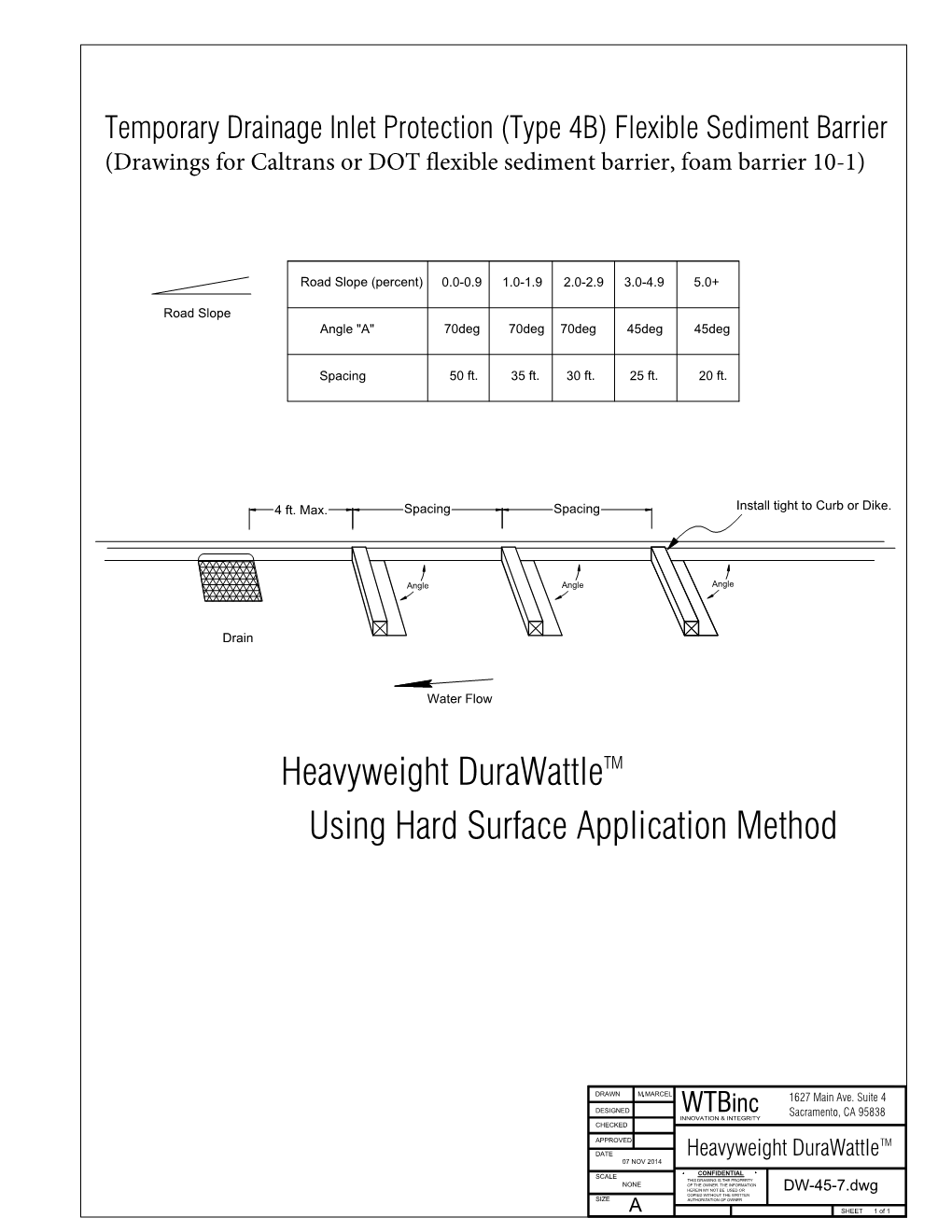

Temporary Drainage Inlet Protection (Type 4B) – Flexible Sediment Barrier

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Silt Fences Allow Sediment to Settle from Runoff Before Water Leaves the Construction Site

