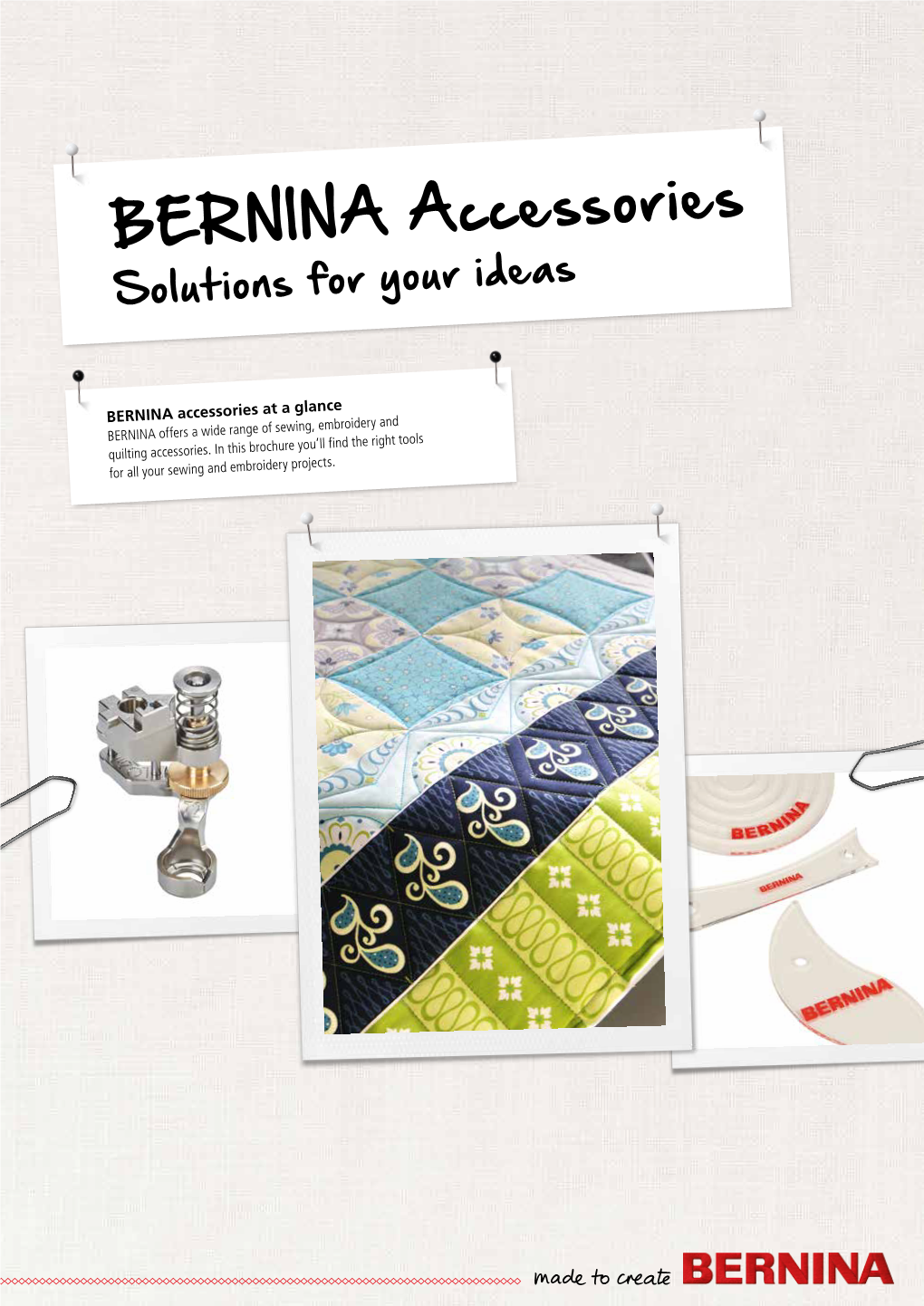

BERNINA Accessories Solutions for Your Ideas

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Islander Sewing Systems: Tuesdays at Two with Janet Pray and Jessica

