Globe Valve Retrofit Solutions Technical Documentation

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Cutting up the Catwalk

University of South Carolina Scholar Commons October 2006 10-24-2006 The aiD ly Gamecock, Tuesday, October 24, 2006 University of South Carolina, Office oftude S nt Media Follow this and additional works at: https://scholarcommons.sc.edu/gamecock_2006_oct Recommended Citation University of South Carolina, Office of Student Media, "The aiD ly Gamecock, Tuesday, October 24, 2006" (2006). October. 15. https://scholarcommons.sc.edu/gamecock_2006_oct/15 This Newspaper is brought to you by the 2006 at Scholar Commons. It has been accepted for inclusion in October by an authorized administrator of Scholar Commons. For more information, please contact [email protected]. dailygamecock.com The University of South Carolina Tuesday, October 24, 2006 Vol. 100, No. 49 ● Since 1908 CEO VISITS Cutting up USC, GIVES WORDS OF the catwalk WISDOM Association of African American Students’ Alumnus makes return fashion show features Battle of the Fakes to campus as executive of Continental Airlines Leslie Bennett After a brief intermission, THE DAILY GAMECOCK the show continued with the Elements collection. Models Catherine Martin The Association of wore weather specific and THE DAILY GAMECOCK African American Students seasonal clothing. The ripped the runway in its clothes included trench Larry Kellner, a graduate annual fashion show. coats, umbrellas, fur coats, of USC and chief executive Models and performers and bikini tops. officer of Continental Airlines for Rip the Runway: Battle The final collection addressed business students of the Fakes Meets the was Got Rocks. Models Monday about his experiences Fashion Show took turns wore a variety of jewelry in the industry and making making appearances and and other accessories, Continental a competitive major strutting their stuff on the including sunglasses. -

Air New Zealand an Accident Waiting to Happen?

AIR NEW ZEALAND AN ACCIDENT WAITING TO HAPPEN? An Air New Zealand jumbo suffers a mid-air flight control fail- ure just past Los Angeles. Why then did the crew fly on to Lon- don in a plane that could have crashed? IAN WISHART breaks the story INVESTIGATE March 2001, 23 If you want to get a spectators perspective on the board were nearly 300 people apparently blissfully un- deaths of nearly 300 men, women and children, it would aware of their impending doom less than half a second be hard to go past the official investigation report into the away. Like all air passengers, they had implicit faith in crash of a Korean jumbo jet on the Pacific island of Guam their pilots. three years ago. It makes chilling reading: The report continues: A hunter and his friend were hunting on Nimitz Hill It appeared as though the plane did not hit the ground during the night of August 6, 1997. The hunter said he until very near where it came to rest. The hunter said he heard the airplane first before he saw it. It was extremely was standing approximately 200 feet from where the air- loud and was so close it caused the ground to vibrate. plane came to rest. He said the noise, ground vibration He said the noise was so loud he could not hear him- and shock of the closeness of the plane caused him and self screaming at his friend. He said the airplane passed his friend to almost return to caveman days. -

Do You Want to Be an FAA Safety Inspector?

Do You Want to be an FAA Safety Inspector? The U.S. Federal Aviation Admini- spectors that were available during stration (FAA) finally has convinced the early years of former U.S. Presi- the U.S. Congress that there is a dent Ronald Reagan. need for additional experienced avia- tion safety inspectors (maintenance) A related congressional concern is in the FAA field offices to closely compliance with safe maintenance monitor maintenance concerns of both practices by the air carriers and fixed aging and newer aircraft (see “Air- base operators which also is an as- craft Aging is a Growing Mainte- pect of safety that can be monitored nance Concern,” March/April Avia- by alert and qualified maintenance tion Mechanics Bulletin). This ac- inspectors. tion is in response to the strong con- cerns expressed by the public and Recognition of the critical role of the media related to the safety of the safety inspector as a key ele- public transport aircraft after recent ment in the safety of air travel brings incidents of apparent structural fail- along with it a heavy responsibility ures caused by corrosion and metal to those who follow this career path. fatigue. The newly hired aviation safety in- spector faces the need to learn quickly The FAA intends to hire some 900 and “get up to speed” with the re- field inspectors. Although all of quirements of expanding traffic and this number cannot be funded at once, technology. He or she must be pre- an official noted that the current pared to face the fact that the newly hiring program will help assure that hired inspector may be regarded as proper maintenance standards are not possessing adequate experience maintained in the air transport in- in established aviation maintenance dustry. -

