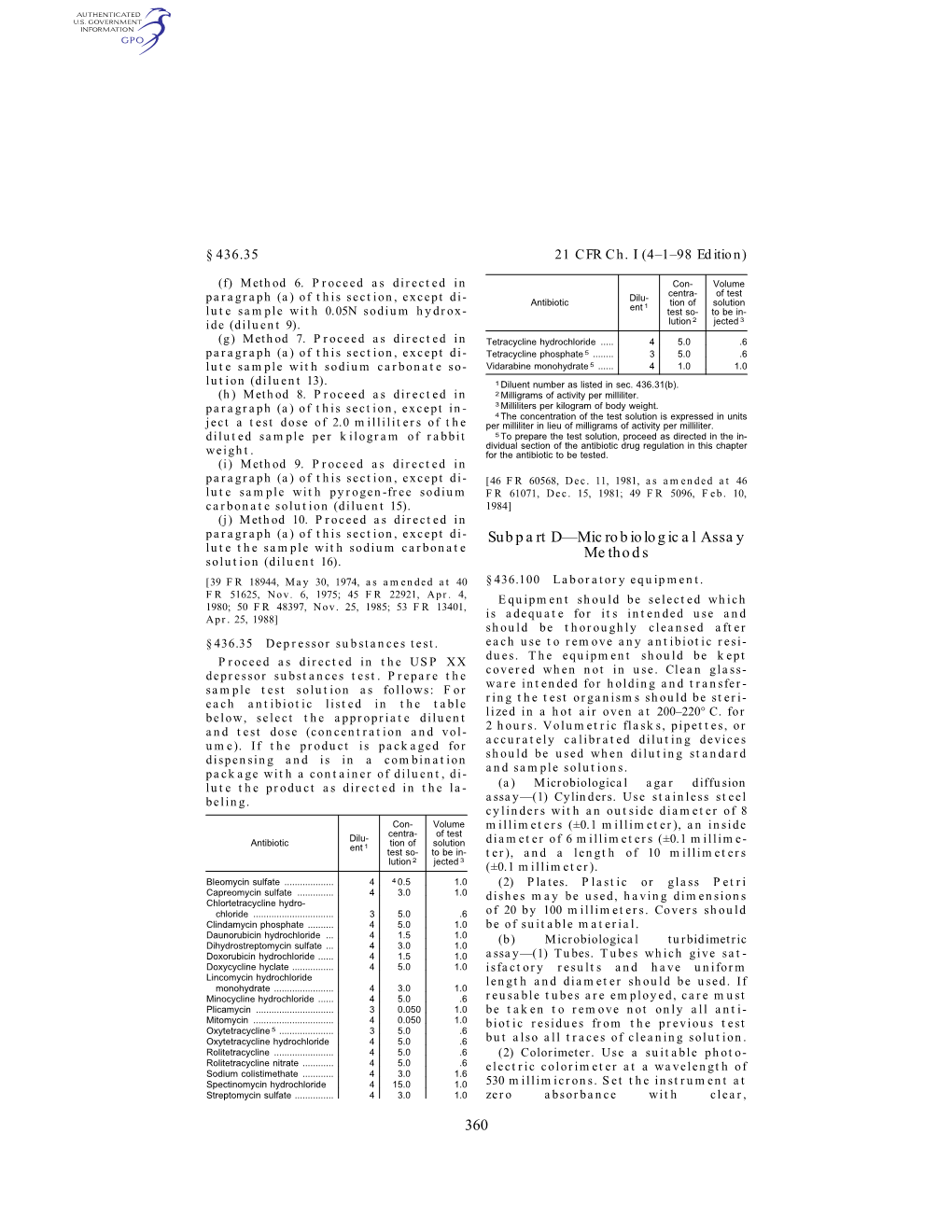

360 Subpart D—Microbiological Assay Methods

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Review Electrochemical Immunosensors for Antibiotics

