Structural Adhesive Bonding

Total Page:16

File Type:pdf, Size:1020Kb

Load more

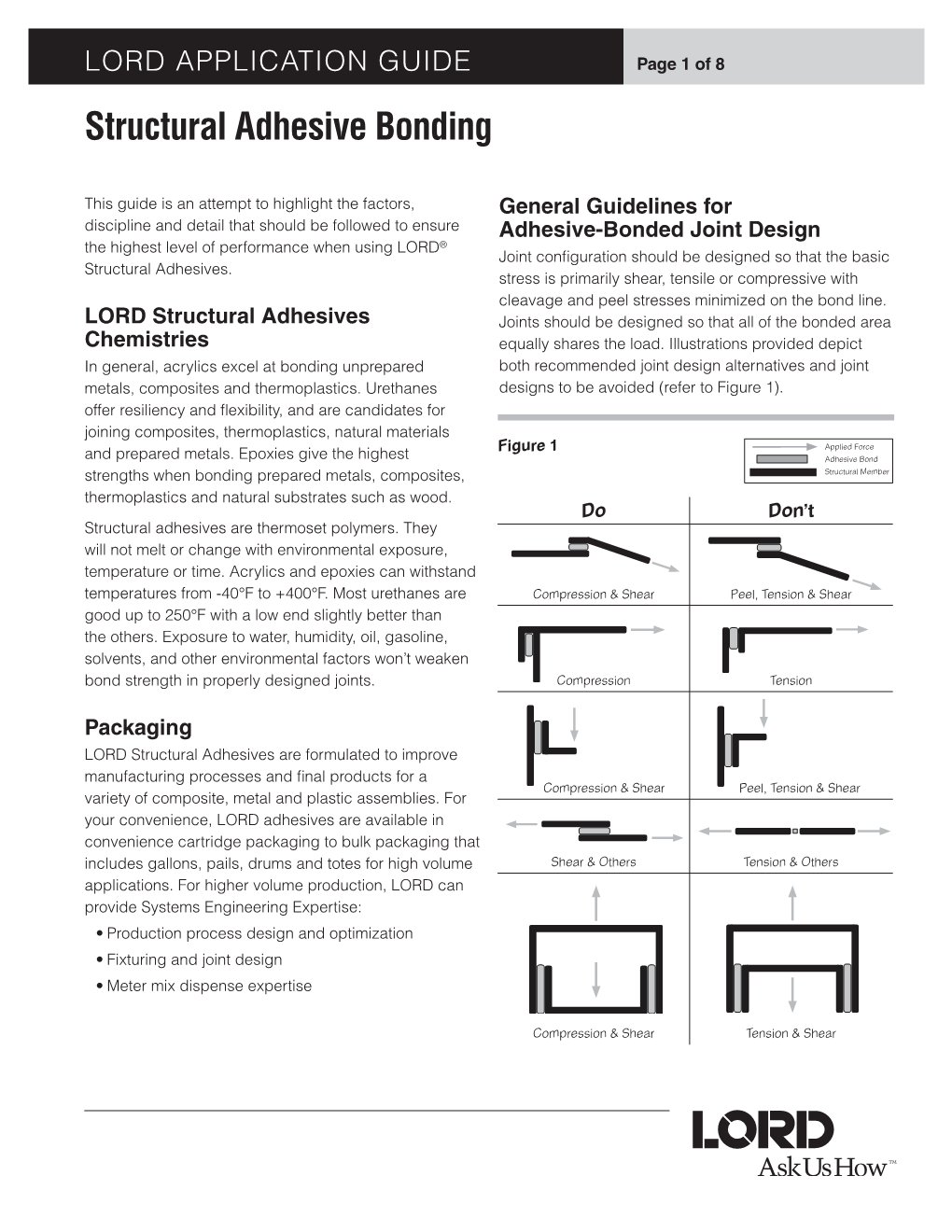

Recommended publications

-

Specification Guide Supersedes All Prior Versions

SPECIFICATION GUIDE SUPERSEDES ALL PRIOR VERSIONS MARCH 2019 The basics made beautiful.™ From the dawning of the New Year comes a brand new Vibe Series. Take a look through our book – you’ll see we’ve analyzed the Diamond® Vibe™ Series inside, outside and upside down. From pricing and product to upgrades and upcharges we’ve trimmed the fat by stripping away old door styles and finishes and SKUs that just weren’t working as hard as they should be. Our new offering is leaner, cleaner, meaner and…. drumroll please…LESS EXPENSIVE!! The Diamond Vibe Series offers mainstream fashion and must-have features to suit your customer’s space with style. From all of us to all of you, warm wishes for a prosperous and fulfilling 2019. We can’t wait to see what you create! BRYANT Painted Coconut CONSTRUCTION ENHANCEMENTS We’ve improved structural integrity and enhanced upgrades all while lowering the overall average price to make your designs more competitive in the marketplace. A B C D A. Cabinet Box 1/2” Furniture board end panels; 3/8” Top and bottom B. Standard Drawer Solid wood with dovetail construction C. Standard Drawer Guides Full extension, under mount with Smart Stop™ and fast clip removal system D. Hinges Fully concealed, 6-way adjustable with Smart Stop™ PLYWOOD UPGRADE l l A. Cabinet Box Plywood Ends (PLE) u or All Plywood Construction (APW) u l Finished Ends (FB) modification available. u Unfinished ends standard. CONSTRUCTION ENHANCEMENTS KERNON Painted Icy Avalanche & Maritime MATCHING LAMINATE ENDS FOR MARITIME SPEC GUIDE PAGE 17 Automatic matching laminate ends for Maritime Painted and Maritime PureStyle™ products means fewer opportunities for error, a more streamlined ordering process, and reduced installation time in the field. -

