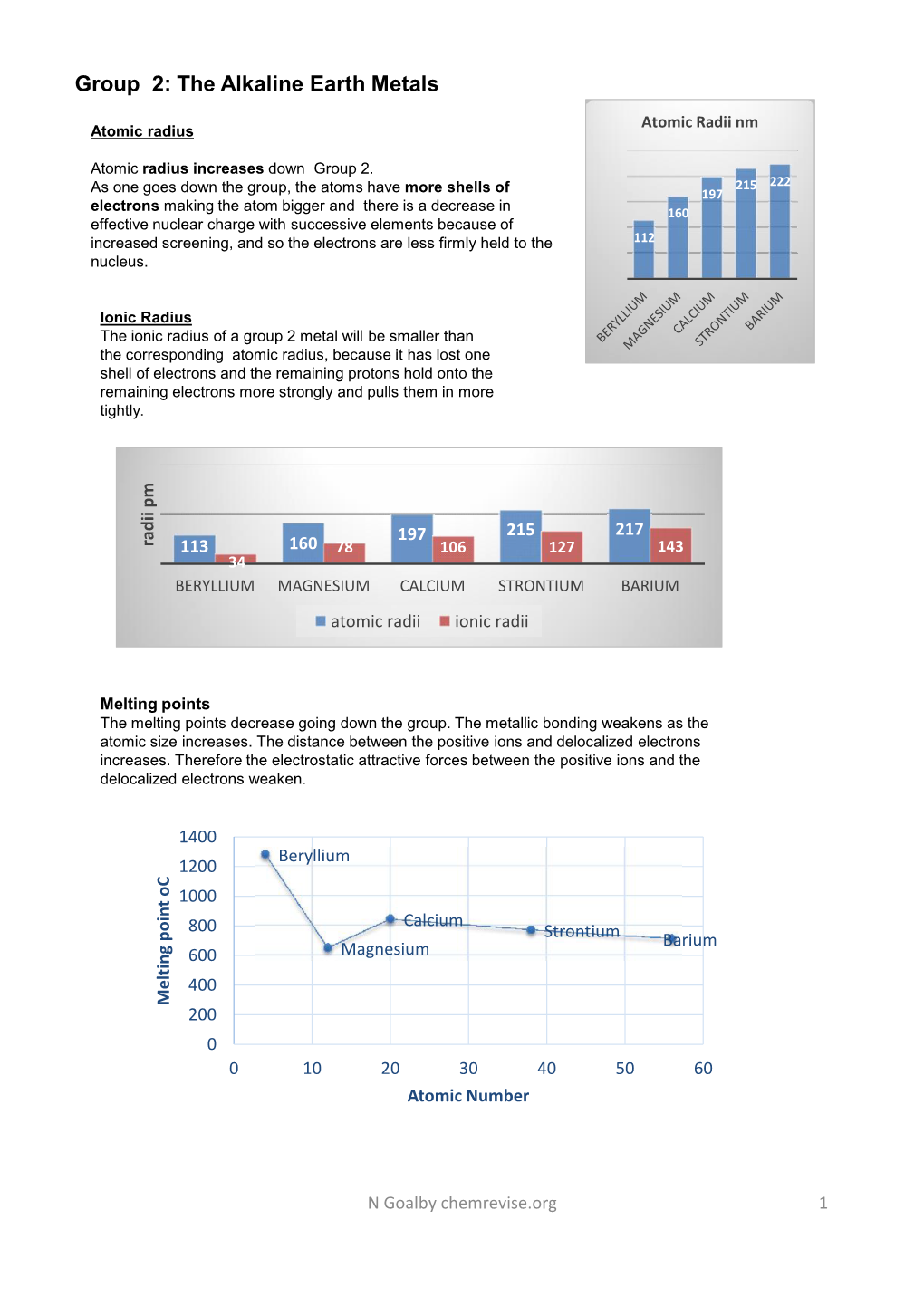

Group 2: the Alkaline Earth Metals Atomic Radii Nm Atomic Radius

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

SDS Contains All of the Information Required by the HPR

SAFETY DATA SHEET Preparation Date: 7/7/2015 Revision Date: 7/6/2018 Revision Number: G2 1. IDENTIFICATION Product identifier Product code: C1115 Product Name: CALCIUM HYDROXIDE, POWDER, REAGENT, ACS Other means of identification Synonyms: Calcium hydrate Carboxide Calcium dihydroxidede calcium (French) CAS #: 1305-62-0 RTECS # EW2800000 CI#: Not available Recommended use of the chemical and restrictions on use Recommended use: Fireproofing coatings. water treatment. Buffering agent. In paper manufacture process. Chemical intermediate. In dental cement. In lubricants. In mortar, plaster, cement and other building and paving materials. In fungicides. In pesticides. In SBR rubber vulcanization. Uses advised against No information available Supplier: Spectrum Chemical Mfg. Corp 14422 South San Pedro St. Gardena, CA 90248 (310) 516-8000 Order Online At: https://www.spectrumchemical.com Emergency telephone number Chemtrec 1-800-424-9300 Contact Person: Martin LaBenz (West Coast) Contact Person: Ibad Tirmiz (East Coast) 2. HAZARDS IDENTIFICATION Classification This chemical is considered hazardous according to the 2012 OSHA Hazard Communication Standard (29 CFR 1910.1200) Considered a dangerous substance or mixture according to the Globally Harmonized System (GHS) Skin corrosion/irritation Category 2 Serious eye damage/eye irritation Category 1 Specific target organ toxicity (single exposure) Category 3 Label elements Danger Product code: C1115 Product name: CALCIUM 1 / 13 HYDROXIDE, POWDER, REAGENT, ACS Hazard statements Causes skin irritation Causes serious eye damage May cause respiratory irritation Hazards not otherwise classified (HNOC) Not Applicable Other hazards Not available Precautionary Statements - Prevention Wash face, hands and any exposed skin thoroughly after handling Avoid breathing dust/fume/gas/mist/vapors/spray Use only outdoors or in a well-ventilated area Wear protective gloves Wear eye/face protection Precautionary Statements - Response IF IN EYES: Rinse cautiously with water for several minutes. -