Islander Sewing Systems: Tuesdays at Two With Janet Pray and Jessica Johnson Index Through June 2019 Subject Type Topics Video Date Alterations Charge at least $10 to hem a pair of pants October 2, 2018 Alterations Tip If asked to hem pants or sew on a button, show the person who asked how October 2, 2018 Alterations Learn how to do alterations for any figure "flaws" and make it a priority for April 9, 2019 one's sewing education Alterations One can just say no to requests for alterations. Give the person who asks for October 2, 2018 alterations a high price; the individual will accept or say no. If one accepts alterations, do it under your conditions Batting Tip Use two layers of Insulbrite or similar batting with a silver backing, not one December 18, 2018 layer. Temporarily adher fabric to back, quilt top, and then put on the binding Bias Tape Maker Demo Make bias tape strip twice as wide as needed using iron and Simplicity Bias July 10, 2018 Tape Maker Books & DVDs Connie Crawford's Patternmaking Made Easy is a textbook, but filled with 3/27/18 & 11/13/2018 good information Books & DVDs Easy Zipper class is available online or on DVD and includes five different 4/24/18 & 8/28/2018 zipper techniques. The class is also on SewBetter.com Books & DVDs Fitting and Pattern Alteration by Elizabeth Leichty and Judith Rasband is an 5/15/2018 & 5/30/18 excellent resource, or take a class from Lorraine Henry Books & DVDs Gail Yellen's It's All About Embelishments is a good resource for decorative April 24, 2018 serger techniques. -

Service Manual

SERVICE MANUAL FOR SINGER MODEL 471U THE SINGER COMPANY From the library of: Superior Sewing Machine & Supply LLC CONTENTS (C MECHANISMS 1) 1 |T| Needle bar mechanism 1 fll] Clutch and brake 29 m Rotary hook mechanism I fi2] Cutter safety device 29 ITj Needle zigzag mechanism 2 [III Needle bar 31 |T| Feed mechanism 3 ini Rotary hook shaft 32 m Clutch mechanism 4 [i^ Upperclamping foot and lower B Cutter mechanism (1) 6 thread cutter 33 B Cutter mechanism (II) 7 [I^ Base needle plate and cutter [Tj Upper thread cutter mechanism 8 position control 34 B Lower thread cutter mechanism 9 Oil Upper clamping foot position control ... 35 [lo] Presser bar lifter mechanism 9 M Rotary hook 35 [li] Lubrication 36 Tension releasing mechanism 10 [2ol Needle sidewise movement ((DISASSEMBLY PROCEDURES)). adjustment 36 (HI Needle zigzag reference m Covers position adjustment 36 m Lower thread cutter HH Scissors assembly position control 38 m Presser HD Scissors guide position control 38 B Rotary hook [24] Covers 39 B Upper thread cutter B Length feed ((ADJUSTMENtH) 40 m Clamping foot 14 m Needle sidewise movement B Cutter safety device 15 adjustment 40 [9] Clutch and brake 15 m Needle bar and rotary U Feed 16 hook adjustment 40 Needle bar 16 m Upper clamping foot lifter un Cam relay 17 adjustment 42 M Upper shaft 17 m Cutter adjustment 44 Auxiliary shaft 18 m Buttonhole width and reference M Needle zigzag 18 position adjustment 46 Needle breakage detection 19 m Upper thread cutter adjustment 48 0 Cutter 19 m Lower thread cutter adjustment 50 Lower shaft -

