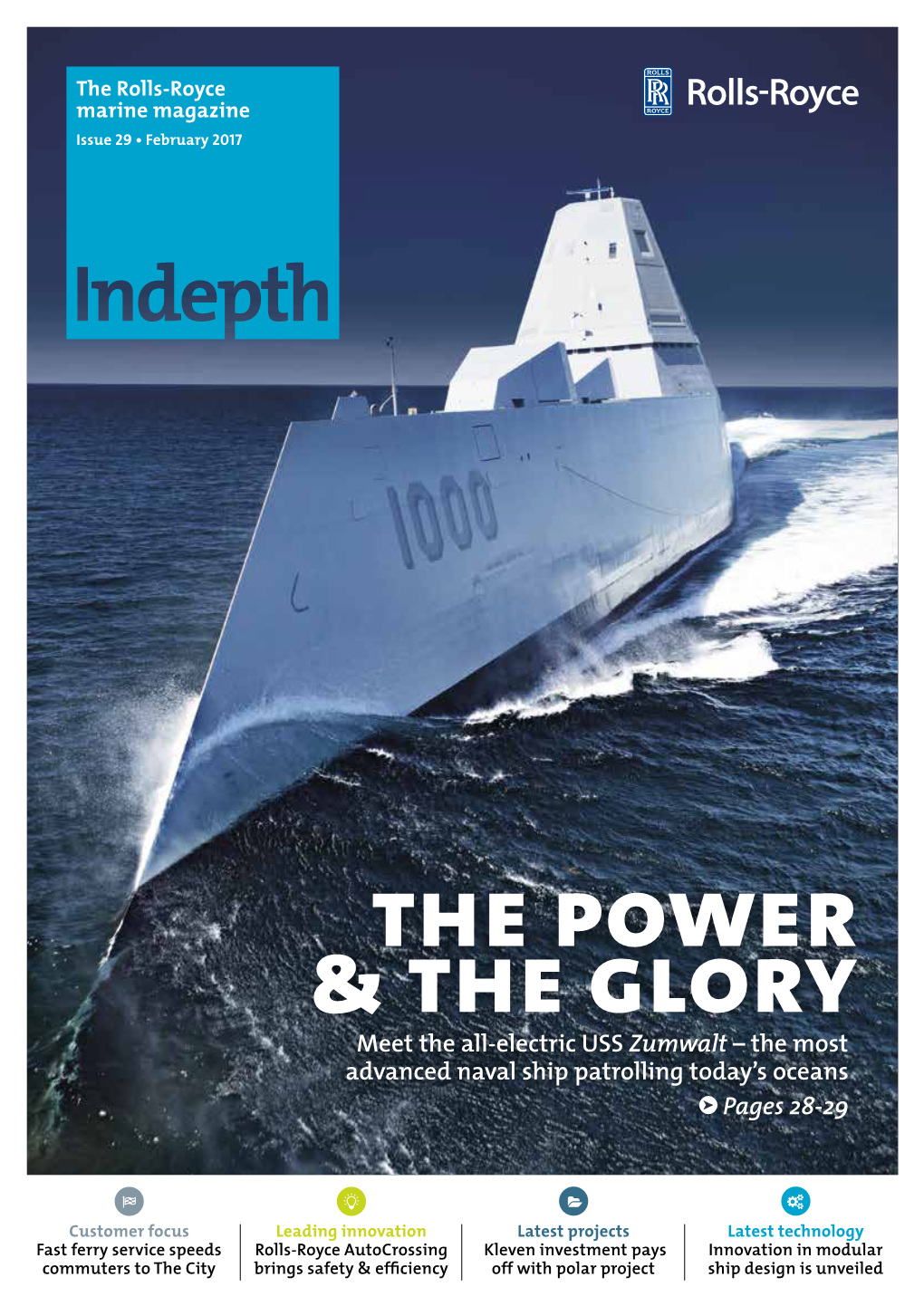

The Power & the Glory

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

An Interview with CAPT James A. Kirk, USN, Commanding Officer, USS ZUMWALT (DDG 1000) Conducted by CAPT Edward Lundquist, USN (Ret)