Review Electrochemical Immunosensors for Antibiotic Detection Aleksandra Pollap and Jolanta Kochana * Department of Analytical Chemistry, Faculty of Chemistry, Jagiellonian University, Gronostajowa 2, 30-387 Kraków, Poland; [email protected] * Correspondence: [email protected]; Tel.: +48-12-6862-416 Received: 27 March 2019; Accepted: 25 April 2019; Published: 1 May 2019 Abstract: Antibiotics are an important class of drugs destined for treatment of bacterial diseases. Misuses and overuses of antibiotics observed over the last decade have led to global problems of bacterial resistance against antibiotics (ABR). One of the crucial actions taken towards limiting the spread of antibiotics and controlling this dangerous phenomenon is the sensitive and accurate determination of antibiotics residues in body fluids, food products, and animals, as well as monitoring their presence in the environment. Immunosensors, a group of biosensors, can be considered an attractive tool because of their simplicity, rapid action, low-cost analysis, and especially, the unique selectivity arising from harnessing the antigen–antibody interaction that is the basis of immunosensor functioning. Herein, we present the recent achievements in the field of electrochemical immunosensors designed to determination of antibiotics. Keywords: antibiotic; immunosensor; antibody; electrochemical; immunoassay; antibacterial resistance 1. Introduction In recent years, a rapid development of analytical methods employing biosensors has been observed. A biosensor is a small analytical device that consists of a bioreceptor and a transducer. The role of a bioreceptor is the recognition of the target analyte, while a transducer converts the biological signal, produced by the bioreceptor and depending on the concentration of analyte molecules, into a measured signal, e.g., electrical, thermal, or optical [1]. -

Technical Information

Technical Information Antibiotic Assay Medium No.1 (Seed Agar) Product Code : DM1003 Application: - Antibiotic Assay Medium No.1 (Seed Agar) is used in the microbiological assay of beta-lactam and other antibiotics. Composition** Ingredients Gms / Litre Peptic digest of animal tissue (Peptone) 6.000 or detecting faecal coliforms drinking in water waste water, seawater and foods samples by MPN Method. Casein enzymic hydrolysate 4.000 Yeast extract 3.000 Beef extract 1.500 Dextrose 1.000 Agar 15.000 Final pH (at 25°C) 6.6±0.2 **Formula adjusted, standardized to suit performance parameters Principle & Interpretation The potency of an antibiotic can be determined by chemical, physical and biological methods. An assay is performed to determine the ability of an antibiotic to kill or inhibit the growth of living microorganisms. Biological tests offer the most convenient m eans of performing an assay (1), since a reduction in the antimicrobial activity of a specific antibiotic reveals changes that is not usually displayed by chemical methods (2). Antibacterial susceptibility testing may be performed by either dilution (turbidimetric) or diffusion methods. The choice o f methodology is based on many factors, including ease of performance, flexibility and use of automated or semi-automated devices for both identification and susceptibility testing (3). Grove and Randall have elucidated antibiotic assays and media in their comprehensive treatise on antibiotic assays (4). Antibiotic Assay Medium No.1 is used in the microbiological assay of ß-lactam and other antibiotics. These media are prepared according to the specifications detailed in various pharmacopoeias (2-6) and by the FDA (7). -

(12) United States Patent (10) Patent No.: US 9,662.400 B2 Smith Et Al

USOO9662400B2 (12) United States Patent (10) Patent No.: US 9,662.400 B2 Smith et al. (45) Date of Patent: *May 30, 2017 (54) METHODS FOR PRODUCING A (2013.01); C08B 37/003 (2013.01); C08L 5/08 BODEGRADABLE CHITOSAN (2013.01); A6 IK 38/00 (2013.01); A61 L COMPOSITION AND USES THEREOF 2300/404 (2013.01) (58) Field of Classification Search (71) Applicant: University of Memphis Research CPC ...... A61K 47/36; A61K 31/00; A61K 9/7007; Foundation, Memphis, TN (US) A61K 9/0024; A61 L 15/28: A61L 27/20; A61L 27/58: A61L 31/042; C08B 37/003 (72) Inventors: James Keaton Smith, Memphis, TN USPC ................................ 514/23, 40, 777; 536/20 (US); Ashley C. Parker, Memphis, TN See application file for complete search history. (US); Jessica A. Jennings, Memphis, (56) References Cited TN (US); Benjamin T. Reves, Memphis, TN (US); Warren O. U.S. PATENT DOCUMENTS Haggard, Bartlett, TN (US) 4,895,724. A * 1/1990 Cardinal .............. A61K9/0024 424,278.1 (73) Assignee: The University of Memphis Research 5,541,233 A 7/1996 Roenigk Foundation, Memphis, TN (US) 5,958,443 A 9/1999 Viegas et al. 6,699,287 B2 3/2004 Son et al. (*) Notice: Subject to any disclaimer, the term of this 6,989,157 B2 1/2006 Gillis et al. patent is extended or adjusted under 35 7,371.403 B2 5/2008 McCarthy et al. 2003, OO15825 A1 1/2003 Sugie et al. U.S.C. 154(b) by 0 days. 2003/0206958 A1 11/2003 Cattaneo et al. -