Sewing Cutting & Pressing Equipment

L & HO RIA US TR EH S O U L D D N D IN SSEEWWIINNGG CCUUTTTTIINNGG && PPRREESSSSIINNGG EEQQUUIIPPMMEENNTT CHANDLER MACHINE U.S.A. L.L.C. www.chandlermachineco.com NEW JERSEY MIAMI LOS ANGELES ©2009 Chandler Machine USA -409 Formerly Chandler Machine Company of Ayer, MA PORTABLE BUTTON SEWER Model CM491 PORTABLE, HAND-OPERATED BUTTON SEWING MACHINE • No electricity needed • No experienced operator necessary. • Instant change for sewing both 2 and 4 hole buttons. • Six to ten seconds to sew on a button. • Automatic stop • Automatic thread-break. • Takes full range of button sizes. • Sews all types of flat buttons, • Twelve firm stitches in every button, with last two stitches double-locking button to material. • Exceptionally durable, high quality construction. • Net Weight (head only)- 37 lbs. • The finest, easiest to own and most practical machine for shirts, pajamas, uniforms, underwear and work clothes. Chandler Model CM491 CLASSIC HAND OPERATED BUTTON SEWER • completely portable and automatic Anyone can learn to • no electric plug or connections necessary Heavy operate it in minutes! • no motor to worry about Steel • no belts to break Stand AMAZINGLY FAST! also available Speedy, sure button replacement for eliminates labor and reduces customer CM491 complaints. This machine will meet all your Chandler Sews Them All tailor and cleaners service requirements! It's even easy enough and fast enough to be on a clothing producton line. End View of CM491 BUTTON SEWER / TACKING MACHINE CM24K MODEL CM24K on optional Single Needle, Single Thread stand Chainstitch, Cylinder Bed Button Sewing And Tacking Machines With Vibrating Clamp, Single Pedal Operation 8-16-32 Parallel Stitches Two Or Four Hole Button Sewing Operation Thread cut by scissor action Speed, Max. -

Ergonomic Tools and Accessories

Ergonomic Tools and Accessories 21.115 Page 1 Tool manufacturers from all industries are now designing tools to be more ergonomic or body-friendly. Tools used repetitively over an extended period of time can cause injury if they’re not ergonomically designed. Sewing and sewing tools are no exception to this rule. Each year, manufacturers of notions and tools are creating more items that are kinder to our hands, backs and necks. It is important that sewers, whether young or old, take as much care as possible when sewing as there is plenty of repetitive motion! This guideline focuses on tools. For information on ergonomic chairs, see Guideline 21.110. Snips & Scissors Fiskars Bent-Handle Scissors are durable There are several varieties of scissors and and offer consistent, exceptional cutting snips engineered with ergonomic handles performance. The ergonomic handle is that provide a comfortable, pain-free grip designed for very comfortable cutting, and when used for long hours at a stretch. the plastic is molded to fit comfortably in your hand. The scissors are designed Below are some choices of ergonomically specifically to avoid touching pressure designed scissors and snips. points and to distribute resistance across Omnigrid® Scissors Ergonomic Thread more of the hand during cutting, thus Snips: These scissors are a good basic pair providing comfortable cutting action. An for many of your sewing needs. They have adjustable tension screw allows you to soft, cushioned handles that greatly reduce reduce or fatigue and are perfect for those with increase the arthritis or carpal tunnel syndrome. The cutting-motion snips fit comfortably in your hand for resistance. -

Pleats, Tucks, & Ruffles

My BERNINA BERNINA ACCESSORIES WORKBOOK PLEATS, TUCKS, & RUFFLES GATHERING PINTUCKS PINTUCKS & STITCHES PLEATING & RUFFLING NARROW TUCKS 48 My BERNINA BERNINA ACCESSORIES WORKBOOK GATHERING Gathering Foot #16 comes in two versions, one for 5.5 mm machines and one for 9 mm machines. They are both called #16 and both have a 5.5 mm needle opening. One is wider than the other and it is designed to fit the wider feed teeth of the larger machines. Supplies & Settings • Three pieces medium weight cotton, one 3” x 6” and two 4” x 12” Gathering Foot #16 • Cotton or polyester thread • Gathering Foot #16 • 80/12 Universal needle • Center needle position • Stitch: Straight Stitch Gathering Attach the gathering foot to the machine, select the Straight Stitch and adjust the stitch length to 5 mm. Swatch #1 1. Place one 12” length of fabric right side up under the foot. 2. Stitch the length of the fabric; it will gather as it goes under the needle. Swatch #2 1. Place the remaining 12” length of fabric right side up under the presser foot. Stitch 2”-3” and stop. Note: There are three things that 2. Insert the 6” length of fabric right side down into affect the amount of gathers: the slot of the foot with the raw edge against the right side of the slot. Fabric Weight—The lighter weight the 3. Continue stitching, carefully guiding both pieces of fabric, the more it gathers. fabric. Guide the fabric being gathered with the left hand and the flat piece of fabric with the right hand. -