SURFACE SITREP Page 1 P PPPPPPPPP PPPPPPPPPPP PP PPP PPPPPPP PPPP PPPPPPPPPP Volume XXXII, Number 4 December 2016 An Interview with CAPT James A. Kirk, USN, Commanding Officer, USS ZUMWALT (DDG 1000) Conducted by CAPT Edward Lundquist, USN (Ret) How would you describe this ship to someone who is not familiar LCS was another ship designed for a very small crew size enabled with DDG 1000? What makes this ship special? by automation. Originally, the crew was going to be 40, with the To a layman, I would describe it as a very large stealth surface objective of 15. And this was another ship, very small crew size, combatant; that generates 78 megawatts of power, enough to which some people would say that the crew size was originally power a small-to-medium size town; and with capabilities like directed as an arbitrary number. But LCS has had problems other destroyers, to do the typical missions that destroyers do with the size of the crew in managing a ship like that. Have you – anti-submarine warfare, anti-air warfare, anti-surface warfare, had or have you learned any lessons from watching how LCS – and the like. Then there are the unique aspects, because of the through their watch standing or their crew training, you know ship’s stealth and its combined their hybrid sailors – have you capabilities, particularly the learned some lessons that advanced gun system (AGS). have been helpful with how We have volume precision you man and train the ship? fires to support the Marines, Certainly there’s been lessons Army, or SEALs that are ashore that have been observed and or going ashore. -

Christening of New Zumwalt-Class Guided Missile Destroyer, the Michael Monsoor

Christening of new Zumwalt-class Guided Missile Destroyer, the Michael Monsoor Gary Lehman, The Scuba Sports Club (photographs and text) On June 18, 2016 the Michael Monsoor (DDG-1001) was christened with great celebration at the General Dynamics / Bath Iron Works shipyard in Bath, Maine. The ship is named after Medal of Honor recipient US Navy Petty Officer and SEAL Michael Monsoor (posthumously-awarded), who was killed in the line of duty selflessly protecting his comrades by throwing himself on an insurgent’s hand grenade to save them in Iraq in 2006. The ship’s sponsor was his mother, Sally Monsoor. She spoke with such warmth, love, affection and respect about her son, receiving a standing ovation from all assembled. Michael Monsoor’s sister and two sisters-in-law were the Matrons of Honor. All were escorted to the ship’s bow for the christening by five members of Monsoor’s SEAL team. Sally Monsoor then broke the champagne against the bow with a great display of foam and streamers. The American flag and US Navy Color Guard was provided by the USS Constitution. (Thus the span of time represented: from the oldest commissioned warship in the world – and the only commissioned US Navy ship in the Fleet to have sunk an enemy vessel - to the newest and most ‘high tech’ ship in the fleet!) The principal speaker was Vice Admiral Joseph Maguire, president and CEO of the Special Operations Warrior Foundation. Undersecretary of the Navy Janine Davidson also participated in the christening. The event was attended by over 1,000 members of the public, the executive team and personnel of General Dynamics/BIW, and Maine’s Senators and local political representatives. -

10-Newsletter-November-2016

Hepworth Group Business and Newsletter Issue 38 November 2016 Quote of the Month “Either you run the day, or the day runs you.” Jim Rohn AWARDS Hepworth International’s Emily Woodall was the winner of the Made in the Midlands Women in Engineering award on 20th October at IET Birmingham. - Quote of the Month - Women in Engineering Award. - Servi supply Eker Design AS - In-Mar Projects - Monitor Marine Update. - Rail Update - Automotive The award was sponsored by FBC Manby Bowdler, represented by Neil Lloyd. After a fantastic ovation from local manufacturing directors and peers, Emily Update explained: “I’m over the moon, I was a bit shocked but it is a great achievement to have. The amount of women engineers out there is very minimal and I would love to - METS, OSEA and see that increase, so if I could do anything to progress that, it would be a real honour.” East Midlands Exhibitions The Women in Engineering Award is dedicated towards recognising the outstanding achievements of women who thrive within an industry which remains largely dominated by male figures. The award continues to grow in popularity each year, as Threeway Pressings Ltd, Wrekin Sheetmetal, Yeoman Pressings Ltd and JSC Rotational were shortlisted this year for their high quality applications. Initially, Emily developed systems for various vehicle designs initially using 2D CAD format before working with Hepworth’s team to get the 3D Solid Works system in place. She then undertook additional training to ensure that Hepworth utilised the full capabilities of the new software, which gave them the edge over their competitors, as they could offer a complete design facility to customers. -