Silt Fence SC-1 BMP Objectives ○ Soil Stabilization ● Sediment Control ○ Tracking Control ○ Wind Erosion Control ○ Non-Storm Water Management ○ Materials and Waste Management Definition and Purpose A silt fence is a temporary linear sediment barrier of permeable fabric designed to intercept and slow the flow of sediment-laden sheet flow runoff. Silt fences allow sediment to settle from runoff before water leaves the construction site. Appropriate Applications Silt fences are placed: n Below the toe of exposed and erodible slopes. n Down-slope of exposed soil areas. n Around temporary stockpiles. n Along streams and channels. Limitations n Not effective unless trenched and keyed in. n Not intended for use as mid-slope protection on slopes greater than 4:1. n Must be maintained to remain effective. n Not intended for use in streams, channels, or anywhere flow is concentrated. n Difficult to install and maintain in windy areas. n Must be removed and disposed of. 70 Design Guidelines and Considerations n Do not use below slopes subject to creep, slumping, or landslides. n Do not use in streams, channels, or anywhere flow is concentrated. n Do not use silt fences to divert flow. n The maximum length of slope upgradient of the silt fence should be 60 m (200 ft) or less to minimize flow volumes and velocities and increase the effectiveness of the silt fence. n Slope of areas draining to fence should be less than 1:1 but can be used below steeper slopes at the Engineers discretion. n Limit to locations suitable for temporary ponding or deposition of sediment. -

National Management Measures to Control Nonpoint Source Pollution from Hydromodification

EPA 841-B-07-002 July 2007 National Management Measures to Control Nonpoint Source Pollution from Hydromodification Cover, Disclaimer, Table of Contents Full document available at http://www.epa.gov/owow/nps/hydromod/index.htm Assessment and Watershed Protection Division Office of Water U.S. Environmental Protection Agency United States Environmental Protection Agency Office of Water Washington, DC 20460 (4503T) EPA 841-B-07-002 July 2007 National Management Measures to Control Nonpoint Source Pollution from Hydromodification Nonpoint Source Control Branch Office of Wetlands, Oceans and Watersheds U.S. Environmental Protection Agency Office of Water July 2007 Disclaimer This document provides technical guidance to states, territories, authorized tribes, and the public for managing hydromodification and reducing associated nonpoint source pollution of surface and ground water. At times, this document refers to statutory and regulatory provisions, which contain legally binding requirements. This document does not substitute for those provisions or regulations, nor is it a regulation itself. Thus, it does not impose legally-binding requirements on EPA, states, territories, authorized tribes, or the public and may not apply to a particular situation based upon the circumstances. EPA, state, territory, and authorized tribe decision makers retain the discretion to adopt approaches to manage hydromodification and reduce associated NPS pollution of surface and ground water on a case-by-case basis that differ from this guidance where appropriate. -

The Evolution of Geosynthetics in Erosion and Sediment Control

Presented at GRI-25, Geosynthetics Research Institute, Long Beach, CA, 2013 THE EVOLUTION OF GEOSYNTHETICS IN EROSION AND SEDIMENT CONTROL C. Joel Sprague TRI/Environmental, Inc., Greenville, SC ABSTRACT Much of the development of geosynthetics technology in environmental applications has been in response to government regulations. This is certainly true for geosynthetics used in erosion and sediment control. Geosynthetics continue to replace traditional materials such as soil and stone in performing important engineering functions in erosion and sediment control applications while simultaneously introducing greater versatility and cost-effectiveness. Geosynthetics are widely used as a “carrier” for degradable materials to the enhancement of vegetative establishment; as nondegradable materials to extend the erosion control limits of vegetation or soil; as primary slope or channel linings; as components in silt fences and turbidity curtains; and as a component in an ever growing array of sediment retention devices. Along with the introduction of geosynthetics into this wide range of applications has come the need for industry-wide initiatives to promote their correct use and new test methods to characterize them. All of which, are a “work in progress”. THE NEED FOR EROSION AND SEDIMENT CONTROLS Much of the development of geosynthetics technology related to erosion and sediment control applications has been in response to government regulations. A progression of regulatory actions has brought a national focus on erosion and sediment control, including: Amendments to the Federal Water Pollution Control Act (1985) - eliminating discharge of any pollutant to navigable waters. The Clean Water Act (1987) - requiring National Pollution Discharge Elimination System (NPDES) Permits for large construction sites. -

