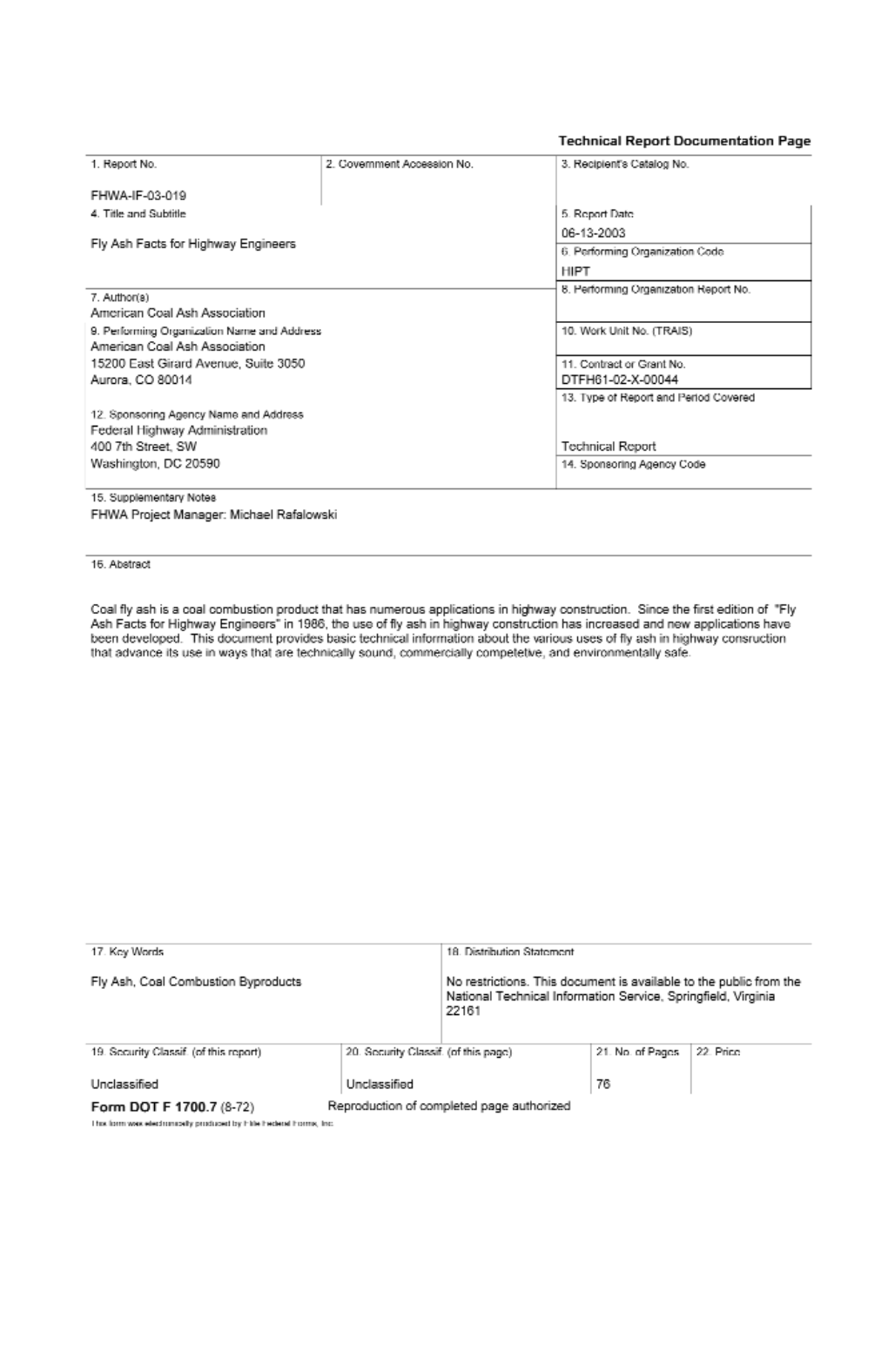

Fly Ash Facts for Highway Engineers in 1986, the Use of Fly Ash in Highway Construction Has Increased and New Applications Have Been Developed

