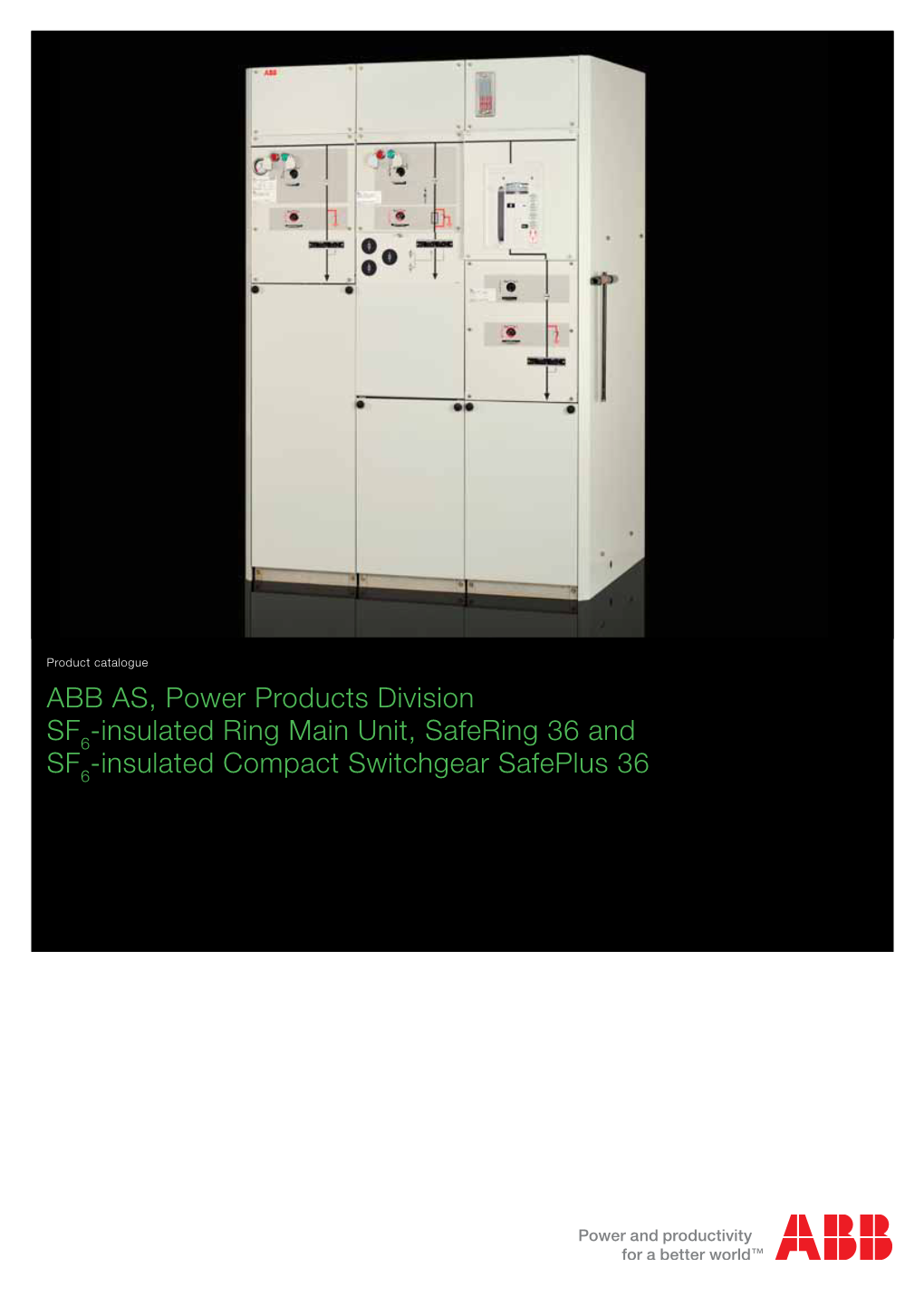

ABB AS, Power Products Division SF -Insulated Ring Main Unit

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

RVAC Professional Solutionslutions , Reliable Powerr Automotive Powering Business Worldwide