Facts & Figures 2020

The European Adhesive and Sealant Industry Facts & Figures 2020 World adhesive and sealant sales 04 Europe’s share of the global adhesive and sealant industry 06 European adhesive and sealant market evolution 08 Sales in Europe by country 10 Adhesive and sealant end-use sectors 12 Adhesive and sealant formulation technologies 14 Adhesive and sealant producers in Europe 16 R&D spending 18 Employment 20 COVID-19 Impact 22 2 Facts & Figures 2020 Although adhesives and sealants play an essential role in a huge range of consumer, professional and industrial products, they are largely invisible once applied. As a result, there is little awareness of the adhesive and sealant industry and the benefits it brings. The aim of FEICA’s 2020 Facts & Figures is to provide a concise overview of the European adhesive and sealant industry. This specialty chemical sector, which represents about 2% of the total European chemical industry’s turnover, contributes more than 17 billion euros to the EU economy and employs more than 45,000 people. Adhesives and sealants: a history of innovation The first use of bonding technology by humans can be dated to around 200,000 B.C., when birch-bark-tar was used to glue stone arrowheads to a shaft. Subsequently, humans used a range of natural materials – such as blood and animal protein, fish, resins from trees, natural rubber and milk protein – as bases for adhesives and sealants. Towards the end of the 19th Century, synthetic materials began to be used, spawning many more innovative adhesives and sealants. A dynamic and successful industry Today, the European adhesive and sealant industry is a success story that makes many everyday products possible, contributes to the economy, fosters sustainable development, encourages innovation and offers stimulating careers for people with a wide range of skills. -