Stream and Lakeshore Restoration Best Management Practice Manual Conservation Practices to Protect Surface and Ground Water

Stream and Lakeshore Restoration Best Management Practice Manual Conservation Practices to Protect Surface and Ground Water Wyoming Department of Environmental Quality Water Quality Division Nonpoint Source Program 2014 Update Document #14-0532 The purpose of this document is to provide information about best management practices that the Wyoming Nonpoint Source Program supports as eligible for Clean Water Act Section 319 funding. This document is prepared as part of the Wyoming Nonpoint Source Management Plan as required by Section 319(b) of the Clean Water Act. WDEQ Stream and Lakeshore Restoration Best Management Practice Manual 2014 THIS PAGE INTENTIONALLY LEFT BLANK WDEQ Stream and Lakeshore Restoration Best Management Practice Manual 2014 Contents Introduction ..................................................................................................................................................... 1 1.1 Purpose of this Document ................................................................................................................ 1 1.2 How to Use this Document .............................................................................................................. 1 1.3 Nonpoint Source Pollution and Hydrologic Modifications ............................................................. 2 1.4 Best Management Practices ............................................................................................................. 3 1.5 Regulatory Considerations ............................................................................................................. -

2003 Fiber Rolls

Fiber Rolls SE-5 Objectives EC Erosion Control : SE Sediment Control ; TR Tracking Control WE Wind Erosion Control Non-Stormwater NS Management Control Waste Management and WM Materials Pollution Control Legend: ; Primary Objective : Secondary Objective Targeted Constituents Description and Purpose Sediment ; A fiber roll consists of straw, flax, or other similar materials Nutrients bound into a tight tubular roll. When fiber rolls are placed at Trash the toe and on the face of slopes, they intercept runoff, reduce its flow velocity, release the runoff as sheet flow, and provide Metals removal of sediment from the runoff. By interrupting the Bacteria length of a slope, fiber rolls can also reduce erosion. Oil and Grease Organics Suitable Applications Fiber rolls may be suitable: Potential Alternatives Along the toe, top, face, and at grade breaks of exposed and SE-1 Silt Fence erodible slopes to shorten slope length and spread runoff as SE-6 Gravel Bag Berm sheet flow SE-8 Sandbag Barrier At the end of a downward slope where it transitions to a SE-9 Straw Bale Barrier steeper slope Along the perimeter of a project As check dams in unlined ditches Down-slope of exposed soil areas Around temporary stockpiles Limitations Fiber rolls are not effective unless trenched January 2003 California Stormwater BMP Handbook 1 of 4 Construction www.cabmphandbooks.com SE-5 Fiber Rolls Fiber rolls at the toe of slopes greater than 5:1 (H:V) should be a minimum of 20 in. diameter or installations achieving the same protection (i.e. stacked smaller diameter fiber rolls, etc.). -