Gas Insulated Ring Main Unit RVAC Professional solutionslutions , Reliable powerr Automotive Powering business worldwide Aerospace Eaton delivers the power inside hundreds of products that are answering the demands of today’s fast changing world. We help our customers worldwide manage the power they need for buildings, aircraft, trucks, cars, machinery and entire businesses. And we do it in a way that consumes fewer resources. Next generation Powering Greener Buildings Truck transportation and Businesses Eaton is driving the Eaton’s Electrical Group is a development of new leading provider of power technologies – from hybrid quality, distribution and control drivetrains and emission control solutions that increase energy systems to advanced engine efficiency and improve power components – that reduce fuel quality, safety and reliability. consumption and emissions in Our solutions offer a growing trucks and cars. portfolio of “green” products and services, such as energy Higher expectations audits and real-time energy consumption monitoring. We continue to expand our Eaton’s Uninterruptible Power aerospace solutions and Hydraulics Supplies (UPS), variable-speed Hydraulics services to meet the needs of drives and lighting controls help new aviation platforms, conserve energy and increase including the high-flying light jet efficiency. and very light jet markets. Building on our strengths Our hydraulics business combines localised service and support with an innovative portfolio of fluid power solutions to answer the needs of global infrastructure projects, including locks, canals and Electrical dams. 1 RVAC Ring Main Unit The development of current power system focuses on the usage of ecological resources. Low power loss, low maintenance spending, reliable performance, flexible configuration are required on the medium voltage switchgear. -

Eaton RVAC Brochure

Gas Insulated Ring Main Unit RVAC Professional solutlutiioons , Reliable power Automotive Powering business worldwide Aerospace Eaton delivers the power inside hundreds of products that are answering the demands of today’s fast changing world. We help our customers worldwide manage the power they need for buildings, aircraft, trucks, cars, machinery and entire businesses. And we do it in a way that consumes fewer resources. Next generation Powering Greener Buildings Truck transportation and Businesses Eaton is driving the Eaton’s Electrical Group is a development of new leading provider of power technologies – from hybrid quality, distribution and control drivetrains and emission control solutions that increase energy systems to advanced engine efficiency and improve power components – that reduce fuel quality, safety and reliability. consumption and emissions in Our solutions offer a growing trucks and cars. portfolio of “green” products and services, such as energy Higher expectations audits and real-time energy consumption monitoring. We continue to expand our Eaton’s Uninterruptible Power aerospace solutions and Hydraulics Supplies (UPS), variable-speed Hydraulics services to meet the needs of drives and lighting controls help new aviation platforms, conserve energy and increase including the high-flying light jet efficiency. and very light jet markets. Building on our strengths Our hydraulics business combines localised service and support with an innovative portfolio of fluid power solutions to answer the needs of global infrastructure -

Switching Operator's Manual Distribution Switching

Switching Operator’s Manual Distribution Switching Document Number: 5011675 SECTION ONE Introduction: Distribution Switching Table of Contents 1. Introduction: Distribution Switching ...................................................... 1-1 1.1 Purpose .............................................................................................. 1-1 1.2 Content .............................................................................................. 1-1 1.2.1 Manual One .................................................................................... 1-1 1.2.2 Manual Two .................................................................................... 1-3 1.3 Switching Operator Authorisation Levels ............................................ 1-3 i Switching Operator's Manual One List of Figures No table of figures entries found. List of Tables No table of figures entries found. ii 1. Introduction: Distribution Switching 1.1 Purpose Manual One provides the switching operator with information on the distribution network configuration, apparatus and switching operations. The manual covers the Horizon Power distribution networks associated with the microgrid and Pilbara Grid systems. Manual Two provides the switching operator with information on the transmission network configuration, apparatus and switching operations. This manual covers the transmission network associated with the Pilbara Grid. Both manuals are intended to be used as a resource for all switching operators and also a major resource for the training modules in -