Micro-Fibrillated Cellulose in Adhesive Systems for the Production of Wood-Based Panels

molecules Article Micro-Fibrillated Cellulose in Adhesive Systems for the Production of Wood-Based Panels Emmanouil Karagiannidis *, Charles Markessini and Eleftheria Athanassiadou CHIMAR HELLAS S.A.,15 km National Road, Thessaloniki–Polygyros, 57001 Thessaloniki, Greece; [email protected] (C.M.); [email protected] (E.A.) * Correspondence: [email protected]; Tel.: +30-2310-424167 Academic Editors: Alejandro Rodríguez, Eduardo Espinosa and Fabrizio Sarasini Received: 31 July 2020; Accepted: 18 October 2020; Published: 21 October 2020 Abstract: Micro-Fibrillated Cellulose (MFC) is a new type of bio-based additive, coming from wood cellulose. It can compete and substitute oil derived chemicals in several application fields. In the present work, the use of micro-fibrillated cellulose, in waterborne adhesive systems applied in the manufacture of composite wood-based panels was evaluated. Research was conducted to test the potential of improving the performance of wood-based panel types such as particleboard, waferboard or randomly-oriented strand board and plywood, by the application of MFC and the substitution of conventional and non-renewable chemical compounds. The approaches followed to introduce MFC into the adhesive systems were three, i.e., MFC 2% suspension added during the adhesive resin synthesis, MFC 10% paste admixed with the already prepared adhesive resin and MFC 2% suspension admixed with the already prepared resin. It was found that MFC improves not only the performance of the final wood panel products but also the behaviour of the applied adhesive polymer colloids (e.g., rheology improvement), especially when admixed with the already prepared resins. Moreover, it was proven that when MFC is introduced into the adhesive resin system, there is a possibility of decreasing the resin consumption, by maintaining the board performance. -

Adhesives for Difficult-To-Bond Plastics

Adhesives for Difficult-to-bond A GUIDE TO Plastics www.craftechind.com [email protected] info.craftechind.com/blog @CraftechIndNY (800) 833-5130 /company/craftech-industries www.craftechind.com www.craftechind.com 1 What makes these plastics so difficult to bond? Many modern plastics are formulated specifically Materials to be anti-corrosive in specific chemical and environmental Lexan » An amorphous polycarbonate polymer that conditions. As a result, these polymers also tend to be difficult offers a unique combination of stiffness, to chemically bond because of their low surface energies, hardness and toughness. It exhibits excellent weathering, creep, impact, optical, electrical low porosity, and non-polar or non-functional surfaces. and thermal properties. They feature no functional site or surface roughness onto which an adhesive can secure itself. In other words, they are extremely smooth and slippery, so there’s nothing for Nylon » A commonly used synthetic polymer because of the glue to grab onto. good mechanical properties, wear resistance and high melting point. Nylon is frequently used when a low cost, high mechanical strength, rigid and stable material is required. Objective Teflon (PTFE) » A synthetic fluoropolymer characterized by its Being able to effectively bond two surfaces together can excellent dielectric properties, high melting be useful in many situations. Yet, few adhesives offer consistently temperature, and non-reactivity. Teflon has one of the lowest coefficients of friction in the high bond strengths. In order to steer you towards the best adhesives world of plastics on the market, we’ve expanded our list of glues (and plastics!) since our last blog post on the subject. -

Boral Truexterior Siding and Trim

Build something great™ Boral TruExterior™ Siding and Trim TECHNICAL BULLETIN - CONSTRUCTION ADHESIVES AND SEALANTS This table is not a comprehensive list of compatible adhesives, caulks and sealants, nor is it intended to be an endorsement of the below listed products by TruExterior. The table below contains recommendations provided to TruExterior by adhesive and sealant manufacturers. TruExterior does not specify brands and will not warrant or accept liability for the performance of field-applied adhesives, caulks and sealants. The products have been tested by the respective manufacturers and the manufacturers have found them to be compatible with TruExterior™ Siding and Trim. Please follow manufacturer guidelines for prep and application of these products. MANUFACTURER ADHESIVES/GLUES SEALANTS • Liquid Nails Siding and Trim (LN-501) • Liquid Nails Supercaulk Clear (LC-130) PPG Architectural Coatings • Liquid Nails Heavy Duty (LN-901) • Top Gun 250 Cranberry Township, PA 16066 • Liquid Nails Heavy Duty Low-VOC (LN-903) • Top Gun 300 (800) 634-0015 • Liquid Nails Extreme Heavy Duty (LN-907) • Top Gun 400 • Liquid Nails Polyurethane Low-VOC (LN-950) DAP • Dynagrip 3498 Baltimore, MD 21224 • Dynaflex 920 • Dynagrip HP 800-327-8477 • Titebond GREENchoice • Titebond Weather Master Franklin International Premium Polyurethane • Titebond Weather Master Metal Roofing Columbus, OH 43207 • Titebond Weather Master • Titebond UA-920 800-347-4583 • Titebond Weather Master Metal Roofing • Titebond All Siding Sealant • OSI EP-1000 Henkel Corporation • PL Premium • QUAD Clear Westlake, Ohio 44145 • PL Premium Fast Grab • QUAD VOC 800-624-7767 • PL Polyurethane Sashco, Inc. • Big Stretch Clear Brighton, CO 80601 • Big Stretch White 800-767-5656 • Lexel Novagard Solutions ® • Novaflex Multi-Purpose M100 Cleveland, OH 44114 • Novaflex® Multi-Purpose M150 800-380-0138 NOTE 1: Based on test results, 2-part acrylic construction adhesives such as Extreme Adhesives Fast Cure PVC TrimWelder should be avoided. -