Bob Harkins Took This Photo of the Irish Sea, As the Storm Subsided, from the Deck of the Tall Ship Roald Amundsen

BOB HARKINS TOOK THIS PHOTO OF THE IRISH SEA, AS THE STORM SUBSIDED, FROM THE DECK OF THE TALL SHIP ROALD AMUNDSEN. 62 JULY 2009 / YACHTING www.yachtingmagazine.com KNOTS! AFTER VOLUNTEERS 110 ABOARD A STEEL TALL SHIP FIGHT THE MIGHTY IRISH SEA, THEY HAVE A STORy— AND FRIENDSHIPS— THAT WILL LAST FOREVER. BY BOB HARKINS www.yachtingmagazine.com JULY 2009 / YACHTING 63 I served in the United States Navy for 21 years and I’ve been a rec- went through a day of training together—practicing working aloft, reational boater for most of my life. But in all those years, I’ve never line-handling, standing watch, and emergency procedures. experienced a storm like the one of March 2008, in the Irish Sea. The weather was bright and beautiful as we left Lisbon on Since my retirement in 2005, I’ve been a volunteer crew member March 3, but that afternoon it started turning against us. The wind of the U.S. Brig Niagara out of Erie, Pennsylvania. It’s brought me into picked up, blowing 40 to 50 knots, and the seas became much rough- contact with several sail-training ships and their crews, who ply the er. Very soon about half of our crew was seasick. The storm lasted waters teaching the curious about nautical history and the traditions overnight and it wasn’t until two days later that the last of our seasick of seamanship. Naturally, when sailors get together, there’s a lot of talk cases had completely recovered. about previous adventures on other ships, and this was how I first For the next few days, as we headed north past the Iberian penin- heard about the German brig Roald Amundsen. -

The North West Passage

THE "GJOA" expedition, 1903-1907. THE NORTH WEST PASSAGE BY ROALD AMUNDSEN. Downloaded from www.greatestedventurers.com Downloaded from www.greatestedventurers.com ROALD AMUNDSEN'S THE NORTH WEST PASSAGE" BEING THE RECORD OF A VOYAGE OF EXPLORATION OF THE SHIP "GJOA" 1903-1907 BY ROALD AMUNDSEN WITH A SUPPLEMENT BY FIRST LIEUTENANT HANSEN VICE-COMMANDER OF THE EXPEDITION WITH ABOUT ONE HUNDRED AND THIRTY-NINE ILLUSTRATIONS AND THREE MAPS Vol. I E. p. BUTTON AND COMPANY 1908 5 Downloaded from www.greatestedventurers.com '/-/ Q VJ.\ Published November 23rd, 1907. Privilege of Copyright in the United States reserved, under the Act approved March 3rd, 1905, by H. Aschehoug and Co. Downloaded from www.greatestedventurers.com 2)eC)icatcb TO H.E. Dr. FRIDTJOF NANSEN, G.C.V.O., NORWEGIAN MINISTER TO THE COURT OF ST. JAMES, WITH THE DEEPEST GRATITUDE FROM KOALD AMUNDSEN. Downloaded from www.greatestedventurers.com PREFACE. I TENDER my warmest and most heartfelt thanks to the small party of brave men who followed me through the North West Passage and risked their lives to ensure the success of my undertaking. A loving thought will again and again travel back to the lonely grave looking out on the boundless ice-desert, and grateful memories will arise of him who laid down his young life on the field of action. I tender my best thanks to Mr. Axel Steen, meteoro- logist, to His Excellency Professor Dr. G. von Neumayer, to Professor Ad. Schmidt, and to Professor Johannes Edler for the valuable assistance they rendered me with reference to the difficult magnetic problem connected with the Expedition. -

