Wo 2010/085712 A2

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Transport of Dangerous Goods

ST/SG/AC.10/1/Rev.16 (Vol.I) Recommendations on the TRANSPORT OF DANGEROUS GOODS Model Regulations Volume I Sixteenth revised edition UNITED NATIONS New York and Geneva, 2009 NOTE The designations employed and the presentation of the material in this publication do not imply the expression of any opinion whatsoever on the part of the Secretariat of the United Nations concerning the legal status of any country, territory, city or area, or of its authorities, or concerning the delimitation of its frontiers or boundaries. ST/SG/AC.10/1/Rev.16 (Vol.I) Copyright © United Nations, 2009 All rights reserved. No part of this publication may, for sales purposes, be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, electrostatic, magnetic tape, mechanical, photocopying or otherwise, without prior permission in writing from the United Nations. UNITED NATIONS Sales No. E.09.VIII.2 ISBN 978-92-1-139136-7 (complete set of two volumes) ISSN 1014-5753 Volumes I and II not to be sold separately FOREWORD The Recommendations on the Transport of Dangerous Goods are addressed to governments and to the international organizations concerned with safety in the transport of dangerous goods. The first version, prepared by the United Nations Economic and Social Council's Committee of Experts on the Transport of Dangerous Goods, was published in 1956 (ST/ECA/43-E/CN.2/170). In response to developments in technology and the changing needs of users, they have been regularly amended and updated at succeeding sessions of the Committee of Experts pursuant to Resolution 645 G (XXIII) of 26 April 1957 of the Economic and Social Council and subsequent resolutions. -

1 Transformer Oil 2 Residual Fuel Oil 3 Diesel Oil Heavy 4

1 TRANSFORMER OIL 2 RESIDUAL FUEL OIL 3 DIESEL OIL HEAVY 4 SPINDLE OIL MIXTURES CONTAINING 5 CRUDE OIL 6 MOTOR OIL 7 ROAD OIL 8 FUEL OIL NO.4 9 FUEL OIL NO.5 10 FUEL OIL NO.6 LUBRICATING OILS AND 11 BLENDING STOCKS 12 PENETRATING OIL 13 TURBINE OIL 3 14 ROOFERS FLUX 15 CRUDE OIL 16 STRAIGHT RUN RESIDUE OCTAMETHYLCYCLOTETRA 17 SILOXANE BENZENEPROPANOIC ACID, 3,5- 1,1- 3,5-BIS(1,1-DIMETHYLETHYL 18 4- ), -C7-C9 4-HYDROXY-C7-C9ALCOHOL S BRANCHED AND LINEAR 19 1- -1- 1-PHENYL-1-XYLYL ETHANE BENZENETRICARBOXYLIC 20 ACID, TRIOCTYL ESTER 21 CASTOR OIL IMIDAZOLIUM COMPOUNDS, 1- -4,5- -1- 1-BENZYL-4,5-DIHYDRO-1-(H 22 -2- YDROXYETHYL)-2-NORCOC O ALKYL, CHLORIDES 4 2-PROPENOIC ACID 2- POLYMER WITH 4- 1,1- 4-(1,1-DIMETHYLETHYL)PHE 2,5- NOL,FORMALDEHYDE, 23 2- 2,5-FURANDIONE, 65% / 2-METHYLOXIRANE AND OXIRANE (65% IN NAPHTHA/XYLENE) 24 n-PENTYL PROPIONATE 25 -2- 2-ETHYLHEXYL ACRYLATE 26 DECYL ACRYLATE 27 RAPESEED OIL RAPESEED OIL (low erucic acid 4% 28 containing less than 4% free fatty acids) RAPE SEED OIL FATTY ACID 29 METHYL ESTERS ALCOHOLS (C12-C13), C12-C13 30 PRIMARY, LINEAR AND ESSENTIALLY LINEAR 31 C13+ ALCOHOLS (C13+) 5 ALCOHOLS (C14-C18), C14-C18 32 PRIMARY, LINEAR AND ESSENTIALLY LINEAR ALCOHOLS (C8-C11), C8-C11 33 PRIMARY, LINEAR AND ESSENTIALLY LINEAR ACID OIL MIXTURE FROM SOYABEAN, CORN (maize) 34 AND SUNFLOWER OIL REFINING NAPHTHALENE CRUDE 35 (MOLTEN) 36 SOYABEAN OIL SOYBEAN OIL FATTY ACID 37 METHYL ESTER 38 BUTYLBENZENE (all isomers) 39 TALLOW 40 TALLOW FATTY ACID (2- BIS(2-ETHYLHEXYL) 41 ) TEREPHTHALATE 42 -(2- ) DI-(2-ETHYLHEXYL) -