2018.12.13 THB Catalogue Safering Safeplus 12 24Kv

— PRODUCT CATALOGUE Gas-insulated ring main unit and gas-insulated compact switchgear SafeRing/SafePlus 12-24 kV • High reliability and safety • Fully sealed for lifetime • A wide range of functional units — Gas-insulated ring main unit and gas-insulated compact switchgear SafeRing/SafePlus 12-24 kV — 061 – 062 17 Extension of switchgear Table of contents 063 18 Base frame 064 19 Low voltage compartment/ top entry box – 066 005 – 007 1 Introduction 065 20 Motor operation 008 – 009 2 Design philosophy 067 21 Transformer protection – 070 010 3 Outer assembly 068 22 Fuse-links – 076 011 4 Inner design 071 23 Relays – 078 012 – 013 5 Production 077 24 Capacitive voltage indicators 014 – 018 6 Safety 079 25 Short-circuit indicators 019 7 Applications SafeRing/ SafePlus 080 26 Manometers/pressure indicators 020 – 026 8 Applications SafeRing 081– 082 27 Key interlocks 027 – 049 9 SafePlus modules 083 – 087 28 Smart grid applications 050 10 Mini-metering (integrated metering) 088 29 Low version switchgear – 096 051 11 Combisensor 089 30 Dimensions – 103 052 – 053 12 SeSmart 097 31 Technical data 054 – 056 13 Mechanisms 104 32 Environmental certification 057 14 Cable bushings 058 – 059 15 Cable termination 060 16 Cable test bushings 4 GAS-INSULATED RING MAIN UNIT AND GAS-INSULATED COMPACT SWITCHGEAR PRODUCT CATALOGUE 061 – 062 17 Extension of switchgear 063 18 Base frame 064 19 Low voltage compartment/ top entry box – 066 005 – 007 1 Introduction 065 20 Motor operation 008 – 009 2 Design philosophy 067 21 Transformer protection – 070 010 3 Outer -

Work Or Testing on Ring Main Units Without a Busbar Earth Facility With

WORK OR TESTING ON RING MAIN UNITS OPSAF-11-065 WITHOUT A BUSBAR EARTH FACILITY WITH Issue No. 2 THE CIRCUIT BREAKER CABLE BOX LIVE 1. SCOPE This document details the Approved procedure for work or testing on 33kV ring main units where the cable connected to the circuit breaker cable box remains Live, but the absence of a busbar earthing facility prevents the application of Basic Safety Rule A3, CSI 1 and OPSAF-10-003 (PSSI 3). This procedure confirms in writing the Approved manner for work or testing to proceed in order to comply with General Provision GP3 – Special Instructions. 2. ISSUE RECORD This is a Reference document. The current version is held on the EN Document Library. It is your responsibility to ensure you work to the current version. Issue Date Issue No Author Amendment Details January 2012 Issue 1 Dave Naylor Initial Issue: 5 Page Document February 2019 Issue 2 Dave Naylor To reflect the withdrawal of OPSAF-11-021 (MSP 2.10) 3. ISSUE AUTHORITY Author Owner Issue Authority Name: Dave Naylor Name: Gary Evans Name: Colin Taylor Title: Operational Safety Title: Operational Assurance Title: Director Processes and Engineer Manager Technology 4. REVIEW This is a Reference document which has a five year retention period after which a reminder will be issued to review and extend retention or archive. DISTRIBUTION This document is part of the Management Safety Procedures but does not have a maintained distribution list. © SP Power Systems Limited 1 of 6 MSP 2.4.15 WORK OR TESTING ON RING MAIN UNITS OPSAF-11-065 WITHOUT A BUSBAR EARTH FACILITY WITH Issue No. -

Ring Main Unit SF6 Gas Insulated Ring Main Units RMU Ring Main Unit SF6 Gas Insulated Ring Main Units

