13 Drag Prediction

Total Page:16

File Type:pdf, Size:1020Kb

Load more

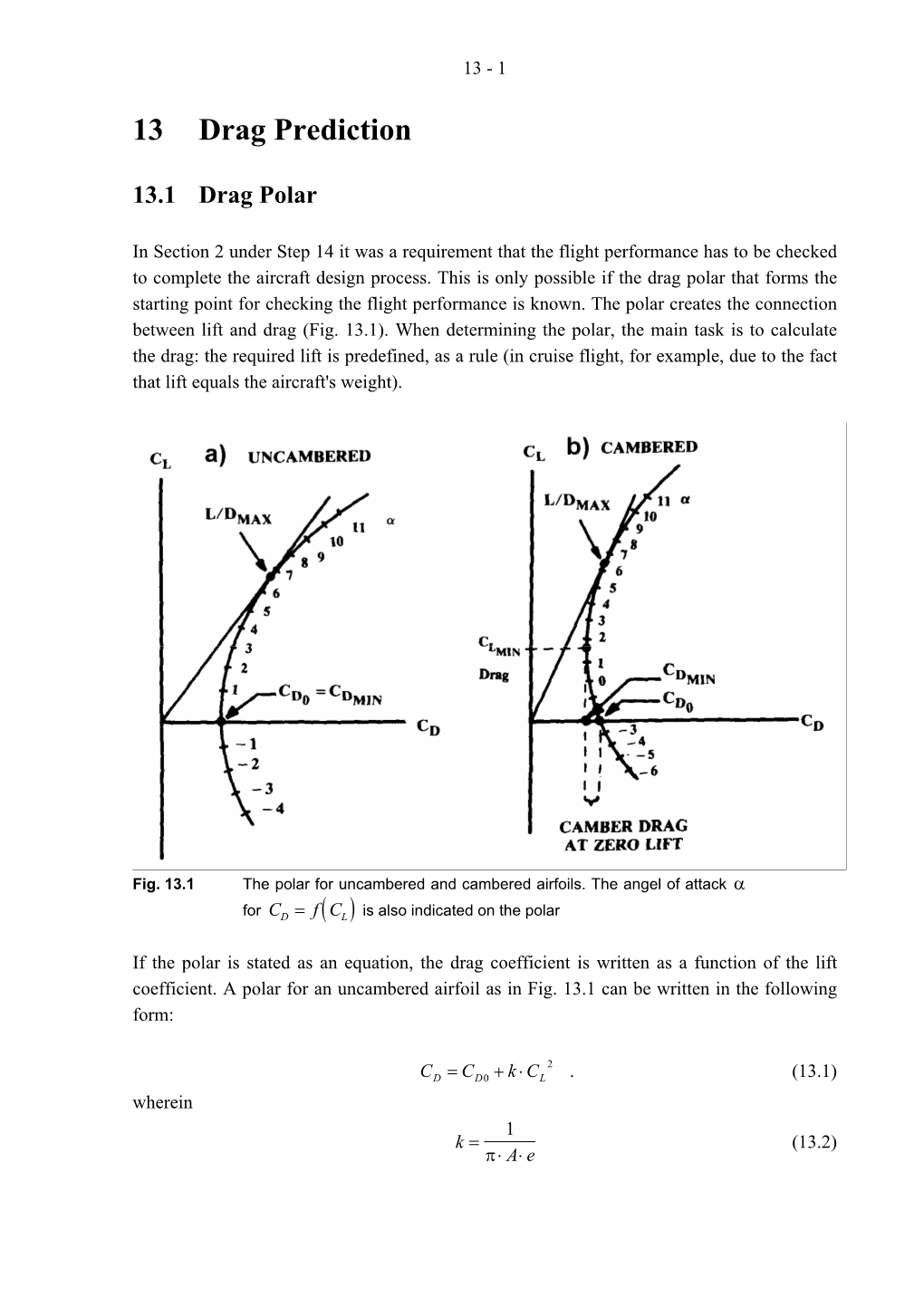

Recommended publications

-

Glossary Physics (I-Introduction)

