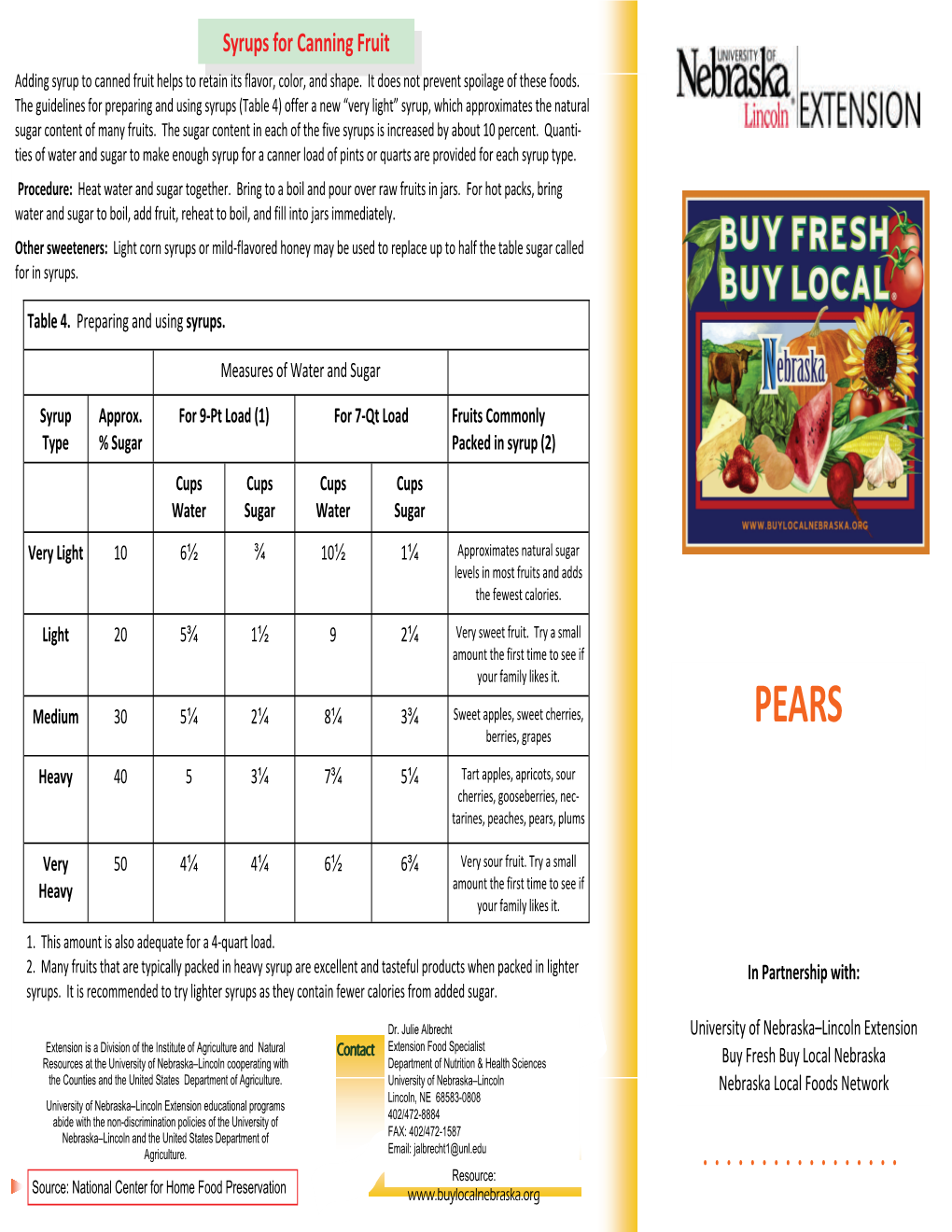

Syrups for Canning Fruit Adding Syrup to Canned Fruit Helps to Retain Its Flavor, Color, and Shape

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Great Food, Great Stories from Korea

