Fluid Flow Conditioning for Meter Accuracy and Repeatability

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

CHARACTERIZATION of AIRFLOW THROUGH an AIR HANDLING UNIT USING COMPUTATIONAL FLUID DYNAMICS by Andrew Evan Byl a Thesis Submitte

CHARACTERIZATION OF AIRFLOW THROUGH AN AIR HANDLING UNIT USING COMPUTATIONAL FLUID DYNAMICS by Andrew Evan Byl A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science In Mechanical Engineering MONTANA STATE UNIVERSITY Bozeman, Montana November 2015 ©COPYRIGHT by Andrew Evan Byl 2015 All Rights Reserved ii TABLE OF CONTENTS 1. INTRODUCTION ...........................................................................................................1 2. BACKGROUND .............................................................................................................5 HVAC Systems .............................................................................................................. 5 Air Filters ................................................................................................................ 6 Flow Conditioners and Baffles ............................................................................... 7 Fan Types ................................................................................................................ 8 Heat Exchangers ................................................................................................... 12 Computational Fluid Dynamics ................................................................................... 15 CFD in the HVAC Industry .................................................................................. 17 Methods of Characterizing Flow ................................................................................. -

Computational Analysis of the Flow Field Downstream of Flow Conditioners

EI-NO-- NTNU Trondheim Norges teknisk-naturvitenskapelige universitet DqktorIngenioravhandling 1997:29 1 0 2 2 Institutt for mekanikk, termo- og fluiddynamikk Trondheim MTF-rapport 1997:149 (D) moners TA am Computational analysis of the flow field downstream of flow conditioners Asbjern Erdal February 1997 Thesis for the dr. ing. degree Department of Applied Mechanics, Thermodynamics and Fluid Dynamics Norwegian University of Science and Technology Page 2 DISCLAIMER Portions of this document may be illegible in electronic image products. Images are produced from the best available original document. Abstract A flow conditioner (FC) is a device installed upstream of a flow meter in order to remove swirl and to correct a distorted flow profile generated by inappropriate installation conditions. Using an FC can reduce installation effects in flow measurements. Numerous attempts have been made to isolate metering stations from piping-induced disturbances, and many different FCs have been designed. Some have proved capable of meeting the flow quality requirements in the metering standards, but doubts have remained about the factors dictating their performance. The design methods used earlier, such as screen theory, cannot give a fundamental understanding of how an FC works. This thesis shows, however, that computational fluid dynamic (CFD) techniques can be a valuable tool to examine several parameters which may affect the performance of an FC. It is, among other things, shown that the flow pattern through a complex geometry, like a 19-hole plate FC, can be simulated with good accuracy by a k-s turbulence model. The calculations illuminate how variation in pressure drop, overall porosity, grading of porosity across the cross-section and the number of holes affect the performance of FCs. -

TYPICAL OPERATING POLICIES and PROCEDURES (Ref Chap 2, Sec

Appendix A TYPICAL OPERATING POLICIES AND PROCEDURES (ref Chap 2, Sec. 2.5.2.1. and 2.5.3.2) Downloaded from http://asmedigitalcollection.asme.org/ebooks/book/chapter-pdf/2797178/859605_bm.pdf by guest on 24 September 2021 PROCEDURES FOR MANAGEMENT OF DOCUMENTATION Document Management Manual Document New, Merge and Revision Process Operating Policies and Procedures Management System Guiding Principles and Policies Procedure Template Procedure Template Directions GENERAL PROCEDURES Assembling a Flanged Connection Canadian Electrical Work Procedures Communication Procedures Compressed Gas Cylinders and Compressed Air Contractor Employee Control Procedure Crane and Rigging Use Electric Motor Bearing Lubrication Guidelines Field Planned Inspection Procedure Fitness to Work Flange Bolt Tightening Guidelines for Venting of Sweet Natural Gas High-Pressure Quick-Opening Closures Procedure Hoisting, Lifting, Towing and Winching Hydrates in Pipelines Long-Term Standby Procedure Machine Guarding Safety Magnetic Particle Inspection Procedure Motor Vehicle Operation Natural Gas Flexible Hose Procedure Natural Gas Leak Detection Procedure One Call Procedure Operation of Heavy Equipment Operations Center Evacuation Procedure Owner/User Inspection Program for Inspection and Maintenance of Pressure Equipment Including Repairs and Alterations 667 668 I Pipeline Operation & Maintenance—A Practical Approach Physical Security and Incident Reporting Pile Driving Procedure Portable Gas Detection of Atmosphere Pre-job Procedure Region Site Orientation Procedure -