Antibiotic Assay Medium No. 3 (Assay Broth) Is Used for Microbiological Assay of Antibiotics. M042

HiMedia Laboratories Technical Data Antibiotic Assay Medium No. 3 (Assay Broth) is used for M042 microbiological assay of antibiotics. Antibiotic Assay Medium No. 3 (Assay Broth) is used for microbiological assay of antibiotics. Composition** Ingredients Gms / Litre Peptic digest of animal tissue (Peptone) 5.000 Beef extract 1.500 Yeast extract 1.500 Dextrose 1.000 Sodium chloride 3.500 Dipotassium phosphate 3.680 Potassium dihydrogen phosphate 1.320 Final pH ( at 25°C) 7.0±0.2 **Formula adjusted, standardized to suit performance parameters Directions Suspend 17.5 grams in 1000 ml distilled water. Heat if necessary to dissolve the medium completely. Sterilize by autoclaving at 15 lbs pressure (121°C) for 15 minutes. Advice:Recommended for the Microbiological assay of Amikacin, Bacitracin, Capreomycin, Chlortetracycline,Chloramphenicol,Cycloserine,Demeclocycline,Dihydrostreptomycin, Doxycycline, Gentamicin, Gramicidin, Kanamycin, Methacycline, Neomycin, Novobiocin, Oxytetracycline, Rolitetracycline, Streptomycin, Tetracycline, Tobramycin, Trolendomycin and Tylosin according to official methods . Principle And Interpretation Antibiotic Assay Medium is used in the performance of antibiotic assays. Grove and Randall have elucidated those antibiotic assays and media in their comprehensive treatise on antibiotic assays (1). Antibiotic Assay Medium No. 3 (Assay Broth) is used in the microbiological assay of different antibiotics in pharmaceutical and food products by the turbidimetric method. Ripperre et al reported that turbidimetric methods for determining the potency of antibiotics are inherently more accurate and more precise than agar diffusion procedures (2). Turbidimetric antibiotic assay is based on the change or inhibition of growth of a test microorganims in a liquid medium containing a uniform concentration of an antibiotic. After incubation of the test organism in the working dilutions of the antibiotics, the amount of growth is determined by measuring the light transmittance using spectrophotometer. -

Prediction of Premature Termination Codon Suppressing Compounds for Treatment of Duchenne Muscular Dystrophy Using Machine Learning

Prediction of Premature Termination Codon Suppressing Compounds for Treatment of Duchenne Muscular Dystrophy using Machine Learning Kate Wang et al. Supplemental Table S1. Drugs selected by Pharmacophore-based, ML-based and DL- based search in the FDA-approved drugs database Pharmacophore WEKA TF 1-Palmitoyl-2-oleoyl-sn-glycero-3- 5-O-phosphono-alpha-D- (phospho-rac-(1-glycerol)) ribofuranosyl diphosphate Acarbose Amikacin Acetylcarnitine Acetarsol Arbutamine Acetylcholine Adenosine Aldehydo-N-Acetyl-D- Benserazide Acyclovir Glucosamine Bisoprolol Adefovir dipivoxil Alendronic acid Brivudine Alfentanil Alginic acid Cefamandole Alitretinoin alpha-Arbutin Cefdinir Azithromycin Amikacin Cefixime Balsalazide Amiloride Cefonicid Bethanechol Arbutin Ceforanide Bicalutamide Ascorbic acid calcium salt Cefotetan Calcium glubionate Auranofin Ceftibuten Cangrelor Azacitidine Ceftolozane Capecitabine Benserazide Cerivastatin Carbamoylcholine Besifloxacin Chlortetracycline Carisoprodol beta-L-fructofuranose Cilastatin Chlorobutanol Bictegravir Citicoline Cidofovir Bismuth subgallate Cladribine Clodronic acid Bleomycin Clarithromycin Colistimethate Bortezomib Clindamycin Cyclandelate Bromotheophylline Clofarabine Dexpanthenol Calcium threonate Cromoglicic acid Edoxudine Capecitabine Demeclocycline Elbasvir Capreomycin Diaminopropanol tetraacetic acid Erdosteine Carbidopa Diazolidinylurea Ethchlorvynol Carbocisteine Dibekacin Ethinamate Carboplatin Dinoprostone Famotidine Cefotetan Dipyridamole Fidaxomicin Chlormerodrin Doripenem Flavin adenine dinucleotide -

