01/05/2018 & 02/05/2018 Shri R

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Issues Pertaining to Ministry of Environment & Forest S

ISSUES PERTAINING TO MINISTRY OF ENVIRONMENT & FOREST S.No. Name of the Issues in Brief Action to be taken Company and Location 1 SAIL Expert Appraisal Committee (EAC), Environmental Clearance to be Gua Ore Mines, MOEF considered the Environment granted at the earliest to resume Jharkhand Clearance (EC) proposal on 24.2.11 the operations at mine. and recommended for grant of EC for Duargaiburu lease of Gua ore mines. Grant of Environment Clearance is awaited from MoEF. The Mine is closed since 15.6.11. Chiria Iron Ore Mine Expert Appraisal Committee (EAC) of Environmental Clearance to be (Sukri-Latur lease), MoEF considered the environment granted at the earliest to resume Jharkhand clearance proposals of Sukri-latur the operations at mine. lease of Manoharpur (Chiria) Iron Ore Mine 21.12.2009 and recommended for grant of environment clearance. Grant of environment clearance is awaited. The mine is closed since 21.3.09 2 Posco India Steel Plant Environment Clearance This EC should be revalidated ISP Project at Revalidation immediately to avoid Paradip, - Current status: Expert Appraisal unnecessary noises raised by Jagatsinghpur, Committee (EAC) recommended NGO and anti-project entities etc Odisha revalidation of 4-mtpa steel plant during the implementation of Environment Clearance in as-it-is land acquisition by GoO. form in its meeting held on 14th June 2012. Revalidation recommendation has, however, been awaiting MoEF approval till date. 3 Jindal Steel & Power Ltd Angul Project, Issues of Iron Ore Slurry Pipeline Being a linear project it should Odisha Project be exempted from the MOEF clearance: Recommendations of the Report of the Committee constituted under the Chairmanship of Shri J.M. -

Notice Final Voter List Election2

Page 1 V O T E R L I S T - E L E C T I O N 2017 Rgn.N Father's/ Husband's Qualifin. S.No. Name Address District o. Name for Reg. 1 2 3 4 5 6 7 1 1 Kamlesh Chandra Shil Shri Kartik Chandra Shil P.V. No.-7, Po. Kapsi Kanker D.Pharma 2 2 Kunj Ram Shri Chamru Q.No. 29/7, Banki Mongra Korba D.Pharma 3 3 Tufail Ahmed Mohd. Israil Artision Block, Chirmiri (w) Korea D.Pharma 4 5 Pradeep Kumar Jain Shri Rambilash Jain Vill.- Keshgwan Korea D.Pharma Steel Nagar, Camp-I, Road No.- 5 6 Manish Kumar Agrawal Shri Khanjanchi Lal Durg D.Pharma 8, Post - Bhilai c/o. Prashant Medicose, Post - 6 7 Pratap Narayan Singh Shri Jag Narayan Singh Surguja D.Pharma Jarahi Morh, M/409 Near Bus Stand, Post - 7 8 Sawan Kumar Shri Surendra Kumar Bastar D.Pharma Kondagaon Q.No. - M/108, Rajgamar 8 9 Arun Kumar Mishra Shri Shiv Narayan Korba D.Pharma Colony, Post - Ompur Katainar, Q.No. CH/142, Post - 9 10 Ganga Prasad Shri Sukhi Ram Korba D.Pharma Banki Mongra Shri Birendra Kumar H.No. 31/551, Azad Chowk, 10 11 Vikas Shukla Raipur D.Pharma Shukla Brahaman Para, Raipur 11 12 Vinod Kumar Agrawal Shri Ratan Lal Hospital Colony. Post - Surajpur Surguja D.Pharma Sapna Garments, Sanjay 12 13 Smt. Shailja Gupta Shri Saran Gupta Korea D.Pharma Chowk, Post - Baikunthpur C.H.C. Kartala, Post - Bhaishma 13 15 Sushma Singh Shri Dhyan Singh Korba D.Pharma 495674 Qtr. -

