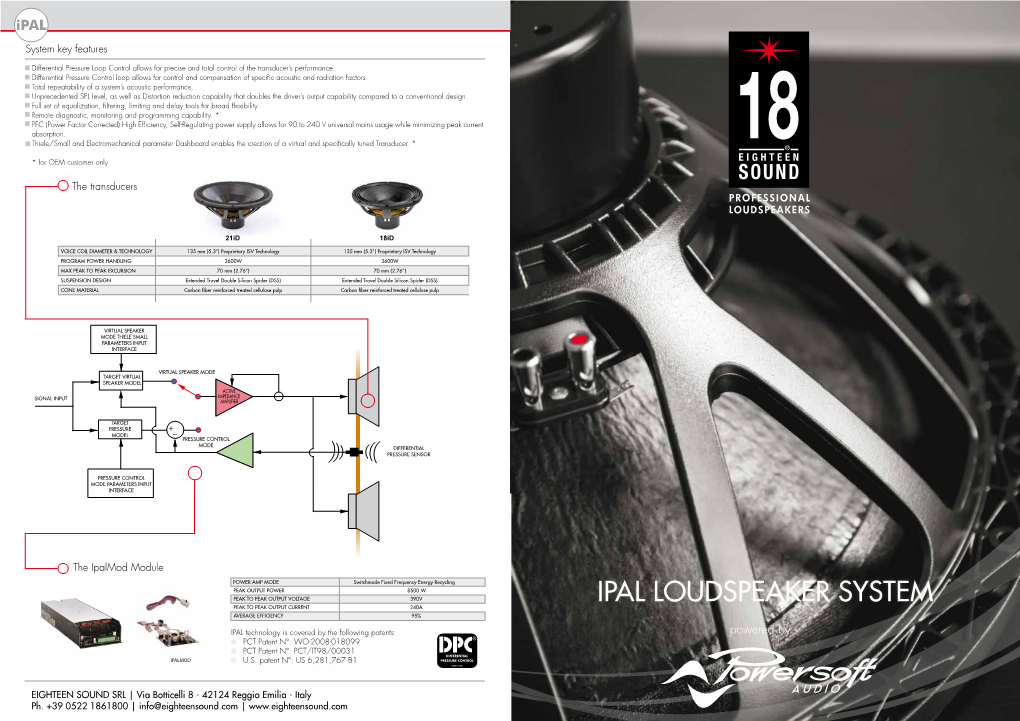

Ipal Loudspeaker System Peak to Peak Output Current 240A Average Efficiency 95%

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

A GUIDE to USING FETS for SENSOR APPLICATIONS by Ron Quan

Three Decades of Quality Through Innovation A GUIDE TO USING FETS FOR SENSOR APPLICATIONS By Ron Quan Linear Integrated Systems • 4042 Clipper Court • Fremont, CA 94538 • Tel: 510 490-9160 • Fax: 510 353-0261 • Email: [email protected] A GUIDE TO USING FETS FOR SENSOR APPLICATIONS many discrete FETs have input capacitances of less than 5 pF. Also, there are few low noise FET input op amps Linear Systems that have equivalent input noise voltages density of less provides a variety of FETs (Field Effect Transistors) than 4 nV/ 퐻푧. However, there are a number of suitable for use in low noise amplifier applications for discrete FETs rated at ≤ 2 nV/ 퐻푧 in terms of equivalent photo diodes, accelerometers, transducers, and other Input noise voltage density. types of sensors. For those op amps that are rated as low noise, normally In particular, low noise JFETs exhibit low input gate the input stages use bipolar transistors that generate currents that are desirable when working with high much greater noise currents at the input terminals than impedance devices at the input or with high value FETs. These noise currents flowing into high impedances feedback resistors (e.g., ≥1MΩ). Operational amplifiers form added (random) noise voltages that are often (op amps) with bipolar transistor input stages have much greater than the equivalent input noise. much higher input noise currents than FETs. One advantage of using discrete FETs is that an op amp In general, many op amps have a combination of higher that is not rated as low noise in terms of input current noise and input capacitance when compared to some can be converted into an amplifier with low input discrete FETs. -

