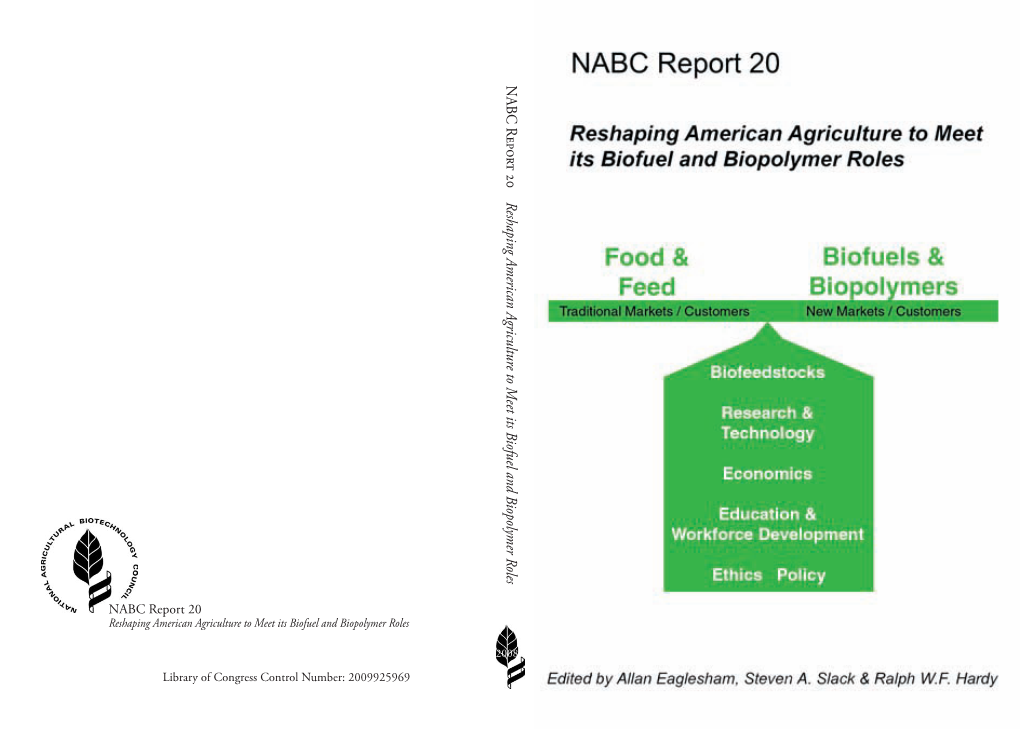

NABC R Eport 20 Reshaping American Agriculture to M Eet Its

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Politics Core SPARTANS@I DERAT Wcnlom STATE UNIWSITT 2005

Politics Core SPARTANS@I DERAT wcnlom STATE UNIWSITT 2005 1NC Shells Links, Continued Bush Good - Energy Bill 3-5 Guantanamo Bay Bush Bad - Energy Bill 6-7 Bush Good - Partisan Uniqueness Bush Good - Tom Delay Energy Bill Will Pass Bush Bad Will Pass 8 Bush Bad - Specter AT: MTBE Blocks 9 Bush Bad - A2: GOP Lx AT: Won't Pass - Court Battle 10 Other Links Energy Bill Won't Include ANWR 11 Korematsu - Bush Bad Energy Bill Won't Pass Oversight Board - Bush Bad Won't Pass 12 Oversight Board - Bush Good Won't Pass - No MTBE Compromise 13 Carnivore - Bush Bad Generic Links Extraordinary Rendition - Bush Bad Bush Good Workplace Drug Testing - Bush Good 2NC 14 Courts Links - Bush Good Generic Bush Good 2NC 15 Agency Links - General Ext. Partisanship 16 Internal Links A2: Public Popularity 17 Political Capital Bush Bad Political Capital KeyIFinite Ext: Concession 18 A2: Political Capital Public 2NC 19 WinnersILosers Specific Links Losers Lose PATRIOT Act Winners Win Bush Bad 1NC 20 A2: Winners Win Bush Bad - Bipart 2 1 GOP and Democrats Bush Bad - Dems 22 Moderate GOP Key A2: GOP Backlash 23 GOP Base Key Bush Good - Loss 24 GOP Unity Key Bush Good - General 2 5 Democrats Key Racial Profiling Concessions Bush Bad - 1NC 2 6 A2: Concessions Bad Bush Bad - 2NC 2 7 A2: Concessions Ext; Bush Bad - Win 28 Flip Flop Ext: Bush Bad - Dems 2 9 Flip Flops Kill Agenda Bush Good - 1 NC 30 A2: Flip Flops Bush Good - 2NC 3 1 Focus Immigration Focus Key Bush Good 1NC A2: Focus Bush good - Political Capital Popularity Bush Good - GOP Backlash Popularity Key Bush -