Mcneilus Front-Loader Manual

OPERATOR’S MANUAL Contender Front Loader Publication No. 1474268 © 2013 McNeilus Truck and Manufacturing, Inc. Rev. 0918 Disclaimer: This manual must not be used to repair your vehicle. Repair information is available by calling McNeilus Customer Service at (888) 686-7278. The information in this Operator’s Manual will be your guide to operation and operator maintenance for this equipment. All information, illustrations, and specifications in this manual are based on the information available at the time this manual was published. The illustrations used in this manual are intended as representative reference views only. Because of our continuous product improvement policy, we may modify information, illustrations, and/or specifications to explain and/or exemplify a product, service, or maintenance improvement. We reserve the right to make any change at any time without notice. Go to www.streetsmartparts.com for current information. No part of this publication may be reproduced by any means - graphic, electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval systems for any use or purpose - without the written permission of McNeilus Truck and Manufacturing, Inc. For assistance in ordering the Waste Collection For assistance in ordering OSHA Publications, contact: Vehicle Safety Guide, contact: U.S. Department of Labor/OSHA National Waste and Recycling Association OSHA Publications 1550 Crystal Drive • Suite 804 P.O. Box 37535 Arlington, VA 22202 Washington, D.C. 20210 Telephone: 800-424-2869 • Fax: 202-966-4824 Telephone: 202-693-1888 • Fax: 202-693-2498 Contender Front Loader © 2013 McNeilus Truck and Manufacturing, Inc. Foreword 1.0 Identification Plate A McNeilus Truck and Manufacturing, Inc. -

1977 Transmode W403 Engine Owner's Operating Manual

X-7780B 1977 TRANSMODE OPERATIN G MANUAL (WITH 403 CUBIC INCH ENGINE ) IMPORTANT OPERATING, SAFETY AND MAINTENANCE INSTRUCTION S GMC GM Part No . 2024791 "T f A WORD TO GMC OWNERS . This manual has been prepared to acquaint you with the operation an d maintenance of only the chassis and body components of your TransMod e Vehicle, and to provide important safety information . It is supplemented b y two convenient folders which provide additional information on vehicle maintenanc e and warranties . We urge you to read these publications carefully and follow th e recommendations to help assure the most enjoyable and trouble free operation of your vehicle. When it comes to service, remember that your GMC Motorhome dealer knows your chassis and body components best and is interested in you r complete satisfaction . Return to him for Guardian Maintenance Service an d any other assistance you may require. GMC Truck and Coach maintains a number of Zone Offices throughout th e country. Should you have a problem that cannot be handled through norma l channels, follow the procedure presented in Section 6 of this manual under the heading, "Owner Assistance". We would like to take this opportunity to thank you for choosing a GM C product—and assure you of our continuing interest in your motoring pleasur e and satisfaction. GMC Truck & Coach Divisio n FOR CONTINUING SATISFACTION KEEP YOUR VEHICL E ALL GM. GENERAL MOTORS PARTS ARE IDENTIFIED B Y GM ONE OF THESE TRADEMARKS : Delco GMC TRANSMODE VEHICL E Operating Manual This manual should be considered a permanent part of the vehicle, an d must remain with the vehicle at time of resale . -

The International Comanche Society

MAY 2007 VOLUME 34, NO. 5 The Official Membership Publication of The International Comanche Society The Comanche Flyer is the official monthly member publication of the International Comanche Society P.O. Box 1810 Volume 34, No. 5 • May 2007 Traverse City, MI 49685-1810 U.S.: 888-300-0082 www.comancheflyer.com Other: 231-946-3712 Fax: 231-946-6180 Published By the International Comanche Society, Inc. Email: [email protected] www.comancheflyer.com CONTENTS ICS President 2 Letter from the President Lawrence Paratz Lawrence Paratz Tel: + 61-3-9817-1222 Cover Story: Comanche Spirit E-mail: [email protected] 4 N8062Y is a Work Horse/Time Machine Bruce Brandon Managing Editor Kim Blonigen 6 Nominating Committee Report E-mail: [email protected] ICS Board of Directors & Tribe Chiefs Display Advertising Manager 7 John Shoemaker 2006-2007 ICS Standing Committees, (800) 773-7798 Tool Loan Program, and Technical Directors Fax: (231) 946-9588 E-mail: [email protected] 9 CFF-Approved CFIs Trading Post & Classified Advertising Nancy A. Whitten Technically Speaking (800) 773-7798 10 Online Intelligence — Fax: (231) 946-9588 E-mail: [email protected] Nose Wheel Taxi Lights Graphic Design The Best of the Flyer Koren Herriman E-mail: [email protected] 14 Emergency Gear Extention, How to: Mike Dolin Printer Tribe News Village Press 2779 Aero Park Drive 20 What’s Happening with Keith Johnson Traverse City, MI 49685-0629 the Northeast Tribe — www.villagepress.com Dealing with Weather: ICS Technical Directors A Trip from my Logbook Bill Creech Tel: (915) 581-3401 (9:00 a.m.-9:00 p.m. -