The Fundamentals of Fluid Flow Conditioning

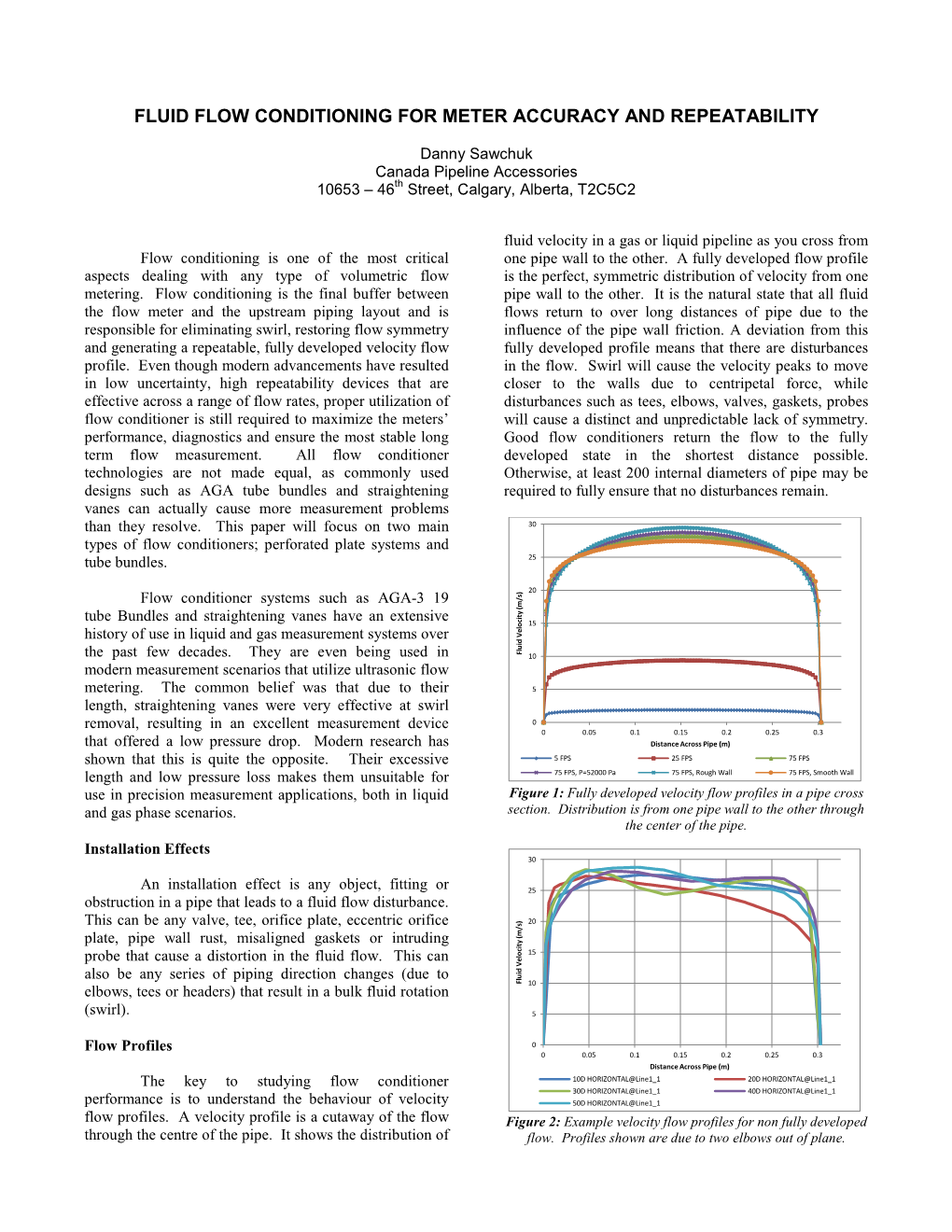

The Fundamentals of Fluid Flow Conditioning Danny Sawchuk Canada Pipeline Accessories 10653- 46th Streeet, Calgary, Alberta, T2C5C2 2 Introduction Flow conditioning is one of the most critical aspects dealing with any type of volumetric flow metering. Flow conditioning is the final buffer between the flow meter and the upstream piping layout. Flow conditioning is responsible for eliminating swirl, restoring profile symmetry, and generating a repeatable, fully developed velocity flow profile. Modern advancements have resulted in low uncertainty, high repeatability devices that are effective across a range of flow rates. However, proper utilization of flow conditioners is still required to maximize the meters’ performance and diagnostics to ensure the most stable long-term flow measurement. All flow conditioner technologies are not made equal, as commonly used designs such as AGA tube bundles and straightening vanes can actually cause more measurement problems than they resolve. This paper will focus on two main types of flow conditioners: perforated plate flow conditioners, and straightening vanes such as tube bundles. Over the past few decades, flow conditioner systems such as AGA-3 19 Tube Bundles and straightening vanes have an extensive history of use in liquid and gas measurement systems. They are even being used today in modern measurement scenarios that utilize ultrasonic flow metering. Historically, the common belief was that due to their length, straightening vanes must be very effective at swirl removal, and must result in an excellent measurement device that offered a low pressure drop. Modern research has shown that this is quite the opposite. We now know that their excessive length and low pressure loss makes them unsuitable for use in precision measurement applications, both in liquid and gas phase scenarios. -

A STANDARD for USERS and MANUFACTURERS of THERMAL DISPERSION MASS FLOWMETERS by John G

A STANDARD FOR USERS AND MANUFACTURERS OF THERMAL DISPERSION © MASS FLOW METERS BY John G. Olin, Ph.D CEO, Founder Sierra Instruments, Inc. October 15, 2008 FOREWORD Thermal dispersion mass flowmeters comprise a family of instruments for the measurement of the total mass flow rate of a fluid, primarily gases, flowing through closed conduits. The operation of thermal dispersion mass flowmeters is attributed to L.V. King who, in 1914 (Ref. 1), published his famous King’s Law revealing how a heated wire immersed in a fluid flow measures the mass velocity at a point in the flow. King called his instrument a “hot-wire anemometer”. However, it was not until the 1960’s and 1970’s