Sí Hay Tecnología Para Tratar Basura

Toma posesión Solicita Calderón Austria es a la gente: nuevo director SUPERADO de API Manzanillo DenuncIen A por Alemania DIARIO DE MANZANILLO delIncuenTes NACIONAL 10-A DEPORTES 1-C www.diariodecolima.com Colima, CoIima. Martes 17 de Junio de 2008 Año 55. No. 18,303 $5.00 RIESGO Las huellas de rodamiento de la avenida Ignacio Sandoval, en la zona norte de esta capital, representan un peligro para los automovilistas, pues el concreto tiene un marcado desnivel. A esto se agrega la mala iluminación, piedras sueltas y baches que existen en esta arteria vial. (Foto Horacio Medina) En México ¿A DÓNDE VA LA BASURA? Armería (El Campanario) Regularización aprobada Sí hay tecnología Villa de Álvarez Contempla clausura Cuauhtémoc (Cerro Colorado) para tratar basura Clausurado Semarnat: Ningún funcionario de Colima asistió a presentación de diver- Ixtlahuacán (San Gabriel) sos proyectos Regularizado Hugo RAMÍREZ PULIDO los diferentes proyectos de plan- para conocer el funcionamiento conviene”. tas de residuos sólidos, al cual no de una planta de tratamiento de Dijo que se tendrá que ser Manzanillo (Tapeixtles) El delegado de la Semarnat, Raúl asistió ningún funcionario estatal residuos sólidos. muy cuidadoso en ese aspecto, Arredondo Nava, afirmó que de Colima. Arredondo comentó que para ya que otras ciudades han tenido Realiza obras complementarias para tener mayores márgenes de México cuenta con la tecnología Tengo la información con ese tipo de plantas, Banobras ha malas experiencias al realizar eficiencia. necesaria aplicable a plantas de todas las propuestas, “hay ejem- ofrecido recursos a fondo perdi- estos procesos. tratamiento de residuos sólidos, plos de plantas que están funcio- do, “el proyecto lo paga la misma “En ocasiones los han dejado que se podría adaptar a las nece- nando, que podemos ver lo que institución cuando se solicita el con el producto sin procesar y han Minatitlán (Las Villas) sidades en la entidad. -

A New Land-Grant Mission for the 21St Century

ASPB News THE NEWSLETTER OF THE AMERICAN SOCIETY OF PLANT BIOLOGISTS Volume 37, Number 6 November/December 2010 President’s Letter Inside This Issue A New Land-Grant Mission for the 21st Century New Officers/Committees As I begin my term as president, I growth curve at which instabilities in Assume Posts express my appreciation for the op- food and energy security mount as portunity to serve the one society that resources of arable land and adequate Call for 2011 ASPB Award Nominations has molded my entire professional fresh water diminish. We are on a career. Over my 35 years as a member trajectory to reach 9 billion people Teaching Tools Featured of ASPB, I’ve seen the Society become a by 2030, increasing food, water, and at FESPB Congress truly global community that promotes energy demand by at least 50%, with- Call for Applications: SURF and serves plant biology research: out considering aggravating factors almost one-half of our membership of climate change, increased urban- currently resides outside the United ization, and increased demand from States. I also thank my immediate two Nick Carpita developing countries to attain Western predecessors, Tuan-hua David Ho and standards of living. Sally Assmann, for their superb job in strengthen- Developed countries have brought these issues ing focus on the role ASPB continues to play in into political focus as a basis of establishing new the globalization of plant biology. Together they funding priorities for the research needed to meet provided guidance for the formation last year of unprecedented needs. Not only is it a moral impera- the Global Plant Council (GPC), a new partnership tive for the most prosperous countries of the world of plant societies spanning six continents. -