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

White Concrete & Colored Concrete Construction

WHITE CEMENT CONCRETE AND COLORED CONCRETE CONSTRUCTION and developers Owners seeking dynamic architectural results demand the benefits that only white or colored concrete can deliver. Informed designers rely on careful selection of materials and attention to mixing and placement details to achieve eye-catching architectural and decorative finishes. Because of its versatility, concrete offers endless design possibilities. A wide variety of decorative looks are achieved by using colored aggregates and pigments, and by varying surface finishes, treatments, and textures. Combining white cement with pigments and colored aggregates expands the number of colors available to discerning customers. Colors are cleaner and more intense because pigments and specialty Figure 1. The Condell Medical Center is built with load-bearing precast concrete aggregates don’t have to overcome the panels with an architectural finish achieved by using white cement. grayish paste of common concrete. Courtesy of Condell Medical Center. Mix Designs • CSA A3000 cements that conform to the Canadian From a structural design perspective, white cement-based Standards Association standards for Cementitious Materials concrete mixes are identical to gray cement-based mixes. Mix • American Association of State Highway and Transportation designs for white or colored concrete differ from common Officials, AASHTO M85 Standard Specification for Portland concrete in that they are formulated based on each ingredient’s Cement effect on concrete color. Listed in order of decreasing -

Experimental Investigation on Nano Concrete with Nano Silica and M-Sand

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 06 Issue: 03 | Mar 2019 www.irjet.net p-ISSN: 2395-0072 EXPERIMENTAL INVESTIGATION ON NANO CONCRETE WITH NANO SILICA AND M-SAND Mohan Raj.B1, Sugila Devi.G2 1PG Student, Nadar Saraswathi College of Engineering and Technology, Theni, Tamilnadu, India. 2Assistant Professor, Nadar Saraswathi College of Engineering and Technology, Theni, Tamilnadu, India. ---------------------------------------------------------------------***--------------------------------------------------------------------- Abstract - The influence of Nano-Silica on various material is Nano Silica (NS). The advancement made by the properties of concrete is obtained by replacing the cement study of concrete at Nano scale has proved the Nano silica is with various percentages of Nano-Silica. Nano-Silica is used as much better than silica fume used in conventional concrete. a partial replacement for cement in the range of 3%, 3.5%, Now, the researchers are capitalizing on nanotechnology to and 10% for M20 mix. Specimens are casted using Nano-Silica innovate a new generation of concrete materials that concrete. Laboratory tests conducted to determine the overcome the above drawbacks and trying to achieve the compressive strength, split tensile and flexural strength of sustainable concrete structures. Evolution of materials is Nano-Silica concrete at the age of 7, 14 and 28 days. Results need of the day for improved or better performance for indicate that the concrete, by using Nano-Silica powder, was special engineering applications and modifying the bulk able to increase its compressive strength. However, the density state of materials in terms of composition or microstructure is reduce compared to standard mix of concrete. -

Portland Cement Types I, IA, II

Product Data Sheets Portland Cement Types I, IA, II, III General Purpose, General Purpose Air Entrained Type I, Moderate Sulfate Resistance and Moderate Heat of Hydration Properties and High Early Strength Type III Manufacturer: Provides higher strengths at an earlier Fairborn Cement Company age as compared to Type I. Type III is Fairborn Cement Company 3250 Linebaugh Rd very similar to Type I, except its offers the following Cement Xenia, OH 45385 particles have been ground finer, Types: 800-762-0040 making it more reactive. Type III Portland cements are useful when I www.fairborncement.com quick form turn- around times are IA Product Description: necessary. Type I, Type IA, Type II, Type III II Cements. Quality: III Fairborn Cement Company is Type I committed to quality and takes pride in IL (10) This is a general-purpose cement that the products we manufacturer. We is suitable for all uses where the manufacture products using only high Oil Well (Class A) special properties of other types of quality raw materials and strict quality MIAMI Masonry N,S,M Portland cement are not required. control procedures. Fairborn Cement Company is the local leader in quality MIAMI Color Colored Type IA cement production. Masonry N,S Same as Type I except an air entraining MIAMI Mortar Cement N,S admixture has been added during the Standards: manufacturing process. Used where Type I, Type IA, Type II, Type III cement Block Cement exposure to freeze-thaw cycles in the meets the standard requirements of the presence of de-icing chemicals is following: expected. -