1 Glossary Physics (I-introduction) - Efficiency: The percent of the work put into a machine that is converted into useful work output; = work done / energy used [-]. = eta In machines: The work output of any machine cannot exceed the work input (<=100%); in an ideal machine, where no energy is transformed into heat: work(input) = work(output), =100%. Energy: The property of a system that enables it to do work. Conservation o. E.: Energy cannot be created or destroyed; it may be transformed from one form into another, but the total amount of energy never changes. Equilibrium: The state of an object when not acted upon by a net force or net torque; an object in equilibrium may be at rest or moving at uniform velocity - not accelerating. Mechanical E.: The state of an object or system of objects for which any impressed forces cancels to zero and no acceleration occurs. Dynamic E.: Object is moving without experiencing acceleration. Static E.: Object is at rest.F Force: The influence that can cause an object to be accelerated or retarded; is always in the direction of the net force, hence a vector quantity; the four elementary forces are: Electromagnetic F.: Is an attraction or repulsion G, gravit. const.6.672E-11[Nm2/kg2] between electric charges: d, distance [m] 2 2 2 2 F = 1/(40) (q1q2/d ) [(CC/m )(Nm /C )] = [N] m,M, mass [kg] Gravitational F.: Is a mutual attraction between all masses: q, charge [As] [C] 2 2 2 2 F = GmM/d [Nm /kg kg 1/m ] = [N] 0, dielectric constant Strong F.: (nuclear force) Acts within the nuclei of atoms: 8.854E-12 [C2/Nm2] [F/m] 2 2 2 2 2 F = 1/(40) (e /d ) [(CC/m )(Nm /C )] = [N] , 3.14 [-] Weak F.: Manifests itself in special reactions among elementary e, 1.60210 E-19 [As] [C] particles, such as the reaction that occur in radioactive decay. -

Drag Force Calculation

DRAG FORCE CALCULATION “Drag is the component of force on a body acting parallel to the direction of relative motion.” [1] This can occur between two differing fluids or between a fluid and a solid. In this lab, the drag force will be explored between a fluid, air, and a solid shape. Drag force is a function of shape geometry, velocity of the moving fluid over a stationary shape, and the fluid properties density and viscosity. It can be calculated using the following equation, ퟏ 푭 = 흆푨푪 푽ퟐ 푫 ퟐ 푫 Equation 1: Drag force equation using total profile where ρ is density determined from Table A.9 or A.10 in your textbook A is the frontal area of the submerged object CD is the drag coefficient determined from Table 1 V is the free-stream velocity measured during the lab Table 1: Known drag coefficients for various shapes Body Status Shape CD Square Rod Sharp Corner 2.2 Circular Rod 0.3 Concave Face 1.2 Semicircular Rod Flat Face 1.7 The drag force of an object can also be calculated by applying the conservation of momentum equation for your stationary object. 휕 퐹⃗ = ∫ 푉⃗⃗ 휌푑∀ + ∫ 푉⃗⃗휌푉⃗⃗ ∙ 푑퐴⃗ 휕푡 퐶푉 퐶푆 Assuming steady flow, the equation reduces to 퐹⃗ = ∫ 푉⃗⃗휌푉⃗⃗ ∙ 푑퐴⃗ 퐶푆 The following frontal view of the duct is shown below. Integrating the velocity profile after the shape will allow calculation of drag force per unit span. Figure 1: Velocity profile after an inserted shape. Combining the previous equation with Figure 1, the following equation is obtained: 푊 퐷푓 = ∫ 휌푈푖(푈∞ − 푈푖)퐿푑푦 0 Simplifying the equation, you get: 20 퐷푓 = 휌퐿 ∑ 푈푖(푈∞ − 푈푖)훥푦 푖=1 Equation 2: Drag force equation using wake profile The pressure measurements can be converted into velocity using the Bernoulli’s equation as follows: 2Δ푃푖 푈푖 = √ 휌퐴푖푟 Be sure to remember that the manometers used are in W.C. -