G20070600/Ltr-07-0569/Edats

EDO Principal Correspondence Control FROM: DUE: / / EDO CONTROL: G20070600 DOC DT: 08/16/07 FINAL REPLY: Samuel W. Bodman, DOE TO: Chairman Klein FOR SIGNATURE OF : ** GRN ** CRC NO: 07-0569 DESC: ROUTING: Intelligence Program at DOE - Safeguarding Reyes (EDATS: SECY-2007-0301) Virgilio Kane Ash Ordaz Cyr/Burns DATE: 08/30/07 Hagan, ADM Sheron, RES ASSIGNED TO: CONTACT: Dyer, NRR Weber, NMSS NSIR Zimmerman Laufer, OEDO SPECIAL INSTRUCTIONS OR REMARKS: For Appropriate Action. EDATS Number: SECY-2007-0301 Source: SECY GeealIfrmto Assigned To: NSIR OEDO Due Date: NONE Other Assignees: SECY Due Date: NONE Subject: Intelligence Program at DOE - Safeguarding Description: CC Routing: ADM; RES; NRR; NMSS ADAMS Accession Numbers - Incoming: NONE Response/Package: NONE I.Ote norain Cross Reference Number: G20070600, LTR-07-0569 Staff Initiated: NO Related Task: Recurring Item: NO File Routing: EDATS Agency Lesson Learned: NO Roadmap Item: NO Action Type: Appropriate Action Priority: MediumL Sensitivity: None Signature Level: No Signature Required Urgency: NO OEDO Concurrence: NO OCM Concurrence: NO OCA Concurrence: NO Special Instructions: For Appropriate Action. Originator Name: Samuel W. Bodman Date of Incoming: 8/16/2007 Originating Organization: DOE Document Received by SECY Date: 8/29/2007 Addressee: Chairman Klein Date Response Requested by Originator: NONE Incoming Task Received: Letter Page 1 of l OFFICE OF THE SECRETARY CORRESPONDENCE CONTROL TICKET Date Printed: Aug 28, 2007 12:16 PAPER NUMBER: LTR-07-0569 LOGGING DATE: 08/27/2007 ACTION OFFICE: EDO AUTHOR: Samuel Bodman AFFILIATION: DOE ADDRESSEE: Dale Klein SUBJECT: Capabilities of the DOE and its contractors bring to bear on national security challenges ACTION: Appropriate DISTRIBUTION: LETTER DATE: 08/16/2007 ACKNOWLEDGED No SPECIAL HIANDLING: NOTES: FILE LOCATION: ADAMS DATE DUE: DATE SIGNED: EDO -- G20070600 The Secretary of Energy Washington, D.C. -

2006-10-26 Agenda

AGENDA MEETING OF THE UTAH STATE BOARD OF REGENTS October 26, 2006 Utah State Board of Regents Office of the Commissioner of Higher Education Board of Regents Building, The Gateway 60 South 400 West Salt Lake City, Utah 84101-1284 STATE BOARD OF REGENTS MEETING OCTOBER 26, 2006 REGENTS’ OFFICES, SALT LAKE CITY, UTAH Agenda 9:00 a.m. - COMMITTEE OF THE WHOLE 10:00 a.m. (Large Board Room, Lobby Level) 1. Welcome and Overview 2. Resolution in Memory of Former Regent Jay Dee Harris 3. 2007-2008 USHE Budget Request (including Utah Education Network) Tab A 4. State Building Board’s Final Recommendations on Capital Projects Tab B 10:00 a.m. - 11:00 a.m. MEETINGS OF BOARD COMMITTEES ACADEMIC (PROGRAMS) COMMITTEE Commissioner’s Board Room, 5th Floor ACTION: 1. University of Utah – Master of Health Care Administration Tab C 2. Utah State University – Master of Science Degree in Computer Engineering Tab D INFORMATION: 3. Information Calendar, Programs Committee Tab E A. University of Utah i. Jazz Studies Track in Master of Music Degree ii. Interdisciplinary Graduate Certificate in Historic Preservation B. Southern Utah University – Program Name Change C. Salt Lake Community College – Organization Changes in the School of Business 4. University of Utah – Graduate Council Reviews Tab F FINANCE AND FACILITIES COMMITTEE Large Board Room, Lobby Level ACTION: 1. Proposed Revisions to Policies R926, Use of Office-Owned IT Resources, and R927, Tab G Use and Security of Property 2. Approval of First-Tier Tuition Range for 2007-2008 Tab H 3. Utah State University – Proposed Institutional Investment Policy Tab I 4. -

