ramrod vs I Miss Elyse 21-1 Elyse 10:45a I Miss Elyse throttles Team Ramrod in their league debut with a mercy run win after three innings 1/5/2020 Top Gun vs Lightly Toasted 10-9 Toasted 12:00p Toasted wins with a game ending double play that included a play at the plate 1/12/2020 Aventura's Finest vs Team Venezuela 6-4 Finest 8:15a Finest beats Venezuela in a rematch of the 2019 Fall Championship 1/12/2020 Minyan vs Team Ramrod 17-2 Minyan 9:30a Minyan runs away with it behind some strong defence and stellar pitching 1/12/2020 Los Titanes vs Top Gun 15-7 Top Gun 10:45a Top Gun bats come alive as they down Los Titanes 1/12/2020 Lightly Toasted vs Los Titanes 12-4 Toasted 12:00p Toasted continues its winning ways by easily handling Los Titanes 1/19/2020 Team Ramrod vs Lightly Toasted 19-7 Toasted 8:15a Toasted pulls away with hot bats to extend their winning streak to three 1/19/2020 Team Venezuela vs Top Gun 16-2 Venezuela 9:30a Venezuela pounds Top Gun with a steady onslaught of hits 1/19/2020 Minyan vs Ely-M 12-10 Ely-M 10:45a Ely-M holds on in a tight game vs Minyan 1/19/2020 Ely-M vs Los Titanes 17-1 Ely-M 12:00p Ely-M breaks out the bats big time with a thrashing of -

Cannes Critics Week Panel Films Screened During TIFF Cinematheque's Fifty Years of Discovery: Cannes Critics Week (Jan. 18-22

Cannes Critics Week panel Films screened during TIFF Cinematheque’s Fifty Years of Discovery: Cannes Critics Week (Jan. 18-22, 2012) In honour of the fiftieth anniversary of Semaine de la Critique (Cannes Critics Week), TIFF Cinematheque invited eight local and international critics and opinion-makers to each select and introduce a film that was discovered at the festival. The diversity of their selections—everything from revered art-house classics to scrappy American indies, cutting-edge cult hits and intriguingly unknown efforts by famous names—testifies to the festival’s remarkable breadth and eclecticism, and its key role in discovering new generations of filmmaking talent. Programmed by Brad Deane, Manager of Film Programmes. Clerks. Dir. Kevin Smith, 1994, U.S. 92 mins. Production Co.: View Askew Productions / Miramax Films. Introduced by George Stroumboulopoulos, host of CBC’s Stroumboulopoulos Tonight, formerly known as The Hour. Stroumboulopoulos on Clerks: “When Kevin Smith made Clerks and it got on the big screen, you felt like our voice was winning.” Living Together (Vive ensemble). Dir. Anna Karina, 1973, France. 92 mins. Production Co.: Raska Productions / Société Nouvelle de Cinématographie (SNC). Introduced by author and former critic for the Chicago Reader, Jonthan Rosenblum. Rosenblum on Living Together: “I saw Living Together when it was first screened at Cannes in 1973, and will never forget the brutality with which this gently first feature was received. One prominent English critic, the late Alexander Walker, asked Anna Karina after the screening whether she realized that her first film was only being shown because she was once married to a famous film director; she sweetly asked in return whether she should have therefore rejected the Critics Week’s invitation. -