Fiber Rolls Se-5

FIBER ROLLS SE-5 Objectives Erosion Control - EC Sediment Control - SE Tracking Control - TC Wind Erosion Control - WE Non-Storm Water Management - NS Materials and Waste Management - WM Legend DESCRIPTION AND PURPOSE Removal Effectiveness A fiber roll consists of straw, flax, or other similar materials that are rolled ◍ Unknown ○ Low or bound into a tight tubular roll and placed on the toe and face of slopes to ◒ Medium ● High intercept runoff, reduce its flow velocity, release the runoff as sheet flow, Targeted Constituents and provide removal of sediment from the runoff ○ Sediment ○ Nutrients APPROPRIATE APPLICATIONS ○ Trash • Along the toe, top, face, and at grade breaks of exposed and erodible ○ Metals slopes to shorten slope length and spread runoff as sheet flow. ○ Bacteria Oil and Grease • Along the perimeter of a project. ○ ○ Organics • As check dams in unlined ditches. Potential Alternatives • Below the toe of exposed and erodible slopes. Click here to enter text • Down-slope of exposed soil areas. • Around temporary stockpiles This BMP may be implemented on a project-by-project basis with other BMPs when determined necessary and feasible by the Engineer. LIMITATIONS • Not effective unless trenched. • Fiber rolls at the toe of slopes greater than 1:5 should be a minimum of 24 in. diameter or installations achieving the same protection (i.e. stacked smaller diameter fiber rolls, etc.). • Fiber rolls should not to be used for drainage inlet protection. • Difficult to move once saturated. • If not properly trenched in, fiber rolls could be transported by high flows. • Fiber rolls have limited sediment capture zone. CONSTRUCTION HANDBOOK OCTOBER 2002 1 OF 3 SE-5 FIBER ROLLS IMPLEMENTATION Fiber Roll Materials • Fiber rolls should be either - Prefabricated rolls or - Rolled tubes of erosion control blanket. -

Developing Your Stormwater Pollution Prevention Plan

Developing Your Stormwater Pollution Prevention Plan A Guide for Construction Sites Who? Construction site operators (generally, the person who has operational control over construction plans and/or the person who has day-to-day supervision and control of activities occurring at the construction site) Where? Construction sites required to comply with stormwater discharge requirements What? A guide to help you develop a good Stormwater Pollution Prevention Plan (SWPPP) Why? Stormwater runoff from construction sites can cause significant harm to our rivers, lakes, and coastal waters A SWPPP is required (by your construction general permit) and will help you prevent stormwater pollution A SWPPP is more than just a sediment and erosion control plan. It describes all the construction site operator’s activities to prevent stormwater contamination, control sedimentation and erosion, and comply with the requirements of the Clean Water Act Purpose of this Guidance Document This document provides guidance to construction site operators that need to prepare a SWPPP in order to receive NPDES permit coverage for their stormwater discharges. The Clean Water Act provisions, EPA regulations and EPA’s Construction General Permit described in this document contain legally binding requirements. This document does not substitute for those provisions, regulations or permit, nor is it a regulation or permit itself. It also does not substitute for requirements under State law or construction general permits issued by States. It does not impose legally-binding requirements on EPA, States, or the regulated community, and may not apply to a particular situation based upon the circumstances. EPA and State decisionmakers retain the discretion to adopt approaches on a case-by-case basis that differ from this guidance where appropriate. -

