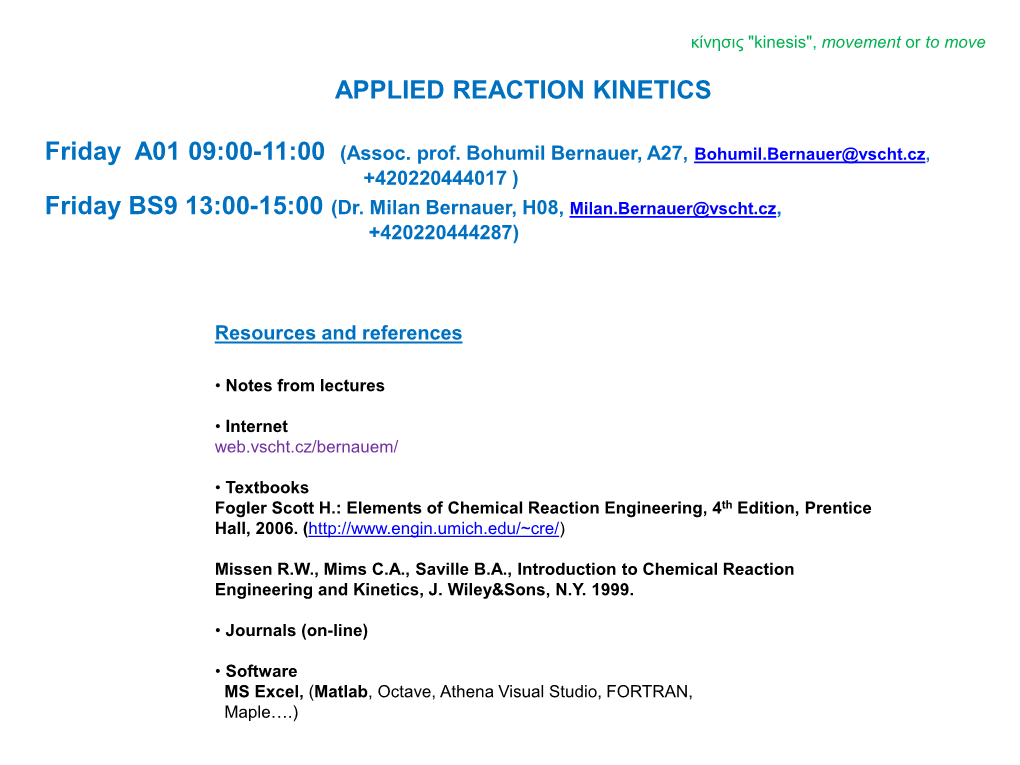

Applied Reaction Kinetics

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

THERMODYNAMICS of REACTING SYSTEMS 2.1 Introduction This Chapter Explains the Basics of Thermodynamic Calculations for Reacting Systems

ChE 505 – Chapter 2N Updated 01/26/05 THERMODYNAMICS OF REACTING SYSTEMS 2.1 Introduction This chapter explains the basics of thermodynamic calculations for reacting systems. Reaction stoichiometry, heat and entropy of reaction as well as free energy are considered here. Only single phase systems are considered here. Phase equilibrium will be addressed in the next chapter. Examples and MATLAB calculations of the chemical equilibria are provided at the end of the chapter. 2.2 Reaction Stoichiometry The principle of conservation of each atomic species applied to every well defined chemical reaction leads to reaction stoichiometry. Imagine that we have placed an invisible envelope around a finite mass of reactants and the contents of that envelope are our system in its initial state. We can count the atoms of each atomic species present in each reactant species. A chemical reaction takes place in the system. Upon reaction completion, we recount the number of each atomic species. The total number of atoms of each of the elements present in remaining reactions and products formed must remain constant. The principle of conservation of mass applied to each atomic species yields the ratio in which molecules of products are formed and molecules of reactants are reacted. The representation of chemical species by a chemical formula indicates how many atoms of each species are there in a molecule of the species under consideration. Hence, in a molecule of carbon dioxide (CO2), there are: one atom of carbon, C, and two atoms of oxygen, O. In a molecule of methane, CH4, here is one atom of carbon and 4 of hydrogen, etc. -