Aircraft Collection

A, AIR & SPA ID SE CE MU REP SEU INT M AIRCRAFT COLLECTION From the Avenger torpedo bomber, a stalwart from Intrepid’s World War II service, to the A-12, the spy plane from the Cold War, this collection reflects some of the GREATEST ACHIEVEMENTS IN MILITARY AVIATION. Photo: Liam Marshall TABLE OF CONTENTS Bombers / Attack Fighters Multirole Helicopters Reconnaissance / Surveillance Trainers OV-101 Enterprise Concorde Aircraft Restoration Hangar Photo: Liam Marshall BOMBERS/ATTACK The basic mission of the aircraft carrier is to project the U.S. Navy’s military strength far beyond our shores. These warships are primarily deployed to deter aggression and protect American strategic interests. Should deterrence fail, the carrier’s bombers and attack aircraft engage in vital operations to support other forces. The collection includes the 1940-designed Grumman TBM Avenger of World War II. Also on display is the Douglas A-1 Skyraider, a true workhorse of the 1950s and ‘60s, as well as the Douglas A-4 Skyhawk and Grumman A-6 Intruder, stalwarts of the Vietnam War. Photo: Collection of the Intrepid Sea, Air & Space Museum GRUMMAN / EASTERNGRUMMAN AIRCRAFT AVENGER TBM-3E GRUMMAN/EASTERN AIRCRAFT TBM-3E AVENGER TORPEDO BOMBER First flown in 1941 and introduced operationally in June 1942, the Avenger became the U.S. Navy’s standard torpedo bomber throughout World War II, with more than 9,836 constructed. Originally built as the TBF by Grumman Aircraft Engineering Corporation, they were affectionately nicknamed “Turkeys” for their somewhat ungainly appearance. Bomber Torpedo In 1943 Grumman was tasked to build the F6F Hellcat fighter for the Navy. -

ALL-Star All- American Games Extra INFO!

WELCOME TO THE NEW TOP GUN – USA SPORTS BASEBALL ALL-STAR REGIONAL CHAMPIONSHIPS Aug. 6th , 7th , & 8th, 2021 ALL-STAR / ALL- AMERICAN GAMES Sept. 3rd, 4th, 5th, & 6th, 2021 GAMES PROGRAM Dear Coaches & Parents Coaches and Parents, While we work hard to make sure that your players have the ultimate experiences at our Top Gun – USA Sports events, we know that none of this would be possible without YOU!!! Whether it’s taking a day off work to travel to these events, using your family vacation days to sit at the ballfields, or the early morning starts, we recognize your endless support and dedication to ensure that these young players have the opportunity to advance their skills while playing the game that they love. Top Gun – USA Sports offers the All – Star/ All – American Games for all of the families attending our event. We take pride in bringing together all things you want in a baseball tournament with fun activities for you and your family on and off the field. At Top Gun – USA Sports it is our mission to give you an event that brings equal level- play, great venues, state of the art perks and awards, but most of all the chance for young athletes to create memories that will last a lifetime. Here at Top Gun – USA Sports we understand firsthand all of the sacrifices that you make each weekend to be part of the travel ball life. We would like to take this opportunity to say thanks to all of the parents, coaches, and supporters that make it possible for YOUR teams to participate in our 2021 Top Gun – USA Sports All – Star/ All - American Games. -

TOP GUN (1986) and the Emergence of the Post-Cinematic by MICHAEL LOREN SIEGEL

5.4 Ride into the Danger Zone: TOP GUN (1986) and the Emergence of the Post-Cinematic BY MICHAEL LOREN SIEGEL Introduction The work of British-born filmmaker Tony Scott has undergone a major critical revision in the last few years. While Scott’s tragic suicide in 2012 certainly drew renewed vigor to this reassessment, it was well underway long before his death. Already by the mid-2000s, Scott’s brash, unapologetically superficial, and yet undeniably visionary films had been appropriated by auteurists and film theorists alike to support a wide range of arguments.[1] Regardless of what we may think of the idea of using auteurism and theory to “rescue” directors who were for decades considered little more than action hacks—an especially meaningful question in the digital age, given the extent to which auteur theory’s acceptance has increased in direct proportion to the growth of online, theoretically informed film criticism—it would be difficult to deny the visual, aural, narrative, thematic, and energetic consistency of Scott’s films, from his first effort, The Hunger (1983), all the way through to his last, Unstoppable (2011). The extreme scale and artistic ambition of his films, the intensity of their aesthetic and affective engagement with Ride into the Danger Zone the present (a present defined, as they constantly remind us, by machines, mass media, masculinity, and militarization), and, indeed, the consistency of their audiovisual design and affect (their bristling, painterly flatness, the exaggerated sense of perpetual transformation and becoming that is conveyed by their soundtracks and montage, the hyperbolic and damaged masculinity of their protagonists)—all of this would have eventually provoked the kind of critical reassessment we are seeing today, even without the new mythos produced around Scott upon his death. -

