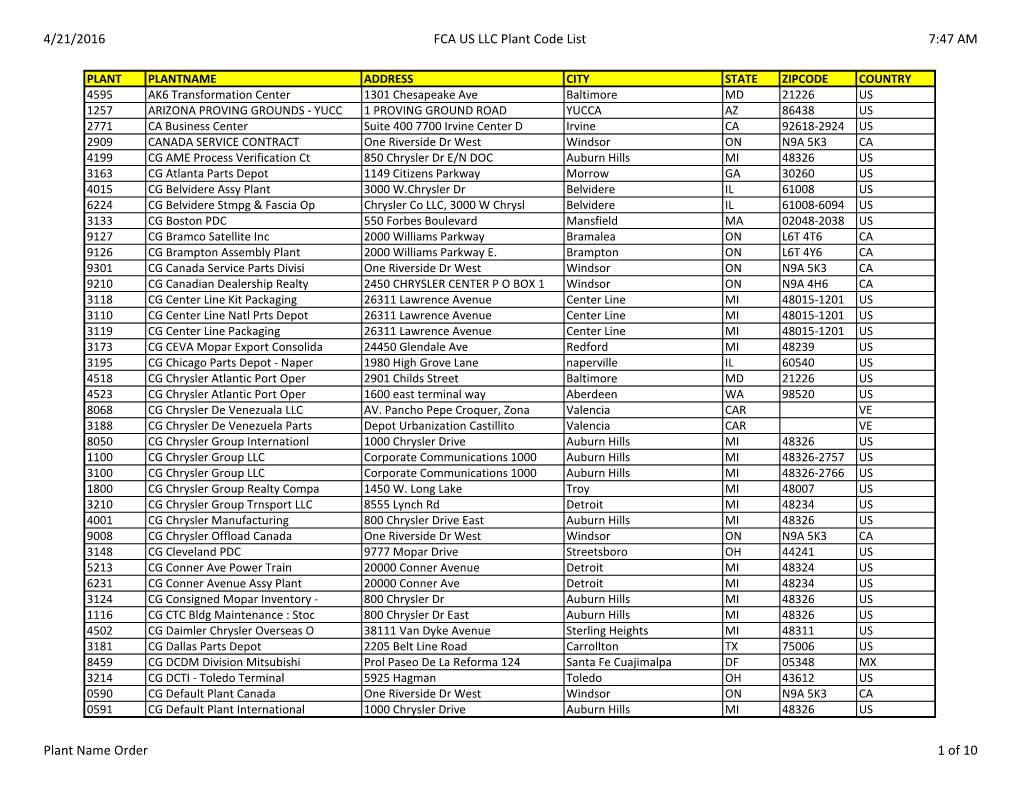

4/21/2016 FCA US LLC Plant Code List 7:47 AM Plant Name Order 1 Of

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Evaluating the Effect of US Domestic Content Requirements

Cross-Border Markets: Evaluating the Effect of U.S. Domestic Content Requirements on the U.S.-Canada Economic Partnership WSHDC-RFP-004 September 15, 2017 Submitted by The Trade Partnership 1701 K Street, NW Suite 575 Washington, DC 20006 1 EXECUTIVE SUMMARY This study examines the effeCt of U.S. domestiC Content requirements on the U.S.-Canada eConomiC partnership. We examine the impaCts by ConduCting in-depth interviews with offiCials at Companies with signifiCant Cross-border trade where domestiC Content requirements do (e.g., Buy America or Buy AmeriCan rules) or Could (e.g., proposed rule requiring U.S. steel in pipelines) shape supply chains. We also spoke to U.S. government agenCies whose proCurement is subjeCt to suCh rules. We found: U.S. domestic content requirements can impact U.S. companies by limiting sourcing options and increasing product costs, both of which negatively impact U.S. jobs and competitiveness. • Buy AmeriCa requirements Can prevent Companies from purChasing some inputs from preferred suppliers, even if few alternative U.S. suppliers exist. • Many U.S. manufaCturing jobs exist in spite, not beCause, of domestiC Content requirements. • DomestiC Content requirements Can Create additional ComplianCe Costs for Companies selling similar produCts to both CommerCial and federally funded projeCts. • Taking additional steps to Comply with domestiC Content requirements Can inCrease the priCe of goods signifiCantly without leading to a similar increase in U.S. jobs. Proposed domestic content changes that could prevent companies from sourcing from Canada would disrupt existing supply chains and harm many U.S. businesses, particularly in the short term. -