Chemical Thermodynamics - Wikipedia, the Free Encyclopedia 頁 1 / 8

Chemical thermodynamics - Wikipedia, the free encyclopedia 頁 1 / 8 Chemical thermodynamics From Wikipedia, the free encyclopedia Chemical thermodynamics is the study of the interrelation of heat and work with chemical reactions or with physical changes of state within the confines of the laws of thermodynamics. Chemical thermodynamics involves not only laboratory measurements of various thermodynamic properties, but also the application of mathematical methods to the study of chemical questions and the spontaneity of processes. The structure of chemical thermodynamics is based on the first two laws of thermodynamics. Starting from the first and second laws of thermodynamics, four equations called the "fundamental equations of Gibbs" can be derived. From these four, a multitude of equations, relating the thermodynamic properties of the thermodynamic system can be derived using relatively simple mathematics. This outlines the mathematical framework of chemical thermodynamics.[1] Contents ■ 1 History ■ 2 Overview ■ 3 Chemical energy ■ 4 Chemical reactions ■ 4.1 Gibbs function ■ 4.2 Chemical affinity ■ 4.3 Solutions ■ 5 Non equilibrium ■ 5.1 System constraints ■ 6See also ■ 7 References ■ 8 Further reading ■ 9 External links History In 1865, the German physicist Rudolf Clausius, in his Mechanical Theory of Heat, suggested that the principles of thermochemistry, e.g. such as the heat evolved in combustion reactions, could be applied to the principles of thermodynamics. [2] Building on the work of Clausius, between the years 1873-76 the American mathematical physicist Willard Gibbs published a series of three papers, the most famous one being the paper On the Equilibrium of Heterogeneous Substances. In these papers, Gibbs showed how the first two laws of thermodynamics could be measured graphically and mathematically to determine both the thermodynamic equilibrium of chemical reactions as well as their tendencies to occur or proceed. -

Reaction Rates As Virtual Constraints in Gibbs Energy Minimization*

Pure Appl. Chem., Vol. 83, No. 5, pp. 1063–1074, 2011. doi:10.1351/PAC-CON-10-09-09 © 2011 IUPAC, Publication date (Web): 4 April 2011 Reaction rates as virtual constraints in Gibbs energy minimization* Pertti Koukkari‡, Risto Pajarre, and Peter Blomberg VTT Technical Research Centre of Finland, P.O. Box 1000, FI-02044 VTT, Finland Abstract: The constrained Gibbs energy method has been developed for the use of immate- rial entities in the formula conservation matrix of the Gibbs energy minimization problem. The new method enables the association of the conservation matrix with structural, physical, chemical, and energetic properties, and thus the scope of free energy calculations can be extended beyond the conventional studies of global chemical equilibria and phase diagrams. The use of immaterial constraints enables thermochemical calculations in partial equilibrium systems as well as in systems controlled by work factors. In addition, they allow the intro- duction of mechanistic reaction kinetics to the Gibbsian multiphase analysis. The constrained advancements of reactions are incorporated into the Gibbs energy calculation by using addi- tional virtual phases in the conservation matrix. The virtual components are then utilized to meet the incremental consumption of reactants or the formation of products in the kinetically slow reactions. The respective thermodynamic properties for the intermediate states can be used in reaction rate formulations, e.g., by applying the reaction quotients. Keywords: constrained Gibbs energy minimization; reaction quotients; reaction rates; virtual components; virtual species. INTRODUCTION The formulation of irreversible chemical–thermodynamic systems far from equilibrium has been devel- oped over a period of several decades. -