Sheet 4 SWPP Plan

CITY OF MOORPARK GRADING PLAN MERIDIAN HILLS SLOPE FAILURE REPAIR DESIGNED BY: GENERAL NOTES & PROJECT INFORMATION SHEET Planning Civil Engineering Flood Control/Hydrology DRAWN BY: Geotechnical Engineering Geology Water Resources Environmental CITY OF MOORPARK OF CHECKED BY: PUBLIC WORKS DEPARTMENT DRAWING NO. APPROVED BY: ENGINEERING DIVISION CITY OF MOORPARK GRADING PLAN MERIDIAN HILLS SLOPE FAILURE REPAIR DESIGNED BY: GENERAL NOTES & PROJECT INFORMATION SHEET Planning Civil Engineering Flood Control/Hydrology DRAWN BY: Geotechnical Engineering Geology Water Resources Environmental CITY OF MOORPARK OF CHECKED BY: PUBLIC WORKS DEPARTMENT DRAWING NO. APPROVED BY: ENGINEERING DIVISION 6 DESIGNED BY: REVIEWED BY: DISCRETIONARY 5 PERMIT NO. SHEET ____________ 4 DRAWN BY: 3 CITY OF MOORPARK OF ____________ CHECKED BY: ENGINEERING 2 PROJECT NO. DRAWING NO. 1 APPROVED BY: PUBLIC WORKS DEPARTMENT DESCRIPTION OF REVISION R.C.E. APP'D. DATE LOT 111 LOT 113 LOT 112 6 DESIGNED BY: REVIEWED BY: DISCRETIONARY 5 PERMIT NO. Planning Civil Engineering Flood Control/Hydrology DRAWN BY: SHEET ____________ 4 Geotechnical Engineering Geology Water Resources Environmental 3 CITY OF MOORPARK OF ____________ CHECKED BY: ENGINEERING 2 PROJECT NO. DRAWING NO. 1 APPROVED BY: PUBLIC WORKS DEPARTMENT DESCRIPTION OF REVISION R.C.E. APP'D. DATE FINISHED GROUND EXISTING GROUND SURFACE *4' MAX. SLOPE PER PLAN *4' Min. AS NEEDED TO ENSURE 3' THICK FILL MIN. INSTALL 4" TEE SUBDRAIN OUTLET COMPACTED FILL 90% MIN 2% SUBDRAIN (TYPICAL) 4" NON PERFORATED PIPE 3' min. TILTED BACK 5% 10' KEYWAY NOTE: UNDERGROUND SERVICE ALERT THE EXISTENCE AND LOCATION OF ANY UNDERGROUND UTILITY ORE EF YO OFESSIO B U PR NA PIPES OR STRUCTURE SHOWN ON THESE PLANS ARE OBTAINED D L IG D W. -

Natural-Fiber Products Can Help Reduce the Short and Long-Run Costs of Controlling Sediment

Natural-Fiber Products can Help Reduce the Short and Long-Run Costs of Controlling Sediment By Greg Northcutt Biodegradable sediment control products can play a key role in protecting water quality during and after soil-disturbing activities at construction sites. Done properly, erosion control practices, such as establishing perennial vegetation or installing grade control structures, turf reinforcement mats or gabions, can reduce the need for sediment control practices by stabilizing the soil permanently. However, when construction activities prevent the use of permanent erosion control practices, sediment control measures can be installed around the perimeter of the site and around storm drain inlets to trap sediment in stormwater runoff until erosion control measures can be installed. Dealing with Challenges Silt fence, made of non-degradable synthetic fabric, and straw bales have been among the more popular, traditional sediment control practices. These materials can pose some challenges to project owners and contractors. Consider silt fence. “In a highly dynamic construction environment, maintenance of silt fence can be very costly,” says erosion and sediment control consultant John McCullah, CPESC, Salix Applied Earthcare, Redding, CA. “In some cases, it may be impossible to prevent construction activities from destroying them and trucks from running over them and damaging the products. In addition, there are the added costs of removing, transporting and disposing of the silt fence fabric when the project is completed.” As a result of such problems, some contractors tend to leave silt fence in place after it has served its purpose. That’s the assessment of erosion and sediment control consultant, Jerald Fifield, CPESC, CISEC, president of HydroDynamics, Inc., Parker, Colo. -