North American Manufacturing Operations

Contact: Jodi Tinson North American Manufacturing Operations UNITED STATES, CANADA and MEXICO ASSEMBLY OPERATIONS* Manufacturing Facility Location Products Belvidere Assembly Belvidere, Ill. Jeep® Cherokee Brampton Assembly Brampton, Ont. Chrysler 300, Dodge Challenger, (Canada) Dodge Charger Detroit Assembly Complex - Detroit Jeep Grand Cherokee, Jeep Grand Jefferson Cherokee SRT, Dodge Durango Detroit Assembly Complex - Detroit Jeep Grand Cherokee L Mack Saltillo Truck Assembly Saltillo (Mexico) Ram 1500 Classic (Regular Cab and Crew Cab); Ram 2500, 3500, 4500 and 5500 Heavy Duty; DX Chassis Cab (Mexico Market) Saltillo Van Assembly Saltillo (Mexico) Ram ProMaster Sterling Heights Assembly Sterling Heights, Ram 1500 (Quad Cab and Crew Cab) Mich. Toledo Assembly Complex Toledo, Ohio Jeep Gladiator (South plant); Jeep Wrangler (2 plants) (North plant) Toluca Assembly Toluca (Mexico) Jeep Compass Warren Truck Assembly Warren, Mich. Ram 1500 Classic (Quad Cab and Crew Cab) Windsor Assembly Windsor, Ont. Chrysler Pacifica (Chrysler Pacifica Hybrid), (Canada) Chrysler Voyager and Chrysler Grand Caravan (Canadian market only) *Conner Avenue Assembly Plant (Detroit) ceased production in August 2017. Currently being used as the Conner Event Center. POWERTRAIN OPERATIONS Manufacturing Facility Location Products Dundee Engine Plant Dundee, Mich. 2.4-liter (I-4) Tigershark; 3.6-liter (V-6) Pentastar Upgrade Kokomo Engine Plant (formerly Kokomo, Ind. Being converted to a production site for Indiana Transmission Plant II) the GMET4 engine Saltillo Engine Saltillo (Mexico) 2.0-liter (I-4) Tigershark; 2.0-liter (I-4) E-100 Tigershark; 2.4-liter (I-4) Tigershark; 2.4-liter (I-4) E-100 Tigershark; 5.7-liter (V-8) HEMI®;6.2-liter (V-8) Supercharged Hellcat HEMI; 6.4- liter (V-8) Apache SRT HEMI; 6.4-liter (V- 8) BGE HEMI Saltillo South Engine Saltillo (Mexico) 3.6-liter (V-6) Pentastar Upgrade; 3.6- liter (V-6) Pentastar PHEV Trenton Engine Complex (2 Trenton, Mich. -

Daimler-Chrysler-Vehicle-Problems

Dodge Chrysler Vehicles - Poor Quality Reliability Safety Defects Page 1 of 17 DAIMLERCHRYSLER DODGE CHRYSLER VEHICLES - IMPORTANT CONSUMER INFORMATION BEFORE YOU BUY Dodge, Chrysler formerly DaimlerChrysler has had a history of excessive vehicle quality issues, safety defects and poor service. This continued despite the 1998 Chrysler merger with Daimler Benz and constant claims by DaimlerChrysler that this was a significant benefit to consumers. If anything, given the dramatic quality decline, it seems Mercedes Benz may have embraced some of the cost cutting quality standards at Chrysler to increase overall profitability. The problems continue despite stylish new vehicles and claims of new stringent quality standards by Chrysler to regain consumer confidence. Chrysler continues to deceive consumers regarding known potentially life threatening vehicle defects such as unsafe Seatbelts and Steering which continue to put consumer lives at risk every day. Chrysler still refuses to recall several common serious safety defects that cannot be absolved through mergers and buyouts. Chrysler continues to reduce its warranty expense through an aggressive refusal to honor many valid warranty claims while blaming the consumer whenever possible, such as defective engines where on schedule oil changes can be proven. Consumers often attribute this to being a dealer problem while failing to recognize that this is because Chrysler pressures dealers to keep warranty costs to a minimum, even for known problems and defects. Chrysler will do everything it can to avoid covering common problems under warranty whenever possible by blaming consumers or claiming issues cannot be duplicated. We believe Chrysler is the most negligent, deceptive, misleading and arrogant automobile manufacturer that does not deserve your business. -