EI Du Pont De Nemours and Company

UNITED STATES SECURITIES AND EXCHANGE COMMISSION WASHINGTON, D.C. 20549-4561 DIVSION OF CORPORATION FINANCE Februar 16,2010 Eri T. Hoover Senior Counsel E. i. du Pont de Nemours and Company DuPont Legal, D8048-2 1007 Market Street Wilmington, DE 19898 Re: E. I. du Pont de Nemours and Company Incoming letter dated December 23,2009 Dear Mr. Hoover: Ths is in response to your letters dated December 23,2009 and Januar 13,2010 concerng the shareholder proposal submitted to DuPont by Wiliam Steiner. We also have received letters on the proponent's behalf dated Janua 12,2010 and Janua 14,2010. Our response is attched to the enclosed photocopy of your correspondence. By doing this, we avoid having to recite or sumarze the facts set forth ùi the correspondence. Copies of all of the correspondence also will be provided to the proponent. In connection with this matter, your attention is directed to the enclosure, which sets fort a brief discussion of the Division's informal procedures regàrding shareholder prupusals. Senior Special Counsel Enclosures cc: John Chevedden ***FISMA & OMB Memorandum M-07-16*** Februar 16,2010 Response of the Office of Chief Counsel Division of Corporation Finance Re: E. i. du Pont de Nemours and Company Incoming letter dated December 23,2009 The proposal recommends that the board adopt a policy requiring that the proxy statement for each anual meeting contain a proposal, submitted by and supported by company management, seeking an advisory vote of shareholders to ratify and approve the board Compensation Committee Report and the executive compensation policies and practices set fort in the Compensation Discussion and Analysis. -

The RT Review

Vol. 13, No. 3, October 2005 The RT Review The Latest on Environmental Issues From Your Solution-Oriented Environmental Services Firm • Environmental Engineers & Scientists • Geologists • Remedial Contractors RTENV.COM NEW REPORT SHOWS PROGRESS NEW GENERATION OF BROWNFIELD SITES REDUCING AIR POLLUTION IN EASTERN UNITED STATES RECEIVING TOP ATTENTION 2004 decreases in emissions of ozone forming The next generation of Brownfield sites are Redevelopment of the Bellmawr site poses a nitrogen oxides (NOx) signal that ozone air quality already turning out to be all that planners and number of challenges, including that a connector throughout the eastern US is improving. According those concerned about the environment wanted ramp between the North-South freeway and I- to a new report released in mid-August, “Evaluating to see happen as the nation accommodates 295 is proposed to be installed in the near future Ozone Control Programs in the Eastern United population growth. In Pennsylvania and New across the site as part of the New Jersey States: Focus on the NOx Budget Trading Program, Jersey, legislatures and governors, several years Department of Transportation’s “Missing 2004”, EPA’s rule, known as the “NOx SIP Call,” ago, created both economic and permit expedit- Moves” project. Bellmawr’s long-time mayor, ing incentives which are now coming to fruition. Joseph Petruzzi, has called for proper closure of has yielded reductions to improve air quality for Now, projects are even being put forth which can the landfill as part of any aspect of site redevel- more than 100 million people. The NOx SIP Call include transportation infrastructure improve- opment. -