Indian Medical Association

Page 1 of 69 Printed on 09/0 ** Indian Medical Association (Hqrs.) Membership List - Working All Members State Name : CHHATTISGARH Receipts for Members issued between / / to / / whose names have been entered in computer from / / till / / Branch Name : AMBIKAPUR ; SM:0, CM:0, L:31, CL:14 Dr. AGRAWAL, DINDAYAL Dr. AGRAWAL, LALIT KUMAR Dr. AGRAWAL, MAHABIR PD. CGH/6/2/1/71295/1999-00/L CGH/998/2/35/119668/2005-06/CL CGH/7/2/2/56882/1996-97/L Dr. AGRAWAL, KIRAN BHATTAPARA AMBIKAPUR-497001, DIST. SARGUJA AGRASEN -WARD, AGRASEN CHOWK, `SHREYAS` 22/251, RAMANUJ WARD, JAIL ROAD, CHHATISGARH. AMBIKAPUR - 497 001, CHHATTISGARH. AMBIKAPUR-497 001, MADHYA PRADESH. Dr. BAISH, SHARDA PRASAD Dr. BANERJI, PRASHASTHI KUMAR Dr. BANSAL, ASHOK KUMAR CGH/1004/2/41/119676/2005-06/L CGH/8/2/3/24057/1991-92/L CGH/9/2/4/25900/1992-93/CL Dr. BANSAL, ASHA NEAR JODAPIPAL KEDARPUR, AMBIKAPUR - 497 001, PRIVATE PRACTITIONER, BABUPARA, JAIL ROAD, COLLECTOR BURGLOW ROAD, DIST. SURGUJA, CHHATTISGARH. AMBIKAPUR - 497001, DIST. SURGUJA, MADHYA PRADESH. AMBIKAPUR - 497001, MADHYA PRADESH. Dr. BHAGAT, AZAD Dr. BHALLA, UJAGAR SINGH BAWA Dr. EKKA, SUSHIL CGH/10/2/5/83782/2001-02/L CGH/11/2/6/24058/1991-92/CL CGH/13/2/8/73836/1999-00/CL Dr. BHALLA, C.K. Dr. SNEH LATA EKKA, EASTER FUNDUR DIHARI PATEL PARA (RAJWADE BHAVAN) 70, DARRI PARA, DIST.HOSPITAL, SURGUJA, AMBIKAPUR - 497 001, MADHYA PRADESH. AMBIKAPUR - 497001, MADHYA PRADESH. AMBIKAPUR-497001, MADHYA PRADESH. Dr. FIRDOSI, NOORUL HASAN Dr. FIRDOUSI, FAIZUL HASAN Dr. GOYAL, MALAY RANJAN CGH/14/2/9/77733/2000-01/L CGH/993/2/34/118924/2005-06/L CGH/15/2/10/18127/1991-92/CL Dr. -

Durg District, Chhattisgarh

For official use GOVERNMENT OF INDIA MINISTY OF WATER RESOURCES Nawgarh CENTRAL GROUND WATER BOARD Bemetara Saja Berla Dhamdha GROUND WATER BROCHURE OF DURG DISTRICT, CHHATTISGARH 2012 Durg -2013 Patan Gunderdehi Dondi Lohara Balod Gurur Dondi Regional Director North Central Chhattisgarh Region, Reena Apartment, IInd Floor, NH-43, Pachpedi Naka, Raipur-492001 (C.G.) Ph. No. 0771-2413903, 2413689 E-mail: rdnccr- [email protected] DISTRICT AT A GLANCE DURG DISTRICT) By J.R.Verma, Scientist “B” 1. GENERAL INFORMATION i) Geographical area (Sq. km) 8701.80 ii) Administrative Divisions (As on 2009) a) Number of Tehsil/ Block 11/12 b) Number of Panchayat/ Villages 998/1176 iii) Population as on 2011 Census 1316140 iv) Annual Normal Rainfall (IMD,2008) 1142 mm v) Average Annual Rainfall (1994-12) 1055.56mm 2. GEOMORPHOLOGY i) Major Physiographic Units Two; Chhattisgarh Plain ii) Major Drainages Mahanadi, Seonath. 3. LAND USE (Sq. km) As on 2009 i) Forest Area 709.11 ii) Net Area Sown 5469.61 iii) Double cropped Area 2392.76 4. MAJOR SOIL TYPES Red & yellow soil, Black soil 5. AREA UNDER PRINCIPAL CROPS, in Rice: 2325.95, Pulses:555.28 Sq. km (As on 2011) Wheat: 186.90, 6. IRRIGATION BY DIFFERENT SOURCES (2011) (Areas in Sq. km. and Numbers of Structures) i) Dugwells 1458/16.69 ii) Tubewells/Borewells 33938/917.94 iii) Canals 296/1272.24(1788 km) iv) Ponds 306/27.29 v) Other sources 126.15 vi) Net Irrigated Area 2360.31 vii) Gross Irrigated Area 3174.33 7. NUMBERS OF GROUND WATER MONITORING WELLS OF CGWB (As on 31.3.2012) i) No of Dugwells 39 ii) No of Piezometers 25 8. -