Chrysler Group Reports Full Year 2011 Net Income Of

CHRYSLER GROUP REPORTS FULL YEAR 2011 NET INCOME OF $183 MILLION CHRYSLER GROUP’S FULL YEAR 2011 MODIFIED OPERATING PROFIT MORE THAN DOUBLED TO $2 BILLION WITH FREE CASH FLOW OF $1.9 BILLION Chrysler Group full year 2011 net income improved to $183 million from a net loss of $652 million in 2010 and despite a $551 million loss on extinguishment of debt in Q2 2011; fourth quarter net income was $225 million, the highest quarterly net income since the Company began operations in 2009 Net revenue for the year was $55.0 billion, up 31 percent from a year ago; fourth quarter net revenue increased 41 percent to $15.1 billion Modified Operating Profit(b) grew to $2.0 billion for the year, 2.5 times higher than 2010, and $508 million in the fourth quarter Free Cash Flow(e) for full year 2011 totaled $1.9 billion driving Cash(d) at year end 2011 to $9.6 billion compared with $7.3 billion a year ago Net industrial debt(f) was reduced by nearly 50 percent to $2.9 billion at December 31, 2011, from $5.8 billion a year ago Worldwide vehicle sales for full year 2011 totaled 1,855,000, up 22 percent from 2010; fourth quarter worldwide vehicle sales were 479,000, up 28 percent compared with a year ago U.S. market share increased to 10.5 percent for full year 2011, up from 9.2 percent a year ago, driven primarily by a 43 percent increase in U.S. retail sales Worldwide vehicle shipments were 2.0 million for full year 2011, up from 1.6 million a year ago Chrysler Group achieved its third and final performance event in January 2012 by committing to produce its new fuel-efficient vehicle, increasing Fiat S.p.A.’s ownership interest to 58.5 percent AUBURN HILLS, Mich., Feb. -

Chrysler Increases Revenue by $1M Per Day Without Increasing Costs

Chrysler Case Study www.SIMUL8.com/case-studies Chrysler increases revenue by $1m per day without increasing costs Leading automotive manufacturer Chrysler Headquartered in Auburn Hills, Michigan, The Fiat Chrysler Group operates 33 manufacturing facilities in increased revenue by $1m a day without four countries and employs more than 52,000 people. increasing costs and coped with increased The Brampton Assembly plant builds the Chrysler demand for their new 2015 models. 300, Dodge Charger and Dodge Challenger with an annual output of 200,000 units. With the release of the new models, a substantial rise in customer demand was expected. As a result, the plant was tasked with improving daily production rate from 930 to 969 units to meet this increase. Steve Lin, a member of Chrysler’s simulation team, utilized SIMUL8’s powerful simulation software to study the line speed at Trim Chassis Final (TCF) and assess potential changes to increase the number of units produced each day. Chrysler Case Study Using SIMUL8, Chrysler achieved: Increased revenue by $1m per Increased manufacturing Met increased customer day without increasing costs throughput by 39 units per day demand for a new range of models How did Chrysler use simulation to increase throughput? Chrysler’s simulation team used a base was quickly identified that two specific and remove costly bottlenecks. After the simulation of their Brampton Assembly stations were causing a production first trial, these lines were ranked again plant to understand the impact of bottleneck. As these were automatic and any new bottlenecks were identified. changing line speeds. With each machines with no staff working at them, Further trials were then conducted manufacturing plant having its own base the team were able to use the simulation to speed up the new bottleneck lines simulation, process improvement changes to look at what would happen if cycle until the target had been reached. -