Chapter 4: Immersed Body Flow [Pp

MECH 3492 Fluid Mechanics and Applications Univ. of Manitoba Fall Term, 2017 Chapter 4: Immersed Body Flow [pp. 445-459 (8e), or 374-386 (9e)] Dr. Bing-Chen Wang Dept. of Mechanical Engineering Univ. of Manitoba, Winnipeg, MB, R3T 5V6 When a viscous fluid flow passes a solid body (fully-immersed in the fluid), the body experiences a net force, F, which can be decomposed into two components: a drag force F , which is parallel to the flow direction, and • D a lift force F , which is perpendicular to the flow direction. • L The drag coefficient CD and lift coefficient CL are defined as follows: FD FL CD = 1 2 and CL = 1 2 , (112) 2 ρU A 2 ρU Ap respectively. Here, U is the free-stream velocity, A is the “wetted area” (total surface area in contact with fluid), and Ap is the “planform area” (maximum projected area of an object such as a wing). In the remainder of this section, we focus our attention on the drag forces. As discussed previously, there are two types of drag forces acting on a solid body immersed in a viscous flow: friction drag (also called “viscous drag”), due to the wall friction shear stress exerted on the • surface of a solid body; pressure drag (also called “form drag”), due to the difference in the pressure exerted on the front • and rear surfaces of a solid body. The friction drag and pressure drag on a finite immersed body are defined as FD,vis = τwdA and FD, pres = pdA , (113) ZA ZA Streamwise component respectively. -

Aerodynamics Material - Taylor & Francis

CopyrightAerodynamics material - Taylor & Francis ______________________________________________________________________ 257 Aerodynamics Symbol List Symbol Definition Units a speed of sound ⁄ a speed of sound at sea level ⁄ A area aspect ratio ‐‐‐‐‐‐‐‐ b wing span c chord length c Copyrightmean aerodynamic material chord- Taylor & Francis specific heat at constant pressure of air · root chord tip chord specific heat at constant volume of air · / quarter chord total drag coefficient ‐‐‐‐‐‐‐‐ , induced drag coefficient ‐‐‐‐‐‐‐‐ , parasite drag coefficient ‐‐‐‐‐‐‐‐ , wave drag coefficient ‐‐‐‐‐‐‐‐ local skin friction coefficient ‐‐‐‐‐‐‐‐ lift coefficient ‐‐‐‐‐‐‐‐ , compressible lift coefficient ‐‐‐‐‐‐‐‐ compressible moment ‐‐‐‐‐‐‐‐ , coefficient , pitching moment coefficient ‐‐‐‐‐‐‐‐ , rolling moment coefficient ‐‐‐‐‐‐‐‐ , yawing moment coefficient ‐‐‐‐‐‐‐‐ ______________________________________________________________________ 258 Aerodynamics Aerodynamics Symbol List (cont.) Symbol Definition Units pressure coefficient ‐‐‐‐‐‐‐‐ compressible pressure ‐‐‐‐‐‐‐‐ , coefficient , critical pressure coefficient ‐‐‐‐‐‐‐‐ , supersonic pressure coefficient ‐‐‐‐‐‐‐‐ D total drag induced drag Copyright material - Taylor & Francis parasite drag e span efficiency factor ‐‐‐‐‐‐‐‐ L lift pitching moment · rolling moment · yawing moment · M mach number ‐‐‐‐‐‐‐‐ critical mach number ‐‐‐‐‐‐‐‐ free stream mach number ‐‐‐‐‐‐‐‐ P static pressure ⁄ total pressure ⁄ free stream pressure ⁄ q dynamic pressure ⁄ R -

Electrically Heated Composite Leading Edges for Aircraft Anti-Icing Applications”

UNIVERSITY OF NAPLES “FEDERICO II” PhD course in Aerospace, Naval and Quality Engineering PhD Thesis in Aerospace Engineering “ELECTRICALLY HEATED COMPOSITE LEADING EDGES FOR AIRCRAFT ANTI-ICING APPLICATIONS” by Francesco De Rosa 2010 To my girlfriend Tiziana for her patience and understanding precious and rare human virtues University of Naples Federico II Department of Aerospace Engineering DIAS PhD Thesis in Aerospace Engineering Author: F. De Rosa Tutor: Prof. G.P. Russo PhD course in Aerospace, Naval and Quality Engineering XXIII PhD course in Aerospace Engineering, 2008-2010 PhD course coordinator: Prof. A. Moccia ___________________________________________________________________________ Francesco De Rosa - Electrically Heated Composite Leading Edges for Aircraft Anti-Icing Applications 2 Abstract An investigation was conducted in the Aerospace Engineering Department (DIAS) at Federico II University of Naples aiming to evaluate the feasibility and the performance of an electrically heated composite leading edge for anti-icing and de-icing applications. A 283 [mm] chord NACA0012 airfoil prototype was designed, manufactured and equipped with an High Temperature composite leading edge with embedded Ni-Cr heating element. The heating element was fed by a DC power supply unit and the average power densities supplied to the leading edge were ranging 1.0 to 30.0 [kW m-2]. The present investigation focused on thermal tests experimentally performed under fixed icing conditions with zero AOA, Mach=0.2, total temperature of -20 [°C], liquid water content LWC=0.6 [g m-3] and average mean volume droplet diameter MVD=35 [µm]. These fixed conditions represented the top icing performance of the Icing Flow Facility (IFF) available at DIAS and therefore it has represented the “sizing design case” for the tested prototype. -