1 Dalli Mechanised Mine 30 Mpr 13006 Kondekasa Balod

MCDR INSPECTION REPORT 1.0 GENERAL SN Particulars Details 1 Name of the Mine DALLI MECHANISED MINE 2 Total Lease Area (Ha) with breakup of Non- Total Lease Area - 719.60 Ha. (Part) forest and forest land Non Forest - 436.00 Ha. Forest - 283.60 Ha. 3 Mine code 30 MPR 13006 4 IBM Registration Number under rule 45 of 5662/2011/IBM MCDR, 1988 5 Name of the lessee, Address, phone, email Bhilai Steel Plant, Steel Authority of India Ltd. and fax number Shri Kalyan Maity (Director R-M&L) Ispat Bhawan, Lodhi Road, New Delhi Ph- 01124366219, Fax- 01124369355 Email- [email protected] 5a Date of Inspection 7-12-2016 6 Village KONDEKASA 7 Taluka/Mandal Taluka – DALLI-RAJHARA 8 District BALOD 9 Pincode 491228 10 State CHHATTISGARH 11 Post office DALLI RAJHARA 12 Nearest police station DALLI RAJHARA 13 Nearest Railway station DALLI RAJHARA 14 Date of Grant of Mining Lease 05.11.1962 15 Date of Execution 30.4.1963 16 Date of opening of Mine 05.11.1962 17 Date of first Renewal, if applicable and NA its period & expiry 18 Date of second Renewal, if applicable Second Renewal- 01.06.2003 and its period & expiry Period & Expiry – 20 years, 31.05.2023 19 Date of submission of renewal NA application if Mining Operations are continuing under deemed extension 1 20 Name of the Nominated Owner with SHRI KALYAN MAITY, Address, phone, email, fax number and date of appointment Dir (Raw Material & Logistics), Ispat Bhawan, Lodhi Road, New Delhi 21 Name of the Mine Agent with Address, Shri Samir Swarup, phone, email, fax number and date of DGM cum Agent(DMM & DMNL), appointment Off Address: Dalli Administrative Building, 22 Name of the Mines Manager with Shri C.Srikant, Mine Manager, Address, phone, email, fax number and 07882851804(Off), 9407982915 date of appointment in mines 23 Name of the Mining Engineer, Shri Satyendra Kumar, Qualification and total experience with AMIE(Mining), 15 yrs exp in various mines. -

Common Service Center List

CSC Profile Details Report as on 15-07-2015 SNo CSC ID District Name Block Name Village/CSC name Pincode Location VLE Name Address Line 1 Address Line 2 Address Line 3 E-mail Id Contact No 1 CG010100101 Durg Balod Karahibhadar 491227 Karahibhadar LALIT KUMAR SAHU vill post Karahibhadar block dist balod chhattisgarh [email protected] 8827309989 VILL & POST : NIPANI ,TAH : 2 CG010100102 Durg Balod Nipani 491227 Nipani MURLIDHAR C/O RAHUL COMUNICATION BALOD DISTRICT BALOD [email protected] 9424137413 3 CG010100103 Durg Balod Baghmara 491226 Baghmara KESHAL KUMAR SAHU Baghmara BLOCK-BALOD DURG C.G. [email protected] 9406116499 VILL & POST : JAGANNATHPUR ,TAH : 4 CG010100105 Durg Balod JAGANNATHPUR 491226 JAGANNATHPUR HEMANT KUMAR THAKUR JAGANNATHPUR C/O NIKHIL COMPUTER BALOD [email protected] 9479051538 5 CG010100106 Durg Balod Jhalmala 491226 Jhalmala SMT PRITI DESHMUKH VILL & POST : JHALMALA TAH : BALOD DIST:BALOD [email protected] 9406208255 6 CG010100107 Durg Balod LATABOD LATABOD DEKESHWAR PRASAD SAHU LATABOD [email protected] 9301172853 7 CG010100108 Durg Balod Piparchhedi 491226 PIPERCHEDI REKHA SAO Piparchhedi Block: Balod District:Balod [email protected] 9907125793 VILL & POST : JAGANNATHPUR JAGANNATHPUR.CSC@AISEC 8 CG010100109 Durg Balod SANKARAJ 491226 SANKARAJ HEMANT KUMAR THAKUR C/O NIKHIL COMPUTER ,TAH : BALOD DIST: BALOD TCSC.COM 9893483408 9 CG010100110 Durg Balod Bhediya Nawagaon 491226 Bhediya Nawagaon HULSI SAHU VILL & POST : BHEDIYA NAWAGAON BLOCK : BALOD DIST:BALOD [email protected] 9179037807 10 CG010100111 -