Microstructural and Compressive Strength Analysis for Cement Mortar with Industrial Waste Materials

Available online at www.CivileJournal.org Civil Engineering Journal Vol. 6, No. 5, May, 2020 Microstructural and Compressive Strength Analysis for Cement Mortar with Industrial Waste Materials Zahraa Fakhri Jawad a, Rusul Jaber Ghayyib a, Awham Jumah Salman a* a Al-Furat Al-Awsat Technical University, Najaf, Kufa, Iraq. Received 06 December 2019; Accepted 02 March 2020 Abstract Cement production uses large quantities of natural resources and contributes to the release of CO2. In order to treat the environmental effects related to cement manufacturing, there is a need to improve alternative binders to make concrete. Accordingly, extensive study is ongoing into the utilization of cement replacements, using many waste materials and industrial. This paper introduces the results of experimental investigations upon the mortar study with the partial cement replacement. Fly ash, silica fume and glass powder were used as a partial replacement, and cement was replaced by 0%, 1%, 1.5%, 3% and 5% of each replacement by the weight. Compressive strength test was conducted upon specimens at the age of 7 and 28 days. Microstructural characteristic of the modified mortar was done through the scanning electron microscope (SEM) vision, and X-ray diffraction (XRD) analysis was carried out for mixes with different replacements. The tests results were compared with the control mix. The results manifested that all replacements present the development of strength; this improvement was less in the early ages and raised at the higher ages in comparison with the control specimens. Microstructural analysis showed the formation of hydration compounds in mortar paste for each replacement. This study concluded that the strength significantly improved by adding 5% of silica fume compared with fly ash and glass powder. -