The Man Who Built a Billion Dollar Fortune Off Pirates of The

February 22, 2019 The Man Who Built a Billion‐Dollar Fortune Off ‘Pirates of the Caribbean’ By Tom Metcalf ‘Top Gun’ producer joins Spielberg, Lucas in billionaire club CSI and ‘Pirates of the Caribbean’ franchises drive fortune Johnny Depp as Captain Jack Sparrow and Jerry Bruckheimer Photographer: Mark Davis/Getty Images While the glitz and glamour of show business will be on full display Sunday at the Academy Awards, one of Hollywood’s most successful producers will be merely a bystander this year. Don’t weep for Jerry Bruckheimer, however. The man behind classic acon films like “Top Gun” and “Beverly Hills Cop” has won a Hollywood status far rarer than an Oscar ‐‐ membership in the three‐comma club. While stars sll reap plenty of income, the real riches are reserved for those who control the content. The creaves who’ve vaulted into the ranks of billionairedom remains thin, largely the preserve of household names like Steven Spielberg and George Lucas, who had the wherewithal to enter film producon and se‐ cured rights to what they produced. Bruckheimer has been just as successful on the small screen, producing the “CSI: Crime Scene Invesgaon” franchise. He’s sll at it, with a pilot in the works for CBS and “L.A.’s Finest,” a spinoff of “Bad Boys,” for Char‐ ter Communicaons’ new Spectrum Originals, set to air in May. “Jerry is in a league all of his own,” said Lloyd Greif, chief execuve officer of Los Angeles‐based investment bank Greif & Co. “He’s king of the acon film and he’s enjoyed similar success in television.” The TV business is changing, with a new breed of streaming services such as Nelix Inc. -