RMU Ring Main Unit SF6 Gas Insulated Ring Main Units RMU Ring Main Unit SF6 Gas Insulated Ring Main Units 24kV LFL type Based on maximizing efficiency and reliability of the power technology helps offering optimized solutions for your environment Susol RMU is enable to install on medium voltage distribution network and mainly used for protection of transformers in compact substations. It is used for medium voltage distribution in compact substations, small buldings, residential housing complex, large shopping malls, airports, wind power, and solar power comprising medium voltage networks. The concept of Susol RMU is offering a choice of other switch-fuse combination or Circuit Breaker with relay for protection of the transformer. 02 | LSIS Co., Ltd. Contents 24kV LCL type 24kV Extensible type 36kV LCL type Certified quality STL (The Short-Circuit Testing Liaison, KERI), ISO 9001, ISO 14001 LSIS has integrated a functional organization into each of its units, the main purpose of which is to check quality and ensure the adherence to standards. Routine quality check While producing Susol RMU, various routine tests are taken for product capacity. Tested items are as shown follows. •Filling pressure check •Tightness check •Manual and motor operation check •Dielectric check Contents •Contact resistance check •OCR operation check Features 05 Ordering Information 07 Configuration (Non-Extensible RMU) 08 Configurations (Extensible RMU) 11 Main characteristics 12 Types and diagrams 13 Major components 14 Accessories 20 Dimensions 25 LSIS Co., Ltd. | 03 RMU Non-Extensible: CB Feeder (LCL) & Fuse Feeder (LFL) RMU Extensible: LBS Feeder (L), CB Feeder (C) & Fuse Feeder (F) 24kV LFL type 24kV LCL type 04 | LSIS Co., Ltd. -

M-RING 36 Medium Voltage Ring-Main-Unit

M-RING 36 SF6 Insulated Ring Main Unit Metal-Enclosed (LSC2A) according to About us 3B Energy can propose a huge number of Pro- ducts related to Energy sector. We are active in the whole world of Power Transmission and Distribu- tion. Medium Voltage switchgears, Medium Voltage switches, Low Voltage PC, Low Voltage MCCs with fix and withdrawable units, Transformers, Cabinets; 3B Energy can propose a wide range of Products for fulfilling any request and need. 3B Energy is very active and smart in assisting customers for finding Solutions related to Energy sector. We can support the customer during engi- neering phase of the plant, during purchasing steps, for the supply and after-sales services. 3B Energy is a real “turnkey” Solution provider; Packa- ge Substations, Transfomer Substations, Mobile Cabinets; we can propose a complete solution set for letting the customer have one player only for his whole plant. 3B Energy can propose a complete and detailed list of Services which can cover each step of Engine- ering phase. Our technical staff is highly expert and professional and can support the customer star- ting from the base design of a single component till a complete apparatus for electrical application. We can design and project every component the customer may need: a single contact or a complete switching device, we can develop and engineer the technology for any product or application of Energy sector 2 www.3b-energy.com M-RING 36 Contents About us 2 Introduction 4 Main technical data 6 Unit Types 8 Foundations 14 www.3b-energy.com 3 M-RING 36 Introduction GENERAL M-RING 36 Series Ring Main Unit is an extendable SF6 gas insulated metal enclosed switchgear at rated voltage 40.5kV. -

SF6 Gas Insulated Ring Main Unit RMU a Compact Switchgear Solution for Secondary Power Distribution Networks

www.lsis.biz SF6 Gas Insulated Ring Main Unit RMU A Compact switchgear solution for secondary power distribution networks. Super Solution Ring Main Unit Ring Main Unit The best solution for Power Distribution Contents 4 Features 6 Configurations 8 Intelligent application 10 Main characteristics Detailed characteristics for each 15 Optional components 20 Operational sequence 21 Dimensions 22 Quality assurance RMU A Compact Switchgear Solution for Secondary Distribution (Ring Main Unit Up to 24kV, SF6 -Insulated) Susol RMU is enable to install on medium voltage distribution network and mainly used for protection of transformers in compact substations. It is used for medium voltage distribution in compact substations, small buildings, residential housing complex, large shopping malls, airports, wind power, etc. comprising medium voltage networks. The concept of Susol RMU is offering a choice of other switch-fuse combination or circuit breaker with relay for protection of the transformer. function [ 12 Load Break Switch 13 Circuit Breaker 14 Fuse combination Switch 14 Cable compartments ] RMU is the solution to meet your medium voltage power distribution line needs. Susol RMU is a compact ring main unit combining all MV functional units to enable to supply and protect transformers on the secondary distribution network. Susol RMU can be supplied in various and different configurations suitable for most switching applications in 12/17.5/24 kV distribution networks. 4 Technology Durability and usefulness �Metal enclosed unit for Indoor installation and type tested. �Metal enclosed tank is hermetically sealed, it means this is �Insulated by SF6 Gas. independent of environmental effects such as dirt, small insects, �Maintenance free and easy installation. -