Barium Nitrate Solution 0.1M

Safety Data Sheet Barium Nitrate Solution 0.1M 1. PRODUCT AND COMPANY IDENTIFICATION Product Name: Barium Nitrate Solution 0.1M Synonyms/Generic Names: None SDS Number: 85.20 Product Use: For Educational Use Only Manufacturer: Columbus Chemical Industries, Inc. N4335 Temkin Rd. Columbus, WI. 53925 For More Information Contact: Ward's Science 5100 West Henrietta Rd. PO Box 92912-9012 Rochester, NY 14692 (800) 962-2660 (Monday-Friday 7:30-7:00 Eastern Time) In Case of Emergency Call: CHEMTREC - 800-424-9300 or 703-527-3887 (24 Hours/Day, 7 Days/Week) 2. HAZARDS IDENTIFICATION OSHA Hazards: Oxidizer, Toxic by ingestion, Toxic by inhalation, Irritant Target Organs: Kidney, Liver, Blood, Heart, Gastrointestinal system, Bone marrow, Spleen, Nerves Signal Words: Warning Pictograms: GHS Classification: Oxidizing liquid Category 3 Acute toxicity, Oral Category 4 Acute toxicity, Inhalation Category 4 Skin irritation Category 3 Eye irritation Category 2A GHS Label Elements, including precautionary statements: Hazard Statements: H272 May intensify fire; oxidizer. H302+H332 Harmful if swallowed or in contact with skin. H316 Causes mild skin irritation. H319 Causes serious eye irritation. Revised on 01/08/2013 Page 1 of 6 Precautionary Statements: P220 Keep/store away from clothing/combustible materials. P305+P351+P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses if present and easy to do so. Continue rinsing. Potential Health Effects Eyes Causes eye irritation. Inhalation Toxic if inhaled. Causes respiratory tract irritation. Skin May be harmful if absorbed through skin. Causes skin irritation. Ingestion Toxic if swallowed. NFPA Ratings HMIS Ratings Health 2 Health 2 Flammability 0 Fire 0 Reactivity 0 Reactivity 0 Specific hazard N/A Personal E 3. -

Preparation of Barium Strontium Titanate Powder from Citrate

APPLIED ORGANOMETALLIC CHEMISTRY Appl. Organometal. Chem. 13, 383–397 (1999) Preparation of Barium Strontium Titanate Powder from Citrate Precursor Chen-Feng Kao* and Wein-Duo Yang Department of Chemical Engineering, National Cheng Kung University, Tainan, 70101, Taiwan TiCl4 or titanium isopropoxide reacted with INTRODUCTION citric acid to form a titanyl citrate precipitate. Barium strontium citrate solutions were then BaTiO3 is ferroelectric and piezoelectric and has added to the titanyl citrate reaction to form gels. extensive applications as an electronic material. It These gels were dried and calcined to (Ba,Sr)- can be used as a capacitor, thermistor, transducer, TiO3 powders. The gels and powders were accelerometer or degausser of colour television. characterized by DSC/TGA, IR, SEM and BaTiO3 doped with strontium retains its original XRD analyses. These results showed that, at characteristics but has a lower Curie temperature 500 °C, the gels decomposed to Ba,Sr carbonate for positive temperature coefficient devices under and TiO2, followed by the formation of (Ba,Sr)- various conditions. TiO3. The onset of perovskite formation oc- Besides solid-state reactions, chemical reactions curred at 600 °C, and was nearly complete at have also been used to prepare BaTiO3 powder. 1 1000 °C. Traces of SrCO3 were still present. Among them the hydrolysis of metal alkoxide , The cation ratios of the titanate powder oxalate precipitation in ethanol2, and alcoholic prepared in the pH range 5–6 were closest to dehydration of citrate solution3 are among the more the original stoichiometry. Only 0.1 mol% of the attractive methods. In 1956 Clabaugh et al.4 free cations remained in solution. -