By Dr. Norbert Doerry 1989

The Evolution of the 2014 - Electric Warship by Dr. Norbert Doerry 1989 he end of the Cold War marked the beginning of a multi-decade evolution of the surface combatant into the Electric Warship. At ASNE Day 1989, Dr. Cy Krolick and CAPT Clark (Corky) Graham presented the concept of Technology Clusters to advocate the synergistic research and development of surface combatant technology. Technology Clusters promised to Tenable concurrent systems engineering and component R&D, provide programmatic stability, and decrease fleet introduction time. The first cluster, Cluster A, consisted of integrated electric drive, advanced propulsor system, ICR gas turbine, integrated electrical distribution system with pulse power, machinery monitoring and control, advanced auxiliary system, and low observability/ loiter power system. The foundational Cluster A would be an enabler for the introduction other clusters, most notably, Cluster E, Electromagnetic Pulse Power. Over the next several decades, these technologies would mature, be incrementally introduced into ship designs, and culminate in the delivery of the first modern electric warship to the U.S. Navy that featured an Integrated Power System (IPS), USS Zumwalt (DDG 1000). Modern electric power technology has also been introduced into auxiliary ships (T-AKE 1 class and MLP 1 class), amphibious warship ships (LPD 17, LHD 8 and LHA 5 class), aircraft carriers, submarines, and into DDG 51 flight upgrades. Furthermore, directed energy weapons such as the Laser Weapon System (LaWS) are beginning to be fielded, and the Electromagnetic Railgun (EMRG) is currently transitioning from an Innovative Naval Prototype (INP) into a weapon system technology development program. High power radar, such as the Air and Missile Defense Radar (AMDR), have also been enabled by increased electric power availability from electric warship technology. -

Navy's Futuristic-Looking USS Zumwalt Arrives in Homeport 8 December 2016

Navy's futuristic-looking USS Zumwalt arrives in homeport 8 December 2016 The U.S. Navy's biggest, most expensive and most class are being built in Maine. technologically advanced destroyer arrived at its homeport on Thursday after a nearly four-month © 2016 The Associated Press. All rights reserved. transit that included some hiccups, such as a high- profile breakdown in the Panama Canal. The USS Zumwalt arrived in San Diego to a welcoming ceremony that included the commander of naval surface forces, Vice Adm. Tom Rowden. The ship has a crew of 147 officers and sailors, and its commanding officer is Capt. James Kirk. "We have looked forward to pulling into San Diego for a long time," Kirk said. The Zumwalt departed Maine shipbuilder Bath Iron Works in September before being commissioned into service in Baltimore in October. It made several additional port calls en route to its final destination. During the trip, the first-in-class ship was sidelined for repairs a couple of times, including after it lost propulsion in the Panama Canal, necessitating a tow and an extended stay for repairs. In San Diego, the crew and contractors will begin installation of combat systems and further testing and evaluation. The 610-foot-long warship features new technology including an electric power plant that drives it, an inward-sloping tumblehome hull, a composite deckhouse that hides sensors and an angular shape to minimize its radar signature. The futuristic-looking ship weighs in at nearly 15,000 tons, about 50 percent heavier than current destroyers. But the crew size is half of the 300 personnel of other destroyers, thanks to advanced automation. -

U.S. Navy Subsistence

U.S. NAVY SUBSISTENCE HEADQUARTERS PERSONNEL NAVAL SUPPLY SYSTEMS COMMAND 5450 Carlisle Pike Mechanicsburg, PA 17055-0791 www.navsup.navy.mil ASHORE INSTALLATION FOOD SERVICE COMMANDER USS CONSTITUTION NSF DEVESELU, ROMANIA Rear Adm. Michelle C. Skubic, SC USN Bldg. 5 PSC 825 BOX 51 Charlestown, MA 02129 FPO AE 09712-0001 CHIEF OF STAFF NSA ANNAPOLIS NSF REDZIKOWO, POLAND Capt. Timothy L. Daniels, SC, USN 58 Bennion Rd. PSC 826 BOX 1 Annapolis, MD 21402 FPO AE 09761-0001 *MWR Operated VICE COMMANDER NSF DIEGO GARCIA Michael T. Madden NAF ATSUGI, JAPAN PSC 466, Box 24, Annex 13 PSC 477, Box 4 FPO AP 96595-0024 FPO AP 96306 FLEET SERVICES SUPPORT NAS FALLON Capt. Jose L. Feliz, SC, USN NSB BANGOR (NB KITSAP) Silver State Club (717) 605-7254 1100 Hunley Rd., Suite 203 Churchill Ave., Bldg. 324 Silverdale, WA 98315 Fallon, NV 89496 *MWR-operated DIRECTOR, FOOD SERVICE DIVISION NAVAL CONSOLIDATED BRIG Lt. Cmdr. Ryan J. Wodele, SC, USN CHARLESTON NAS JRB FORT WORTH (717) 605-1854 1050 Remount Rd., Bldg. 3107 Military Pkwy. Galley, Bldg. 1506 North Charleston, SC 29046 Fort Worth, TX 76127-6200 FOOD SERVICE POLICY, GALLEY NAVAL CONSOLIDATED BRIG NS GREAT LAKES MANAGEMENT AND AUTOMATION CHESAPEAKE Great Lakes, IL 60088-5001 Charles Folsom 500 Wilderness Rd. *Contractor-operated Boot Camp Chesapeake, VA 23322 (717) 605-6941 *Satellite Mess NS GUANTANAMO BAY, CUBA PSC 1005 Box 33 FLEET READINESS, MENU, NAVAL CONSOLIDATED BRIG MIRAMAR FPO AE 09593 AND EQUIPMENT 46141 Miramar Way, Suite 1 San Diego, CA 92145 NCBC GULFPORT Pamela Beward Colmer Dining Facility, Bldg. -