Transducers and Sensors

3/7/2017 TRANSDUCERS AND SENSORS Dr. Ibrahim Al-Naimi Closed‐loop Control System 1 3/7/2017 CHAPTER ONE Introduction Functional Elements of a Measurement System • Basic Functional Elements 1‐Transducer Element 2‐ Signal Conditioning Element 3‐ Data Presentation Element • Auxiliary Functional Elements A‐ Calibration Element B‐ External Power supply 2 3/7/2017 Functional Elements of a Measurement System Transducer and Signal Conditioning 3 3/7/2017 Transducer Element • The Transducer is defined as a device, which when actuated by one form of energy, is capable of converting it to another form of energy. The transduction may be from mechanical, electrical, or optical to any other related form. • The term transducer is used to describe any item which changes information from one form to another. Transducer Element • The Transducer element normally senses the desired input in one physical form and convert it to an output in another physical form. For example, the input variable to the transducer could be pressure, acceleration, or temperature and the output of transducer may be disp lacemen t, voltage, or resitistance change depending on the type of transducer element. 4 3/7/2017 Transducer Element • Single stage • Double stage Single Stage Transducer 5 3/7/2017 Double Stage Transducer Typical Examples of Transducer Elements 6 3/7/2017 Typical Examples of Transducer Elements Typical Examples of Transducer Elements 7 3/7/2017 Transducers classification • Based on power type classification ‐ Active transducer (Diaphragms, Bourdon Tubes, tachometers, piezoelectric, etc…) ‐ Passive transducer (Capacitive, inductive, photo, LVDT, etc…) Transducers classification • Based on the type of output signal ‐ Analogue Transducers (stain gauges, LVDT, etc…) ‐ Digital Transducers (Absolute and incremental encoders) 8 3/7/2017 Transducers classification • Based on the electrical phenomenon or parameter tha t may be chdhanged due to the whole process. -

Transducers in Audio ● Transducer: Any Mechanism That Transforms One Form of Energy Into Another Form of Energy

Transducers in Audio ● Transducer: Any mechanism that transforms one form of energy into another form of energy. ○ Physical energy into mechanical energy ○ Physical energy into electrical energy ○ Mechanical energy into electrical energy ○ Vice versa Audio is primarily concerned with turning physical acoustic energy into electrical energy and back again. What are our two most basic audio transducers? scienceaid.net https://socratic.org/questions/what-part-of-the-ear-contains-the-sensory-receptors-for-hearing From Acoustic to Electric Energy First...a short trip into basic electrical theory... Michael Faraday http://www.rigb.org/our-history/michael-faraday Electro-magnetism Faraday’s Law of Induction: Basically, any change in the magnetic field of a coil of wire will cause a voltage to be induced in a wire. Conversely, any change in the voltage on a coil of wire will cause the magnetic field to change. This is called electromagnetism, and the field created is called an electro-magnetic field. Capacitance When two conductors are given an opposite charge, an electric or more specifically a capacitive field is generated around them. When the relationship between the two conductors (for example the distance between them) changes it causes measurable effects on the charges. http://hyperphysics.phy-astr.gsu.edu/hbase/electric/imgele/cap.png Capacitance When two conductors are given an opposite charge, a electric or more specifically a capacitive field is generated around them. When the relationship between the two conductors, for example the distance between them, changes is causes measurable effects on the charges. http://hyperphysics.phy-astr.gsu.edu/hbase/electric/imgele/cap.png ● Alternating Current (AC) vs Direct Current (DC) ○ AC charge changes from positive to negative across the zero axis. -

Basic Physics of Ultrasonographic Imaging

BASIC PHYSICS OF ULTlVlSONOGRAPHIC IMAGING Diagnostic Imaging and Laboratory Technology Essential Health Technologies Health Technology and Pharmaceuticals WORLD HEALTH ORGANIZATION Geneva BASIC PHYSICS OF ULTRASONOGRAPHIC IMAGING Editor Harald Ostensen Author Nimrod M. Tole, Ph.D. Associate Professor of Medical Physics Department of Diagnostic Radiology University of Nairobi WORLD HEALTH ORGANIZATION WHO Library Cataloguing-in-Publication Data Tole, Nimrod M. Basic physics of ultrasonic imaging / by Nimrod M. Tole. 1. Ultrasonography I. Title. ISBN 92 41592990 (NLM classification: WN 208) © World Health Organization 2005 All rights reserved. Publications of the World Health Organization can be obtained from WHO Press, World Health Organization, 20 Avenue Appia, 1211 Geneva 27, Switzerland (tel: +41 22 791 2476; fax: +41 22791 4857; email: [email protected]). Requests for permission to reproduce or translate WHO publications - whether for sale or for noncommercial distribution - should be addressed to WHO Press, at the above address (fax: +41 22791 4806; email: [email protected]). The designations employed and the presentation of the material in this publication do not imply the expression of any opinion whatsoever on the part of the World Health Organization concerning the legal status of any country, territory, city or area or of its authorities, or concerning the delimitation of its frontiers or boundaries. Dotted lines on maps represent approximate border lines for which there may not yet be full agreement. The mention of specific companies or of certain manufacturers' products does not imply that they are endorsed or recommended by the World Health Organization in preference to others of a similar nature that are not mentioned. -