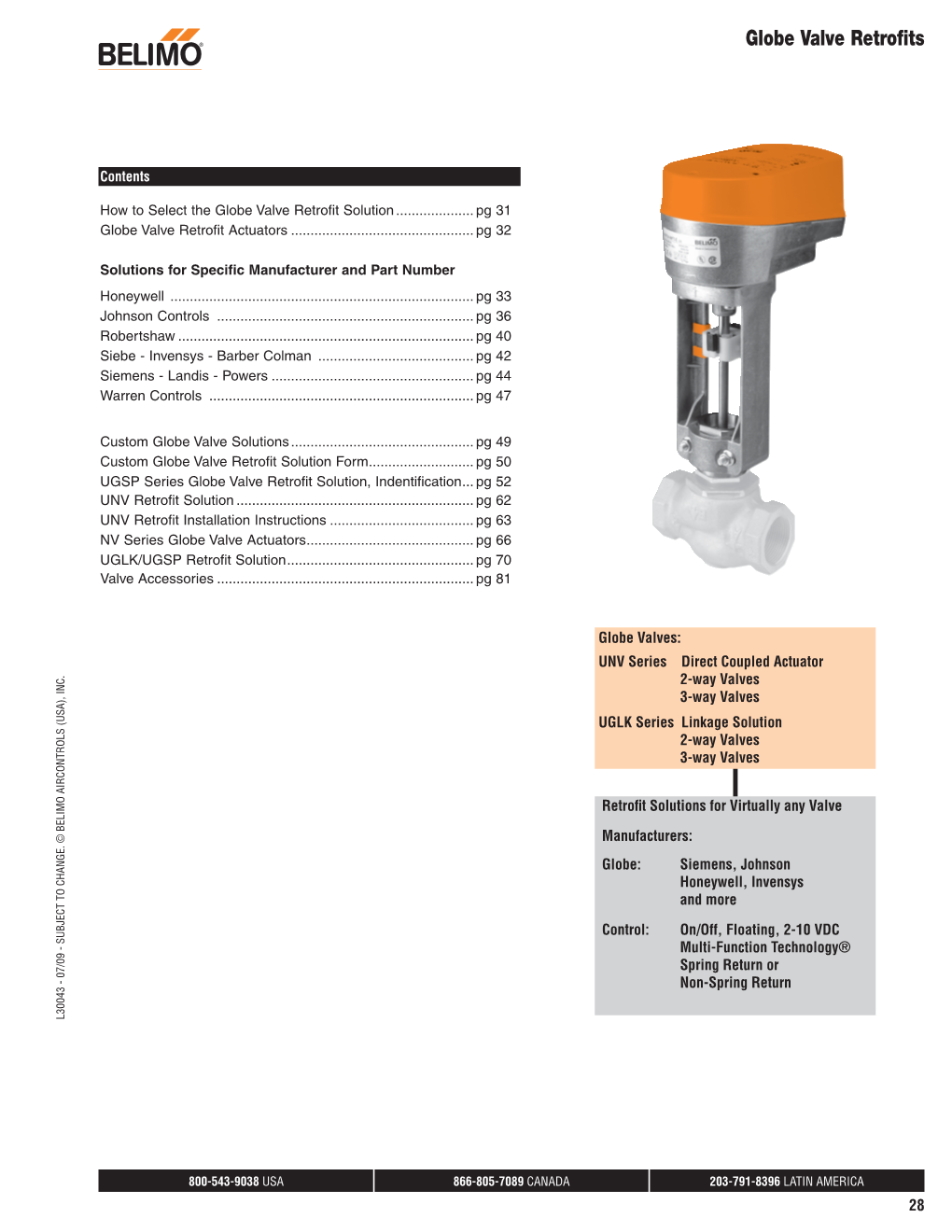

Retrofit Solutions Technical Documentation

® Retrofit Solutions Technical Documentation Effective July 2009 Belimo Project: New York Times Building, New York Times Belimo Project: New York Why Retrofi tting Makes Sense Valves and actuators are responsible for ensuring reliable functioning hydronic and air control HVAC systems all over the world. With innovative technology, verified quality and easy handling during installations and operation, they boost the performance and efficiency of integrated building technology. Are you in need of a solution for a broken linkage, leaky hydraulic actuator, non-functioning electric or pneumatic actuator? Do you have a need for replacing a non-functioning application within a day or so? Belimo provides airside and waterside retrofit application solutions, with direct coupled or remote access linkages, and efficient actuators. Damaged linkages and/or actuators resulting in non-functioning HVAC system applications, used to mean a loss of properly functioning systems leading to a degradation of energy efficiency, consumer comfort, time, and labor. Replacing a valve along with the actuator, or trying to determine how to fix an airside linkage, is not always a sensible solution. Taking a system off-line to replace various components is not only laborious, it’s expensive. Facilities can lose thousands of dollars a day during maintenance shut-down. With retrofit solutions, this problem simply goes away. Valves and Damper applications can be quickly and conveniently restored without any interruption in service. In fact, entire systems can often be updated in a day. A poorly functioning or even non-functioning system can be transformed into a high functioning, more efficient system. Belimo provides many retrofits that are compatible with all major control systems, so there is no need to replace other system controls. -

Negligence in the Operation of Business Aircraft

Western Michigan University ScholarWorks at WMU Master's Theses Graduate College 6-1965 Negligence in the Operation of Business Aircraft Daniel J. Garber Follow this and additional works at: https://scholarworks.wmich.edu/masters_theses Part of the Business Administration, Management, and Operations Commons Recommended Citation Garber, Daniel J., "Negligence in the Operation of Business Aircraft" (1965). Master's Theses. 