NROTCU Rutgers-Princeton Newsletter Fall 2016 New Student Orientation 2016

NROTCU Rutgers-Princeton Newsletter Fall 2016 New Student Orientation (Pages 1-2) Scarlet Day of Service (Pages 2-3) USS JOHN P MURTHA Commissioning Ceremony (Pages 3-4) USS ZUMWALT Commissioning Ceremony (Pages 4-5) Holy Cross MEC (Pages 5-6) Fall 2016 FEX (Pages 6-7) Turkey Bowl (Pages 7-8) Admiral Harris Visit (Pages 8-9) USS NEW JERSEY Visit (Pages 9-10) Princeton Crisis Simulation (Page 10) News From the Fleet (Pages 11-12) Winter Commissioning Ceremony (Page 12) New Student Orientation 2016 NROTCU Rutgers-Princeton welcomed 24 new 4/C Midshipmen this past August for our 5th annual New Student Orientation. Of the 24, 15 were attend- ing Rutgers, with 9 attending Princeton; our number of Princeton Midshipmen only continues to grow! A hand-selected group of our 1/C and 2/C Midshipmen took on the roles of MIDN Staff for the week, including the group's first ever MIDN Corpsman, MIDN 3/C Noristz! By 1600 that first day, we led our new 4/C out to Joint Base McGuire-Dix-Lakehurst, NJ for new student orientation into the unit. Throughout the four days on base, the Midshipmen woke up each morning for physical training, drill instruction, and briefs on various topics ranging from how to wear their uniforms to recommended guidelines for nutrition and sleep. The Midshipmen completed their inventory Physical Fitness Tests/Physical Read- iness Tests and swim qualifications as an official evaluation of their physical 1 NROTCU Rutgers-Princeton Newsletter Fall 2016 physical readiness. And finally, they completed their first fast-paced hike as a unit. -

N a V Y C a S H B U L L E T

Volume 13: Issue 4 Oct/Nov/Dec/ 2016 N A V Y C A S H B U L L E IN THIS ISSUE: T October/November/December Sailor of the Month Navy Cash List of SOP Change Notices I Additional Resources Future Training Events N Supply Corps History Points of Contact SH1 Edward Carr and SH2 Mateasha Mccoggle, Deputy Disbursing Officers onboard USS ZUMWALT DDG 1000 home ported San Diego California, have been selected as the Navy Cash Sailor of the Month of October 2016. Assigned to a minimal manned crew with only two SH’s no PS’s, and no DISBO these two hard charging PO’s navigated through multiple challenges during the install of Navy Cash on this new class ship. They built the operation from ground up spending countless late nights and weekends to support move aboard for the crew and to make Navy Cash available for the Ship Store to open, and to support the ability to sale meals to the wardroom and civilian shipboard riders on the maiden voyage from Bath Maine to home port San Diego. In Baltimore for commissioning ceremony they processed $200K of emblematic sales in Navy Cash, producing $50K toward the MWR fund greatly enhancing the crew’s morale. These two highly motivated and dynamic sailors established over 250 Navy Cash accounts and issued over 250 Navy Cash cards. These outstanding SH’s accomplished all of this while simultaneously standing up and operating the ship store, laundry, barber, and standing three section duty. These two Petty Officers devotion to duty and service to the crew are unmatchable. -