Two Vehicle Fatality Crash NARRATIVE

NEWS RELEASE | FOR IMMEDIATE RELEASE | January 1, 2021 Two Vehicle Fatality Crash What: Two vehicle fatality crash Where: West edge of Bismarck Expressway Bridge When: 01/01/2020 0216 AM Road Conditions: Frost Weather Conditions: Fog Crash Involvement: Two vehicles Type of Crash: Head on Agencies Involved: NDHP, Bismarck/Mandan PD, Morton County SO Vehicle No. 1: 2015 Chrysler 200 Driver No. 1: Female (24), Cherry Creek, SD - Fatal Restraints: Seatbelt/Airbag Passenger: Male (25), Bismarck - Injured Restraints: Unrestrained/Airbag Passenger Female (28), Fort Yates, ND - Injured Vehicle No. 2: 2008 Dodge Ram Driver No. 2: Kenyon Eagle (18) Bismarck, ND - Injured Restraints: Seatbelt/Airbag Charges: Driving under the influence NARRATIVE: A Dodge Ram was traveling west bound crossing the Bismarck Expressway Bridge. A Chrysler Sedan was traveling east bound in the west bound lanes. The driver of the Dodge attempted to avoid collision with the wrong way driver by steering right. Just west of the bridge the vehicles hit head on in the outside lane. The Chrysler spun counterclockwise into the north ditch. The Chrysler came to rest on the outer edge of the ditch facing south bound. The Dodge came to rest in the outside lanes facing west. The occupants in the Chrysler required Southwest Region | 601 Channel Drive | Bismarck, ND 58501 PHONE: (701) 328-2467 | FAX: (701) 328-1717 | ND.gov/NDHP extrication. The driver of the sedan was pronounced dead at the scene. The passengers and driver of the Dodge were transported to Sanford in Bismarck by Metro Ambulance. The crash remains under investigation by the NDHP. -

Fca Us Llc Detroit, Michigan

FINAL REPORT FCA US LLC DETROIT, MICHIGAN JEFFERSON NORTH ASSEMBLY PLANT (JNAP) EU-COAT THERMAL OXIDIZERS (TAR-A & TAR-BJ RWDI #1900746 March 11, 2019 SUBMITTED TO SUBMITTED BY Karen Kajiya-Mills Brad Bergeron, A.Sc.T., d.E.T. Michigan Department of Environmental Senior Project Manager I Principal Quality [email protected] Air Quality Division Technical Programs Unit (TPU) RWDI AIR Inc. Constitution Hall 2nd Floor, South Consulting Engineers Scientists 525 West Allegan Street & Lansing, Michigan 48909~7760 451 O Rhodes Drive I Suite 530 Windsor, Ontario N8W 5K5 Wilhelmina Mclemore District Supervisor I Air Quality Division T: 519.823.1311 I ext. 2428 [email protected] F: 519.823.1316 Michigan Department of Environmental Quality 27700 Donald Court Warren, Michigan 48092-2793 FCAUS LLC Jefferson North Assembly Plant 2101 Conner Ave Detroit, Michigan 48215 This document is intended for the sole use of the party to whom it is addressed and may contain !nformatlon that is privileged and/or confidentlal. If you h.ive received thls ln error. pleilse notify us !mmed!ately. Accessible document formats provided upon request rwdi.com ® RWDI name and logo are registered trademarks in Canada and the United States of America. JEFFERSON NORTH ASSEMBLY PLANT (JNAP) E·COATTHERMAL OXIDIZERS (TAR·A & TAR·B) DESTRUCTION EFFICIENCY TESTING FCAUSLLC RWDl#l900746 March 11, 2019 EXECUTIVE SUM MARY RWDI AIR Inc. (RWDI) was retained by Fiat Chrysler Automobiles US LLC (FCA) to complete destruction efficiency (DE) testing for volatile organic compounds (VOCs) on the two (2) thermal oxidizers (TOs) controlling the emissions from the E-Coat Oven (EU-ECOAT) at the Jefferson North Assembly Plant UNAP) located in Detroit, Michigan. -