Equilibrium and the Driving Forces for Electrochemical Processes

Part I Electrochemical Thermodynamics and Potentials: Equilibrium and the Driving Forces for Electrochemical Processes Prof. Shannon Boettcher Department of Chemistry University of Oregon 1 Chemical Thermodynamics Consider a chemical reaction: , , aA + bB cC + dD ∆ = ∆ ∆ − What criteria do⇆ we use to determine if the reaction goes forward or • Gibbs free energy can be used to calculate the backwards? maximum reversible work that may be performed by system at a constant temperature and pressure. • Gibbs energy is minimized when a system reaches chemical equilibrium at constant pressure and temperature. 2 Chemical Thermodynamics If not at standard state, then: = ∆ + ln ap is the activity of product p ∆ ar is the activity of reactant r vi is the stoichiometric number of i = = 0 γi is the activity coefficient of i ∏ γ ∏ c is the concentration of i i 0 ∏ ci is the standard state concentration of i ∏ γ 0 • Activity coefficients are “fudge” factors that all for the use of ideal thermodynamic equations with non-ideal solutions. • For dilute solutions, γi goes to 1 3 Chemical Thermodynamics Consider that the Gibbs energy can be written as a sum of enthalpy and entropy terms: = irreversible heat maximum ∆reversible ∆total heat− ∆ released/gained by the work released/gained reaction by reaction 4 Electrochemical Thermodynamics Consider the following thought experiment Zn + 2AgCl Zn2+ + 2Ag + 2Cl- do chemical reaction in do electrochemical reaction in do electrochemical reaction in B C in second calorimeter A calorimeter: calorimeter:⇆ calorimeter, resistor - e- e Q Zn + 2AgCl → r Zn2+ + 2Ag + 2Cl- Zn Ag/AgCl Zn Ag/AgCl Zn2+ - Cl 2+ Zn Qc Cl- Qc = = -233 kJ/mol Qc = = -233 kJ/mol = lim = -43 kJ/mol ∆ ∆ all species at standard state, extent of reaction small = lim ∆ →∞ = -190 kJ/mol ∆ →∞ Qc + Qr = = -233 kJ/mol Example from Bard and Faulkner 5 ∆ Electrochemical Thermodynamics Gibbs energy change is the maximum reversible work the system can do. -

OCN421 Lecture 5

Chpt. 5 - Chemical Equilibrium James W. Murray (10/03/01) Univ. Washington Why do we need to study chemical equilibria? The material in this lecture comes from the field of of chemical thermodynamics. A rigorous presentation is included in an appendix for those interested. For the purpose of this class there are only a few basic concepts you need to know in order to conduct equilibrium calculations. With these calculations we can predict chemical composition using chemical models. The main questions we ask are: 1. Is a geochemical system at chemical equilibrium? 2. If not, what reaction (s) are most likely to occur? Here are some examples of problems where equilibrium calculations are useful. Example 1: Diatoms exist in surface seawater The solubility of diatom shell material (called opal) is written as: SiO2. 2H2O (Opal) ↔ H4SiO4 (diatom shell material) (silicic acid) There are two chemical problems here: 1) The surface ocean is everywhere undersaturated with respect to Opal, yet diatoms grow. And furthermore they are preserved in sediments over long time periods (millions of years). 2) The favored form of solid SiO2(s) at earth surface conditions is quartz not opal! Why does opal form instead? This reaction would be written as: . SiO2 H2O (Opal) ↔ SiO2 (quartz) Example 2: Acid mine drainage Imagine a stream in Idaho that has been grossly contaminated by waste material from decades of silver mining activity but has been left to recover for the past 10 years. As an environmental chemist you are interested in the pollutant fluxes and the form of the pollutant in the sediments. -

Affinity’: Historical Development in Chemistry and Pharmacology

Bull. Hist. Chem., VOLUME 35, Number 1 (2010) 7 ‘AFFINITY’: HISTORICAL DEVELOPMENT IN CHEMISTRY AND PHARMACOLOGY R B Raffa and R .J. Tallarida, Temple University School of Pharmacy (RBR) and Temple University Medical School (RJT) ‘Affinity’ is a word familiar to chemists and pharma- Affinity as Proximity cologists. It is used to indicate the qualitative concept of ‘attraction’ between a drug molecule and its receptor From the derivation of the word from the Latin, it can molecule without specification of the mechanism (as be seen that affinity originally referred to the proximity in, drug A has affinity for receptor R) and to indicate of two things (6): a relative measure of the concept (as in, drug A by the Affinity [L. affinitas, from affinis, adjacent, related by following measure has greater affinity than does drug B marriage (as opposed to related by blood, consanguin- for receptor R). It also is used to quantify the concept ity); ad, to, and finis, end] (as in, the affinity of drug A for receptor R is some nM This use is purely descriptive in that it refers to a situa- value). Unfortunately, the meaning and use of affinity tion that already exists, i.e., the marriage has taken place have diverged historically such that a pharmacologist already. No predisposing or mechanistic explanation was would likely be puzzled by the recent statement in Kho- explicit––that is, although the state of being ‘related by ruzhii et al. (1) “… the binding affinity, or equivalently marriage’ is recognized as being attributable to emotional binding free energy [emphasis added]…”, whereas a or social driving forces, the final state (the marriage) is chemist would not (2). -