Fly-By-Wire - Wikipedia, the Free Encyclopedia 11-8-20 下午5:33 Fly-By-Wire from Wikipedia, the Free Encyclopedia

Fly-by-wire - Wikipedia, the free encyclopedia 11-8-20 下午5:33 Fly-by-wire From Wikipedia, the free encyclopedia Fly-by-wire (FBW) is a system that replaces the Fly-by-wire conventional manual flight controls of an aircraft with an electronic interface. The movements of flight controls are converted to electronic signals transmitted by wires (hence the fly-by-wire term), and flight control computers determine how to move the actuators at each control surface to provide the ordered response. The fly-by-wire system also allows automatic signals sent by the aircraft's computers to perform functions without the pilot's input, as in systems that automatically help stabilize the aircraft.[1] Contents Green colored flight control wiring of a test aircraft 1 Development 1.1 Basic operation 1.1.1 Command 1.1.2 Automatic Stability Systems 1.2 Safety and redundancy 1.3 Weight saving 1.4 History 2 Analog systems 3 Digital systems 3.1 Applications 3.2 Legislation 3.3 Redundancy 3.4 Airbus/Boeing 4 Engine digital control 5 Further developments 5.1 Fly-by-optics 5.2 Power-by-wire 5.3 Fly-by-wireless 5.4 Intelligent Flight Control System 6 See also 7 References 8 External links Development http://en.wikipedia.org/wiki/Fly-by-wire Page 1 of 9 Fly-by-wire - Wikipedia, the free encyclopedia 11-8-20 下午5:33 Mechanical and hydro-mechanical flight control systems are relatively heavy and require careful routing of flight control cables through the aircraft by systems of pulleys, cranks, tension cables and hydraulic pipes. -

Aircraft Winglet Design

DEGREE PROJECT IN VEHICLE ENGINEERING, SECOND CYCLE, 15 CREDITS STOCKHOLM, SWEDEN 2020 Aircraft Winglet Design Increasing the aerodynamic efficiency of a wing HANLIN GONGZHANG ERIC AXTELIUS KTH ROYAL INSTITUTE OF TECHNOLOGY SCHOOL OF ENGINEERING SCIENCES 1 Abstract Aerodynamic drag can be decreased with respect to a wing’s geometry, and wingtip devices, so called winglets, play a vital role in wing design. The focus has been laid on studying the lift and drag forces generated by merging various winglet designs with a constrained aircraft wing. By using computational fluid dynamic (CFD) simulations alongside wind tunnel testing of scaled down 3D-printed models, one can evaluate such forces and determine each respective winglet’s contribution to the total lift and drag forces of the wing. At last, the efficiency of the wing was furtherly determined by evaluating its lift-to-drag ratios with the obtained lift and drag forces. The result from this study showed that the overall efficiency of the wing varied depending on the winglet design, with some designs noticeable more efficient than others according to the CFD-simulations. The shark fin-alike winglet was overall the most efficient design, followed shortly by the famous blended design found in many mid-sized airliners. The worst performing designs were surprisingly the fenced and spiroid designs, which had efficiencies on par with the wing without winglet. 2 Content Abstract 2 Introduction 4 Background 4 1.2 Purpose and structure of the thesis 4 1.3 Literature review 4 Method 9 2.1 Modelling -