General Disclaimer One Or More of the Following Statements May Affect

General Disclaimer One or more of the Following Statements may affect this Document This document has been reproduced from the best copy furnished by the organizational source. It is being released in the interest of making available as much information as possible. This document may contain data, which exceeds the sheet parameters. It was furnished in this condition by the organizational source and is the best copy available. This document may contain tone-on-tone or color graphs, charts and/or pictures, which have been reproduced in black and white. This document is paginated as submitted by the original source. Portions of this document are not fully legible due to the historical nature of some of the material. However, it is the best reproduction available from the original submission. Produced by the NASA Center for Aerospace Information (CASI) NASA CR - 159480 EXXON/GRUS. 1KWD. 78 NIGH PERFORMANCE, HIGH DENSITY HYDROCARBON FUELS J. W. Frankenfeld, T. W. Hastings, M. Lieberman and W. F. Taylor EXXON RESEARCH AND ENGINEERING COMPANY prepared for NATIONAL AERONAUTICS AND SPACE ADMINISTRATION (NASA-CR-159''PO) HIGH PEPPOFMANCF, HIGH V79-20267 DENSTTv HYDR I-CARBON FTIELS (Exxon P.esearch and Engineering Co.) 239 rp HC A11/MF A01 CSCL 21D 'Inclas G3/28 19456 NASA Lewis Research Center Contract NAS 3-20394 Qnr{l,,Y^ ^'Pr I€ ^i NASA CR - 159480 EXXON/GRUS . 1KWD . 78 L: HIGH PERFORMANCE, HIGH DENSITY HYDROCARBON FUELS J. W. Frankenfeld, T. W. Hastings, M. Lieberman and W. F. Taylor EXXON RESEARCH AND ENGINEERING COMPANY prepared for NATIONAL AERONAUTICS AND SPACE ADMINISTRATION NASA Lewis Research Center Contract NAS 3-20394 FOREWARD The research described in this report was performed at Exxon Research and Engineering Company, Linden, New Jersey and Contract NAS 320394 with Mr. -

Dibasic Acids for Nylon Manufacture

- e Report No. 75 DIBASIC ACIDS FOR NYLON MANUFACTURE by YEN-CHEN YEN October 1971 A private report by the PROCESS ECONOMICS PROGRAM STANFORD RESEARCH INSTITUTE MENLO PARK, CALIFORNIA CONTENTS INTRODUCTION, ....................... 1 SUMMARY .......................... 3 General Aspects ...................... 3 Technical Aspects ..................... 7 INDUSTRY STATUS ...................... 15 Applications and Consumption of Sebacic Acid ........ 15 Applications and Consumption of Azelaic Acid ........ 16 Applications of Dodecanedioic and Suberic Acids ...... 16 Applications of Cyclododecatriene and Cyclooctadiene .... 17 Producers ......................... 17 Prices ........................... 18 DIBASIC ACIDS FOR MANUFACTURE OF POLYAMIDES ........ 21 CYCLOOLIGOMERIZATIONOF BUTADIENE ............. 29 Chemistry ......................... 29 Ziegler Catalyst ..................... 30 Nickel Catalyst ..................... 33 Other Catalysts ..................... 34 Co-Cyclooligomerization ................. 34 Mechanism ........................ 35 By-products and Impurities ................ 37 Review of Processes .................... 38 A Process for Manufacture of Cyclododecatriene ....... 54 Process Description ................... 54 Process Discussion .................... 60 Cost Estimates ...................... 60 A Process for Manufacture of Cyclooctadiene ........ 65 Process Description ................... 65 Process Discussion .................... 70 Cost Estimates ...................... 70 A Process for Manufacture of Cyclodecadiene -