Ring Main Unit RMU a Compact Switchgear Solution for Secondary Power Distribution Networks

www.lsis.biz SF6 Gas Insulated Ring Main Unit RMU A Compact switchgear solution for secondary power distribution networks. Super Solution Ring Main Unit Ring Main Unit The best solution for Power Distribution Contents 4 Features 6 Configurations 8 Intelligent application 10 Main characteristics Detailed characteristics for each 15 Optional components 20 Operational sequence 21 Dimensions 22 Quality assurance RMU A Compact Switchgear Solution for Secondary Distribution (Ring Main Unit Up to 24kV, SF6 -Insulated) Susol RMU is enable to install on medium voltage distribution network and mainly used for protection of transformers in compact substations. It is used for medium voltage distribution in compact substations, small buildings, residential housing complex, large shopping malls, airports, wind power, etc. comprising medium voltage networks. The concept of Susol RMU is offering a choice of other switch-fuse combination or circuit breaker with relay for protection of the transformer. function [ 12 Load Break Switch 13 Circuit Breaker 14 Fuse combination Switch 14 Cable compartments ] RMU is the solution to meet your medium voltage power distribution line needs. Susol RMU is a compact ring main unit combining all MV functional units to enable to supply and protect transformers on the secondary distribution network. Susol RMU can be supplied in various and different configurations suitable for most switching applications in 12/17.5/24 kV distribution networks. 4 Technology Durability and usefulness �Metal enclosed unit for Indoor installation and type tested. �Metal enclosed tank is hermetically sealed, it means this is �Insulated by SF6 Gas. independent of environmental effects such as dirt, small insects, �Maintenance free and easy installation. -

Power Distribution and Automation Product Portfolio

engineering intelligent solutions www.lucyelectric.com Power distribution and automation product portfolio engineering intelligent solutions Lucy Electric is a global leader in secondary power distribution solutions with over 100 years’ industry experience. Specialising in high-performance switchgear, we develop and supply intelligent solutions and services for utility, industrial and commercial applications. This enables the safe and reliable distribution of energy to homes and businesses worldwide. To find out more about us, visit: www.lucyelectric.com Page 2 Contents Applications 4 Low Voltage Distribution Cabinets 46 AcuLok 48 Medium Voltage Ring Main Units 6 Multi Service Distribution Board, vertical 49 Aegis 36 8 Multi Service Distribution Board, horizontal 50 Aegis Plus 9 Sub Mains Distribution Board 51 Sabre 10 Trident 11 Low Voltage Cut Outs 53 Scimitar 12 Heavy duty 55 Metering Units Integrated CT 56 Aegis Plus 13 Pole mounted 57 Aegis 36 14 ABC distribution box 58 Sabre 15 Indoor house service 59 Oil 16 Outdoor house service 60 Medium Voltage Air Insulated Switchgear 17 Low Voltage Air Insulated Switchgear 61 SMART CDC 62 SMART CLAD 18 SMART CCM 63 INECLAD 19 SMART VAC 20 Energy Services INEMOTOR 21 64 Busbar Ducts 22 High/Medium Voltage 24 Rapier DSB 26 Rapier GX 27 Rapier SAX 28 Isolating links 29 Dropout fuses 30 Distribution network monitoring, control and automation 32 Gemini 3 platform 33 Gemini 3 Modular RTU 36 Gemini 3 Mini RTU 37 Gemini SCADA solutions 38 MCU 318 40 MCU 520 41 SlimSensor 42 Data Centre 43 Page 3 Product -