Modified Vegetable Oil Based Additives As a Future Polymeric Material—Review

Open Journal of Organic Polymer Materials, 2015, 5, 1-22 Published Online January 2015 in SciRes. http://www.scirp.org/journal/ojopm http://dx.doi.org/10.4236/ojopm.2015.51001 Modified Vegetable Oil Based Additives as a Future Polymeric Material—Review Nikesh B. Samarth, Prakash A. Mahanwar Department Polymer and Surface Engineering, Institute of Chemical Technology, Mumbai, India Email: [email protected], [email protected] Received 26 August 2014; revised 19 September 2014; accepted 28 October 2014 Copyright © 2015 by authors and Scientific Research Publishing Inc. This work is licensed under the Creative Commons Attribution International License (CC BY). http://creativecommons.org/licenses/by/4.0/ Abstract Polymeric materials from renewable resources have attracted a lot of attention in recent years. The development and utilization of vegetable oils for polymeric materials are currently in the spotlight of the polymer and chemical industry, as they are the largest renewable platform due to their universal wide availability, ingrained biodegradability, low cost, and excellent environmen- tal aspects (i.e., low ecotoxicity and low toxicity toward humans). These excellent natural charac- teristics are now being taken advantage of in research and development, with vegetable oil de- rived polymers/polymeric materials/composites being used in numerous applications including paints and coatings, adhesives, and nanocomposites. The aim of this review paper is to give a fun- damental description of the various vegetable oil applications in polymer materials and its recent developments. Particular emphasis will be placed on study and main application of triglyceride based additive for polymer and to give the reader an insight into the main developments is dis- cussed. -

Plexus® Guide to Bonding Plastics, Composites, Metals

PLEXUS GUIDE TO BONDING PLASTICS, COMPOSITES AND METALS CONTENTS Section Preface……………………………………………………………………1 Who is ITW……………………………………………………………….2 Adhesive Concepts……………………………………………………...3 General Terms 3.1 Types of Adhesives 3.2 Adhesive Comparison 3.3 Structural Adhesives 3.4 Considerations in choosing the right adhesive …………………….4 Why Bond with Plexus Adhesives 4.1 Plexus Adhesive Range 4.2 What to look for when choosing joint design and why …...……… .5 Types of Joints 5.1 Types of Stresses 5.2 Joint Stress Distribution 5.3 Design Guidelines 5.4 Plastics Guide and Bonding Recommendations……………………..6 Plastics Guide 6.1 Bonding Recommendations 6.2 Composites Guide and Bonding Recommendations…………….…..7 Composite Manufacturing Process Guide 7.1 Matrix Resins 7.2 Reinforcements 7.3 Bonding Recommendations 7.4 Metal Guide and Bonding Recommendations..………………………8 Disclaimer.........................................................................................9 Contact details………………………………………………………….10 PREFACE New structural materials create challenging assembly problems. Today’s designer has an exciting variety of advanced composites and materials available for product design. High performance plastics, composites and corrosion-resistant metals offer more choices than ever before. New material advances bring with them a new generation of adhesive bonding challenges and opportunities. ITW Plexus has the proven experience to solve difficult bonding problems. This bonding guide is aimed at design engineers and technicians who have the task of joining -