Flammable Liquids and Solids Chemical Class Standard Operating Procedure

1 Flammable Liquids and Solids Chemical Class Standard Operating Procedure Flammable Liquids and Solids H224 H225 H226 H227 H228 This SOP is not a substitute for hands-on training. Print a copy and insert into your laboratory SOP binder. Department: Chemistry Date SOP was written: Thursday, July 1, 2021 Date SOP was approved by PI/lab supervisor: Thursday, July 1, 2021 Name: F. Fischer Principal Investigator: Signature: ______________________________ Name: Matthew Rollings Internal Lab Safety Coordinator or Lab Manager: Lab Phone: 510.301.1058 Office Phone: 510.643.7205 Name: Felix Fischer Emergency Contact: Phone Number: 510.643.7205 Tan Hall 674, 675, 676, 679, 680, 683, 684 Location(s) covered by this SOP: Hildebrand Hall: D61, D32 1. Purpose This SOP covers the precautions and safe handling procedures for the use of Flammable Liquids and Solids. For a list of Flammable Liquids and Solids covered by this SOP and their use(s), see “List of Chemicals”. Procedures described in Section 12 apply to all materials covered in this SOP. A change to the “List of Chemicals” does not constitute a change in the SOP requiring review or retraining. If you have questions concerning the applicability of any recommendation or requirement listed in this procedure, contact the Principal Investigator/Laboratory Supervisor or the campus Chemical Hygiene Officer at [email protected]. Rev. Date: 2021-06-29 2 Flammable Liquids and Solids Chemical Class Standard Operating Procedure 2. Physical & Chemical Properties/Definition of Chemical Group Flammable liquid means a liquid having a flash point1 of not more than 199.4 °F (93 °C). -

Accuracy and Methodologic Challenges of Volatile Organic Compound–Based Exhaled Breath Tests for Cancer Diagnosis: a Systematic Review and Pooled Analysis

1 Supplementary Online Content Hanna GB, Boshier PR, Markar SR, Romano A. Accuracy and Methodologic Challenges of Volatile Organic Compound–Based Exhaled Breath Tests for Cancer Diagnosis: A Systematic Review and Pooled Analysis. JAMA Oncol. Published online August 16, 2018. doi:10.1001/jamaoncol.2018.2815 Supplement. eTable 1. Search strategy for cancer systematic review eTable 2. Modification of QUADAS-2 assessment tools eTable 3. QUADAS-2 results eTable 6. STARD assessment of each study eTable 7. Summary of factors reported to influence levels of volatile organic compounds within exhaled breath eFigure 1. Risk of bias and applicability concerns using QUADAS-2 eFigure 2. PRISMA flowchart of literature search eTable 4. Details of studies on exhaled volatile organic compounds in cancer eTable 5. Cancer VOCs in exhaled breath and their chemical class. eFigure 3. Chemical classes of VOCs reported in different tumor sites. This supplementary material has been provided by the authors to give readers additional information about their work. © 2018 American Medical Association. All rights reserved. Downloaded From: https://jamanetwork.com/ on 10/01/2021 2 eTable 1. Search strategy for cancer systematic review # Search 1 (cancer or neoplasm* or malignancy).ab. 2 limit 1 to abstracts 3 limit 2 to cochrane library [Limit not valid in Ovid MEDLINE(R),Ovid MEDLINE(R) Daily Update,Ovid MEDLINE(R) In-Process,Ovid MEDLINE(R) Publisher; records were retained] 4 limit 3 to english language 5 limit 4 to human 6 limit 5 to yr="2000 -Current" 7 limit 6 to humans 8 (cancer or neoplasm* or malignancy).ti. 9 limit 8 to abstracts 10 limit 9 to cochrane library [Limit not valid in Ovid MEDLINE(R),Ovid MEDLINE(R) Daily Update,Ovid MEDLINE(R) In-Process,Ovid MEDLINE(R) Publisher; records were retained] 11 limit 10 to english language 12 limit 11 to human 13 limit 12 to yr="2000 -Current" 14 limit 13 to humans 15 7 or 14 16 (volatile organic compound* or VOC* or Breath or Exhaled).ab. -