that industrial-grade thermal dispersion mass flowmeters finally emerged. This standard covers the thermal dispersion type of thermal mass flowmeter. The second type is the capillary tube type of thermal mass flowmeter, typically provided in its mass flow controller configuration. Both types measure fluid mass flow rate by means of the heat convected from a heated surface to the flowing fluid. In the case of the thermal dispersion, or immersible, type of flowmeter, the heat is transferred to the boundary layer of the fluid flowing over the heated surface. In the case of the capillary tube type of flowmeter, the heat is transferred to the bulk of the fluid flowing through a small heated capillary tube. The principles of operation of the two types are both thermal in nature, but are so substantially different that two separate standards are required. Additionally, their applications are much different. -

Influence of Flow Disturbances on Measurement Uncertainty of Industry-Standard LNG Flow Meters

Draft paper submitted as a journal publication June 2020 Influence of Flow Disturbances on Measurement Uncertainty of Industry-Standard LNG Flow Meters Asaad Kenbar1 and Menne Schakel2 1- TUV SUD National Engineering Laboratory, East Kilbride, G75 0QF, Scotland, [email protected] 2- VSL B.V. Dutch Metrology Institute, Thijsseweg 11, 2629JA Delft, The Netherlands, [email protected] Abstract In the last decade significant progress has been achieved in the development of measurement traceability for LNG inline metering technologies such as Coriolis and ultrasonic flow meters. In 2019, the world’s first LNG research and calibration facility has been realised thus enabling calibration and performance testing of small and mid-scale LNG flow meters under realistic cryogenic conditions at a maximum flow rate of 200 m3/hr and provisional mass flow measurement uncertainty of 0.30% (k = 2) using liquid nitrogen as the calibration fluid. This facility enabled the work described in this paper to be carried out to achieve three main objectives; the first is to reduce the onsite flow measurement uncertainty for small and mid-scale LNG applications to meet a target measurement uncertainty of 0.50% (k = 2), the second is to systematically assess the impact of upstream flow disturbances and meter insulation on meter performance and the third is to assess transferability of meter calibrations with water at ambient conditions to cryogenic conditions. SI-traceable flow calibration results from testing six LNG flow meters (four Coriolis and two ultrasonic, see acknowledgement section) with water and liquid nitrogen (LIN) under various test conditions are fully described in this paper. -