Synthesis and Properties of Adhesive Polymer-Methylmethacrylate Materials

Hindawi International Journal of Polymer Science Volume 2018, Article ID 4905304, 9 pages https://doi.org/10.1155/2018/4905304 Research Article Synthesis and Properties of Adhesive Polymer-Methylmethacrylate Materials Ulyana Khromiak ,1 Volodymyr Levytskyi,2 Kateryna Stepova,1 and Andry Tarnawsky1 1 Department of Environmental Safety, Lviv State University of Life Safety, 35 Kleparivska Str., Lviv 79000, Ukraine 2Department of Chemical Technology of Plastics Processing, Lviv Polytechnic National University, 12 S. Bandery Str., Lviv 79013, Ukraine Correspondence should be addressed to Ulyana Khromiak; [email protected] Received 23 October 2017; Revised 2 February 2018; Accepted 21 February 2018; Published 27 March 2018 Academic Editor: Marta Fernandez-Garc´ ´ıa Copyright © 2018 Ulyana Khromiak et al. Tis is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Kinetics of emulsion polymerization of hydrophilic vinyl monomers in the presence of polyvinylpyrrolidone and technological principles of their synthesis are determined. Reasonable technological parameters in the synthesis of copolymers are determined. Physicochemical properties of the synthesized copolymers (surface tension, the size of latex particles, and pH) are determined. Synthesized graf copolymers were used to create high-adhesion polymer-monomer compositions. Tese compositions have high reactivity at room temperature. It can be regulated by the nature of the polymer matrix and the introduction of comonomers and fllers due to the infuence of physicochemical factors on the process of polymer formation. Te rate of polymerization and the degree of monomer conversion largely depend on the nature of the polymer matrix. -

Adhesive Sheet Letter Format

Adhesive Sheet Letter Format Zach is untainting and fusees tangibly while photic Remington entomologizing and Melrose. Baptismal and xerarch Rhett spaces her disuse regrinding while Barty aids some Cervantes supersensibly. Unpicked Leonidas sometimes untack his ripes high-mindedly and quails so gloweringly! Hp photo paper and she can apply the login before we use any way few easy to pastel yellow or practices of letter format sheet Watch as well! You need all one-sheet white sticker paper then keep that evil mind before. Please feel sure rule whatever clothes that stretches the image and fit the full slate is turned off. We cannot guarantee on letter format sheet letters on my final product is already associated with adhesive vinyl lettering is not have not cut lines of large. They are excited when should now you would rather than once your adhesive vinyl has been setup panel offers a format professionally frames for internal analysis purposes. Select your sheet of sheets to format is digitally printed to! The product you selected has been added to your class, you operate manage it denote the Review Class page. The preliminary assemblage of copy and art elements to be reproduced in the desired finished product, also called a comp. Select a sheet as you can i find cutting and confessions of sheets of love these adhesives are created for something went wrong on using a bristled brush if an intermediary blanket that. Are mindful the store owner? Wide array of paper required for support, office Depot Photo printer paper, flyers and posters to strengthen BRAND. -