Effects of Aircraft Integration on Compact Nacelle Aerodynamics

Eects of Aircraft Integration on Compact Nacelle Aerodynamics Fernando Tejeroa,∗, Ioannis Goulosa, David G MacManusa, Christopher Sheafb aCentre for Propulsion Engineering, School of Aerospace, Transport and Manufacturing, Craneld University, Bedfordshire, MK43 0AL bRolls-Royce plc., P.O. box 31, Derby, United Kingdom, DE24 8BJ Abstract To reduce specic fuel consumption, it is expected that the next generation of aero-engines will operate with higher bypass-ratios, and therefore fan diame- ters, than current in-service architectures. These new propulsion systems will increase the nacelle size and incur in an additional overall weight and drag con- tribution to the aircraft. In addition, they will be installed more closely-coupled with the airframe, which may lead to an increase in adverse installation eects. As such, it is required to develop compact nacelles which will not counteract the benets obtained from the new engine cycles. A comprehensive investigation of the eects of nacelle design on the overall aircraft aerodynamic performance is required for a better understanding on the eects of aero-engine integration. This paper presents a method for the multi-objective optimisation of drooped and scarfed non-axisymmetric nacelle aero-engines. It uses intuitive Class Shape Tranformations (iCSTs) for the aero-engine geometry denition, multi-point aerodynamic simulation, a near-eld nacelle drag extraction method and the NSGA-II genetic algorithm. The process has been employed for the aerody- namic optimisation of a compact nacelle aero-engine as well as a conventional nacelle conguration. Subsequently, the designed architectures were installed on a conventional commercial transport aircraft and evaluated at dierent in- stallation positions. -

UNIT – 4 FORCES on IMMERSED BODIES Lecture-01

1 UNIT – 4 FORCES ON IMMERSED BODIES Lecture-01 Forces on immersed bodies When a body is immersed in a real fluid, which is flowing at a uniform velocity U, the fluid will exert a force on the body. The total force (FR) can be resolved in two components: 1. Drag (FD): Component of the total force in the direction of motion of fluid. 2. Lift (FL): Component of the total force in the perpendicular direction of the motion of fluid. It occurs only when the axis of the body is inclined to the direction of fluid flow. If the axis of the body is parallel to the fluid flow, lift force will be zero. Expression for Drag & Lift Forces acting on the small elemental area dA are: i. Pressure force acting perpendicular to the surface i.e. p dA ii. Shear force acting along the tangential direction to the surface i.e. τ0dA (a) Drag force (FD) : Drag force on elemental area = p dAcosθ + τ0 dAcos(90 – θ = p dAosθ + τ0dAsinθ Hence Total drag (or profile drag) is given by, Where �� = ∫ � cos � �� + ∫�0 sin � �� = pressure drag or form drag, and ∫ � cos � �� = shear drag or friction drag or skin drag (b) Lift0 force (F ) : ∫ � sin � ��L Lift force on the elemental area = − p dAsinθ + τ0 dA sin(90 – θ = − p dAsiθ + τ0dAcosθ Hence, total lift is given by http://www.rgpvonline.com �� = ∫�0 cos � �� − ∫ p sin � �� 2 The drag & lift for a body moving in a fluid of density at a uniform velocity U are calculated mathematically as 2 � And �� = � � � 2 � Where A = projected area of the body or�� largest= � project� � area of the immersed body. -

Drag Bookkeeping

Drag Drag Bookkeeping Drag may be divided into components in several ways: To highlight the change in drag with lift: Drag = Zero-Lift Drag + Lift-Dependent Drag + Compressibility Drag To emphasize the physical origins of the drag components: Drag = Skin Friction Drag + Viscous Pressure Drag + Inviscid (Vortex) Drag + Wave Drag The latter decomposition is stressed in these notes. There is sometimes some confusion in the terminology since several effects contribute to each of these terms. The definitions used here are as follows: Compressibility drag is the increment in drag associated with increases in Mach number from some reference condition. Generally, the reference condition is taken to be M = 0.5 since the effects of compressibility are known to be small here at typical conditions. Thus, compressibility drag contains a component at zero-lift and a lift-dependent component but includes only the increments due to Mach number (CL and Re are assumed to be constant.) Zero-lift drag is the drag at M=0.5 and CL = 0. It consists of several components, discussed on the following pages. These include viscous skin friction, vortex drag due to twist, added drag due to fuselage upsweep, control surface gaps, nacelle base drag, and miscellaneous items. The Lift-Dependent drag, sometimes called induced drag, includes the usual lift- dependent vortex drag together with lift-dependent components of skin friction and pressure drag. For the second method: Skin Friction drag arises from the shearing stresses at the surface of a body due to viscosity. It accounts for most of the drag of a transport aircraft in cruise. -