GREAT FOOD, GREAT STORIE FOOD, GREAT GREAT A Tableau of a Diamond Wedding Anniversary GOVERNMENT PUBLICATIONS This is a picture of an older couple from the 18th century repeating their wedding ceremony in celebration of their 60th anniversary. REGISTRATION NUMBER This painting vividly depicts a tableau in which their children offer up 11-1541000-001295-01 a cup of drink, wishing them health and longevity. The authorship of the painting is unknown, and the painting is currently housed in the National Museum of Korea. Designed to help foreigners understand Korean cuisine more easily and with greater accuracy, our <Korean Menu Guide> contains information on 154 Korean dishes in 10 languages. S <Korean Restaurant Guide 2011-Tokyo> introduces 34 excellent F Korean restaurants in the Greater Tokyo Area. ROM KOREA GREAT FOOD, GREAT STORIES FROM KOREA The Korean Food Foundation is a specialized GREAT FOOD, GREAT STORIES private organization that searches for new This book tells the many stories of Korean food, the rich flavors that have evolved generation dishes and conducts research on Korean cuisine after generation, meal after meal, for over several millennia on the Korean peninsula. in order to introduce Korean food and culinary A single dish usually leads to the creation of another through the expansion of time and space, FROM KOREA culture to the world, and support related making it impossible to count the exact number of dishes in the Korean cuisine. So, for this content development and marketing. <Korean Restaurant Guide 2011-Western Europe> (5 volumes in total) book, we have only included a selection of a hundred or so of the most representative. -

STAR SWEETENERS the Best of the Naturals

STAR SWEETENERS The Best of the Naturals Become sugar savvy! The term "natural" as applied to sweeteners, can mean many things. The sweeteners recommended below will provide you with steady energy because they take a long time to digest. Natural choices offer rich flavors, vitamins and minerals, without the ups and downs of refined sugars. Sugar substitutes were actually the natural sweeteners of days past, especially honey and maple syrup. Stay away from man-made artificial sweeteners including aspartame and any of the "sugar alcohols" (names ending in ol). In health food stores, be alert for sugars disguised as "evaporated cane juice" or "can juice crystals." These can still cause problems, regardless what the health food store manager tells you. My patients have seen huge improvements by changing their sugar choices. Brown rice syrup. Your bloodstream absorbs this balanced syrup, high in maltose and complex carbohydrates, slowly and steadily. Brown rice syrup is a natural for baked goods and hot drinks. It adds subtle sweetness and a rich, butterscotch-like flavor. To get sweetness from starchy brown rice, the magic ingredients are enzymes, but the actual process varies depending on the syrup manufacturer. "Malted" syrups use whole, sprouted barley to create a balanced sweetener. Choose these syrups to make tastier muffins and cakes. Cheaper, sweeter rice syrups use isolated enzymes and are a bit harder on blood sugar levels. For a healthy treat, drizzle gently heated rice syrup over popcorn to make natural caramel corn. Store in a cool, dry place. Devansoy is the brand name for powdered brown rice sweetener, which contains the same complex carbohydrates as brown rice syrup and a natural plant flavoring. -

Selecting, Preparing, and Canning Fruit and Fruit Products

Complete Guide to Home Canning Guide 2 Selecting, Preparing, and Canning Fruit and Fruit Products 2-2 Guide 2 Selecting, Preparing, and Canning Fruit and Fruit Products Table of Contents Section .......................................................................................................................Page 2 General ...............................................................................................................................2-5 Preparing and using syrups ..................................................................................................2-5 Fruit and Fruit Products Apple butter ........................................................................................................................2-6 Apple juice ..........................................................................................................................2-6 Apples—sliced .....................................................................................................................2-7 Applesauce .........................................................................................................................2-7 Spiced apple rings ...............................................................................................................2-8 Spiced crab apples ...............................................................................................................2-9 Apricots—halved or sliced ....................................................................................................2-9 Berries—whole -

Za'atar-Spiced Beet Dip with Goat Cheese by Adapted by Laura and Alan Rabishaw, Inspired by YOTAM OTTOLENGHI