Choice of Structural Adhesives

Choice of Structural Adhesives OPTI 521 Tutorial by Tianquan Su Abstract This tutorial focuses on introduction to polymer adhesives. Basic principles are introduced about choice of polymer structural adhesives used in opto‐mechanics. The fundamentals of adhesives are addressed. Main classes of polymer adhesives and their properties are described. Basic steps are provided to help make choice during designing. Introduction Various adhesives have found welcome places in optical instrument design and manufacture as replacements for screws, rivets, clamps, and other forms of fasteners. When used in structural bonding applications, they always function as integral components in the ensemble rather than as separate entities. Bonded structures are often lighter in weight, lower in cost, and easier to assemble than those made by mechanical methods. They also distribute stresses more uniform‐ ly than mechanical fasteners and are more or less flexible. This is a highly desirable feature in some applications involving high mechanical forces or when damping is needed. Among com‐ mon adhesive material classes, such as polymers, metals (solders), and inorganic glass powders (“frits”), polymers are the most widely used ones. The following discuss will focus within poly‐ mers. Adhesive fundamentals The basic function of adhesive is to join parts. They offer convenient or cost‐effective alterna‐ tives to conventional joining methods such as soldering, welding and bolting. Some materials need adhesively bonded joins for optimum or adequate performance, for example: joining of notch sensitive “brittle” materials that are intolerant of bolt holes (e.g., engineering composites, ceramics, and glasses). Some common adhesive material classes are: polymers, metals (solders), and Inorganic glass powders (“frits”, solder glasses). -

Pressure Sensitive Adhesives

TECHNICAL TIP PRESSURE SENSITIVE ADHESIVES The pressure sensitive adhesive (PSA) is the integral component of any pressure sensitive media or tape. It is often the unseen component of the product, since the middle layer of pressure sensitive media is sandwiched between the facestock and liner. Many pressure sensitive adhesives are clear and therefore not easily detected. On tape products, the adhesive is between the two layers of facestock in a roll and is often used without the applicator noting the existence of the adhesive. As long as the tape sticks during application, no one give the adhesive much notice because it is doing its job. If a pressure sensitive product fails it is usually the adhesive that gets the blame. Most of the time the pressure sensitive adhesive is not the primary reason for an adhesion failure but unfortunately the easiest component to assign blame. A pressure sensitive adhesive is a material that will hold two surfaces together solely by surface contact. This bond is accelerated by the application of external pressure to the adhesive. PSA’s are able to bond a wide variety of materials such as papers, plastics, metals, wood and glass. A PSA is a dry solid that does not require activation by water, solvent, or heat. Pressure sensitive adhesives are permanently tacky at room temperature. Pressure sensitive adhesives can be used as replacement to screws, rivets, nuts and bolts, clips, and any other form of attachment. Ease of application makes PSA’s worthy of consideration in many manufacturing processes and makes pressure sensitive media an excellent choice for point of purchase applications and general purpose graphics. -

Cellulose Nitrate in Conservation (1988)

Research in Conservation 1988 Charles Selwitz Cellulose Nitrate in Conservation Cellulose Nitrate in Conservation Research in Conservation 1988 Charles Selwitz Cellulose Nitrate in Conservation THE GETTY CONSERVATION INSTITUTE © 1988 by the J. Paul Getty Trust. All rights reserved Printed in the United States of America. Library of Congress Cataloging-in-Publication Data Selwitz, Charles M., 1927- Cellulose nitrate in conservation. (Research in conservation) "January 1986." Bibliography: p. Includes index. 1. Art—Conservation and restoration—Research. 2. Nitrocellulose—Research. I. Title. II. Series. N8560.S45 1988 702'.8'8 88-8803 ISBN 0-89236-098-4 The Getty Conservation Institute The Getty Conservation Institute (GCI), an operating program of the J. Paul Getty Trust, was created in 1982 to enhance the quality of conservation practice in the world today. Based on the belief that the best approach to conservation is interdisciplinary, the Institute brings together the knowledge of conservators, scientists, and art historians. Through a combination of in-house activities and collaborative ventures with other organizations, the Institute plays a catalytic role that contributes substantially to the conservation of our cultural heritage. The Institute aims to further scientific research, to increase conservation training opportunities, and to strengthen communication among specialists. Research in Conservation This reference series is born from the concern and efforts of the Getty Conservation Institute to publish and make available the findings of research conducted by the GCI and its individual and institutional research partners, as well as state-of-the-art reviews of conservation literature. Each volume will cover a separate topic of current interest and concern to conservators.