Chapter 1 Introduction to Measurement Systems

4/3/2019 Advanced Measurement Systems and Sensors Dr. Ibrahim Al-Naimi Chapter one Introduction to Measurement Systems 1 4/3/2019 Outlines • Control and measurement systems • Transducer/sensor definition and classifications • Signal conditioning definition and classifications • Units of measurements • Types of errors • Transducer/sensor transfer function • Transducer characteristics • Statistical analysis Closed-loop Control System 2 4/3/2019 Measurement System Transducer and Signal Conditioning 3 4/3/2019 Transducer Element • The Transducer is defined as a device, which when actuated by one form of energy, is capable of converting it to another form of energy. The transduction may be from mechanical, electrical, or optical to any other related form. • The term transducer is used to describe any item which changes information from one form to another. Transducer and Sensor • Transducers are elements that respond to changes in the physical condition of a system and deliver output signals related to the measured, but of a different form and nature. • Sensor is the initial stage in any transducer. • The property of transducer element is affected by the variation of the external physical variable according to unique relationship. 4 4/3/2019 Transducers classification • Based on power type classification - Active transducer (Diaphragms, Bourdon Tubes, tachometers, piezoelectric, etc…) - Passive transducer (Capacitive, inductive, photo, LVDT, etc…) Transducers classification • Based on the type of output signal - Analogue Transducers (stain -

Maximizing Efficiency in Active Loudspeaker Systems

Maximizing Efficiency in Active Loudspeaker Systems Wolfgang Klippel, KLIPPEL GmbH, Dresden, Germany Increasing the efficiency of the electro-acoustical conversion is the key to modern audio devices generating the required sound output with minimum size, weight, cost and energy. There is unused potential for increasing the efficiency of the electro-dynamical transducer by using a nonlinear motor topology, a soft suspension and cultivating the modal resonances in the mechanical and acoustical system. However, transducers optimized for maximum efficiency are more prone to nonlinear and unstable behavior. Nonlinear adaptive control can compensate for the undesired signal distortion, protect the transducer against overload, stabilize the voice coil position and cope with time varying properties of the suspension. The paper discusses the design of modern active systems that combine the new opportunities provided by software algorithms with the optimization of the hardware components in the transducer and power amplifier. reducing power consumption in portable 1 Introduction applications with limited battery capacity. The user of loudspeakers, headphone and other For this discussion, the paper provides new audio devices expects that the audio signal can be definitions of the efficiency to consider the influence reproduced at sufficient amplitude and quality but of the spectral properties of the complex audio prefers products which are smaller, lighter, less cost signals (e.g. music). The paper explains the intensive and provide a longer stand-alone operation difference between efficiency and voltage in personal applications. sensitivity, which is a second important Creating such an audio product requires a characteristic of the transducer required to match the combination of hardware and software components transducer with the power amplifier. -

Practical Recommendations for Using Sound Transducers

ICaD 2013 6–10 july, 2013, Łódź, Poland international Conference on auditory Display The 19th International Conference on Auditory Display (ICAD-2013) July 6-10, 2013, Lodz, Poland The 19th International Conference on Auditory Display (ICAD-2013) July 6-10, 2013, Lodz, Poland The 19thPRACTICAL International Conference on Auditory RECOMMENDATIONS Display (ICAD-2013) FORJu USINGly 6-10, 2013, Lodz, Poland PRACTICAL RECOMMENDATIONS FOR USING SOUND TRANSDUCERS WITH GLASS SOUNDMEMBERANE TRANSDUCERS AS AUDITORY DISPLAY WITH BASED GLASS ON MEASUREMENTS MEMBERANE AND SIMULATIONSPRACTICAL RECOMMENDATIONS FOR USING SOUND TRANSDUCERS WITH GLASS ASPRACTICAL AUDITORY RECOMMENDATIONS DISPLAY FOR BASED USINGMEMBERANE SOUND ON TRANSDUCERS MEASUREMENTS AS AUDITORY WITH DISPLAY GLASS BASED ON MEASUREMENTS AND MEMBERANE AS AUDITORY DISPLAY BASED ON MEASUREMENTSSIMULATIONS AND György WersényANDi SIMULATIONS József Répás György Wersényi József Répás SzéchenyiGyörgyGyörgy István WersényiWersény Universityi , SzéchenyiJózsefJózsef IstvánRépás Répás University, DepartmentSzéchenyi of István Telecommunications University, , DepartmentSzéchenyi of Telecommunications, István University, Department of Telecommunications, SzéchenyiDepartment István University of Telecommunications,, Széchenyi István University, Széchenyi István University, Széchenyi István University, H-9026,H-9026, Győr, Győr, Egyetem Egyetem t. 1, Hungaryt. 1, Hungary DepartmentH-9026,H-9026, of TelecommunicationsGyőr, Győr, Egyetem Egyetem t. t.1, Hungary1,,Hungary Department of Telecommunications, -