ACUMER™ 9000 Mineral Slurry Dispersant

Technical Data ACUMER™ 9000 Mineral Slurry Dispersant Description ACUMER™ 9000 is a sodium salt of an acrylic acid-based polymer. It is a highly effective dispersant for aqueous calcium hydroxide and magnesium hydroxide slurries. Features and • Controlling phase separation Benefits • Reducing caking and clogging of equipment • Aiding the remixing of slurries after settling Typical Properties Property Typical Value Appearance Clear, light amber solution Total solids, % 44 pH 7.5 Density (lb/gal, @ 25°C) 10.8 Brookfield viscosity, (mPa.s/cps @ 25°C) 500 These properties do not constitute specifications. Performance Many problems can be encountered in producing calcium hydroxide or magnesium hydroxide slurries, including: • Wettability • Phase separation • Caking • Pumping • Pipe clogging • Remixing after setting • Slurry viscosity Calcium Hydroxide Figure 1 shows the efficiency of ACUMER 9000 as a dispersant for 30% calcium hydroxide slurry. Figure 1. ACUMER 9000 Dosage vs. Viscosity (30% Lime Slurry) Page 1 of 4 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow Form No. 812-00352-0216BBI ACUMER™ 9000 / Dow Oil, Gas & Mining The following table shows the positive effect of ACUMER™ 9000 dosage on lime slurry stability. Lower dosage (0.2%) gives higher slurry viscosity and lower syneresis (liquid phase separation). The desired slurry properties can be controlled by optimizing the dispersant dosage. Effect of ACUMER 9000 Dispersant on 30% Lime Slurry1 Stability After 8 Days at Room Temperature Initial Make-Down Dosage, % (solids basis) Syneresis Gel3 Flowed4 Viscosity2 0.2 2080 1.7 98.3 93.3 0.4 810 12.0 88.0 97.1 0.6 382 16.5 83.5 96.3 130% lime slurry was prepared by mixing 210 grams of slaked lime with 490 grams of deionized water (including additives) for five minutes in a Waring blender at high speed. -

Federal Law and Vertebrate Pest Control

University of Nebraska - Lincoln DigitalCommons@University of Nebraska - Lincoln Proceedings of the 1st Vertebrate Pest Vertebrate Pest Conference Proceedings Conference (1962) collection February 1962 FEDERAL LAW AND VERTEBRATE PEST CONTROL Justus C. Ward Director, Pesticides Regulation Division, Agricultural Research Service, U.S. Department of Agriculture Follow this and additional works at: https://digitalcommons.unl.edu/vpcone Part of the Environmental Health and Protection Commons Ward, Justus C., "FEDERAL LAW AND VERTEBRATE PEST CONTROL" (1962). Proceedings of the 1st Vertebrate Pest Conference (1962). 25. https://digitalcommons.unl.edu/vpcone/25 This Article is brought to you for free and open access by the Vertebrate Pest Conference Proceedings collection at DigitalCommons@University of Nebraska - Lincoln. It has been accepted for inclusion in Proceedings of the 1st Vertebrate Pest Conference (1962) by an authorized administrator of DigitalCommons@University of Nebraska - Lincoln. FEDERAL LAW AND VERTEBRATE PEST CONTROL By: Justus C. Ward, Director, Pesticides Regulation Division, Agricultural Research Service, U.S. Department of Agriculture Presented at the Vertebrate Pest Control Conference, Sacramento, California, February 6 and 7, 1 962 Shortly after the passage of the Federal Insecticide Act of 1910> mammal control specialists in the Bureau of Biological Survey began to consider a similar law to cover the chemicals with which they were concerned. Work on the project went slowly a nd spasmodically, but reached the point of having a Federal Rodenticide Act available for study and possible revision in 1928. At this time, the mammal control chemicals in use were limited to strychnine -- alkaloid and sulphate -arsenic, barium carbonate, th allium sulphate, phosphorus, s odium and calcium cyanide, carbon disulphide, and red squill. -

The Historic Touring Car Challenge Is a Series of Invitation Races for Touring Cars That Competed During the Period 1966 to 1990 Inclusive

2018 Series Regulations for the Historic Touring Car Challenge Supported by The Historic Touring Car Challenge is a series of invitation races for Touring Cars that competed during the period 1966 to 1990 inclusive. Specific requirements are covered under ‘Eligibility’ below. The Historic Sports Car Club will be the organising club. There will be five rounds of the HTCC in 2018: May 4th – 6th Donington Historic Festival 60 mins June 2nd - 3rd Thruxton 50th Anniversary 2 x 30 mins July 20th – 22nd Silverstone Classic 45 mins August 27th Oulton Park Gold Cup 50 mins October 19th – 21st Algarve Classic Festival 120 mins RACE DETAILS Each race will be for two (or exceptionally one) driver entries, open strictly by the invitation of Motor Racing Legends, to drivers of all nationalities holding a minimum of a National ‘A’ or International Historic race licence. For UK races, a minimum of a National ‘B’ will be acceptable. Each race will feature a compulsory pit stop and driver change where relevant. The car must be at rest for a minimum of 60 seconds during the pit stop. Any car failing to make a pit stop will be excluded from the results. Any car failing to make a pit stop within the pit window will incur a Drive-Through penalty. The exception to this rule will be the Algarve Classic Festival meeting. Separate pit-stop regulations will be published for this race. ELIGIBILITY The Historic Touring Car Challenge is open to Touring Cars complying with the following FIA regulations: Group A from 1st January 1982 to 31st December 1990; Group 2 from 1st January 1966 to 31st December 1981; Group 5 from 1st January 1966 to 31st December 1969; All cars must conform to the relevant sections Appendix ‘J’ of the International Sporting Code of the period; and to technical requirements of the current Appendix ‘K’ of the International Sporting Code. -