Medium Voltage Ring Main Unit

Medium Voltage Ring Main Unit 17.5 kV, 630 A, 50/60 Hz, SF6 INSULATED JEESM6 SERIES www.alhamad.ae Medium Voltage Al Hamad is the leading manufacturing enterprise specialized in Low voltage CONTENTS to Medium voltage electrical PRODUCT INTRODUCTION 04 products. PRODUCT FEATURES 06 • TECHNOLOGY FEATURES • DURABILITY & USEFULNESS • SAFETY FEATURES Headquartered in Abu Dhabi, the increased demands of the UAE, the company covers entire products in upcoming years MENA region and provide expert and worked collaboratively to APPLICATIONS 09 solutions in view of the local manufacture and provide high • APPLICABLE STANDARDS environment, requirements and quality solutions in utilities and necessities. many industrial applications. • OPERATING CONDITIONS With an extensive experience The team is dedicated to of more than 2 decades and a providing Electrical Solutions RMU EXTENSIBLE FEATURE 10 thorough knowledge on Low and to multiple sectors including Medium voltage products, the utilities, Oil & Gas, Defense & team at Al Hamad understand infrastructure segment. PRODUCT ELEMENTS 11 • PRODUCT REPRESENTATION • RING SWITCH • VACUUM CIRCUIT BREAKER • DISCONNECTOR SWITCH • VPIS • SF6 PRESSURE INDICATOR • FPI/EFI TECHNICAL DATA 14 DIMENSIONAL DETAILS 15 PRODUCTS 16 3 www.alhamad.ae Medium Voltage The range can be used in steel tank of grade 316L The housing is treated using PRODUCT indoor/outdoor applications with an ingress protection of galvanized sheet steel and and is available in extensible, IP-67, thereby limiting any in-house oven cured painting INTRODUCTION non-extensible and modular leakages. The structural after 6 stage pretreatment form to comply various tank welding ensures high process to withstand iRing family JEES M6 Ring main unit is factory-assembled, type-tested (KEMA, Netherlands application requirements. -

Sabre Ring Main Unit Sabre Catalogue Table of Contents

Sabre Ring Main Unit Sabre catalogue Table of contents Introduction to Lucy Electric 3 Product panorama 4 Introduction to Sabre 5 Installation and operating conditions 6 Safety features 6 Application example 9 Standards 9 The Sabre range 10 Non extensible range 10 Extensible range 12 Mounting style 17 Product characteristics 19 i. Product presentation 19 ii. User interface and interlocking mechanism 20 iii. Ring switch 21 iv. Vacuum circuit breaker 21 v. Circuit breaker protection 22 a. TLF 22 b. Protection relays 24 vi. Protection CTs for TLF and relays 27 vii. Bushings 27 Options and accessories 28 i. Secondary injection 28 ii. Actuators (motors) 28 iii. Cable boxes, glands and accessories 29 iv. Bus bar couplings 30 v. MV sensors 30 vi. Watchdog for relays 30 vii. Operation counter 30 viii. Castell locks 30 ix. Protection trip remote indicator 30 x. Shunt trip coils 31 xi. Earth fault indicators (EFI) 31 Cable terminations 32 Remote terminal unit (RTU) 33 Smart grid ready 34 Technical data sheet 35 Dimensions 37 Models, options and accessories 47 Sabre models and options order form 53 Air metering unit (AMU) 57 i. Characteristics 57 ii. Mounting style 57 iii. Dimensions 58 iv. Options and Accessories 60 Air metering unit (AMU) order form 66 Sabre accessories order form 68 Page 2 Introduction to Lucy Electric Lucy Electric is a global leader in switching, the capability to manufacture equipment to suit almost protection and automation solutions for any location, climate or situation, Lucy Electric can also electrical distribution systems with over offer maintenance packages and dedicated after sales 100 years’ industry experience.