Za'atar-Spiced Beet Dip with Goat Cheese By Adapted by Laura and Alan Rabishaw, inspired by YOTAM OTTOLENGHI Ingredients 4 medium beets (approximately 1 lb), trimmed —OR Use a product like LOVE’s Beets precooked to skip STEP 1 below 2 small garlic cloves, minced 1 small hot pepper, seeded and minced 2/3 cup plain Greek yogurt 2 tablespoons extra-virgin olive oil 1 tablespoons date syrup 2tsp + za’atar Salt 1/4 cup roasted pistachios, chopped 2 tablespoons goat cheese, crumbled 2 scallions, thinly slice Pita or Crunchy Vegetables, for serving Step 1 Preheat the oven to 350°. Put the beets in a small roasting pan and add 1/4 cup of water. Cover with foil and bake for about 1 hour, until tender. Let cool slightly. Step 2 Peel the beets, cut into wedges and transfer to a food processor. Add the garlic, chile and yogurt and pulse until blended. Add the olive oil, date syrup and za’atar and puree. Season with salt. Scrape into a wide, shallow bowl. Scatter the pistachios, goat cheese and scallions on top and serve with bread. Roasted Beets with Chick Peas Various Recipes Adapted by Laura and Alan Rabishaw Ingredients 4 medium beets (approximately 1 lb), trimmed —OR Use a product like LOVE’s Beets precooked to skip STEP 1 below 1 can Chick Peas, drained and rinsed 2 tbls of your favorite middle eastern spice blend (za’tar, harissa powder, ras al hanout, hawaij or other. You can buy premixed, or google for recipes) Salt and pepper to taste Extra-virgin olive oil Step 1 Preheat the oven to 350°. -

The Map of Maple

the map of maple intensity maple maple toasted baked apple toasted nuts University of VermontUniversity of © brioche roasted marshmallow golden sugar burnt sugar crème brûlée caramel coffee milky fresh butter melted butter condensed milk butterscotch confectionary light brown sugar dark brown sugar molasses toffee spice vanilla cinnamon nutmeg mixed spices fruity raisins prunes aroma and flavor and aroma orange grapefruit peach apricot mango raw nuts floral honey floral blend earthy grassy hay oats mushroom others praline dark chocolate bourbon soy sauce spiced meat leather mineral notes maple sweetness balance intensity taste smooth mineral thin syrupy thick mouthfeel tasting maple syrup The map of maple is a sensory tool, allowing you to explore all the wondrous possibilities of Vermont maple syrup. Here are some hints for tasting on your own. Smell the syrup before tasting. Try to identify any distinct aromas. Take a look at the list of aroma and flavor descriptors as a guide. Take a small sip of the syrup. Move the syrup in your mouth briefly, and feel the texture. See the mouthfeel section for suggestions. Then, evaluate the taste characteristics. See the taste section for suggestions. For all the sensory properties evaluated, always try to asses the quality, quantity and balance of the descriptors identified. Consider the flavor with another sip. See if the sensory “families” help you place the aroma and flavor of the syrup, allowing & you to identify and describe each particular maple syrup. If possible, taste and share your reactions with a friend. Sometimes tasting and talking with others can help your descriptions. why taste and tell? Maple syrup is an old-fashioned yet long-lived taste of Vermont. -