Bernina Bernina Accessories Workbook Bernina

MYMy BERNINA BERNINA ACCESSORIES WORKBOOK BERNINA MASTERY BOOK SERIES Presser Feet and Accessories BERNINA PRESSER FEET ACCESSORIES WORKBOOK 1 ©2019 BERNINA of America. Permission granted to copy and distribute in original form only. Content may not be altered or used in any other form or under any other branding. 06022019 My BERNINA BERNINA ACCESSORIES WORKBOOK TABLE OF CONTENTS INTRODUCTION ....................................... 4 CORDED EDGE ....................................... 25 FEET INFORMATION ................................ 5 NARROW HEM ....................................... 26 SEAMS ..................................................... 6 TRIMMED EDGE ..................................... 27 PATCHWORK SEAM ................................ 7 SPECIALTY FABRICS .............................. 28 STANDARD SEAM .................................... 8 SEWING JEANS & DENIM ...................... 29 KNIT SEAM ............................................... 9 SEWING LEATHER, VINYL & PLASTIC .... 30 FAGOTED SEAM .................................... 10 APPLIQUÉ & DECORATIVE STITCHES .. 31 HEMSTITCHED SEAM ............................. 11 BLANKET STITCH APPLIQUÉ .................. 32 EDGE JOINING SEAM ............................. 12 INVISIBLE APPLIQUÉ .............................. 33 FLAT FELLED SEAM ................................ 13 DECORATIVE STITCHING ....................... 34 CLOSURES ............................................. 14 QUILTING ............................................... 35 MANUAL BUTTONHOLES ..................... -

Powerhouse Museum Lace Collection: Glossary of Terms Used in the Documentation – Blue Files and Collection Notebooks

Book Appendix Glossary 12-02 Powerhouse Museum Lace Collection: Glossary of terms used in the documentation – Blue files and collection notebooks. Rosemary Shepherd: 1983 to 2003 The following references were used in the documentation. For needle laces: Therese de Dillmont, The Complete Encyclopaedia of Needlework, Running Press reprint, Philadelphia, 1971 For bobbin laces: Bridget M Cook and Geraldine Stott, The Book of Bobbin Lace Stitches, A H & A W Reed, Sydney, 1980 The principal historical reference: Santina Levey, Lace a History, Victoria and Albert Museum and W H Maney, Leeds, 1983 In compiling the glossary reference was also made to Alexandra Stillwell’s Illustrated dictionary of lacemaking, Cassell, London 1996 General lace and lacemaking terms A border, flounce or edging is a length of lace with one shaped edge (headside) and one straight edge (footside). The headside shaping may be as insignificant as a straight or undulating line of picots, or as pronounced as deep ‘van Dyke’ scallops. ‘Border’ is used for laces to 100mm and ‘flounce’ for laces wider than 100 mm and these are the terms used in the documentation of the Powerhouse collection. The term ‘lace edging’ is often used elsewhere instead of border, for very narrow laces. An insertion is usually a length of lace with two straight edges (footsides) which are stitched directly onto the mounting fabric, the fabric then being cut away behind the lace. Ocasionally lace insertions are shaped (for example, square or triangular motifs for use on household linen) in which case they are entirely enclosed by a footside. See also ‘panel’ and ‘engrelure’ A lace panel is usually has finished edges, enclosing a specially designed motif. -