Overview and Assessment of Priority Substances Globally and Regionally Addressed and Related Emission Limit Value (Elvs)

UNEP(DEPI)/MED WG. 328/Inf. 1 10 November 2008 ENGLISH MEDITERRANEAN ACTION PLAN MED POL Meeting on the Implementation of NAPs and the Preparation of Legally Binding Measures and Timetables required by Art. 15 of the LBS Protocol Aix-en-Provence (France), 27-28 November 2008 Overview and assessment of priority substances globally and regionally addressed and related Emission Limit Value (ELVs) Background document UNEP/MAP Athens, 2008 Table of Contents 1. INTRODUCTION..................................................................................................... 1 1.1 BACKGROUND................................................................................................... 1 1.2 OBJECTIVES AND SCOPE ................................................................................... 1 2. SUBSTANCES OF CONCERN IN THE MARINE ENVIRONMENT ....................... 2 2.1 ADDRESSING SUBSTANCES OF CONCERN IN THE MEDITERRANEAN: THE LBS PROTOCOL AND THE SAP ............................................................................................. 2 2.2 IDENTIFICATION OF PRIORITY SUBSTANCES: INTERNATIONAL COMPARISON.......... 3 2.2.1 European Union .......................................................................................... 4 2.2.1.1 First initiatives protect the aquatic environment from dangerous substances.......................................................................................................... 4 2.2.1.2 The Water Framework Directive (WFD).............................................. 5 2.2.1.3 The Marine -

The Synthesis of a Water-Soluble Molecule

THE SYNTHESIS OF A WATER-SOLUBLE MOLECULE CONTAINING A HYDROPHOBIC CAVITY by W. HARRY MANDEVILLE B. S. Colorado School of Mines (1971) SUBMITTED IN PARTIAL FULFILLMENT OF'THE REQUIREMENTS FOR THE DEGREE OF DOCTOR OF PHILOSOPHY at the MASSACHUSETTS INSTITUTE OF TECHNOLOGY May 16, 1975 Signature of Author / Department of Chemistry May , 1975 Certified by K Thesis Supervisor Accepted by --~~~~~~~~~ ( Chairman, Departmental ARCHIVES Committee JUN 11 1975 -2- This Doctoral. Thesis has been examined by a committee of the Department of Chemistry as follows: Professor Dietmar Seyferth I/ Chairman Professor George MI.Whitesides \K. u- '|Thesis Supervisor Professor K. Barry Sharpless -3- to SUSIE... 143 for CHRISTMAS and SNOW and to MY PARENTS -4- "You know how when you stand in the rain with your mouth open how rarely the raindrops hit your tongue... Chemistry is a lot like that. I like standing in the rain." April 30, 1975 -5- THE SYNTHESIS of a WATER-SOLUBLE MOLECULE CONTAINING a HYDROPHOBIC CAVITY by W. Harry Mandeville Submitted to the Department of Chemistry at the Massachusetts Institute of Technology, May 16, 1975, in partial fulfillment of the requirements for the degree of Doctor of Philosophy. ABSTRACT Part I: The Synthesis of a Water-Soluble Molecule Containing a Hydrophobic Cavity The syntheses and characterization of three macrocyclic compounds, cyclohexatriaconta[l,2,13,14,25,26-b,b',b"]tris- quinoxaline (1) cyclohexatriaconta[l,2,13,14,25,26-b,b',b"] tris(diethyl 1H,3H,2-oxoimadazo[4,5-g]quinoxalino-l,3-di- a-acetate) (2) and cyclopentatetraconta[1,2,16,17,31,32-b, b',b"]trisqu'lnoxaline (3 are described. -