Product Data Sheet PS-00232, Rev Z April 2021 Micro Motion™ Technical Overview and Specification Summary Product Data Sheet April 2021

Product Data Sheet PS-00232, Rev Z April 2021 Micro Motion™ Technical Overview and Specification Summary Product Data Sheet April 2021 Micro Motion products Emerson’s world-leading Micro Motion Coriolis flow and density measurement devices have set the standard for superior measurement technology. Micro Motion offers the best measurement solutions for any process challenge. Micro Motion advantages Technology leadership Micro Motion is committed to technology innovations that deliver the highest-performing solutions for your complex measurement challenges. Widest breadth of products Micro Motion has the widest range of flow and density measurement devices for virtually any process, application, or fluid. A wide variety of wetted materials, line sizes, and an extensive range of output options enable optimal system integration. Unparalleled value Benefit from expert field and technical application service and support made possible from more than one million meters installed worldwide and over 40 years of flow and density measurement experience. Micro Motion Coriolis flow and density meters ELITE Peak performance Coriolis meter ■ Ultimate real world performance ■ Best fit-for-application ■ Superior measurement confidence F-Series ■ High performance compact drainable Coriolis meter ■ Best flow and density measurement in a compact, drainable flow meter ■ Broadest range of application coverage ■ Superior reliability and safety T-Series Straight tube full-bore Coriolis meter ■ Superior flow measurement in a single straight tube flow meter ■ Comprehensive -

![Improving the Procedures on Cross-Border Metering Stations and Upgrading the SCADA System of the Transmission Network Stations [CWP.09.GE]](https://docslib.b-cdn.net/cover/3677/improving-the-procedures-on-cross-border-metering-stations-and-upgrading-the-scada-system-of-the-transmission-network-stations-cwp-09-ge-11093677.webp)

Improving the Procedures on Cross-Border Metering Stations and Upgrading the SCADA System of the Transmission Network Stations [CWP.09.GE]

ACTIVITY COMPLETION REPORT GEORGIA - Improving the procedures on cross-border metering stations and upgrading the SCADA system of the transmission network stations [CWP.09.GE] INOGATE Technical Secretariat (ITS) and Integrated Programme in support of the Baku Initiative and the Eastern Partnership energy objectives Contract No 2011/278827 A project within the INOGATE Programme Implemented by: Ramboll Denmark A/S (lead partner) EIR Global sprl. The British Standards Institution LDK Consultants S.A. MVV decon GmbH ICF International Statistics Denmark Energy Institute Hrvoje Požar Document title Activity Completion Report: Improving the procedures on cross-border metering stations and upgrading the SCADA system of the transmission network. (CWP.09.GE) Document status Final Name Date Prepared by Phil Winnard 07/03/2016 Raimondas Buckus Checked by Nikos Tsakalidis 10/03/2016 Adrian Twomey Approved by Peter Larsen 06/06/2016 This publication has been produced with the assistance of the European Union. The contents of this publication are the sole responsibility of the authors and can in no way be taken to reflect the views of the European Union. Abbreviations and acronyms atm Atmosphere – obsolete measure of pressure Bar Measure of pressure – SI unit EC European commission EU European Union GGTC Georgian Gas Transportation Company GSM Global System for Mobil Communications IGEM Institution of Gas Engineers and Managers - UK ITS Inogate Technical Secretariat Mbar One thousandth division of 1 Bar Ofgem Office of Gas and Electricity Markets MOP Maximum operating pressure NRV Non Return Valve RIIO UK Energy Regulator (Ofgem) price control model Revenue=Incentives+ Innovation + Outputs PRMS Pressure reduction and metering station PCV Pressure Control Valve PRV Pressure Relief Valve SCADA Supervisory Control and Data Acquisition SDR Standard diameter ratio – used for PE pipe STP Standard Temperature and Pressure UK United Kingdom Contents 1 PART 1 EUROPEAN COMMISSION ...........................................................................................