Samuel W. Bodman Nomination Hearing

S. HRG. 109–1 SAMUEL W. BODMAN NOMINATION HEARING BEFORE THE COMMITTEE ON ENERGY AND NATURAL RESOURCES UNITED STATES SENATE ONE HUNDRED NINTH CONGRESS FIRST SESSION TO CONSIDER THE NOMINATION OF SAMUEL W. BODMAN TO BE SECRETARY OF ENERGY JANUARY 19, 2005 ( Printed for the use of the Committee on Energy and Natural Resources U.S. GOVERNMENT PRINTING OFFICE 99–513 PDF WASHINGTON : 2005 For sale by the Superintendent of Documents, U.S. Government Printing Office Internet: bookstore.gpo.gov Phone: toll free (866) 512–1800; DC area (202) 512–1800 Fax: (202) 512–2250 Mail: Stop SSOP, Washington, DC 20402–0001 VerDate 0ct 09 2002 11:39 Mar 04, 2005 Jkt 000000 PO 00000 Frm 00001 Fmt 5011 Sfmt 5011 P:\DOCS\99513.TXT SENE3 PsN: SCAN COMMITTEE ON ENERGY AND NATURAL RESOURCES PETE V. DOMENICI, New Mexico, Chairman LARRY E. CRAIG, Idaho JEFF BINGAMAN, New Mexico CRAIG THOMAS, Wyoming DANIEL K. AKAKA, Hawaii LAMAR ALEXANDER, Tennessee BYRON L. DORGAN, North Dakota LISA MURKOWSKI, Alaska RON WYDEN, Oregon RICHARD BURR, North Carolina, TIM JOHNSON, South Dakota MEL MARTINEZ, Florida MARY L. LANDRIEU, Louisiana JAMES M. TALENT, Missouri DIANNE FEINSTEIN, California CONRAD BURNS, Montana MARIA CANTWELL, Washington GEORGE ALLEN, Virginia JON S. CORZINE, New Jersey GORDON SMITH, Oregon KEN SALAZAR, Colorado JIM BUNNING, Kentucky ALEX FLINT, Staff Director JUDITH K. PENSABENE, Chief Counsel BOB SIMON, Democratic Staff Director SAM FOWLER, Democratic Chief Counsel (II) VerDate 0ct 09 2002 11:39 Mar 04, 2005 Jkt 000000 PO 00000 Frm 00002 Fmt 5904 Sfmt 5904 P:\DOCS\99513.TXT SENE3 PsN: SCAN C O N T E N T S STATEMENTS Page Akaka, Hon. -

Annual-Report-06.Pdf

UNIVERSITY OF CONNECTICUT SCHOOL OF ENGINEERING ANNUAL REPORT 2005-06 TABLE OF CONTENTS SCHOOL OF ENGINEERING Annual Report Summary……………………………………………………….. 3 DEPARTMENTS Chemical Engineering Annual Report Summary……………………………………………………… 9 Archival Technical Journal Publications……………………………………… 11 Published Books, Book Chapters, Book Sections & Edited Volumes……….. 15 Conference Proceedings & Other Publications……………………………….. 17 Active Research Grants and Contracts………………………………………... 21 Awards, Honors, Patents………………………………………………….…... 25 Major Professional Activities………………………………………………… 27 Civil & Environmental Engineering Annual Report Summary………………………………………………………35 Archival Technical Journal Publications……………………………………… 37 Published Books, Book Chapters, Book Sections & Edited Volumes……….. 41 Conference Proceedings & Other Publications………………………………. 43 Active Research Grants and Contracts……………………………………….. 49 Awards, Honors, Patents………………………………………………….….. 55 Major Professional Activities………………………………………………… 57 Computer Science & Engineering Annual Report Summary……………………………………………………… 65 Archival Technical Journal Publications……………………………………… 69 Published Books, Book Chapters, Book Sections & Edited Volumes………... 73 Conference Proceedings & Other Publications……………………………….. 75 Active Research Grants and Contracts……………………………………….. 83 Awards, Honors, Patents………………………………………………….….. 89 Major Professional Activities………………………………………………… 91 Electrical & Computer Engineering Annual Report Summary……………………………………………………… 105 Archival Technical Journal Publications………………………………………109 -