Fedex Ground Hazardous Materials Shipping Guide Is Intended to Simplify Title 49 CFR

FedEx Ground Package Systems Inc. is committed to the safe transportation of hazardous materials. It is very important that each person engaged in the transportation of hazardous materials has the proper training and is thoroughly familiar with the Title 49CFR (Code of Federal Regulations) and/or USPS Publication 52. This guide is intended only to assist you in your preparation of hazardous materials shipped via FedEx Ground Package Systems Inc. It is the shipper’s responsibility to ensure each hazardous material package is in compliance with applicable Department of Transportation (D.O.T.) regulations and FedEx Ground Package Systems Inc. requirements. Failure to comply with these regulations and requirements may subject the shipper and carrier to fines and penalties. Improperly prepared hazmat packages or documentation may be subject to an additional charge(s) due to the unexpected hanlding associated with these shipments. Due to the changing nature of D.O.T. regulations and other information, it is impossible to guarantee absolute accuracy of the material contained in this guide. FedEx Ground Package Systems Inc., therefore, cannot assume any responsibility for omissions, errors, misprinting, or ambiguity contained within this guide and shall not be held liable in any degree for any loss or injury caused by such omission or error presented in this publication. Shippers should consult the most current version of the hazardous material regulations. Training is mandatory for those shipping hazardous materials, including limited quantity and other exceptions. The www.shipsafeshipsmart.com battery and hazmat training programs offer shippers an economical source of basic ground battery and/or hazardous materials shipping as well as addressing FedEx Ground specific issues. -

"Hydrocarbons," In: Ullmann's Encyclopedia of Industrial Chemistry

Article No : a13_227 Hydrocarbons KARL GRIESBAUM, Universit€at Karlsruhe (TH), Karlsruhe, Federal Republic of Germany ARNO BEHR, Henkel KGaA, Dusseldorf,€ Federal Republic of Germany DIETER BIEDENKAPP, BASF Aktiengesellschaft, Ludwigshafen, Federal Republic of Germany HEINZ-WERNER VOGES, Huls€ Aktiengesellschaft, Marl, Federal Republic of Germany DOROTHEA GARBE, Haarmann & Reimer GmbH, Holzminden, Federal Republic of Germany CHRISTIAN PAETZ, Bayer AG, Leverkusen, Federal Republic of Germany GERD COLLIN, Ruttgerswerke€ AG, Duisburg, Federal Republic of Germany DIETER MAYER, Hoechst Aktiengesellschaft, Frankfurt, Federal Republic of Germany HARTMUT Ho€KE, Ruttgerswerke€ AG, Castrop-Rauxel, Federal Republic of Germany 1. Saturated Hydrocarbons ............ 134 3.7. Cumene ......................... 163 1.1. Physical Properties ................ 134 3.8. Diisopropylbenzenes ............... 164 1.2. Chemical Properties ............... 134 3.9. Cymenes; C4- and C5-Alkylaromatic 1.3. Production ....................... 134 Compounds ...................... 165 1.3.1. From Natural Gas and Petroleum . .... 135 3.10. Monoalkylbenzenes with Alkyl Groups 1.3.2. From Coal and Coal-Derived Products . 138 >C10 ........................... 166 1.3.3. By Synthesis and by Conversion of other 3.11. Diphenylmethane .................. 167 Hydrocarbons . .................. 139 4. Biphenyls and Polyphenyls .......... 168 1.4. Uses ............................ 140 4.1. Biphenyl......................... 168 1.5. Individual Saturated Hydrocarbons ... 142 4.2. Terphenyls...................... -