Assessment of Wood-Based Fly Ash As Alternative Cement Replacement

sustainability Article Assessment of Wood-Based Fly Ash as Alternative Cement Replacement Jan Foˇrt 1,2,* , Jiˇrí Šál 2, Jaroslav Žák 2 and Robert Cernˇ ý 1 1 Department of Materials Engineering and Chemistry, Faculty of Civil Engineering, Czech Technical University in Prague, Thákutova 7, 166 29 Prague, Czech Republic; [email protected] 2 Institute of Technology and Business in Ceskˇ é Budˇejovice,Okružní 10, 370 01 Ceskˇ é Budˇejovice, Czech Republic; [email protected] (J.Š.); [email protected] (J.Ž.) * Correspondence: [email protected] Received: 16 October 2020; Accepted: 15 November 2020; Published: 17 November 2020 Abstract: The abandonment of coal energy plants in the near future will result in a substantially reduced availability of the coal fly ash broadly used as an efficient supplementary material. In line with the growth of alternative and renewable energy resources, the amount of biomass-based ash rises substantially. Nevertheless, a diverse chemical composition prevents a broader utilization of biomass-based fly ash compared to coal ash on an industrial scale. On this account, the present work is aimed at investigating the basic physical and mechanical properties of concrete mortars modified by a high volume of biomass fly ash (BFA) from wood combustion. Delivered results confirm a significant potential of BFA in the building industry. Experimental analysis of concrete mortars with BFA reveals preservation or even improvement of compressive and bending strength up to 30 wt.% cement replacement. On the contrary, higher dosages induce a gradual decrease in mechanical performance. The performed Life Cycle Assessment analysis reveals the perspective of BFA incorporation taking into account environmental issues considering the ratio between preservation of mechanical performance per normalized endpoint environmental score that allows a direct comparison with other alternatives. -

Vermiculite Concrete Introduction Vermiculite Concrete Is a Low Density Non-Structural Construction Product

Vermiculite Concrete Introduction Vermiculite concrete is a low density non-structural construction product. It is insulating (both thermally and acoustically) and intrinsically fire resistant. It is normally made simply by mixing exfoliated vermiculite as the aggregate, with cement and water, plus additives such as plasticisers if required. The ratio of exfoliated vermiculite aggregate to cement and the vermiculite grade can be varied to the properties such as strength and insulation as required for the concrete. The applications for vermiculite concrete are however, all non-structural. Vermiculite concretes can also be produced containing other lightweight aggregates, such as expanded perlite, to give differing physical properties. Normally the type of cement used in these mixes is Ordinary Portland Cement (O.P.C), although a higher initial strength may be obtained using Rapid Hardening Portland Cement (R.H.P.C). For high temperature refractory applications, high alumina (luminate in the USA) cements may be used with great success to manufacture lightweight in-situ cast insulation mixes and back up insulation products. However, these applications are beyond the scope of this specific application note. Applications for Vermiculite Concrete The principal applications for vermiculite concrete are for in-situ site mixed applications such as: • Floor and roof screeds • Void filling insulation mixes around chimneys, back boilers and fire backs • Blocks and slabs • Swimming pool bases [see separate application note for this application] Vermiculite concrete can be easily cut, sawed, nailed or screwed. The lower density vermiculite concrete screeds are usually covered with a denser topping mix of 4:1 or 5:1 sand to cement mix to a minimum depth of 25mm (1 inch); the screed and denser more load distributing topping should ideally be laid monolithically to prevent dis-bonding and shear fracturing between the screed and the topping. -

Alkali-Silica Reactivity: an Overview of Research

SHRP-C-342 Alkali-Silica Reactivity: An Overview of Research Richard Helmuth Construction Technology Laboratories, Inc. With contributions by: David Stark Construction Technology Laboratories, Inc. Sidney Diamond Purdue University Micheline Moranville-Regourd Ecole Normale Superieure de Cachan Strategic Highway Research Program National Research Council Washington, DC 1993 Publication No. SHRP-C-342 ISBN 0-30cL05602-0 Contract C-202 Product No. 2010 Program Manager: Don M. Harriott Project Maxtager: Inam Jawed Program AIea Secretary: Carina Hreib Copyeditor: Katharyn L. Bine Brosseau May 1993 key words: additives aggregate alkali-silica reaction cracking expansion portland cement concrete standards Strategic Highway Research Program 2101 Consti!ution Avenue N.W. Washington, DC 20418 (202) 334-3774 The publicat:Lon of this report does not necessarily indicate approval or endorsement by the National Academy of Sciences, the United States Government, or the American Association of State Highway and Transportation Officials or its member states of the findings, opinions, conclusions, or recommendations either inferred or specifically expressed herein. ©1993 National Academy of Sciences 1.5M/NAP/593 Acknowledgments The research described herein was supported by the Strategic Highway Research Program (SHRP). SHRP is a unit of the National Research Council that was authorized by section 128 of the Surface Transportation and Uniform Relocation Assistance Act of 1987. This document has been written as a product of Strategic Highway Research Program (SHRP) Contract SHRP-87-C-202, "Eliminating or Minimizing Alkali-Silica Reactivity." The prime contractor for this project is Construction Technology Laboratories, with Purdue University, and Ecole Normale Superieure de Cachan, as subcontractors. Fundamental studies were initiated in Task A. -