Are We Losing Our Edge (Time).Pages

Are We Losing Our Edge? The U.S. still leads the world in scientific innovation. But years of declining investment and fresh competition from abroad threaten to end our supremacy By MICHAEL D. LEMONICK Feb. 13, 2006 Gabriel Aeppli was born in Switzerland, but when he was 1 year old, his father came to the U.S. to pursue a career as a mathematician. Back then, America was a scientific "city on the hill," a place where enormous resources, academic freedom, a tradition of skepticism and a history of excellence lured everyone from astronomers to zoologists from all over the world, and like Aeppli's father, many of them never had any interest in leaving. Aeppli, now 48, attended M.I.T., where he got a Ph.D. in electrical engineering, and went on to work at Bell Labs, the legendary research arm of AT&T. Then he moved on to the NEC research laboratory, outside Princeton, N.J., as a senior research scientist. But while industrial labs used to be well-funded havens for freewheeling scientific inquiry, says Aeppli, "my career was limited because opportunities to lead were very few." So he left for an academic job in Britain. He now holds a chair in physics at University College London and also directs the London Center for Nanotechnology. "I've been able to start with a clean sheet of paper and create something unique in a world-class city," he says. "We doubt that could be done anywhere else." Edison Liu is a Hong Kong native who studied in the U.S. -

February Aps News 2006.Qxp

February 2006 Volume 15, No.2 APS NEWS www.aps.org/apsnews A Publication of the American Physical Society Inside this issue DOE Picks University of California to Use the Sorting, sorting... Head Los Alamos Management Team New APS Logo he Department of Energy of exceptionally high caliber,” said announced in December its Energy Secretary Samuel Bodman Tdecision to award the contract at a press conference in December to manage Los Alamos National announcing the decision to award the Laboratory to Los Alamos National contract to the UC/Bechtel team. Security, LLC. (LANS), a partner- Bodman stressed that the new con- ship led by the University of tract would not be a continuation of California, partnered with Bechtel the previous contract. “This is a new Corporation, a huge engineering, con- contract, with a new team, marking struction and project management a new approach to management at Los Photo credit: Ernie Tretkoff company. Alamos.” The 2006 March Meeting received more than 6500 abstracts, and The University of California has That new approach includes a new sorting them all into sessions is a highly non-trivial task. Undaunted, For camera ready versions a dedicated group of volunteers, part of which is pictured here, gath- run Los Alamos National Lab since attitude towards monetary compen- of the logo visit the lab was created in 1943. But a sation. The new contract, which http://www.aps.org/logo.cfm ered at APS headquarters in College Park on December 9 and 10 for series of safety, security, and financial begins June 1, has an initial term of this purpose. -

Global Brazil and US-Brazil Relations

Global BrazilGlobal and U.S.-Brazil Relations The Council on Foreign Relations sponsors Independent Task Forces to assess issues of cur- rent and critical importance to U.S. foreign policy and provide policymakers with concrete judgments and recommendations. Diverse in backgrounds and perspectives, Task Force members aim to reach a meaningful consensus on policy through private and nonpartisan deliberations. Once launched, Task Forces are independent of CFR and solely responsible for the content of their reports. Task Force members are asked to join a consensus signifying that they endorse “the general policy thrust and judgments reached by the group, though not necessarily every finding and recommendation.” Each Task Force member also has the option of putting forward an additional or a dissenting view. Members’ affiliations are listed for identification purposes only and do not imply institutional endorsement. Task Force ob- servers participate in discussions, but are not asked to join the consensus. Task Force Members Richard Armitage Robert L. Grenier Armitage International L.C. Kroll Associates Reza Aslan John M. Keane University of California, Riverside Keane Advisors, LLC J. Brian Atwood Michael Krepon University of Minnesota Henry L. Stimson Center David W. Barno Sloan C. Mann National Defense University Development Transformations Samuel R. Berger Daniel Markey Albright Stonebridge Group Council on Foreign Relations Karan K. Bhatia John A. Nagl Independent Task Force Report No. 66 General Electric Company Center for a New American Security Marshall M. Bouton John D. Negroponte Chicago Council on Global Affairs McLarty Associates Samuel W. Bodman and James D. Wolfensohn, Chairs Kara Bue Charles S. Robb Julia E.