United States Patent 19 11 Patent Number: 6,156,692 Nubel Et Al

USOO6156692A United States Patent 19 11 Patent Number: 6,156,692 Nubel et al. (45) Date of Patent: *Dec. 5, 2000 54 RUTHENIUM-CONTAINING CATALYST WO 98/39346 9/1998 WIPO. COMPOSITION FOR OLEFIN METATHESIS OTHER PUBLICATIONS 75 Inventors: Philip O. Nubel; Craig Lane Hunt; C. Grunwald et al., Advance ACS Abstracts, vol. 4, No. 6, David S. Choi, all of Naperville; Tobin p. 140, Mar. 15, 1996. J. Marks, Evanston, all of Ill. Gruenwald, C., et al., “Five-Coordinate 16-Electron Car bene- and Vinylidenruthenium (II) Complexes Prepared 73 Assignee: BP Amoco Corporation, Chicago, Ill. from RuC12(C8H12)n or from the New Dihydridoruthe nium (IV) Compound RuH2C12(PiPr3)2]", Organometal * Notice: This patent is Subject to a terminal dis lics (1996), 15: 1960–1962. claimer. Demonceau, A., et al., Novel Ruthenium-Based Catalyst Systems for the Ring-Opening Metathesis Polymerization 21 Appl. No.: 08/842,251 of Low-Strain Cyclic Olefins, Macromolecules (1997), 30: 3127-3136. 22 Filed: Apr. 24, 1997 K.J. Ivin, “Summary of Catalyst Systems”, Olefin Metathe Related U.S. Application Data sis, Academic Press, New York, 1983, p. 34. 60 Provisional application No. 60/016,554, Apr. 30, 1996, and Porri, L., et al., “Ring-Opening Polymerizataion of provisional application No. 60/033,257, Dec. 6, 1996. Cycloolefins with Catalysts Derived from Ruthenium and Iridium', Die Makromolekulare Chemie, 1974, 175: (51) Int. Cl. ................................................ B01J 31/00 3097-31.15. 52 U.S. C. ... ... 502/155; 502/150, 502/152; Demonceau, A., et al., “Ruthenium-catalysed ring-opening 502/158; 502/169; 502/162 metathesis polymerization of cycloolefins initiated by dia 58 Field of Search .................................... -