Identifying Handmade and Machine Lace Identification

Identifying Handmade and Machine Lace DATS in partnership with the V&A DATS DRESS AND TEXTILE SPECIALISTS 1 Identifying Handmade and Machine Lace Text copyright © Jeremy Farrell, 2007 Image copyrights as specified in each section. This information pack has been produced to accompany a one-day workshop of the same name held at The Museum of Costume and Textiles, Nottingham on 21st February 2008. The workshop is one of three produced in collaboration between DATS and the V&A, funded by the Renaissance Subject Specialist Network Implementation Grant Programme, administered by the MLA. The purpose of the workshops is to enable participants to improve the documentation and interpretation of collections and make them accessible to the widest audiences. Participants will have the chance to study objects at first hand to help increase their confidence in identifying textile materials and techniques. This information pack is intended as a means of sharing the knowledge communicated in the workshops with colleagues and the public. Other workshops / information packs in the series: Identifying Textile Types and Weaves 1750 -1950 Identifying Printed Textiles in Dress 1740-1890 Front cover image: Detail of a triangular shawl of white cotton Pusher lace made by William Vickers of Nottingham, 1870. The Pusher machine cannot put in the outline which has to be put in by hand or by embroidering machine. The outline here was put in by hand by a woman in Youlgreave, Derbyshire. (NCM 1912-13 © Nottingham City Museums) 2 Identifying Handmade and Machine Lace Contents Page 1. List of illustrations 1 2. Introduction 3 3. The main types of hand and machine lace 5 4. -

1T3 FUN to SEW Withasewing Machine

, .. _t '.- - - -. 'S -. -q z 1 . --: - ;'Y-, -' - -''..r.:-.-.-- _..4_..'4.._.3. - .5 5 ..5_ 'S r' _.5. q_ - .5 . 5. , I - cs__S.. .\ '.. -. .,c_. -. -.-_ -. -. - -'.-- i '-'-' S.._;1( -' .l._\s j - ' "- - S't -' j .5 5' 5-. .5. :-'cs-'.. '. .4 -S '. 5--I sV. q-'-c. I.\...'.. .L.I.c_--._5..1. - .5 -. -\ - )-S 'a ' _5 5._. - - -S '5.' -.--: .';- 'eI;, .-. ._..-.Sz- . .5.._ I_s._ 'S -'t:,. &._''.%str s.'. - .- . .,r. -: ...>-. '-- : - . .' ,-- .' '-.-'-..- :...:- L - :-cs-.-.-.5;n5.. .-.. .' S . ,.- : .'. _%'__ i._' _5.____._I___s5_-. \.'.'. -'''P S 5... -.-_._S..'pJ.. ... - .- -. -' .\cs.1"5.-:. - --.5----- ?. - -P ._ S' P. -.-, --:. '-. \ :--'' .' .- 5.. '-.-__.., ....... -. - .'.-' -. .- .. :- -.''-::, -.-. ::.-.'-..--5.__.5 _-. % .sI. 1T3 FUN TO SEW withasewing machine COOPERATIVE EXTENSION SERVICE PHASE 1 OREGON STATE UNIVERSITY, CORVALLIS 4-H CLUB SERIES 1-85 It's Fun to Sew- -With the Sewing Machine Prepared by HILDEGARDE STRUEFERT Extension Clothing Specialist Oregon State University, Corvallis PHASE 1 Where to find page Yourguide for the project ---------------------------------------------------------------------------------- 1 Planyour project-------------------------------------------------------------------------------------------------- 1 Become acquainted with your sewing tools ----------------------------------------------------2 Measuringtools ----------------------------------------------------------------------------------------------2 Cuttingtools---------------------------------------------------------------------------------------------------- -

Yarn Couching

Threads n Scissors Machine Yarn Couching IMPORTANT: PLEASE READ Materials These designs are made to be used with a Freemotion Yarn Stabilizer: Couching Foot. Please check with your dealer regarding this Either two layers of foot for your machine. water soluble OR I own a Bernina Artista and use the #43 foot 1 layer of cutaway The designs are smaller than a regular design. Be sure to use a large hoop for these designs. The Yarn Couching Foot is Freemotion Yarn Couching Foot LARGER than a normal embroidery foot and needs the extra space not to hit into the hoop. 2mm diameter yarn or Before starting any Yarn Couching Design, snap the Yarn cording to be used with foot Couching Foot firmly into place, put your hoop into the ma- chine and LIFT the pressure foot. Check the design or Trace Fabric of choice, I used the design to be sure that the foot won’t hit the embroidery suede type fabric hoop when stitching. When you are sure all is right, you may start stitching your designs. Embroidery thread Follow these Instructions to continue with the stitching of your design. No 80 embroidery needle or needle rec- ommended to be used Hoop either 2 layers of water soluble stabilizer OR 1 layer of cutaway stabilizer with couching foot with your fabric. Using a normal embroidery foot, stitch out the design leaving the last color. Some of the Designs may have the same color used two or three times at the end. Don’t stitch these yet. These are color stops used for the yarn or cording. -