To Start with Pasta

FOOD MENU - 2021 8 Raffles Avenue, #01-13D, Singapore 039802 To start with Plain Fries $10 Pizza Fries $18 Straight cut fries in salt serve with house dip. The one that make us famous fries, beef peperoni, cheese sauce. Truffle Fries $15 Straight cut fries in truffle oil and dried oregano, parmesan Mexicano Taco Fries $18 cheese serve with our tartar sauce. Fries seasoned with taco flavor, salsa served with nacho cheese dip. Choice of beef or chicken toppings. $15 Salted Egg Fries $10 Salted egg seasoned fries, served with sweet and spicy salted Fish Skin egg sauce. Umami flavor fish skin serve with sweet and spicy sauce. Nachos $14 Calamari $16 Tortilla chips with mango salsa, nacho cheese dip. Buttered squid rings serve with tartar sauce and lemon wedge. $18 Shripm Gambas $18 Saute shrimp in buttery garlic and onion serve with salsa or Spicy Buffalo Wings house salad, grilled lime. Spicy or regular buffalo wings satisfy with beer match, served with tartar sauce. Har Cheong Kai $15 Salted Egg Chicken Wings $18 Well known prawn paste wings. Salted eggs, chicken wings, satisfy with beer match. Pasta Aglio Olio (Shrimp or Chicken) $20 Creamy Chicken Mushroom $20 Spaghetti pasta tossed in garlic, chilli flakes topped with Penne pasta in creamy sauce mushroom. Topped with grilled parmesan and basil. chicken breast, parmesan and parsley. Seafood Pasta $20 Bolognese Pasta $20 Spaghetti pasta and squid ring king prawns, tossed in our Ground beef in marinara sauce. homemade marinara sauce, topped with shave parmesan chopped parsley. Chicken Alfredo (Spaghetti/Penne) $20 Fettuccine pasta/penne, cream, garlic, chicken breast, parsley, Classic Carbonara $20 parmesan and chives on top. -

New Home Grocery List

New Home Grocery List Canned and Packaged Food Done Item Quantity Notes Rice Pasta Tomato Sauce Canned Beans Canned Corn Canned Fish (Tuna or Sardines) Canned Soup Broth (Vegetable, Beef or Chicken) Cereal or Oatmeal Lentils Snacks Done Item Quantity Notes Pretzels Chips and Crackers Popcorn Granola bars Dried fruits Nuts Baked Goods Done Item Quantity Notes Bread Rolls Bagels Muffins Cookies Beverages Done Item Quantity Notes Coffee Tea Bottled water Juices (Orange, Apple, Cranberry, etc.) Seltzer Page 1 of 6 New Home Grocery List Spices Done Item Quantity Notes Sea Salt Black Pepper Crushed Red Pepper Paprika Oregano Basil Parsley Rosemary Garlic Powder Cilantro Chili Powder Cumin Ginger Cinnamon Turmeric Condiments Done Item Quantity Notes Olive Oil Cooking Oil (vegetable, canola etc.) Vinegar Ketchup Mustard Mayo Soy Sauce Hot Sauce Salad Dressing Pickles Worcestershire Sauce BBQ Sauce Steak Sauce Maple Syrup Honey Jam or Jelly Nut Butter (Peanut, Almond, etc.) Page 2 of 6 New Home Grocery List Frozen Food Done Item Quantity Notes Mixed Vegetables Fruit Meat (Burgers, Chicken nuggets, etc.) Veggie Burgers Pizza French Fries Waffles Pancakes Ice-cream Fresh Food Done Item Quantity Notes Apples Oranges Bananas Berries Tangerines Grapes Peaches Plums Tomatoes Cucumbers Avocados Lemon Lime Lettuce Spinach Green Beans Broccoli Asparagus Beets Celery Carrots Potatoes Mushrooms Peppers Onions Garlic Page 3 of 6 New Home Grocery List Meat, Poultry, and Seafood Done Item Quantity Notes Chicken Fish Shrimp Steak Ground Beef Ground Turkey Eggs -

A Carrot by Any Other Name… New Looks at Your Old Co-Op by Shannon Szymkowiak, Promotions & Education Manager & WFC Owner

20 WINTER 2013 GARBANZO GAZETTE back 40 special items in your produce department by Claire Musech, Produce Buyer/ Receiver & WFC Owner You may have already noticed the for flowers, and you receive and 15% have a gorgeous assortment of Poin- bright, new addition to your Co-op—it’s discount if you are a WFC Owner! Place settias, Norfolk Pines, Frosty Ferns, fresh flower bouquets and plants! them at the Customer Service Counter, Rosemary Cones, Golden Cypress and I have had the pleasure of working with or with anyone in the Produce Depart- Silver Bush set to arrive on December Koehler and Dramm Wholesale Florist ment or you can just call it in. 13th. Guarantee your first choice by put- in Minneapolis to bring you beautiful ting in a special order with the Produce We are also working on sourcing local and affordable cut flower bouquets, Department today as quantities are and regional fall mums from the Amish arrangements and plants. We have limited. and an assortment of local hanging been able to provide a unique selection baskets in the spring. This is a small Add a distinguishing touch to your of house plants ranging from traditional but exciting step towards our store goal Holiday gathering by arriving with ones like Ivy and Pathos to the unusual of having 20 percent of all products a Co-op made fruit and vegetable tray varieties like Venus fly trap and sold be LOCAL by the year 2020! or fruit and gift basket. We are happy Cypress. Whether you are choosing to take special requests within 48 hours a gift to brighten someone’s day Everyone loves flowers for the Holidays. -