The Effects of Alkali-Silica Reaction on the Mechanical Properties of Concretes with Three Different Types of Reactive Aggregate

Technical Paper Okpin Na* DOI: 10.1002/suco.201400062 Yunping Xi Edward Ou Victor E. Saouma The effects of alkali-silica reaction on the mechanical properties of concretes with three different types of reactive aggregate This paper investigates the degradation of the mechanical prop- environment, the product of ASR is expansive, which is erties of concretes made with three types of aggregate affected detrimental to concrete structures [1, 2]. by alkali-silica reaction (ASR). Three standard testing methods ASR is a chemical reaction between the reactive – ASTM C289, JASS 5N T-603 and ASTM C1260 – were used to silica in the aggregate and the alkalis (Na2O and K2O) in identify the reactivity of ASR of the three aggregates selected. Portland cement. This chemical reaction produces alkali- The test results show that all three aggregates are potentially silica gel swelling with the absorption of the moisture deleterious. A new acceleration method based on JASS 5N T-603 from the surrounding cement paste. The expansive gel and ASTM C1260 was proposed for concrete specimens. In the can cause cracking in the concrete. Therefore, the neces- acceleration method, cylindrical concrete specimens were used, sary conditions for the expansive ASR gel to form in the additional alkali material was added to the concrete mixture and concrete are a sufficiently high alkali concentration in the the specimens were stored under conditions similar to ASTM cement, high moisture content in the concrete and reac- C1260. The preconditioned concrete specimens were then used tive aggregates. for evaluating the mechanical properties of the ASR-affected In order to control or prevent the occurrence of concrete in terms of strength and stiffness. -

Portland Cement Concrete

B Highway Materials Engineering Course PARTICIPANT WORKBOOK Portland Cement Concrete MODULE G Ti Table of Contents About This Workbook .................................................................................................................. 2 Course Overview .......................................................................................................................... 3 Introduction ................................................................................................................................. 3 Module G Overview ..................................................................................................................... 4 Module Goals ............................................................................................................................... 5 Learning Outcomes ...................................................................................................................... 5 ILT Instruction Icons ..................................................................................................................... 9 Module G Lesson 8 Review ..................................................................................................... G8-1 Module G Lesson 9 Basic Mix Design and Proportioning ....................................................... G9-1 Module G Lesson 10 Reinforcing and Corrosion ..................................................................G10-1 Module G Lesson 11 Hot Topics ...........................................................................................G11-1 -

Reducing Cement Content in Concrete Mixtures

No. 0092-08-08 Wisconsin Highway Research Program • http://wisdotresearch.wi.gov/whrp December 2011 Reducing Cement Content in Concrete Mixtures oncrete mixtures contain crushed rock or gravel, and sand, bound together by Portland cement in combination with supplemental cementitious materials (SCMs), which harden through Ca chemical reaction with water. Portland cement is the most costly component of concrete mixtures, and its production creates significant amounts of green house gases. To reduce costs and environmental impacts, current WisDOT practice allows a for replacement of a portion of Portland cement supplemental cementitious materials (SCMs) such as coal fly ash or slag cement, both industrial by-products of coal and iron production, respectively. WisDOT has set a maximum limit on Portland cement replacement through use of SCMs to ensure its performance on concrete pavements. Therefore, the only opportunity to reduce the usage of Portland cement is to lower the required cementitious materials content for WisDOT approved mix designs. The potential benefits in terms of economic costs and environmental impacts are significant, however decreasing the cementitious materials content of a mixture too drastically can reduce pavement strength and durability. It can also reduce workability, or the ease with which a mixture can be compacted and placed during construction. What’s the Problem? Research was needed to help determine the minimum amount of cementitious material that WisDOT can use in its concrete mixtures and still preserve pavement performance. Several other upper Mid- western states allow the use of concrete mixtures with a lower minimum cementitious material content PUTTING RESEARCH TO WORK TO RESEARCH PUTTING than currently required by WisDOT specifications, but there is a lack of data on the long-term perfor- mance of pavements built with these mixtures. -