S.No. Student Name DOB (DD/MM/YYYY) Father Name Mother Name Gender Caste Email Id Mobile No

Minority Person With Parent Annual S.No. Student Name DOB (DD/MM/YYYY) Father Name Mother Name Gender Caste Email Id Mobile No. Aadhaar No. (in 12 digit) Village City Tehsil District State Pin Code Status Disability Income (In Rs.) 1 AAKANKSHA SAHU 2/5/1998 SURESH SAHU SUREKHA SAHU FEMALE OBC NO NO 40000 [email protected] 7999774737 615706580533 BEMETARA BEMETARA BEMETARA BEMETARA CG 491335 2 AARTI SHARMA 1/5/1994 SANAT KUMAR SHARMA SHAILDEVI SHARMA FEMALE GN NO NO 50000 [email protected] 9589787695 860605528118 SANKARA HASDA BERLA BEMETARA CG 490036 3 AISHWARYA YADAV 4/8/1995 SANAT YADAV MEENA YADAV FEMALE OBC NO NO 20000 [email protected] 7470445716 790633972729 SAMBALPUR SAMBALPUR BHANUPRATAPPUKANKER CG 494635 4 AKANKSHA 5/1/1997 RAM KUMAR PASWAN REKHA DEVI FEMALE SC NO NO 50000 [email protected] 9753952971 844639385390 SEMARIYA NANDINI DHAMDHA DURG CG 490036 5 AMIT KUMAR SINGH 5/12/1994 MAHENDRA SINGH HEVANTA DEVI MALE OBC NO NO 70000 [email protected] 9955893141 524643092944 BORSI DURG DURG DURG CG 490001 6 ANCHAL TIWARI 6/18/1996 VIRENDRA VIMLAGANI FEMALE GN NO NO 50000 [email protected] 9179655492 640414371026 DHAMDHA DHAMDHA DHAMDHA DURG CG 491331 7 ANJALI KASHTURE 10/19/1992 MILAP KASHTURE KULESHWAREE FEMALE ST NO NO 50000 [email protected] 7354862848 413770355581 ATRIYA JHAL BEMETARA BEMETARA CG 491335 8 ANKITA NAYAK 7/30/1996 SURENDRA NAYAK BASANTI NAYAK FEMALE GN NO NO 200000 [email protected] 9098218187 501929989124 NANDINI NANDINI DHAMDHA DURG CG 490036 9 ANNU DESHLAHARE 6/30/1996 -