Strontium Chromate from Austria and France

Strontium Chromate from Austria and France Investigation Nos. 731-TA-1422-1423 (Preliminary) Publication 4836 October 2018 U.S. International Trade Commission Washington, DC 20436 U.S. International Trade Commission COMMISSIONERS David S. Johanson, Chairman Irving A. Williamson Meredith M. Broadbent Rhonda K. Schmidtlein Jason E. Kearns Catherine DeFilippo Director of Operations Staff assigned Kristina Lara, Investigator Samantha DeCarlo, Industry Analyst Tana von Kessler Economist Jennifer Brinckhaus, Accountant KaDeadra McNealy, Statistician David Goldfine, Attorney Douglas Corkran, Supervisory Investigator Address all communications to Secretary to the Commission United States International Trade Commission Washington, DC 20436 U.S. International Trade Commission Washington, DC 20436 www.usitc.gov Strontium Chromate from Austria and France Investigation Nos. 731-TA-1422-1423 (Preliminary) Publication 4836 October 2018 CONTENTS Page ....................................................................................................................... 1 ........................................................................................................ 3 Introduction ................................................................................................................ I‐1 Background ................................................................................................................................ I‐1 Statutory criteria and organization of the report .................................................................... -

Material Safety Data Sheet Version 3.4 Revision Date 09/03/2012 Print Date 02/06/2014

SIGMA-ALDRICH sigma-aldrich.com Material Safety Data Sheet Version 3.4 Revision Date 09/03/2012 Print Date 02/06/2014 1. PRODUCT AND COMPANY IDENTIFICATION Product name : Strontium chloride solution Product Number : 69042 Brand : Sigma Supplier : Sigma-Aldrich 3050 Spruce Street SAINT LOUIS MO 63103 USA Telephone : +1 800-325-5832 Fax : +1 800-325-5052 Emergency Phone # (For : (314) 776-6555 both supplier and manufacturer) Preparation Information : Sigma-Aldrich Corporation Product Safety - Americas Region 1-800-521-8956 2. HAZARDS IDENTIFICATION Emergency Overview OSHA Hazards Irritant GHS Classification Skin irritation (Category 3) Eye irritation (Category 2A) GHS Label elements, including precautionary statements Pictogram Signal word Warning Hazard statement(s) H316 Causes mild skin irritation. H319 Causes serious eye irritation. Precautionary statement(s) P305 + P351 + P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. HMIS Classification Health hazard: 2 Flammability: 0 Physical hazards: 0 NFPA Rating Health hazard: 2 Fire: 0 Reactivity Hazard: 0 Potential Health Effects Inhalation May be harmful if inhaled. Causes respiratory tract irritation. Skin May be harmful if absorbed through skin. Causes skin irritation. Sigma - 69042 Page 1 of 6 Eyes Causes eye irritation. Ingestion May be harmful if swallowed. 3. COMPOSITION/INFORMATION ON INGREDIENTS Synonyms : Strontium chloridesolution Additive Screening Solution 27/Fluka kit no 78374 Component Classification Concentration Strontium chloride CAS-No. 10476-85-4 Skin Irrit. 2; Eye Dam. 1; 1 - 5 % EC-No. 233-971-6 STOT SE 3; H315, H318, H335 For the full text of the H-Statements and R-Phrases mentioned in this Section, see Section 16 4. -