Application of Various Chemotherapeutic Agents in Experimental Bovine Anaplasmosis S.K

APPLICATION OF VARIOUS CHEMOTHERAPEUTIC AGENTS IN EXPERIMENTAL BOVINE ANAPLASMOSIS S.K. Sharma, D.P. Banerjee, O.P. Gautam To cite this version: S.K. Sharma, D.P. Banerjee, O.P. Gautam. APPLICATION OF VARIOUS CHEMOTHERAPEUTIC AGENTS IN EXPERIMENTAL BOVINE ANAPLASMOSIS. Annales de Recherches Vétérinaires, INRA Editions, 1977, 8 (3), pp.307-313. hal-00900943 HAL Id: hal-00900943 https://hal.archives-ouvertes.fr/hal-00900943 Submitted on 1 Jan 1977 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. APPLICATION OF VARIOUS CHEMOTHERAPEUTIC AGENTS IN EXPERIMENTAL BOVINE ANAPLASMOSIS S.K. SHARMA, D.P. BANERJEE O.P. GAUTAM Department of Veterinary Medicine, College of Veterinary Sciences, Haryana Agricultural University, Hlssar-125004, Haryana, India ’ Résumé UTILISATION DE DIVERS AGENTS CHIMIOTHERAPEUTIQUES AU COURS DE L’ANAPLAS- MOSE BOVINE EXPERIMENTALE. ― Un essai de traitement a été réalisé avec différents agents ehimiothérapeutiques, sur des cas cliniques ou des porteurs inapparents d’ana- plasmose bovine expérimentale. La Dithiosemicarbazone (associée à l’Oxytétracycline), le Chloramphénicol et la Rolitétracycline ont très efficacement entraîné la guérison clinique et l’élimination des agents pathogènes. L’imidocarb a entraîné la guérison clinique sans supprimer complètement les microorganismes. -

Antibiotic Use and Abuse: a Threat to Mitochondria and Chloroplasts with Impact on Research, Health, and Environment

Insights & Perspectives Think again Antibiotic use and abuse: A threat to mitochondria and chloroplasts with impact on research, health, and environment Xu Wang1)†, Dongryeol Ryu1)†, Riekelt H. Houtkooper2)* and Johan Auwerx1)* Recently, several studies have demonstrated that tetracyclines, the antibiotics Introduction most intensively used in livestock and that are also widely applied in biomedical research, interrupt mitochondrial proteostasis and physiology in animals Mitochondria and chloroplasts are ranging from round worms, fruit flies, and mice to human cell lines. Importantly, unique and subcellular organelles that a plant chloroplasts, like their mitochondria, are also under certain conditions have evolved from endosymbiotic - proteobacteria and cyanobacteria-like vulnerable to these and other antibiotics that are leached into our environment. prokaryotes, respectively (Fig. 1A) [1, 2]. Together these endosymbiotic organelles are not only essential for cellular and This endosymbiotic origin also makes organismal homeostasis stricto sensu, but also have an important role to play in theseorganellesvulnerabletoantibiotics. the sustainability of our ecosystem as they maintain the delicate balance Mitochondria and chloroplasts retained between autotrophs and heterotrophs, which fix and utilize energy, respec- multiple copies of their own circular DNA (mtDNA and cpDNA), a vestige of the tively. Therefore, stricter policies on antibiotic usage are absolutely required as bacterial DNA, which encodes for only a their use in research confounds experimental outcomes, and their uncontrolled few polypeptides, tRNAs and rRNAs [1, 3, applications in medicine and agriculture pose a significant threat to a balanced 4]. Furthermore, both mitochondria and ecosystem and the well-being of these endosymbionts that are essential to chloroplasts have bacterial-type ribo- sustain health. -