Norwegian Shipping in the 20Th Century Norway's Successful Navigation of the World's Most Global Industry

PALGRAVE STUDIES IN MARITIME ECONOMICS Stig Tenold Norwegian Shipping in the 20th Century Norway’s Successful Navigation of the World’s Most Global Industry Palgrave Studies in Maritime Economics Series Editors Hercules Haralambides Erasmus School of Economics Erasmus University Rotterdam Rotterdam, The Netherlands Elias Karakitsos EN Aviation & Shipping Research Ltd Athens, Greece Stig Tenold Department of Economics NHH – Norwegian School of Economics Bergen, Norway Palgrave Studies in Maritime Economics is a new, original and timely interdisciplinary series that seeks to be pivotal in nature and improve our understanding of the role of the maritime sector within port economics and global supply chain management, shipping finance, and maritime business and economic history. The maritime industry plays an increas- ingly important role in the changing world economy, and this new series offers an outlet for reviewing trends and developments over time as well as analysing how such changes are affecting trade, transport, the environ- ment and financial markets. Each title in the series will communicate key research findings, shaping new approaches to maritime economics. The core audience will be academic, as well as policymakers, regulators and international maritime authorities and organisations. Individual titles will often be theoretically informed but will always be firmly evidence- based, seeking to link theory to policy outcomes and changing practices. More information about this series at http://www.palgrave.com/gp/series/15187 Stig Tenold Norwegian Shipping in the 20th Century Norway’s Successful Navigation of the World’s Most Global Industry Stig Tenold Department of Economics NHH – Norwegian School of Economics Bergen, Norway Palgrave Studies in Maritime Economics ISBN 978-3-319-95638-1 ISBN 978-3-319-95639-8 (eBook) https://doi.org/10.1007/978-3-319-95639-8 Library of Congress Control Number: 2018952928 © The Editor(s) (if applicable) and The Author(s) 2019. -

Nr. 113 Ii/2020

C 12580 F ntgelt bezahlt NR. 113 II/2020 DP,PVST,E EDITORIAL INHALT Liebe Freundinnen und Freunde der Großsegler Seefahrt und Kunst S.4 Wir leben in Zeiten wie sie die meisten von uns noch nicht erlebt haben. Nicht dass es solche Epidemien Aus unserem bisher nicht gegeben hätte; aber Verein S. 5-7 der Umgang mit der Hong-Kong- verwiesen, in der Hoffnung, dass die Grippe, HIV und den verschiedenen Entscheidungen aus Berlin den 22. Virusgrippen in zurückliegenden August 2020 für dieses Treffen der Kleine News Jahren, mit bis zu 25.000 Toten allein Tall-Ship Friends zulassen. Eine hohe S. 7-11 in Deutschland, war nicht von dieser Teilnehmerzahl wäre wünschenswert, Hysterie geprägt wie wir sie derzeit denn es gilt in die Zukunft zu schauen. Abenteuer Segeln S. 12-23 ertragen sollen. Das „Willkommen an Bord“ ist, Einundzwanzig Die Krankheit ist ernst, aber die bezogen auf die Zahl neuer Mitglieder, Tage S. 12-16 Experten und Politiker haben sie auch etwas bescheidener als in Zeiten Regatta S.17+18 zu einer Katastrophe gemacht und ohne Virus. Ein besondere Empfehlung proben nun den „Notstand“. Selbst an dieser Stelle für unsere neue ANTIGUA der verantwortungsvolle Bürger Spendenaktion zu Gunsten der GREIF. S.19+20 wird entmündigt, seiner Grundrechte Die Rubrik „Kleine News“ ist beraubt und unter „Hausarrest“ „coronafrei“, sieht man von dem ROALD gestellt. Räume die der Einkehr Hinweis auf die Verschiebung AMUNDSEN dienen sind geschlossen, Räume die der Kieler Woche ab, und gibt S.21-23 dem Einkauf dienen dagegen geöffnet. Informationen zu vielfältigen Themen Geschichte der Paradox aber systemimmanent.