Step-By-Step Guide to Better Laboratory Management Practices

Step-by-Step Guide to Better Laboratory Management Practices Prepared by The Washington State Department of Ecology Hazardous Waste and Toxics Reduction Program Publication No. 97- 431 Revised January 2003 Printed on recycled paper For additional copies of this document, contact: Department of Ecology Publications Distribution Center PO Box 47600 Olympia, WA 98504-7600 (360) 407-7472 or 1 (800) 633-7585 or contact your regional office: Department of Ecology’s Regional Offices (425) 649-7000 (509) 575-2490 (509) 329-3400 (360) 407-6300 The Department of Ecology is an equal opportunity agency and does not discriminate on the basis of race, creed, color, disability, age, religion, national origin, sex, marital status, disabled veteran’s status, Vietnam Era veteran’s status or sexual orientation. If you have special accommodation needs, or require this document in an alternate format, contact the Hazardous Waste and Toxics Reduction Program at (360)407-6700 (voice) or 711 or (800) 833-6388 (TTY). Table of Contents Introduction ....................................................................................................................................iii Section 1 Laboratory Hazardous Waste Management ...........................................................1 Designating Dangerous Waste................................................................................................1 Counting Wastes .......................................................................................................................8 Treatment by Generator...........................................................................................................12 -

Strontium-90 and Strontium-89: a Review of Measurement Techniques in Environmental Media

STRONTIUM-90 AND STRONTIUM-89: A REVIEW OF MEASUREMENT TECHNIQUES IN ENVIRONMENTAL MEDIA Robert J. Budnitz Lawrence Berkeley Laboratory University of California Berkeley, CA 91*720 1. IntroiUiction 2. Sources of Enivronmental Radiostrontium 3. Measurement Considerations a. Introduction b. Counting c. •»Sr/"Sr Separation 4. Chemical Techniques a. Air b. Water c. Milk d. Other Media e. Yttrium Recovery after Ingrowth f. Interferences S- Calibration Techniques h. Quality Control 5. Summary and Conclusions 6. Acknowli'J.jnent 7. References -NOTICE- This report was prepared as an account of worK sponsored by the United States Government. Neither the United States nor the United Slates Atomic Energy Commission, nor any of their employees, nor any of their contractors, subcontractors, or their employees, makes any wananty, express or implied, or asjumes any legal liabili:y or responsibility for the accuracy, com pleteness or usefulness of any Information, apparatus, J product or process disclosed, or represents that its use I would not infringe privately owned rights. Mmh li\ -1- 1. INTRODUCTION There are only two radioactive isotopes SrflO of strontium of significance in radiological measurements in the environment: strontium-89 Avg.jS energy 196-1 k«V and strontium-90. 100 Strontium-90 is the more significant from the point of view of environmental impact. 80 Energy keV 644 This is due mostly to its long half-life % Emission 100 (28.1 years). It is a pure beta emitter with 60 Typ* of only one decay mode, leading to yttrium-90 •mission by emission of a negative beta with HUBX * 40 h S46 keV. -

PUBLIC HEALTH STATEMENT Strontium CAS#: 7440-24-6

PUBLIC HEALTH STATEMENT Strontium CAS#: 7440-24-6 Division of Toxicology April 2004 This Public Health Statement is the summary External exposure to radiation may occur from chapter from the Toxicological Profile for natural or man-made sources. Naturally occurring strontium. It is one in a series of Public Health sources of radiation are cosmic radiation from space Statements about hazardous substances and their or radioactive materials in soil or building materials. health effects. A shorter version, the ToxFAQs™, is Man-made sources of radioactive materials are also available. This information is important found in consumer products, industrial equipment, because this substance may harm you. The effects atom bomb fallout, and to a smaller extent from of exposure to any hazardous substance depend on hospital waste and nuclear reactors. the dose, the duration, how you are exposed, personal traits and habits, and whether other If you are exposed to strontium, many factors chemicals are present. For more information, call determine whether you’ll be harmed. These factors the ATSDR Information Center at 1-888-422-8737. include the dose (how much), the duration (how _____________________________________ long), and how you come in contact with it. You must also consider the other chemicals you’re This public health statement tells you about exposed to and your age, sex, diet, family traits, strontium and the effects of exposure. lifestyle, and state of health. The Environmental Protection Agency (EPA) identifies the most serious hazardous waste sites in 1.1 WHAT IS STRONTIUM? the nation. These sites make up the National Priorities List (NPL) and are the sites targeted for Strontium is a natural and commonly occurring long-term federal cleanup activities.