DISTRICT SURVEY REPORT BALOD (Chhattisgarh) AS PER NOTIFICATION NO

2016 DISTRICT SURVEY REPORT BALOD (Chhattisgarh) AS PER NOTIFICATION NO. S.O. 141(E) NEW DELHI, 15TH JANUARY, 2016 OF MINISTRY OF ENVIRONMENT, FOREST AND CLIMATE CHANGE DIRECTORATE OF GEOLOGY AND MINING MINERAL RESOURCES DEPARTMENT Govt. of Chhattisgarh DGM [Type the company name] 04/06/2016 1 Note: The information provided in this report has been prepared from the existing and latest data collected from the concerned authorities. Although utmost care has been taken during editing and printing, still there may be some minor corrections for which the Directorate of Geology & Mining, Regional office Raipur Sonakhan Bhawan, cannot be held responsible. The queries in this regard are most welcome by the concerned office. 1 2 LOCATION MAP 2 3 BALOD A DURG DISTRICT RAJ NANDGAO R A PU R Plnkapr Nehda Arjunda iunderdehi Accholl • Phunra Kosagondl Dondiluhara Latabor .. Bagalkonha DHAMTARI , > > A L O D .Fagundah (Tuagodl Gurur Kusumkasa* * Borldak Sherpar * .Ghotla LEGEND Kochwahl National Highway Chlkhalak, Slnghola Major Road Dond ------ Railway Markato a Distnct Boundary -------- State Boundary River Map not to Scale KANKER ® Distnct HQ Copyright© 2013 www.mapsofindia.com Other Town [Updated on 12th August 2013) Major Town 3 4 4 5 1- INTRODUCTION The Balod district is one of the densely populated and situated in the central part of the Chhattisgarh State covers an area of 3527 sq km. It falls in Survey of India Degree Sheet Nos. 64C, 64D, 64G and 64H bounded by latitude 20°23' to 21°03' N and longitude 80°48' to 81°30 E. It is surrounded by Durg districts in the north, Rajnandgaon District in the west, Dhamtari districts in the east and Kanker district in the south. -