Toledo Machining Plant

Contact: Jodi Tinson Chrysler Group Plans to Invest Nearly $20 Million in Toledo Machining Plant Investment to increase capacity for production of torque converters for new generation, fuel-efficient nine- speed transmission Company’s total investment in U.S. facilities over $5.2 billion since June 2009 April 25, 2013, Auburn Hills, Mich. - Chrysler Group LLC announced today that it will invest $19.6 million in its Toledo Machining Plant in Perrysburg, Ohio, to increase capacity of the torque converter it’s machining for the nine-speed transmission. With this announcement, the Company’s total investments in its U.S. operations since June 2009 increase to over $5.2 billion. The new torque converters will be paired with the next generation, fuel efficient nine-speed front-wheel drive transmission being assembled at Chrysler Group’s Indiana (Kokomo, Ind.) Transmission Plant I. The new transmission will debut in the 2014 Jeep® Cherokee. “The new nine-speed transmission is a critical part of our strategy to meet fuel economy requirements over the next several years and Toledo Machining will play an integral role in bringing this transmission to market,” said Scott Garberding, Senior Vice President, Manufacturing, Chrysler Group LLC. “Securing this additional investment is a testament to the dedication and commitment of the plant’s workforce and helps secure its future long-term.” The investment will fund the installation of new equipment and tooling for additional machining and assembly capacity. Installation is expected to begin in the third quarter of 2014 and will be completed by the end of 2014. In August 2011, a $72 million investment in Toledo Machining was announced to modernize the plant to produce the eight- and nine-speed torque converters on two new production lines and a new steering column for the Dodge Dart and Jeep Cherokee. -

Fiat Chrysler Automobiles

FIAT CHRYSLER AUTOMOBILES VISIT OUR WEBSITE (HTTPS://WWW.FCAGROUP.COM/EN- US/GROUP/REGIONS/PAGES/NORTHAMERICA.ASPX) Fiat Chrysler Automobiles (FCA) is a global automaker that designs, engineers, manufactures and sells vehicles in a portfolio of exciting brands, including Abarth, Alfa Romeo, Chrysler, Dodge, Fiat, Fiat Professional, Jeep®, Lancia, Ram and Maserati. It also sells parts and services under the Mopar name and operates in the components and production systems sectors under the Comau and Teksid brands. FCA employs nearly 200,000 people around the globe. For more details regarding FCA (NYSE: FCAU/ MTA: FCA), please visit www.fcagroup.com. FCA Location Employees FCA US Headquarters & Technology Center Auburn 1,335 Hills MI Belvidere Assembly Plant and Belvidere Satellite Stamping Plant Belvidere IL Under construction Dundee Engine Plant Dundee MI 4,027 Indiana Transmission Plant Kokomo IN Under construction Jefferson North Assembly Plant Detroit MI 37 Kokomo Casting Plant Kokomo IN 7,659 Kokomo Engine Plant Kokomo IN 2,269 / FCA Location Employees Kokomo Transmission Plant Kokomo IN 964 Mack Avenue Engine Complex Detroit MI 6,759 Mt. Elliott Tool & Die Detroit MI 669 Sterling Heights Assembly Plant Sterling 1,796 Heights MI Sterling Stamping Plant Sterling 2,002 Heights MI Tipton Transmission Plant Tipton IN 2,613 Toledo Assembly Complex Toledo OH 68 Toledo Machining Plant Perrysburg 79 OH Trenton Engine Complex Trenton MI 67 Warren Stamping Plant Warren MI 54 Warren Truck Assembly Plant Warern MI 72 Midwest (Chicago) Business -

Rapport Annuel Du Peeic De 2015

DES IDÉES À L’ACTION RAPPORT ANNUEL DU PEEIC DE 2015 Programme d’économie d’énergie dans l’industrie canadienne DES IDÉES À L’ACTION RAPPORT ANNUEL DU PEEIC DE 2015 Programme d’économie d’énergie dans l’industrie canadienne Also available in English under the title: From Ideas to Action – CIPEC Annual Report, 2015 © Sa Majesté la Reine du chef du Canada, représentée par le ministre des Ressources naturelles, 2016 Pour obtenir des renseignements sur les droits de reproduction, veuillez communiquer avec Ressources naturelles Canada à [email protected]. No de cat. M141-3F-PDF (En ligne) ISSN 1920-3357 Table des matières 40 ans à célébrer – Survold des faits ......................... 2 Profils des secteurs de l’industrie ............................. 17 Membres du conseil des groupes de travail Aliments et boissons .......................................... 18 du PEEIC ................................................................. 66 À propos du PEEIC ................................................... 4 Aluminium ......................................................... 20 Leaders du PEEIC par secteur ................................. 68 Notre mission ............................................................ 5 Brasseries .......................................................... 22 Associations professionnelles du PEEIC .................. 85 Communiquez avec le PEEIC .................................... 5 Chaux ................................................................ 24 Ciment .............................................................. -