The Missing Link in the Kinetic Theory of Chemical Reactions and Epidemics L

The missing link in the kinetic theory of chemical reactions and epidemics L. Vanel1* 1Institut Lumière Matière, Univ Claude Bernard Lyon 1, Univ Lyon, CNRS; F-69622, Villeurbanne, France. *Corresponding author. Email: [email protected] In thermodynamics, affinity is the driving force of chemical reactions. At equilibrium, affinity is zero, and the reaction quotient equals the constant of equilibrium. Thermodynamics predicts the timescale of chemical reactions but not rate laws that are purely phenomenological relations. Here, we derive an affinity relaxation theory (ART) that predicts chemical rate laws. Strikingly, the simplest chemical reaction in the ART model has a close resemblance with epidemic models instead of the mass-action rate law, revealing that epidemic models are actually more accurate chemical rate laws than the mass-action law. However, epidemic models appear in turn as an approximation of the ART model, where conceptual incoherencies of epidemic models are exposed and resolved. Furthermore, the mathematical Gompertz solution of the model links chemical rate laws with empirical biological and cancer growth laws. The ART model provides an entirely new framework to describe dynamic phenomena in chemical reactions, epidemics and biology. Introduction The mass-action law introduced in 1864 by Guldberg and Waage (1) was the first equation linking the rate of a chemical reaction to the concentration of reactants. A main idea that quickly followed is that a reaction can occur in two opposite directions and that equilibrium corresponds to the point where the speeds of the forward and backward reaction cancel each other (2). Chemical thermodynamics established a long time ago that mass-action rate laws are compatible with the thermodynamic constant of equilibrium of a chemical reaction (3) and that rate constants depend on the reaction activation energy (4). -

Chemistry 1202 Review/Preview Chapter Five Review Guide Dr

Chemistry 1202 Review/Preview Chapter Five Review Guide Dr. Saundra McGuire Spring 2007 Thermochemistry I. Definitions to Know and Understand System, Surroundings, Energy, Temperature, Heat, Potential Energy, Kinetic Energy, Work II. Heat and Energy A. Potential Energy - the amount of stored energy. B. Kinetic Energy = 1/2 mv2, where m is in kilograms and v is in meters/second. The units of the energy value derived in this manner is the joule. III. Work 1. Work = Force x distance, where force = pressure x area. The force due to gravity = mass x gravitational constant (9.8 m/s2). IV. Internal Energy and the First Law of Thermodynamics A. First Law of Thermodynamics - The total internal energy of an isolated system is constant. B. State Functions - Functions whose value depends only on the present state of the system, not on the path used to arrive at the state. V. Relating ∆E to heat and work A. The first law of thermodynamics is mathematically stated as follows: ∆E = q + w where q is the heat exchanged and w is the work done. The sign conventions for work and heat are as follows: Work done on the system is positive; work done by the system is negative Heat entering the system is positive; heat going out of the system is negative B. Heat (q) and work (w) are two different forms of energy and are therefore equivalent and can be interconverted by using the appropriate conversion factor. C. Enthalpy - heat content (H) Enthalpy, H, has the following relationship to the internal energy and the work: H = E + PV. -