Zigzag Stitch Sewing Machine Comparison Chart (PDF)

Zigzag Stitch Sewing Machine Comparison Chart For a comparison of our straight stitch machines, refer to the Straight Stitch Sewing Machine Comparison Chart (300086XHT) for specifications on Sailrite® Ultrafeed® LS-1, Leatherwork® and Fabricator® Sewing Machines. SEWING MACHINE SAILRITE® ULTRAFEED® SAILRITE® PROFESSIONAL Fully portable machine and easy to carry. Intended for canvas, Full-size industrial machine in a large table. upholstery, awnings and vinyl; can sew leather with appropriate presser feet. Sews 4-point and 2-point zigzag stitch. Intended for sail repair and sailmaking. LSZ-1 Basic LSZ-1 Plus LSZ-1 Premium LSZ-1 (EU) Basic LSZ-1 (EU) Plus LSZ-1 (EU) Premium STANDARD ARM MODEL #300601 #300602 #311603 #220601 #220600 #220603 #500500 TECHNICAL SPECS SHUTTLE Oscillating (Cam/Rocker Arm Driven) Full Rotary, Gear Driven 1/4 hp, 90VDC motor, 550-Watt, 3/4 hp, 110V MOTOR POWER 1/10 hp, 110 volt, AC motor, 1.5 amp 3 amps 1/10 hp, 220-240 volt, AC motor 50/60 Hz, 0.7 amp Workhorse Servo Motor Input 110V AC 5,800 rpm motor MOTOR SPEED 6,600 rpm motor at 1.5 amps 8,200 rpm motor at 0.7 amps 4,500 rpm motor at 4.5 amps at 3 amps POSI-PIN® CLUTCHING SYSTEM WorkerB® Balance Wheel (Compatible with Power Plus® (Compatible with Monster® II Balance Monster® II Balance Power Plus® (Compatible with Monster® II Balance Wheel for hand cranking and FLYWHEEL Wheel for hand cranking and sewing without electricity. Wheel for hand cranking Stitch PRO sewing without electricity. Included in the PREMIUM packages.) Included in the PREMIUM packages.) and sewing without electricity. -

MAINTENANCE, ADJUSTMENT and REPAIR of INDUSTRIAL SEWING MACHINES by WAYNE SNYDER, MASTER RIGGER US ACADEMY of PARACHUTE RIGGING

MAINTENANCE, ADJUSTMENT AND REPAIR OF INDUSTRIAL SEWING MACHINES by WAYNE SNYDER, MASTER RIGGER US ACADEMY of PARACHUTE RIGGING Presented at the PIA INTERNATIONAL PARACHUTE SYMPOSIUM RENO, NEVADA February 2007 MAINTENANCE, ADJUSTMENT AND REPAIR OF INDUSTRIAL SEWING MACHINES PREMISE: You know how to sew and you are working with an “E” thread lock stitch sewing machine and it was sewing and now it’s gone bad. You probably just changed something – 98% of the time just go back and inspect and correct what you just did and you will be back in business. COMMON CASE SCENARIOS: A. Bobbin change B. Top thread change C. Jam D. Broken needle and/or changed needle Before we get into these specific areas, let’s go back and remember the basic way the machines work. All lock stitch machines make the same stitch. 301, 304, or 308: these are just lock stitch machines. “THE FLOW ACTION” • The needle does down • The needle goes below path of hook (Figure 1) • Needle bottoms out (B.D.C.) • Needle comes up (3/32 inch - common measurement), loop forms on hook side of needle (non-long groove side of the needle) (Figure 2) • Hook picks up top thread loop and carries it around bobbin case. (Figure 3) • Hook drops top thread off (Figure 4) • Thread take-up arm takes out slack and sets stitch in goods. (Figure 5) • Think of the bobbin thread as a long straight rod with the top thread spiraled around it. Sew a piece of paper with two different color threads – rip paper to remove it and there is your example.