4041. https://scholarworks.wmich.edu/masters_theses/4041 This Masters Thesis-Open Access is brought to you for free and open access by the Graduate College at ScholarWorks at WMU. It has been accepted for inclusion in Master's Theses by an authorized administrator of ScholarWorks at WMU. For more information, please contact [email protected]. NEGLIGENCE IN THE OPERATION OF BUSINESS AIRCRAF1/ by Daniel J. Garber A Thesis submitted to the Faculty of the School of Graduate Studies in partial fulfillment of the Degree of Master of Business Administration Western Michigan University Kalamazoo, Michigan June 1965 ACKNCMLEDGEMENT My many thanks to Arnold E. Schneider, Dean of the School of Business Administration, Western Michigan Uni versity, for his very helpful suggestions in preparing and writing this dissertation. Daniel J. Garber TABLE OF CONTENTS CHAPTER PAGE INTRODUCTION ••••. 1 Basis for Business Aircraft . 1 Legal Liability • e e e e • • 0 • 0 0 2 Location of Narrative e O • • e • 0 e 3 Liability Insurance • • • • • • • • • 4 Application for This Treatise • • • • 5 I PRE-FLIGHT OPERATIONS e O e • e e e • 0 6 Duty of Company Imposed by Law . 0 • • 6 Negligence Defined o • • • • • • • 0 7 Respondeat Superior 0 e e • e e e e 0 8 Federal Aviation Act . -

2003 Proceedings.Pdf

PROCEEDINGS of the American Academy of Forensic Sciences February 2003 Volume IX Contents Financial Disclosure Index ...........................................................1 Special Sessions ............................................................................4 Breakfast Seminars .......................................................................9 Academy-Wide Luncheons.........................................................12 Workshops & Workshorts ...........................................................13 Scientific Sessions Criminalistics.........................................................................23 Engineering Sciences.............................................................95 General.................................................................................122 Jurisprudence .......................................................................147 Odontology ..........................................................................159 Pathology/Biology ...............................................................187 Physical Anthropology ........................................................239 Psychiatry & Behavioral Science ........................................282 Questioned Documents........................................................294 Toxicology ...........................................................................300 Last Word.............................................................................324 Presenting Author Index ...........................................................327 -