EMA/CVMP/158366/2019 Committee for Medicinal Products for Veterinary Use

Ref. Ares(2019)6843167 - 05/11/2019 31 October 2019 EMA/CVMP/158366/2019 Committee for Medicinal Products for Veterinary Use Advice on implementing measures under Article 37(4) of Regulation (EU) 2019/6 on veterinary medicinal products – Criteria for the designation of antimicrobials to be reserved for treatment of certain infections in humans Official address Domenico Scarlattilaan 6 ● 1083 HS Amsterdam ● The Netherlands Address for visits and deliveries Refer to www.ema.europa.eu/how-to-find-us Send us a question Go to www.ema.europa.eu/contact Telephone +31 (0)88 781 6000 An agency of the European Union © European Medicines Agency, 2019. Reproduction is authorised provided the source is acknowledged. Introduction On 6 February 2019, the European Commission sent a request to the European Medicines Agency (EMA) for a report on the criteria for the designation of antimicrobials to be reserved for the treatment of certain infections in humans in order to preserve the efficacy of those antimicrobials. The Agency was requested to provide a report by 31 October 2019 containing recommendations to the Commission as to which criteria should be used to determine those antimicrobials to be reserved for treatment of certain infections in humans (this is also referred to as ‘criteria for designating antimicrobials for human use’, ‘restricting antimicrobials to human use’, or ‘reserved for human use only’). The Committee for Medicinal Products for Veterinary Use (CVMP) formed an expert group to prepare the scientific report. The group was composed of seven experts selected from the European network of experts, on the basis of recommendations from the national competent authorities, one expert nominated from European Food Safety Authority (EFSA), one expert nominated by European Centre for Disease Prevention and Control (ECDC), one expert with expertise on human infectious diseases, and two Agency staff members with expertise on development of antimicrobial resistance . -

STUDY GUIDE the TETRACYCLINE ANTIBIOTICS 1. Identify the Tetracyclines (Tcs) As First Or Second Generation Agents and by Duratio

STUDY GUIDE THE TETRACYCLINE ANTIBIOTICS 1. Identify the tetracyclines (TCs) as first or second generation agents and by duration of action (short, intermediate and long). 2. Be able to identify the TC rings (A, B, C and D) and number the entire ring system. 3. Which organisms biosynthesize TCs? What are the biochemical precursors? 4. Identify the TWO acidic functionalities of the TC ring system and explain why they are acidic. Identify the basic functionality of the TCs. 5. Why are the TSs compounds zwitterionic at physiological pH? Which salts (of the base) are used and why these salts? 6. Understand the epimerization reaction; where it occurs and what is its significance. 7. Explain the tetracycline elimination reaction involving substituents in Ring C. When and why does this occur? What electronic factor drives this reaction to completion? 8. Why is the elimination reaction less likely to occur with demeclocycline than tetracycline? Why is it less likely with minocycline than demeclocycline? 9. What are the elimination products generally called? Explain why methacycline and meclocycline may also undergo an "elimination- type" reaction like those TCs with a 6-OH group? 10. Identify all of the TCs as acid unstable, intermediate acid stability and acid-stable and know why! Why is this reaction important? 11. What is an epianhydrotetracycline? How does it form and why is it's formation important? 12. How do isotetracyclines form? What is the key functional group in this reaction? Why is this reaction important? 13. What is the chelation reaction, when does it occur and why is it significant? 14. -

WO 2007/147133 Al

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization International Bureau (43) International Publication Date PCT (10) International Publication Number 21 December 2007 (21.12.2007) WO 2007/147133 Al (51) International Patent Classification: (74) Agent: SARUSSI, Steven, J.; Mcdonnel Boehnen HuI- A61K9/20 (2006.01) A61K 31/65 (2006.01) bert & Berghoff LIp, 300 South Wacker Drive, Suite 3200, A61K9/00 (2006.01) A61P 31/00 (2006.01) Chicago, IL 60606 (US). (81) Designated States (unless otherwise indicated, for every (21) International Application Number: kind of national protection available): AE, AG, AL, AM, PCT/US2007/071369 AT,AU, AZ, BA, BB, BG, BH, BR, BW, BY, BZ, CA, CH, CN, CO, CR, CU, CZ, DE, DK, DM, DO, DZ, EC, EE, EG, (22) International Filing Date: 15 June 2007 (15.06.2007) ES, FI, GB, GD, GE, GH, GM, GT, HN, HR, HU, ID, IL, IN, IS, JP, KE, KG, KM, KN, KP, KR, KZ, LA, LC, LK, (25) Filing Language: English LR, LS, LT, LU, LY, MA, MD, ME, MG, MK, MN, MW, MX, MY, MZ, NA, NG, NI, NO, NZ, OM, PG, PH, PL, (26) Publication Language: English PT, RO, RS, RU, SC, SD, SE, SG, SK, SL, SM, SV, SY, TJ, TM, TN, TR, TT, TZ, UA, UG, US, UZ, VC, VN, ZA, (30) Priority Data: ZM, ZW 60/813,925 15 June 2006 (15.06.2006) US 60/814,255 16 June 2006 (16.06.2006) US (84) Designated States (unless otherwise indicated, for every kind of regional protection available): ARIPO (BW, GH, (71) Applicant (for all designated States except US): GM, KE, LS, MW, MZ, NA, SD, SL, SZ, TZ, UG, ZM, SERENEX, INC. -