Muhammara (Roasted Red Pepper and Walnut Dip) Makes About 2 Cups

PITTSBURGH’S HOME FOR KITCHENWARES 412.261.5513 | 1725 Penn Avenue | Pittsburgh, PA 15222 Muhammara (Roasted Red Pepper and Walnut Dip) Makes about 2 cups This muhammara dip is made of roasted red peppers, earthy toasted walnuts, and freshly toasted bread- crumbs. All of these savory items are blended together with a few additional ingredients and one specialty item -- pomegranate molasses. The pomegranate molasses gives a special sweet and tangy depth to the dip -- so delicious! Ingredients: 1 tablespoon lemon juice 3 red peppers, halved and roasted 5 tablespoons olive oil 1 tablespoon olive oil for roasting peppers. 2 tablespoons pomegranate molasses* 1/2 cup walnuts, lightly toasted 1 teaspoon Kosher salt 1/2 cup fine, freshly grated bread crumbs 1/4 teaspoon cayenne pepper (use dry bread, pulse in food processor to create a fine crumb, toast in pan with one tablespoon Optional Garnishes: olive oil until just crispy) 10 walnut halves 2 tablespoons tomato paste Fresh parsley 1 clove garlic, minced Directions: 1. Preheat the oven to 450 degrees F. 2. Halve the peppers, de-seed, brush with olive oil, and place cut side down on a baking sheet. Roast the peppers until softened. Achieve some char on the peppers by broiling for a few minutes. 3. Place the roasted red peppers in a bowl, and cover for 10 minutes. After the peppers have cooled, carefully peel the skins o. 4. While the peppers are roasting, toast the walnuts. In a small dry skillet, toast the walnuts until just fragrant. Set the walnuts aside. 5. In the same skillet, toss the bread crumbs with one tablespoon of olive oil. -

Sumac Rhus Coriaria Tips for Use

Recipes Sumac Rhus coriaria Tips for Use: • The flavor is earthy, citrus and a bit sour • Make a marinade or salad dressing • Add to yogurt or sprinkle on hummus or even sweet potato fries • Add to your favorite meatloaf recipe • Use in making your own blend such as one of the many Za’atar recipes, which vary in different regions and from family to family. • Use Za’atar or other blends on chicken, lamb, fish or vegetables • Mix blends with olive oil for dipping bread • Top popcorn with sumac and salt for a salt and tart flavor Sumac Lemonade 1 cup water Lemon juice ¼ cup sumac syrup Ice Sumac Syrup: 1 cup water, 1 cup honey and 2 tablespoons ground sumac Make sumac syrup by combining water and honey in a small saucepan. Simmer over medium for 5 minutes then stir in sumac and infuse until cool, at least 10 minutes. Strain and store in an airtight container. Make sumac lemonade by combining water or sparkling water with sumac syrup, and a squeeze of lemon juice. Add ice and stir. Shape.com The Health Benefits of Sumac Spice Za’atar 1 tablespoon chopped fresh oregano 1 tablespoon sesame seeds 1 tablespoon sumac 1 teaspoon kosher salt 1 tablespoon ground cumin 1 teaspoon freshly ground black pepper Combine chopped fresh oregano, sumac, ground cumin and sesame seeds. Stir in kosher salt and freshly ground black pepper. Can be made 2 weeks ahead. Store airtight at room temperature. Silvena Rowe Bon appetite, www.bonappetit.com Za’atar Recipe: Middle Eastern Spice Mixure ¼ cup sumac 2 tablespoons marjoram 2 tablespoons thyme 2 tablespoons oregano 1 tablespoon roasted sesame seeds ©2018 by The Herb Society of America www.herbsociety.org 440-256-0514 9019 Kirtland Chardon Road, Kirtland, OH 44094 Recipes 1 teaspoon salt Grind the sesame seeds in a food processor or with a mortar and pestle. -