Fiber Rolls SE-5

Fiber Rolls SE-5 Categories EC Erosion Control SE Sediment Control TC Tracking Control WE Wind Erosion Control Non-Stormwater NS Management Control Waste Management and WM Materials Pollution Control Legend: Primary Category Secondary Category Targeted Constituents Description and Purpose A fiber roll (also known as wattles or logs) consists of straw, Sediment coir, curled wood fiber, or other biodegradable materials bound Nutrients into a tight tubular roll wrapped by plastic netting, which can Trash be photodegradable, or natural fiber, such as jute, cotton, or Metals sisal. Additionally, gravel core fiber rolls are available, which contain an imbedded ballast material such as gravel or sand for Bacteria additional weight when staking the rolls are not feasible (such Oil and Grease as use as inlet protection). When fiber rolls are placed at the Organics toe and on the face of slopes along the contours, they intercept runoff, reduce its flow velocity, release the runoff as sheet flow, and provide removal of sediment from the runoff (through Potential Alternatives sedimentation). By interrupting the length of a slope, fiber rolls can also reduce sheet and rill erosion until vegetation is SE-1 Silt Fence established. SE-6 Gravel Bag Berm SE-8 Sandbag Barrier Suitable Applications Fiber rolls may be suitable: SE-12 Manufactured Linear Sediment Controls ◼ Along the toe, top, face, and at grade breaks of exposed and SE-14 Biofilter Bags erodible slopes to shorten slope length and spread runoff as sheet flow. ◼ At the end of a downward slope where it transitions to a steeper slope. ◼ Along the perimeter of a project. -

9 Fiber Rolls Wattles

FIBER ROLLS/WATTLES DEFINITION & PURPOSE Fiber rolls or straw wattles are a rolled erosion control product filled with straw, flax, rice, coconut fiber material, or composted material. Each roll is wrapped with UV-degradable polypropylene netting or with biodegradable materials like burlap, jute, or coir. These devices are slope dissipaters that reduce velocity of runoff as sheet flow and catch sediment on steep slopes. CONDITIONS FOR EFFECTIVE USE Fiber rolls can be used in areas of low shear stress including: along the toe, top, face, and at grade breaks on exposed and erodible slopes to shorten slope length and spread runoff as sheet flow, at the end of a downward slope where it transitions to a steeper slope, along the perimeter of a project (less than 1/3 acre) or down-slope of a stockpile, and down-slope of other exposed soil areas. See MDNR Guide Section 6-195 for additional guidance. INSTALLATION/CONSTRUCTION PROCEDURES Install fiber roll immediately after rough grading and prior to seeding or mulching. On slopes, install fiber rolls along the contour with a slight downward angle at the end of each row to prevent ponding at the midsection. Turn the ends of each fiber roll upslope (like a j-hook) to prevent runoff from flowing around the roll. Determine using manufacturer’s specification the vertical spacing for slope installations. Straw wattles can float or move if not properly staked and trenched in. OPERATION & MAINTENANCE PROCEDURES Inspect every week and within 48 hours after every rain event that causes stormwater runoff to occur on site. Remove sediment accumulation when it reaches ½ the height of the roll/wattle. -

Erosion and Sediment Control Guidelines

EEERRROOOSSSIIIOOONNN AAANNNDDD SSSEEEDDDIIIMMMEEENNNTTT CCCOOONNNTTTRRROOOLLL GGGUUUIIIDDEEELLLIIINNNEEESSS Department of Environmental Services Revised September 2012 EROSION AND SEDIMENT CONTROL GUIDELINES City of Springfield, Missouri Department of Environmental Services 840 Boonville Ave. P.O. Box 8368 Springfield, Mo 65801-8368 (417) 864-1944 Revised September 2012 PREFACE AND DISCLAIMER PREFACE The purpose of the Manual is to provide a comprehensive and detailed approach towards preventing erosion and controlling sediment on construction sites. It has been updated to include the latest information regarding materials and installation practices that have proven effective over the past years. There are numerous other resources available and readers are encouraged to refer to the reference document listed in the Appendices. Another unique feature of this manual is its educational value. Under the National Pollution Discharge Elimination System (NPDES) rules, public involvement and educational outreach will be a major part of water quality standards. DISCLAIMER The Erosion Prevention and Sediment Control Guidelines Manual was developed for the sole purpose of providing the most updated Erosion Prevention, Run-off Management, Sediment and Tracking Controls, and Pollution Prevention Best Management Practices (BMP's). The contents of this manual should not be interpreted as necessarily representing the policies or recommendations of other referenced agencies or organizations. The mention of trade names, products or companies does not