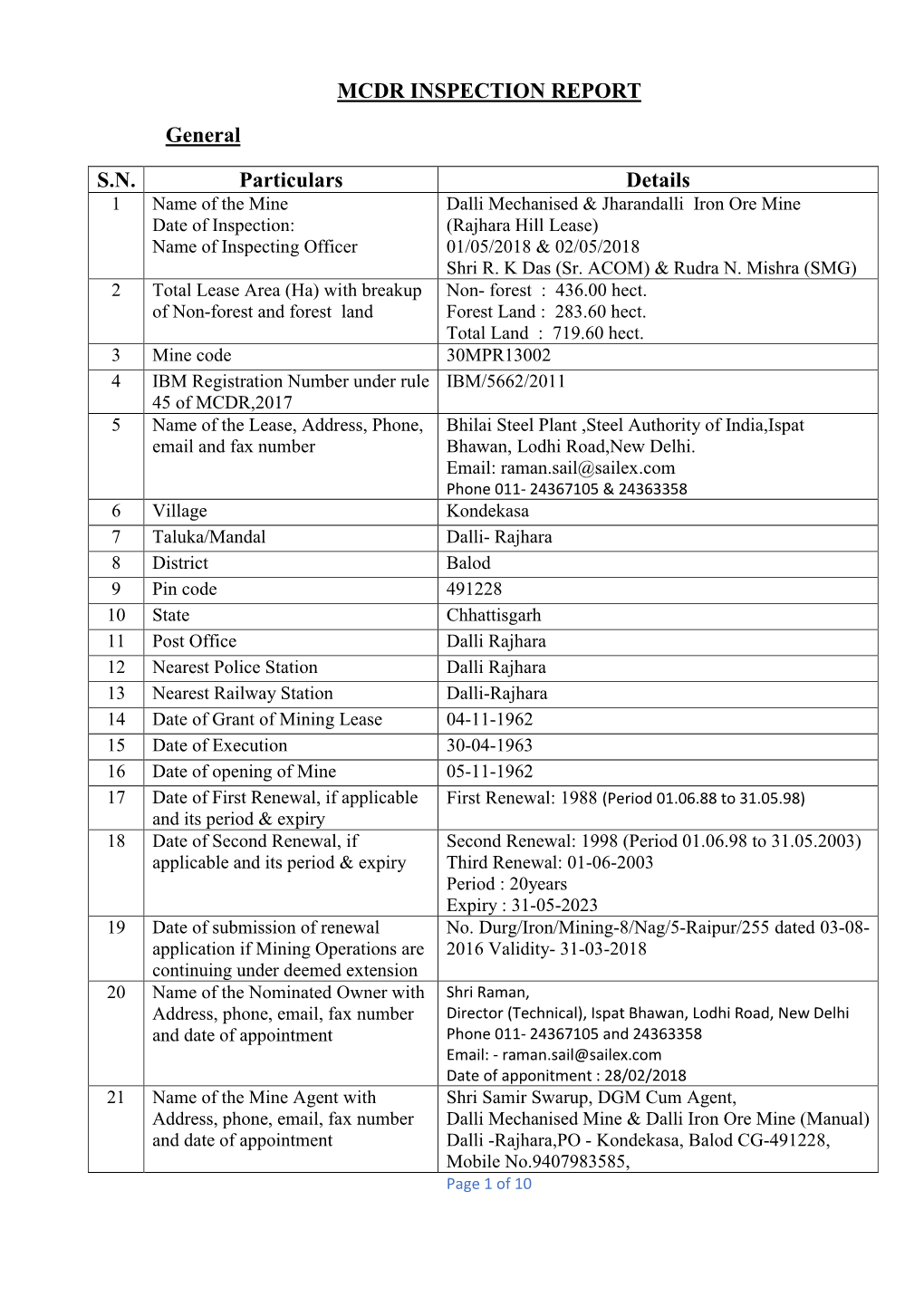

MCDR INSPECTION REPORT General S.N. Particulars Details

MCDR INSPECTION REPORT General S.N. Particulars Details 1 Name of the Mine Dalli Mechanised & Jharandalli Iron Ore Mine Date of Inspection: (Rajhara Hill Lease) Name of Inspecting Officer 07/09/2017 Rudra N. Mishra (SMG) 2 Total Lease Area (Ha) with breakup Non- forest : 436.00 hect. of Non-forest and forest land Forest Land : 283.60 hect. Total Land : 719.60 hect. 3 Mine code 30MPR13002 4 IBM Registration Number under rule IBM/5662/2011 45 of MCDR,1988 5 Name of the Lease, Address, Phone, Bhilai Steel Plant ,Steel Authority of India,Ispat email and fax number Bhawan, Lodhi Road,New Delhi. Email: [email protected] Phone No.- 24366219 6 Village Kondekasa 7 Taluka/Mandal Dalli- Rajhara 8 District Balod 9 Pin code 491228 10 State Chhattisgarh 11 Post Office Dalli Rajhara 12 Nearest Police Station Dalli Rajhara 13 Nearest Railway Station Dalli-Rajhara 14 Date of Grant of Mining Lease 04-11-1962 15 Date of Execution 30-04-1963 16 Date of opening of Mine 05-11-1962 17 Date of First Renewal, if applicable First Renewal: 1988 and its period & expiry 18 Date of Second Renewal, if Second Renewal: 1998 applicable and its period & expiry Third Renewal: 01-06-2003 Period : 20years Expiry : 31-05-2023 19 Date of submission of renewal No. Durg/Iron/Mining-8/Nag/5-Raipur/255 dated 03-08- application if Mining Operations are 2016 Validity- 31-03-2018 continuing under deemed extension 20 Name of the Nominated Owner with Shri Kalian Maity, Director (RM & L), Industrial Address, phone, email, fax number House, 4th to 6th Floor 10 Camac Street, Kolkata- and date of appointment 700017.Email:[email protected], Mobile no.852775508. -

How to Reach Your Exam Center

Distance from Nearest Approximate TC nearest Mode of S.N. City Test Center Name Address Railway From To Fare Remarks Code Railway transport station (in Rs.) Station Route: Durg Rly. Station => Right turn => Green Chowk => from Green Chowk turn left and go straight => CA square (Pulgaon Road) => Patel Chowk => District 30-60/- Pulgaon Chowk, Durg, Chhattisgarh, Railway Pulgaon Court Durg => go straight => PULGAON CHOWK => left 1 Durg Bharti College Of Engineering & Technology 4246 Durg 8 km Bus/Auto (sharing- India - 491001 Station Chowk turn => walkable distance of 500-800 mtrs from Pulgaon private) Chowk. (i) Sharing auto : from Durg Rly. Station to Bharti College via Durg District Court and Pulgaon Chowk - Rs. 30- 60/-. Route : Durg Rly. Station (via Balod Road) => right turn 30-80/- => Green Chowk => go straight on Balod Road and turn Balod Road, Shivaji Nagar, Durg, Railway 2 Durg Chhatrapati shivaji Institute of Technology 1669 Durg 12 km Bus/Auto CSIT Durg (sharing- right at Patel Kirana Store => Pulgaon Chowk => Chhattisgarh, India - 491001 Station private) PULGAON POLICE STATION => go straight on Balod Road => CSIT Durg. Route : (i) from Durg - Durg Rly. Station => on Durg- Dhamdha Road => go straight => Delhi Public School Durg => right turn => Junwani Petrol Pump => Awanti Bai Chowk => on Kurud Road => go straight => MOMO'S CENTRE. (ii) from Bhilai Power House - Bhilai from Durg 10 Durg / Bhilai Sanjay 50-250/- Power House Rly. station => on NH-53 => Shastri Kohka Kurud Road, Bhilai, Bhilai Nagar, km. from Bhilai Railway 3 Bhilai Sanjay Rungta Group Of Colleges Bhilai 1674 Power Bus/Auto Rungta (sharing- Chowk => right turn => Gada Chowk Supela => Chhattisgarh, India - 490024 Power House Station House College private) Sadbhawna Chowk => Awanti Bai Chowk => on Kurud 7 km. -