Flight Safety Digest August 1988

Who Is Flying The Aircraft? Captains decided to put first officers at the controls during severe weather in several air carrier accidents. The author takes a thought-provoking look at that practice. by John A. Pope From January 1983 to June 1987 the U.S. National Trans- currences but less serious than accidents. While the NASA portation Safety Board (NTSB) aviation accident data sys- report says there are no quantitative data, it makes the suppo- tem reports 30 airline accidents/incidents in which the first sition that first officers are performing flying duties at least officer was the pilot flying the aircraft. 40 percent to 45 percent of the time on scheduled airline flights. Three accidents resulted in fatalities: DC-8, three fatalities, Detroit, Michigan, November 1983; DC-9, one fatality, Flying and non-flying duties may be exchanged, but U.S. two minor injuries, Sioux Falls, South Dakota, December Federal Aviation Regulation 91.3 (a) is explicit in defining 1983; and L-1011, 135 fatalities, multiple severe and minor captain or pilot-in-command responsibility. “The pilot-in- injuries, Dallas/Ft. Worth, Texas, August 1985. There were command,” the FAR says, “is directly responsible for and is nine accidents where severe or minor injuries occurred with- the final authority as to the operation of the aircraft.” out any fatalities. That responsibility cannot be transferred. It requires, among Three accidents that do not appear in the NTSB summary other implied duties, compliance with U.S. Federal Aviation should be included because -

X7321C | 1974 Owner's Operating Manual

ord To The G MC Motor Home Owne Congratulations on vour purchase of a GM f ' Motor Home )'()it have opened the way to an endless variety of happy We have prepared this manual to assist you in properly operating and maintaining your Motor Home, and to provide important safety i n formation . We urge you to read this manual carefully andfollow the recommendations contained to help assure the most enjoyable and trouble-free operation o f your vehicle . In the" Warranties" section of this manual you will find the New Vehicle Warranty and the Emission Control . ystems War-rants. When it comes to service, remember that your GM C Motor Ilome Service Outlet knows your vehicle best and is interested in your complete satisfaction. Return to him for service road any other assistance you may require . GM C Truck and Coach maintains a number of "bone Offices throughout the country . Should you have a problem that cannot be handled through normal channels, please fol low the procedure described under the "Owner Assistance" section . Thank you for choosing a GMC Motor Home. We extend our best wishes for many years ofplea ant traveling. Cordially, R . C. Stelter General Sales Manager GMC MOTOR HOME OPERATING MANUAL IMPORTANT This manual should be considered a permanent part of the vehicle and must remain with the vehicle at time of re-sale. All information, illustrations and specifications contained in this manual are based on the latest product information available at the time of pub- lication. The right is reserved to make changes at any time without notice . -

X7680B | 1976 Transmode Owner's Operating Manual

4-1- '&3 Tk, r2 ,s : w A ► G tvv ~'c ry t r c'-_ X-76808 GMC 1976 TRANSMOD E OPERATING MANUA L EFFECTIVE WITH VEHICLE IDENTIFICATION NUMBER TZE336V100880 (23' ) TZE366V100883 (26' ) IMPORTANT' OPERATING, SAFETY AND MAINTENANCE INSTRUCTION S GMC GM Part No . 2010488 A WORD TO GMC OWNERS . This manual has been prepared to acquaint you with the operation an d maintenance of only the chassis and body components of your TransMod e Vehicle, and to provide important safety information . It is supplemented b y convenient folders which provide additional information on vehicl e maintenance, emission control, and warranties. We urge you to read thes e publications carefully and follow the recommendations to help assure the most enjoyable and troublefree operation of your vehicle . When it comes to service, remember that your GMC MotorHome deale r knows your chassis and body components best and is interested in you r complete satisfaction. Return to him for Guardian Maintenance Service an d any other assistance you may require . GMC Truck and Coach maintains a number of Zone Offices throughout th e country . Should you have a problem that cannot be handled through normal channels, follow the procedure presented in Section 6 of this manual under the heading, "Owner Assistance" . We would like to take this opportunity to thank you for choosing a GM C product—and assure you of our continuing interest in your motoring pleasure and satisfaction . GMC Truck & Coach Division FOR CONTINUING SATISFACTION, KEEP YOUR VEHICL E ALL GM . GENERAL MOTORS PARTS ARE IDENTIFIED B Y GM ONE OF THESE TRADEMARKS : GMC TRANSMODE VEHICL E Operating Manual This manual should be considered a permanent part of the vehicle, and must remain with the vehicle at time of resale .