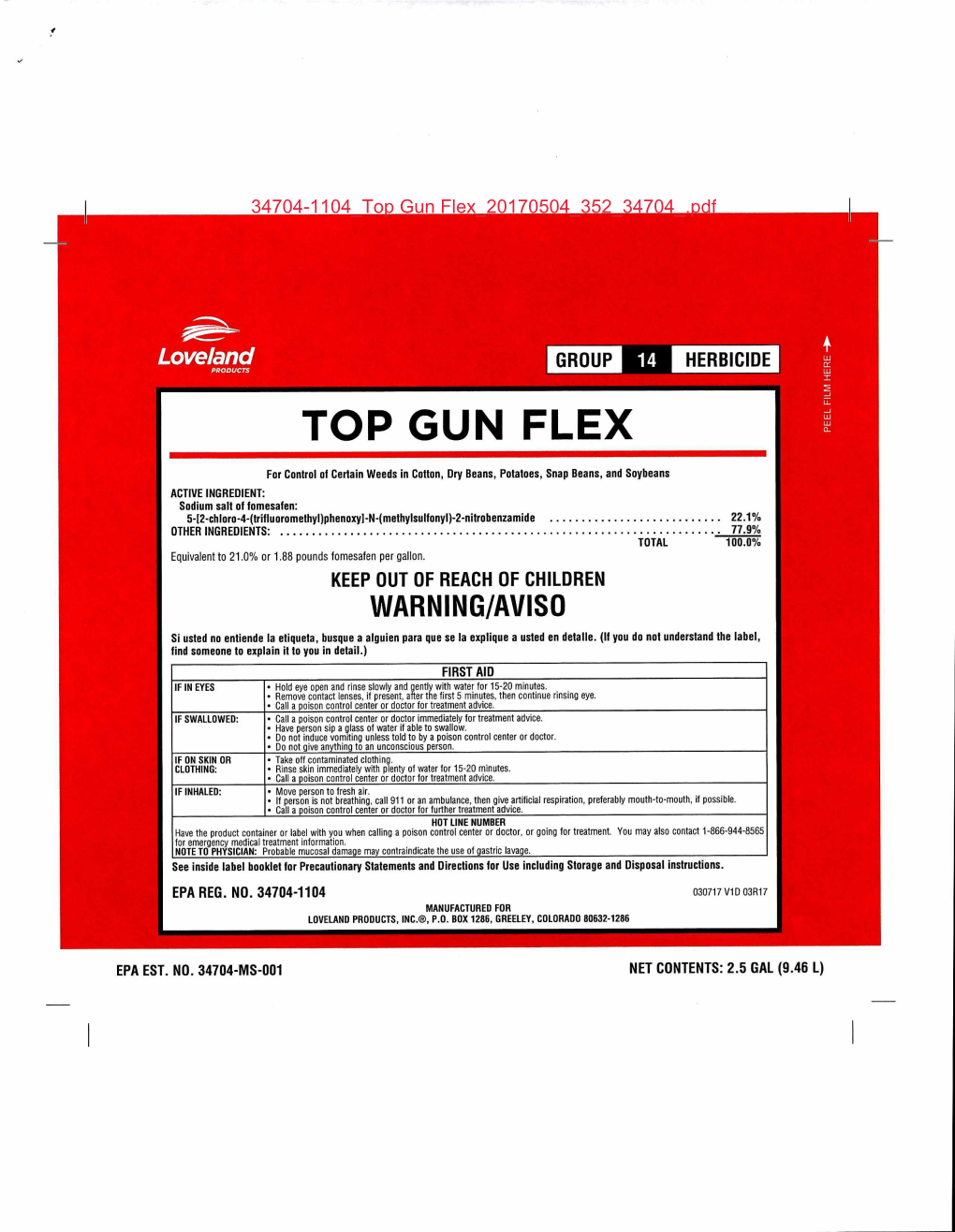

Safety Data Sheet Top Gun® Sds Number: 001058-16-Lpi Sds Revisions: Format Date of Issue: 09/21/16 Supersedes: 12/10/14

SAFETY DATA SHEET TOP GUN® SDS NUMBER: 001058-16-LPI SDS REVISIONS: FORMAT DATE OF ISSUE: 09/21/16 SUPERSEDES: 12/10/14 FOR CHEMICAL EMERGENCY, SPILL, LEAK, FIRE, EXPOSURE OR ACCIDENT, CALL CHEMTREC - DAY OR NIGHT 1-800-424-9300 1. IDENTIFICATION OF THE MATERIAL AND SUPPLIER 1.1 PRODUCT IDENTIFIER: TRADE NAME: TOP GUN® HERBICIDE 1.2 RECOMMENDED USE: FOR CONTROL OF WEEDS IN COTTON, DRY BEANS, POTATOES, SNAP BEANS, AND SOYBEANS 1.3 SUPPLIER DETAILS: LOVELAND PRODUCTS, INC. P.O. Box 1286 • Greeley, CO 80632-1286 1.4 24 Hour Emergency Phone: 1-800-424-9300 - Medical Emergencies: 1-866-944-8565 – Product Information: 1-888-574-2878 (LPI-CUST) U.S. Coast Guard National Response Center: 1-800-424-8802 2. HAZARDS IDENTIFICATION 2.1 Classification of the substance or mixture Classification according to 29 CFR 1910.1200 Eye Damage/Irritation Category 1 H318 Acute Toxicity – Inhalation Category 4 H332 Acute Toxicity – Dermal Category 4 H312 Sensitization – Skin Category 1 H317 2.2 Label elements Signal word: DANGER Hazard Statement: H318 – Causes serious eye damage. H332 – Harmful if inhaled. H312 – Harmful in contact with skin. H317 – May cause an allergic skin reaction. H303 – May be harmful if swallowed. Precautionary Statement: P280 – Wear protective gloves/protective clothing/eye protection/face protection. (Prevention): P261 – Avoid breathing dust/fume/gas/mist/vapors/spray. P271 – Use only outdoors or in a well-ventilated area. P272 – Contaminated work clothing must not be allowed out of the workplace. Precautionary Statement: P305+P351+P338: IF IN EYES: Rinse cautiously with water for several minutes. -