Bhilai Steel Plant the Lease Area Is Approachable from Tahsil

Bhilai Steel Plant BRIEF WRITE UP OF THE PROJECT 1.0 Title of the Project Environment Clearance for Nandini Limestone Mines of Bhilai Steel Plant, M/s Steel Authority of India Limited (SAIL) in Tehsil: Damdha, District: Durg (Chhattisgarh) for Expansion of Lease area from 526.34 ha to 549.03 ha ( Expansion area 22.69 ha) with production capacity remaining same i.e. 1.08 MTPA 2.0 Location / Site Alternatives under Consideration: M/s Bhilai steel plant (BSP), a subsidiary of Steel Authority of India Ltd (SAIL), is having Nandini Mines Mining Lease for excavation of Limestone over an area of 526.54 Ha at Tehsil: Damdha , District: Durg, Chhattisgarh-State. The mine is in operation from 15/06/1958. Location and Extent of Area: The area falls in the Survey of India Topo Sheet No. 64 G/7 near village Ahiwara,Pithora, Deorjhal &Nandini-Khundini in Tehsil Dhamdha. District Durg of Chhattisgarh state and is having the latitude and longitude as given below: Latitude: 210 21’45” North & 210 23’00” North. Longitude 810 24’30” East & 810 26’30” East The lease is situated at about 25 km towards North-East from Bhilai Steel Plant, The lease area is approachable from Tahsil headquarter Dhamdha by road at a distance of about 15 km and is about 30 km from the District headquarter Durg by all season fair road. The nearest Railway Station is Bhilai on Mumbai-Howrah main Railway Line at a distance of about 25 km. 3.0 Topography: The area is more or less flat with ground levels varies from 280 to 290 M AMSL. -

Karhibhadar Nipani Mokha Batler Jamgaon Road

Initial Environmental Examination January 2019 India: Chhattisgarh Road Connectivity Project Karhibhadar Nipani Mokha Batler Jamgaon Road Prepared by Public Works Department, Government of Chhattishgarh for the Asian Development Bank. CURRENCY EQUIVALENTS (as of 31 December 2018) Currency unit = Indian rupee/s (Re/Rs) Re1.00 = $0.01408 $1.00 = Rs71.0008 ABBREVIATION AADT - Annual Average Daily Traffic AAQM - Ambient air quality monitoring ADB - Asian Development Bank ASI - Archaeological Survey of India BDL - Below detectable limit BGL - Below ground level BOD - Biochemical oxygen demand BOQ - Bill of quantity CGWA - Central Ground Water Authority CO - Carbon monoxide COD - Chemical oxygen demand CPCB - Central Pollution Control Board CSC - Construction Supervision Consultant DFO - Divisional Forest Officer DG - Diesel generating set DO - Dissolved oxygen DPR - Detailed project report E&S - Environment and social EA - Executing agency EAC - Expert Appraisal Committee EFP - Environmental Focal Person EHS - Environment Health and Safety EIA - Environmental impact assessment EMOP - Environmental monitoring plan EMP - Environmental management plan ESCAP - United Nations Economic and Social Commission for Asia and Pacific GHG - Greenhouse gas GIS - Geographical information system GOI - Government of India GRC - Grievance redress committee GRM - Grievance redress mechanism HFL - Highest flood level IA - Implementing Agency IEE - Initial Environmental Examination IMD - Indian Meteorological Department IRC - Indian Road Congress IUCN - International