Of Significant in Vitro Antagonism Between Penicillin, Cephalothin, and Rolitetracycline FRANZ D

ANTIMICROBIAL AGENTS AND CHEmoTHzRAPY, Nov. 1976, p. 802-808 Vol. 10, No. 5 Copyright © 1976 American Society for Microbiology Printed in U.S.A. Combination of Bacteriostatic and Bactericidal Drugs: Lack of Significant In Vitro Antagonism Between Penicillin, Cephalothin, and Rolitetracycline FRANZ D. DASCHNERI Children Hospital, Division ofAntimicrobial Therapy, University ofMunich, 8 Munich 2, Germany Received for publication 16 April 1976 Although it is generally believed that bactericidal and bacteriostatic drugs should not be combined in vivo, in vitro experiments using the checkerboard dilution technique revealed no antagonism between penicillin/cephalothin and rolitetracycline but rather additive or synergistic activity of either drug combi- nation in 40 to 50% of20 Escherichia coli and 14 Staphylococcus aureus strains. Slight antagonism occurred only between 3 and 8 h after combining penicillin/ cephalothin and rolitetracycline in either bacteriostatic or bactericidal concen- trations, but not after 24 h of incubation, nor was antagonism found with combinations of these drugs in bacteriostatic concentrations. Neither bacterio- static nor bactericidal activity of penicillin/cephalothin and rolitetracycline was inhibited by pretreatment of one E. coli strain with bacteriostatic rolitetracyc- line or bacteriostatic penicillin/cephalothin concentrations. Penicillin and ceph- alothin could exert a bactericidal effect after 2-h exposure of theE. coli strain to bacteriostatic rolitetracycline concentrations. Combined action of subinhibitory penicillin and rolitetracycline concentrations resulted in more pronounced inhi- bition of growth than either drug alone. The higher activity of penicillin/ cephalothin in combination with rolitetracycline on some E. coli and S. aureus strains might be due to a better access of rolitetracycline into bacterial cells whose cell walls have been weakened by cell wall-active, bactericidal drugs. -

Characterization and in Vitro Release Studies of Tetracycline and Rolitetracycline Imobilized on Anionic Collagen Membranes

Materials Research, Vol. 12, No. 1, 69-74, 2009 © 2009 Characterization and in vitro Release Studies of Tetracycline and Rolitetracycline Imobilized on Anionic Collagen Membranes Gilberto Goissisa*, Maria Helena de Sousab* aDepartamento de Produção, Biotech Biomédica Produtos Médicos e Odontológicos Ltda. Rua Santos Dumont, 800, Vila Celina, 13566-445 São Carlos - SP, Brazil bFaculdade Farmácia, Campus de Jatai, Universidade Federal de Goiás – UFG, Jatai - GO, Brazil Received: June 20, 2008; Revised: January 6, 2009 This work reports the covalent immobilization of tetracycline and rolitetracycline over anionic collagen membranes and the drug release studies as an effort to develop a two stage drug release based on diffusion (fast release) and on the rate of membrane biodegradation (slow release). Independent from casting conditions antibiotics incorporated by dispersion were released in the range from 80 to 100% within 7 hours in concentrations significantly higher than those described for the prevention of bacterial growth. Antibiotic release within this period was predominantly diffusion controlled. Covalent immobilization by a modified azide procedure occurred with preservation of collagen structure independently from pH of casting and reaction conditions. Its expected that anionic collagen membranes with dispersed and covalently bound rolitetracycline or tetracycline, in association with conventional therapy, may significantly reduce membrane induced infections observed post-implantation, one of the major problem associated with periodontal ligaments reconstruction by the Guided Tissue Regeneration procedure. Keywords: antibiotic, immobilization, covalent, release, collagen, membranes 1. Introduction Sustained drug release technology1 is being applied from protein this purpose formulations include tetracycline fibber, doxycycline hormones such as insulin for the treatment of diabetes2 to antibiotics polymer, chlorhexidine chip, minocycline ointment and metronida- for the prevention or minimization of bacterial infection3-5.