Corn Syrup, Grape Syrup, Honey, (A Shengreen , 1975

LABORATORY COMPARISON OF HIGH FRUCTOSE CORN SYRUP, GRAPE SYRUP, HONEY, AND SUCROSE SYRUP AS MAINTENANCE FOOD FOR CAGED HONEY BEES Roy J. BARKER Yolanda LEHNER U.S. Department of Agriculture, Agricultural Research Service, Bee Research Laboratory, 2000 East Allen Road, Tucson, Arizona 85719 SUMMARY Honey or high fructose corn syrup fed to worker bees failed to show any advantage over sucrose syrup. Grape syrup caused dysentery and reduced survival. Caged bees survived longest on sucrose syrup. INTRODUCTION A commercial process utilizes glucose isomerase to convert the glucose from hydrolyzed corn starch to a mixture containing glucose and high levels of fructose (ASHENGREEN, 1975). To humans, fructose is sweeter than glucose or sucrose. Consequently, the higher the content of fructose, the lower the concentration of sugar needed to sweeten food or drinks. Thus, high fructose corn syrup is an economical sweetener for humans. Does isomerized corn syrup provide advantages in bee foods? Its sugar composition closely resembles that of honey, but isomerized sugar may not be sweeter than sucrose to honey bees. In fact, a preference of older bees for sucrose over glucose and fructose may explain why they leave hives containing stored honey to forage for nectar. Nevertheless, beekeepers generally consider honey to be unparalleled as a bee food despite its failure to sustain worker bees as long as sucrose (BARKER and LEHNER, 1974 a, b). High fructose corn syrup offers advantages besides lower cost, such as feeding convenience. Furthermore, some beekeepers find less robbing when bees are fed high fructose corn syrup instead of sucrose syrup. This may be a consequence of lower attraction. -

Lynn Take out Menu 2 Sided 05-21

Saturdays & Sundays ful (fūl) $8.75 v fava bean cooked overnight with aromatic spiceswith tomato, cucumber, parsley, onion + pickled egg +$1 our menu is inspired by the bold, labne shakshuka * $9.75 v poached eggs with garlicky labne, mint, SWEETS fresh flavors found in the street foods drizzled with spicy olive oil, zouk, armenian labne bar $5.75 of the Eastern Mediterranean salad, black olives, pickled turnip + sujuk (armenian sausage) $1.50 banana + almond v +lamb meatball $3.50 banana, almond, pinenuts, cinnamon, honey shakshuka * $9.75 v crushed fresh tomatoes, onion with our spices, blueberry + power seeds vNGF blueberries, chia, pumpkin, sunflower topped with black olive, cilantro, poached egg seeds, walnuts, grape molasses + sujuk (armenian sausage) $1.50 +lamb meatball $3.50 mango + chocolate v NGF mango, pistachios, chocolate pearls, kenefe $9.75 v NGF fresh mint, honey crushed filo dough with anoush’ella cheese wrapped with fresh fruit granola v NGF m’anoush with sesame seeds, orange blossom syrup seasonal fresh fruit, our granola, grape molasses mezze for two $28 v shakshuka, ful, za’atar manoush, hummus m’anoush $7.50 anous’ella omellete $7.50 gluten-free bread +$2.50 two eggs, anoush’ella cheese, tomatoes, cucumber, mint, black olives, green onion, pickled turnip, za’atar nutella chocolate vNGF strawberry, banana, cinnamon, honey, granola anoush’ella smores v NGF nutella with graham crackers, marshmallows anoush’ella peanut butter 35 West Newton St. 1205 Market Street Time Out Market v vegetarian NGF not gluten-free with seasonal berries South End - Boston Lynnfield MA Fenway , MA • Please note that we are not a gluten or nut free facility.