Chemical Substances in Lattice Semiconductor Products

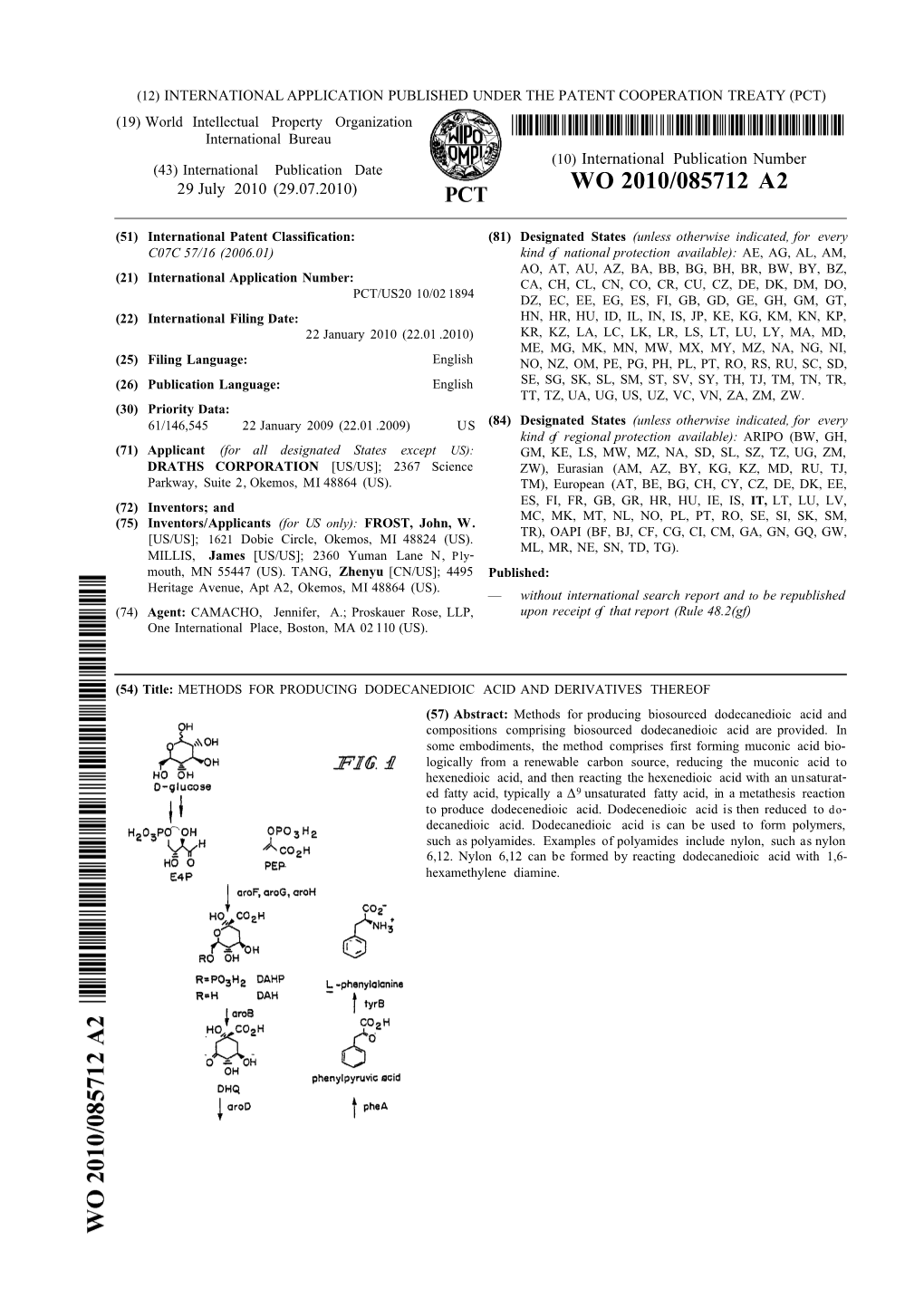

July 8, 2021 Frequently Requested Information Regarding Chemical Substances in Lattice Semiconductor Products Lattice Semiconductor is fully committed to providing environmentally friendly processes, products, and shipping packages that meet our corporate commitment to protect the natural environment. Lattice has been actively tracking and is fully supportive of the various industry efforts throughout the world to phase out the use of undesirable substances from electronic equipment, materials, and manufacturing processes. Lattice Semiconductor Corporation represents that the substances listed below are not intentionally or willfully added to Lattice’s plastic device packages or used in the manufacturing process, excluding trace impurities (see the referenced tables for more detailed listings of certain categories of substances). PLEASE NOTE: This publication is supplemental to Lattice’s RoHS2 Compliance and REACH Compliance declaration letters; substances regulated under these two regulations are not listed in this document. [1,1'-Biphenyl]-4-ol, 3,5-bis(1,1-dimethylethyl)- 2668-47-5 1,2,4-Trichlorobenzene 120-82-1 1,2-Benzenedicarboxylicacid di(C8-10 branched alkyl ester, C9 rich) 68515-48-0 1,2-Dichloroethylene 156-59-2 1,2-Dichloropropane 78-87-5 1,2-Diisopropylnaphthalene 94133-79-6 1,2-Diphenylhydrazine 122-66-7 1,3-Butadiene 106-99-0 1,3-Dichloro-2-propanol 13674-87-8 1,3-Dichlorobenzene 541-73-1 1,3-Dichloroprop-1-ene 542-75-6 1,3-Dichloropropene 10061-02-6 1,3-Diisopropylnaphthalene 57122-16-4 1,4-dicyclohexylbenzene 1087-02-1