We Now Know That the Maximum Level That Avoids

Using ash in concrete is nothing new. h e Romans rials derived from coal combustion products, includ- used volcanic ash in their spectacular construction ing fly ash, nationwide. projects long before the introduction of Portland cement, “Fly ash is composed of the non-combustible mineral having discovered its value as a hardening agent when portion of coal. When coal is consumed in a power plant, mixed with lime. h e ancient Romans used volcanic ash it’s i rst ground to the i neness of powder. Blown into as an admix to erect buildings such as the Pantheon and the power plant’s boiler, the carbon is consumed – leav- Coliseum, roads, and aqueducts. Remember, these struc- ing molten particles rich in silica, alumina, and calcium. tures are more than 2,000 years old. h ese particles solidify as microscopic, glassy spheres Fly ash concrete was first used in the U.S. in the that are collected from the power plant’s exhaust before 1920s for dam construction, when engineers found that it reduced the total cement requirement. Today, as more projects seek LEED certification, ash is resurfac- WE NOW KNOW THAT THE ing as a popular environmentally-friendly alternative MAXIMUM LEVEL THAT AVOIDS to Portland cement. No longer are we using volcanic COMPLICATIONS IN ADHERING FLOOR ash, of course, but coal fly ash is gaining ground as the COVERING IS 15% FLY ASH. green alternative of choice for LEED projects. Many of the projects and the millions of square yards of LEED flooring we’ve installed in recent years used ash in the they can “l y” away – hence the product’s name: l y ash,” cement mixture. -

Portland Cement User's Guide == Steps == # Plan Your Concrete

Portland Cement User’s guide == Steps == # Plan your concrete project carefully. There is a set sequence of steps you must take to be successful, and following them will save you a lot of problems later on. # Purchase or gather the raw materials for your concrete. You will need Portland type I or II cement, masonry or builder's sand or other clean sand, and if you want, as a filler, gravel or crushed limestone. The Portland cement usually comes in one cubic foot bags, weighing in at about 96 pounds each, so you may need help handling them, as well as a truck to haul it. # Build a mixing box, or get a good, sturdy wheel barrow to mix the materials in. If it is a large project, rent a concrete mixer to do the hardest part of the work for you. We have mixed as much as 6 or 8 cubic feet with a mason's hoe and shovel, in a large plastic tub, so not having the best equipment shouldn't stop you from trying it. # Allow yourself time to complete the whole process when you begin. If the concrete is a large "finished" slab, start early in the morning and gather all the help you can. # Build the form you are placing the concrete in, brace it off securely, level and plumb it up, and then carefully measure the dimensions to determine the volume in cubic feet. This is done by multiplying width X length X height in feet. An example would be 5 ft. X 2 ft. -

Report No. REC-ERC-82-1. Fly Ash and Fly Ash Concrete

May 1984 Engineering and Research Center U. S. Department of the Interior Bureau of Reclamation Bureau ot Reclamation TECHNICAL REPORT STANDARD TITLE PAGE Fly Ash and Fly Ash Concrete May 1984 6. PERFORMING ORGANIZATION CODE 7. AUTHOR(S)-. 8. PERFORMING ORGANIZATION Edwin R. Dunstan, Jr. REPORT NO. I REC-ERC-82-1 9. PERFORMING ORGANIZATION NAME AND ADDRESS 10. WORK UNIT NO. Bureau of Reclamation, Engineering and Research Center 11. CONTRACT OR GRANT NO. Denver, Colorado 80225 10781 V0195 13. TYPE OF REPORT AND PERIOD COVERED 2. SPONSORING AGENCY NAME AND ADDRESS Same 14. SPONSORING AGENCY CODE DlBR 15. SUPPLEMENTARY NOTES Microfiche and/or hard copy available at the Engineering and Research Center. Denver. Colorado. Editor: RNW 16. ABSTRACT Fly ash is a residue that results from the combustion of ground or powdered coal. Historically, fly ash has been referred to as a ponolan and is used to reduce the amount of portland cement in concrete. However, in many Western States fly ashes have cementitious properties as well as pozzolanic properties, and they are capable of producing good strengths without portland cement. This study discusses test results of several ashes according to ASTM: C 6 18. Standard Specification for Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Portland Cement Concrete. Many changes are suggested. The replacement of 15 to 25 percent by mass of portland cement in concrete is examined. A few highly cementitious ashes were used to make concrete without portland cement. A new cement was developed that consists of over 90-percent fly ash and anhydrous CaS04.Test data for most concretes include: mix proportions, compressive strength, elasticity, drying shrinkage.