Tom Cruise Suffered from Dyslexia He Was an Athlete Even Though He Had Dyslexia

By: Max Kaplan & Tess Baron Thomas Cruise was born on July 3,1962. His dad Thomas Cruise was an electric engineer, and his mom Mary Cruise was an amateur actress and school teacher. Cruises parents divorced when he was 11. He moved in with his mother in louisvelle Kentucky and then the mother remarried and moved to Glen Ridge New Jersey. Tom cruise suffered from dyslexia he was an athlete even though he had dyslexia. He had a better career at home on the stage. He set a 10 year deadline for his acting carrier. His first appearance in a film was a movie called Endless Love(1981). Tom Cruise’s next film Risky Business (1983) grossed $65 million. It also made cruise a very well recognizable actor. Cruise’s movie Top Gun co-stared Kelly Mcgillis, Anthony Edwards, and Meg Ryan. Tom Cruise's also co-stared with Paul Newman in Color of Money(1986). One of cruise’s biggest hits was mission impossible he’s played in 5 mission impossible. The names of all the Mission impossible’ are Mission impossible (1996), Mission impossible II (2000), Mission impossible III (2006), Mission impossible Ghost Protocol (2011) Mission impossible Rogue Nation (2015). His disability was dyslexia , dyslexia means that you can’t read or learn as easily as other kids. Tom Cruise did not want his fellow classmates to find out about his dyslexia. Cruise used an program called study technology so he can learn how to learn. His accomplishment was learning how to study all by himself. Tom Cruise refused for his dyslexia to get in the way of his career. -

Vogel...From Page 1A White...From Page 1A

Page 6A THE NORTH GEORGIA NEWS December 25, 2019 ...from Page 1A White Vogel...from Page 1A Whitey circa 1995 standing in front of the A-6E Intruder with 12 MK-20 Rockeye, each with 247 smaller bombs inside. Photo/submitted The Vogel Tree Lighting and Christmas Program featured a robust turnout this year, especially given that it was largely interrupted the last two years due to weather. Photo by Lowell Nicholson codename for ‘TOP GUN 2,’” engineer, he decided it was time the A-6E, F-15E and B-1B Whitey said. “As we started to act on his dream of becoming bomber, the latter two being year. Hill said there were 12 have about 80 volunteers out working with the studio, they an aviator by signing up for U.S. supersonic. “The last two years we area churches involved in the here right now.” confided in us that, yes, this Naval Flight Officer training, To this day, Whitey is haven’t been able to have it tree lighting, some outside of For his part, country was the filming of ‘TOP GUN: where he graduated No. 1 in thankful for having received out here (due to weather),” Union County. music class-act Justin Terry MAVERICK,’ and we were his class. the opportunity to serve his Hill said. “We were glad – we “There’s a lot going on,” agreed with Becker, saying that bound at that time not to say Being the country in a role many could thought we’d have to build the Park Manager Jack Becker said. -

Better Ways to Build Monogram's Classic F-14 Tomcat

AIRCRAFT SPECIAL “TOP GUN” + 20 Better ways to build Monogram’s classic F-14 Tomcat By Darren Roberts model contest I attended recently had a category for cuts that make building this kit quite manageable. With some “Modeling the Movies.” Being an F-14 Tomcat fan, I extra effort, the finished product rivals any kit on the market immediately decided to build a jet from the 1986 today. A movie “Top Gun.” It would be a fitting tribute, since Straight out of the box, the Monogram kit wasn’t quite what I 2006 not only marks the 20th anniversary of the movie but also needed for this project. The Tomcats used in the movie had a the end of active service for the Tomcat. By late 2006, the last F- sensor on the tip of the nose known as an “alpha probe;” later 14 squadron will and be replaced by F/A-18E and F Super releases contain this part. They also had the newly installed Hornets. Television Camera System (TCS) under the nose. However, the There are several 1/48 scale F-14 Tomcat models on the mar- Monogram kit fit the bill in every other way. ket, but since I was waxing nostalgic I thought it would be fitting to pull out the old Monogram kit. It was first released in 1981, First things first which makes the kit 25 years old. It’s hard to imagine that much To make construction easier, I implemented shortcuts. First, I cut time has passed! away the stabilators from the top half of the fuselage and set When it first came out, the Monogram F-14 was a quantum them aside to attach later, 1.