Transducers Recommended by Garmin

TRANSDUCER SELECTION 2021 GUIDE CHOOSING THE RIGHT TRANSDUCER PANOPTIX LIVESCOPE™ There are several types of sonar available, each with special capabilities. And each requires a different transducer to work most effectively. For optimum performance, it is very important to match the transducer to your device’s sonar. To start, make sure the transducer you are buying pairs with your unit, and determine what type of sonar technology you would like to add. Read through each section to learn more about the sonar technologies and transducers recommended by Garmin. Our award-winning Panoptix LiveScope sonar brings real-time scanning sonar to life. It shows highly detailed, easy-to-interpret live scanning sonar images of structure, bait and fish swimming below and around your boat in real time, even when your boat SONAR TECHNOLOGY // PAGE 3 ADDITIONAL TRANSDUCERS // PAGE 24 is stationary. • Panoptix Livescope™ • Transom Mount Full capabilities are available with the Panoptix LiveScope • Panoptix Livescope™ Perspective • Thru-hull Traditional System (see below). The Panoptix LiveScope™ LVS12 transducer ® Mode Mount provides an economical solution for your GPSMAP 8600xsv • Thru-hull CHIRP Traditional chartplotter — without the need for a black box -- with 30-degree • Panoptix™ All-seeing Sonar • In-hull 2018 forward and 30-degree down real-time scanning sonar views. • Scanning Sonar System: UHD • Pocket Mount Part no: 010-02143-00 LVS12 • Scanning Sonar System: CHIRP Sonar THREE MODES IN ONE TRANSDUCER ACCESSORIES AND SENSORS // PAGE 32 THE RIGHT MOUNTING // PAGE 10 PANOPTIX LIVESCOPE™ DOWN • Accessories • In-hull Mount • Smart Sensors • Kayak In-hull • NMEA 2000® • Trolling Motor Mount • Transom Mount • Thru-hull Mount Live, easy-to-interpret scanning sonar images of structure and swimming fish in incredible detail below your Panoptix LiveScope LVS12 Down GARMIN TRANSDUCERS // PAGE 12 boat — up to 200’. -

THE IMPACT QF MOSFET-BASED SENSORS * Abstract The

CORE Metadata, citation and similar papers at core.ac.uk Provided by Universiteit Twente Repository Sensors and Actuators, 8 (1985) 109 - 127 109 THE IMPACT QF MOSFET-BASED SENSORS * P BERGVELD Department of Electrical Engmeermg, Twente Unwerslty of Technology, P 0 Box 217, 7500 AE Enschede (The Netherlands) (Received May 21,1985, m revlsed form October 4,1985, accepted October 29, 1985) Abstract The basic structure as well as the physical existence of the MOS held- effect transistor 1s without doubt of great importance for the development of a whole series of sensors for the measurement of physical and chemical environmental parameters The equation for the MOSFET dram current already shows a number of parameters that can be directly influenced by an external quantity, but small technological varlatlons of the orlgmal MOSFET configuration also give rise to a large number of sensing propertles All devices have m common that a surface charge 1s measured m a slllcon chip, depending on an electric field m the adJacent insulator FET-based sensors such as the GASFET, OGFET, ADFET, SAFET, CFT, PRESSFET, ISFET, CHEMFET, REFET, ENFET, IMFET, BIOFET, etc developed up to the present or those to be developed m the near future will be discussed m relation to the conslderatlons mentioned above 1. Introduction The measurement of semiconductor surface charge as a function of an electric field perpendicular to the surface was mentloned as early as 1925 by Llhenfeld and Hell as a possible principle for an electronic device that would not consume any power -

Transducer Amplifier Type S7mz (Option Z)