2015-Dodge-Challenger-Brochure.Pdf

NEW 2015 DODGE CHALLENGER NEW 20:15 CHALLENGER .[1]* ///// MOST POWERFUL MUSCLE CAR. EVER Redesigning an icon isn’t light work. A staunch allegiant is poised at the ready to evaluate every tweak. One false move will ignite a revolt. With designers and engineers who pride themselves as being enthusiasts first, it was capable hands that transformed this modern classic into its newest evolution. This is the new 2015 Dodge Challenger — styled to turn diehards on and outfitted with enough technology to satisfy a new generation of thrill-seekers. One drive assures everyone that its performance is strong enough to uphold the weight of its legendary reputation. As the world’s fastest muscle car ever,[2] Challenger SRT® Hellcat brings powerful bragging rights to the table. The new Supercharged 6.2-liter HEMI® V8 unleashes an Page 2 outrageous 707 horsepower and staggering quarter-mile time in the 10-second range.† // 1971-inspired heritage styling cues // Class-exclusive[1] TorqueFlite® eight-speed automatic // All-new interior // Up to 30 mpg highway‡ with the 3.6-liter engine and 707 horsepower with the Supercharged 6.2-liter SRT® HEMI® V8 // New 485-horsepower Scat Pack model // Most technologically advanced powertrain[3] // Heritage colors // Class-exclusive[1] five-link independent rear suspension // Most technologically advanced vehicle in its class[2] // Class-exclusive[1] seven-inch reconfigurable digital gauge cluster and 8.4-inch touchscreen // Best-in-class[1] cargo volume // Only vehicle in its class[1] with five-passenger seating. *A note about this brochure: all disclaimers and disclosures can be found on the back cover. -

All-New HEMI® with Fuel-Saving MDS Technology Earns Ward's 2009 "10 Best Engines" Award

January 7, 2009 Contact: Dianna Gutierrez (248) 512-2921 (office) (248) 705-7504 (cell) [email protected] Todd Goyer (248) 512-0041 (office) (248) 761-0805 (cell) [email protected] All-new HEMI® with Fuel-Saving MDS Technology Earns Ward’s 2009 "10 Best Engines" Award Refined 5.7-liter HEMI Delivers Improved Fuel Economy, Even More Power and Torque All-new 5.7-liter HEMI® engine recognized by Ward’s for powertrain excellence Sixth “10 Best Engine Award” for 5.7-liter HEMI V-8 engine Expanded utilization of Chrysler’s fuel-saving Multi-displacement System (MDS) operation More power: as much as 390 horsepower More torque: as much as 410 lb.-ft. of torque Auburn Hills, Mich. , Jan 7, 2009 - Now in its second generation, the legendary 5.7-liter HEMI® V-8 engine has once again earned a place on Ward’s distinguished “2009 10 Best Engines” list. Relentlessly delivering powertrain excellence, Chrysler LLC has earned Ward’s "10 Best" award six times in the last seven years with the iconic 5.7-liter HEMI engine. "The HEMI earns the honor not on pure emotion or brute force but with advanced new technology such as variable valve timing, which allows cruising in four-cylinder mode about 40 percent of the time, which is twice as much as the previous-generation Multi-Displacement System cylinder-deactivation system," said Tom Murphy – Executive Director of Ward’s AutoWorld magazine. "A number of Ward’s testers managed to top 19 mpg (12.3 L/100 km) with the HEMI, putting it in line with certain premium V-6s tested." With improved Multi-Displacement System (MDS) technology for increased fuel efficiency, added refinement and more power, the all-new 2009 5.7-liter HEMI V-8 engine delivers world-class performance and technology in nine Chrysler, Jeep and Dodge vehicles.