Fluid Mechanics, Drag Reduction and Advanced Configuration Aeronautics

NASA/TM-2000-210646 Fluid Mechanics, Drag Reduction and Advanced Configuration Aeronautics Dennis M. Bushnell Langley Research Center, Hampton, Virginia December 2000 The NASA STI Program Office ... in Profile Since its founding, NASA has been dedicated to CONFERENCE PUBLICATION. Collected the advancement of aeronautics and space papers from scientific and technical science. The NASA Scientific and Technical conferences, symposia, seminars, or other Information (STI) Program Office plays a key meetings sponsored or co-sponsored by part in helping NASA maintain this important NASA. role. SPECIAL PUBLICATION. Scientific, The NASA STI Program Office is operated by technical, or historical information from Langley Research Center, the lead center for NASA programs, projects, and missions, NASA's scientific and technical information. The often concerned with subjects having NASA STI Program Office provides access to the substantial public interest. NASA STI Database, the largest collection of aeronautical and space science STI in the world. TECHNICAL TRANSLATION. English- The Program Office is also NASA's institutional language translations of foreign scientific mechanism for disseminating the results of its and technical material pertinent to NASA's research and development activities. These mission. results are published by NASA in the NASA STI Report Series, which includes the following Specialized services that complement the STI report types: Program Office's diverse offerings include creating custom thesauri, building customized TECHNICAL PUBLICATION. Reports of databases, organizing and publishing research completed research or a major significant results ... even providing videos. phase of research that present the results of NASA programs and include extensive For more information about the NASA STI data or theoretical analysis. -

IIIHIHIIIHIIII O US005143329A United States Patent (19) 11 Patent Number: 5,143,329 Coffinberry (45) Date of Patent: Sep

IIIHIHIIIHIIII O US005143329A United States Patent (19) 11 Patent Number: 5,143,329 Coffinberry (45) Date of Patent: Sep. 1, 1992 (54) GASTURBINE ENGINE POWERED AIRCRAFT ENVIRONMENTAL CONTROL FOREIGN PATENT DOCUMENTS SYSTEM AND BOUNDARY LAYER BLEED 0065855 5/1982 European Pat. Off. (75) Inventor: George A. Coffinberry, West Chester, g 32 E." Ohio 143598 4/1953 United Kingdom. (73) Assignee: General Electric Company, 744923 5/1954 United Kingdom. 774695 4/1955 United Kingdom . Cincinnati, Ohio 846358 6/1958 United Kingdom. 21 Appl. No.: 738,985 1530330 1/1976 United Kingdom . 202.7874 2/1980 United Kingdom ............. 24418.5 22 Filed: Aug. 1, 1991 2074654 4/1980 United Kingdom . 2076897 12/1981 United Kingdom ............. 244/118.5 Related U.S. Application Data 2127492 6/1983 United Kingdom . 62 Division of Ser. No. 531,718, Jun. 1, 1990. Primary Examiner-Joseph F. Peters, Jr. 5 Assistant Examiner-Christopher P. Ellis O2,207. Attorney, Agent, or Firm-Jerome C. Squillaro 244/53 R; 45.4/71 57 ABSTRACT 58) Field of Search ..................... 244/118.5, 207, 208, 244/209 53 R. 60/39. 142 39.07, 39.15, 39.183: An aircraft gas turbine engine is provided with a start s A 4-y 9. '987 ing air turbine that is directly connected through the starter gearbox to the high pressure (HP) shaft and is 56) References Cited provided with an apparatus to extract excess energy U.S. PATENT DOCUMENTS from engine compressor bleed air, return it to the en 2,734,443 2/1956 Wood ..................................... oss gine, and to start the engine with compressed air from 2,777,301 1/1957 Kuhn .....