RDP Customer Document Technical Manual TRANSDUCER AMPLIFIER TYPE S7MZ (OPTION Z) Doc. Ref CD1225K This manual applies to units of mod status 8 ONWARDS Affirmed by Declaration of Conformity USA & Canada All other countries RDP Electrosense Inc. RDP Electronics Ltd 2216 Pottstown Pike Grove Street, Heath Town, Pottstown, PA 19465 Wolverhampton, WV10 0PY U.S.A. United Kingdom Tel (610) 469-0850 Tel: +44 (0) 1902 457512 Fax (610) 469-0852 Fax: +44 (0) 1902 452000 E-mail [email protected] E-mail: [email protected] www.rdpe.com www.rdpe.com I N D E X 1. INTRODUCTION 4 1.1 IMPORTANT SAFETY TEST INFORMATION. ................................................... 4 1.2 Certificate of EMC Conformity. ............................................................................ 6 2. CONNECTIONS 8 2.1. Supply ................................................................................................................. 8 2.2 Input & Output Connections ................................................................................ 8 2.3 EMC Compliance ................................................................................................ 8 2.4 Connections for LVDT displacement Transducer ................................................ 9 2.5 Connections for Half bridge (differential Inductance) transducer ........................ 9 2.6 Connections for Typical Full Bridge Strain Gauge Transducer ........................... 9 2.7 Connections for 1/4 and 1/2 Bridge Strain Gauge transducers ......................... 10 3. CONTROLS 11 3.1 Coarse/Fine -

1. Transducers and Sensors

EE3.02/A04 Instrumentation 1. Transducers and Sensors 1. Transducers and Sensors By the end of this section you should be able to: • Discuss the definitions/specifications by which sensors are characterised. • Describe common methods for converting a physical parameter into an electrical quantity and give examples of transducers, including those for measurement of temperature, strain, motion, position and light. • Explain how to make sensitive measurements using a Wheatstone bridge, including balancing and offset compensation. • Describe systems for measuring motion, temperature, strain and light intensity. 1.1. Definitions In this course we will be studying Electrical Measurements, and we will necessarily interplay between techniques and hardware used to sense the quantity we wish to measure, techniques and hardware used to process the signal generated by the sensors and also algorithms to interpret the final result. We will be, therefore be dealing with transducers, sensors and actuators. Transducers: Devices used to transform one kind of energy to another. When a transducer converts a measurable quantity (sound pressure level, optical intensity, magnetic field, etc) to an electrical voltage or an electrical current we call it a sensor. We will see a few examples of sensors shortly. When the transducer converts an electrical signal into another form of energy, such as sound (which, incidentally, is a pressure field), light, mechanical movement, it is called an actuator. Actuators are important in instrumentation. They allow the use of feedback at the source of the measurement. However we will pay little attention to them in this course. The study of using actuators and feedback belongs to a course in Control theory. -

Microphones and Loudspeakers

A Tutorial on Acoustical Transducers: Microphones and Loudspeakers Robert C. Maher Montana State University EELE 217 Science of Sound Spring 2012 Test Sound Outline • Introduction: What is sound? • Microphones – Principles – General types – Sensitivity versus Frequency and Direction • Loudspeakers – Principles – Enclosures • Conclusion 2 Transduction • Transduction means converting energy from one form to another • Acoustic transduction generally means converting sound energy into an electrical signal, or an electrical signal into sound • Microphones and loudspeakers are acoustic transducers 3 Acoustics and Psychoacoustics Mechanical Electrical to to Acoustical Acoustical Psychological Acoustical Mechanical propagation to (reflection, to diffraction, Mechanical Electrical absorption, etc.) (nerve signals) 4 What is Sound? • Vibration of air particles • A rapid fluctuation in air pressure above and below the normal atmospheric pressure • A wave phenomenon: we can observe the fluctuation as a function of time and as a function of spatial position 5 Sound (cont.) • Sound waves propagate through the air at approximately 343 meters per second – Or 1125 feet per second – Or 4.7 seconds per mile ≈ 5 seconds per mile – Or 13.5 inches per millisecond ≈ 1 foot per ms • The speed of sound (c) varies as the square root of absolute temperature – Slower when cold, faster when hot – Ex: 331 m/s at 32ºF, 353 m/s at 100ºF 6 Sound (cont.) • Sound waves have alternating high and low pressure phases • Pure tones (sine waves) go from maximum pressure to minimum pressure and back to maximum pressure. This is one cycle or one waveform period (T). T 7 Wavelength and Frequency • If we know the waveform period and the speed of sound, we can compute how far the sound wave travels during one cycle.