New Thermodynamic Paradigm of Chemical Equilibria

New Thermodynamic Paradigm of Chemical Equilibria I B. Zilbergleyt “Nature creates not genera and species, but individua, and our shortsightedness has to seek out similarities so as to be able to retain in mind simultaneously many things.” G. C. Lichtenberg. “The Waste Books”, Notebook A, 1765/1770 . 1. Introduction. These words, though ironically, express the essence of the Ockham’s razor [1] − to employ as less entities as possible to solve maximum of problems. Both reflect the efforts of this work to unite on the same ground some things in chemical thermodynamics that seem at a glance very unlikely. A difference between theoretically comfortable and easy to use isolated chemical systems and real non-isolated systems was recognized long ago. A notion of the open chemical systems non-ideality, offered by G. Lewis in 1907 as a non-ideality of species [2], was a response to that concern. Fugacities and thermodynamic activities, explicitly accounting for this notion, were introduced for non-ideal gases and liquid solutions to replace mole fractions in thermodynamic formulas. Leading to the same habitual linear dependence of thermodynamic potential vs. activity logarithm (instead of concentration), that allowed the thermodynamic functions to keep the same appearance, passing open and closed systems for isolated entities. With this support classical theory has survived unchanged for a century. J. Gibbs is credited for a presentation of phases in the multiphase equilibrium as open subsystems with equal chemical potentials of common components [3]. His insight hasn’t impacted essentially thermodynamic tools for chemical equilibria. First stated in a general way by Le Chatelier’s principle, energy/matter exchange is forcing the open system to change its state. -

The Thermodynamic Natural Path in Chemical Reaction Kinetics

Discrete Dynamics in Nature and Society, Vol. 4, pp. 145-164 (C) 2000 OPA (Overseas Publishers Association) N.V. Reprints available directly from the publisher Published by license under Photocopying permitted by license only the Gordon and Breach Science Publishers imprint. Printed in Malaysia. The Thermodynamic Natural Path in Chemical Reaction Kinetics MOISHE GARFINKLE School of Textiles and Materials Technology, Philadelphia University, Philadelphia, PA 19144-5497, USA (Received 10 June 1999) The Natural Path approach to chemical reaction kinetics was developed to bridge the con- siderable gap between the Mass Action mechanistic approach and the non-mechanistic irreversible thermodynamic approach. The Natural Path approach can correlate empirical kinetic data with a high degree precision, as least equal to that achievable by the Mass-Action rate equations, but without recourse mechanistic considerations. The reaction velocities arising from the particular rate equation chosen by kineticists to best represent the kinetic behavior of a chemical reaction are the natural outcome of the Natural Path approach. Moreover, by virtue of its thermodynamic roots, equilibrium thermodynamic functions can be extracted from reaction kinetic data with considerable accuracy. These results support the intrinsic validity of the Natural Path approach. Keywords: Affinity decay, Irreversible thermodynamics, Natural Path, Mass Action, Reaction velocities INTRODUCTION transformation of reactants to products according to a specific reaction mechanism which can be delin- Stoichiometric chemical reactions have been classi- eated for each reaction by a mechanistic analysis. cally perceived as systems of discrete reacting par- Although the classical approach has served ex- ticles wherein reactant species transform to product tremely well in the elucidation of reaction mech- species. -

The Thermodynamic Natural Path in Chemical Reaction Kinetics

Discrete Dynamics in Nature and Society, Vol. 4, pp. 145-164 (C) 2000 OPA (Overseas Publishers Association) N.V. Reprints available directly from the publisher Published by license under Photocopying permitted by license only the Gordon and Breach Science Publishers imprint. Printed in Malaysia. The Thermodynamic Natural Path in Chemical Reaction Kinetics MOISHE GARFINKLE School of Textiles and Materials Technology, Philadelphia University, Philadelphia, PA 19144-5497, USA (Received 10 June 1999) The Natural Path approach to chemical reaction kinetics was developed to bridge the con- siderable gap between the Mass Action mechanistic approach and the non-mechanistic irreversible thermodynamic approach. The Natural Path approach can correlate empirical kinetic data with a high degree precision, as least equal to that achievable by the Mass-Action rate equations, but without recourse mechanistic considerations. The reaction velocities arising from the particular rate equation chosen by kineticists to best represent the kinetic behavior of a chemical reaction are the natural outcome of the Natural Path approach. Moreover, by virtue of its thermodynamic roots, equilibrium thermodynamic functions can be extracted from reaction kinetic data with considerable accuracy. These results support the intrinsic validity of the Natural Path approach. Keywords: Affinity decay, Irreversible thermodynamics, Natural Path, Mass Action, Reaction velocities INTRODUCTION transformation of reactants to products according to a specific reaction mechanism which can be delin- Stoichiometric chemical reactions have been classi- eated for each reaction by a mechanistic analysis. cally perceived as systems of discrete reacting par- Although the classical approach has served ex- ticles wherein reactant species transform to product tremely well in the elucidation of reaction mech- species.