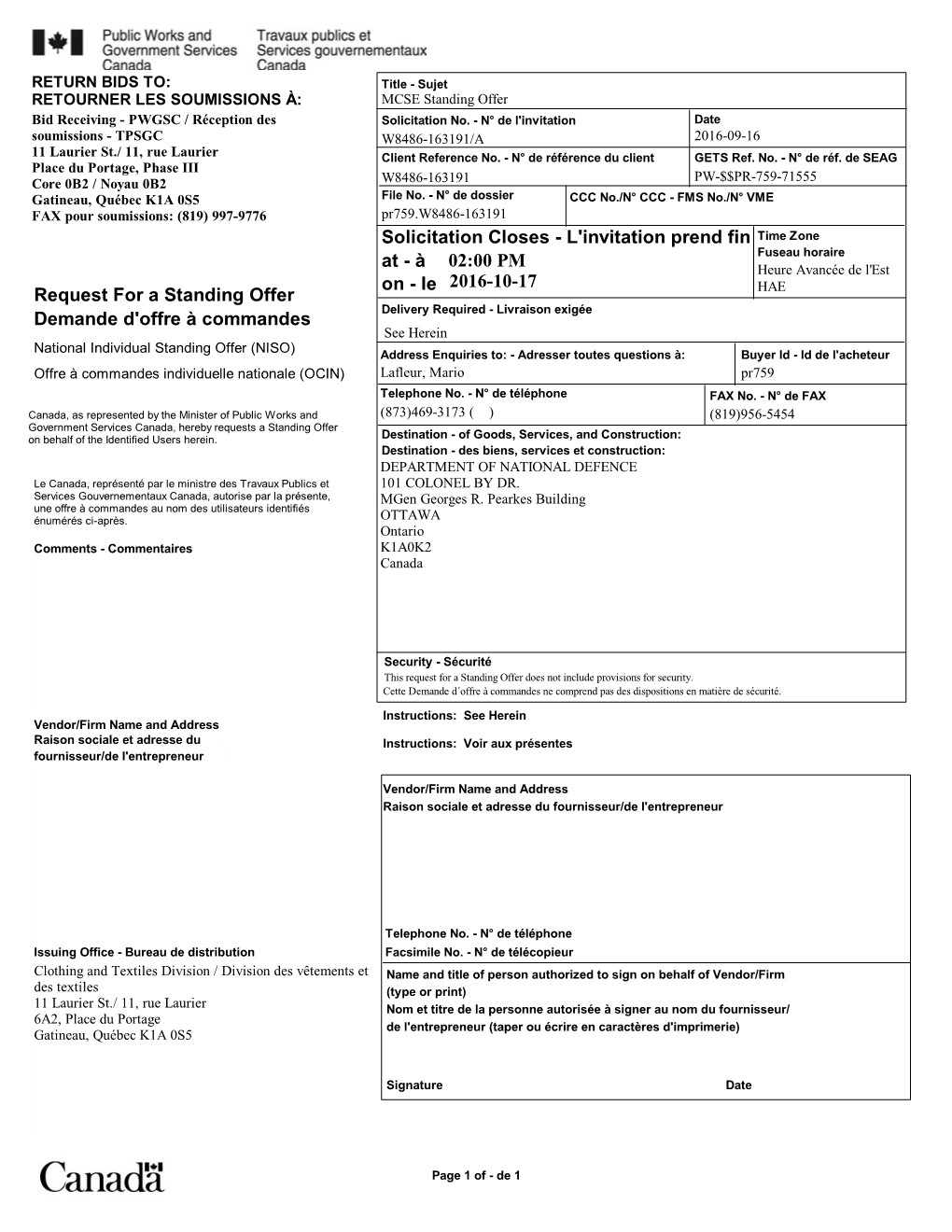

Request for a Standing Offer Demande D'offre À Commandes 02:00 PM 2016-10-17 On

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Outdoor Retailer Summer Market 2019 Colorado Convention Center | Denver, Co Exhibitor List

OUTDOOR RETAILER SUMMER MARKET 2019 COLORADO CONVENTION CENTER | DENVER, CO EXHIBITOR LIST 4OCEAN, LLC ARCTIC COLLECTION AB BIG CITY MOUNTAINEERS 5.11 TACTICAL ARMBURY INC. BIG SKY INTERNATIONAL 7 DIAMONDS CLOTHING CO., INC. ART 4 ALL BY ABBY PAFFRATH BIMINI BAY OUTFITTERS, LTD. 7112751 CANADA, INC. ASANA CLIMBING BIOLITE 8BPLUS ASOLO USA, INC. BIONICA FOOTWEAR A O COOLERS ASSOCIATION OF OUTDOOR RECREATION & EDUCATION BIRKENSTOCK USA A PLUS CHAN CHIA CO., LTD. ASTRAL BUOYANCY CO. BISON DESIGNS, LLC A+ GROUP ATEXTILE FUJIAN CO LTD BITCHSTIX ABACUS HP ATOMICCHILD BLACK DIAMOND EQUIPMENT, LLC ABMT TEXTILES AUSTIN MEIGE TECH LLC BLISS HAMMOCKS, INC. ABSOLUTE OUTDOOR INC AUSTRALIA UNLIMITED INC. BLITZART, INC. ACCESS FUND AVALANCHE BLOQWEAR RETAIL ACHIEVETEX CO., LTD. AVALANCHE IP, LLC BLOWFISH LLC ACOPOWER AVANTI DESIGNS / AVANTI SHIRTS BLUE DINOSAUR ACT LAB, LLC BABY DELIGHT BLUE ICE NORTH AMERICA ADIDAS TERREX BACH BLUE QUENCH LLC ADVENTURE MEDICAL KITS, LLC BACKPACKER MAGAZINE - ADD LIST ONLY BLUE RIDGE CHAIR WORKS AEROE SPORTS LIMITED BACKPACKER MAGAZINE - AIM MEDIA BLUNDSTONE AEROPRESS BACKPACKER’S PANTRY BOARDIES INTERNATIONAL LTD AEROTHOTIC BAFFIN LTD. BOCO GEAR AETHICS BALEGA BODYCHEK WELLNESS AGS BRANDS BALLUCK OUTDOOR GEAR CORP. BODY GLIDE AI CARE LLC BAR MITTS BODY GLOVE IP HOLDINGS, LP AIRHEAD SPORTS GROUP BATES ACCESSORIES, INC. BOGS FOOTWEAR AKASO TECH, LLC BATTERY-BIZ BOKER USA INC. ALCHEMI LABS BC HATS, INC. BOOSTED ALEGRIA SHOES BDA, INC. BORDAN SHOE COMPANY ALIGN TEXTILE CO., LTD. BEAGLE / TOURIT BOTTLEKEEPER ALLIED FEATHER & DOWN BEAR FIBER, INC. BOULDER DENIM ALLIED POWERS LLC BEARDED GOAT APPAREL, LLC. BOUNDLESS NORTH ALOE CARE INTERNATIONAL, LLC BEARPAW BOY SCOUTS OF AMERICA ALOHA COLLECTION, LLC BEAUMONT PRODUCTS INC BOYD SLEEP ALPS MOUNTAINEERING BED STU BRAND 44, LLC ALTERNATIVE APPAREL BEDFORD INDUSTRIES, INC. -

Black Diamond Appoints John Walbrecht As President of Black Diamond Equipment, Ltd

September 27, 2016 Black Diamond Appoints John Walbrecht as President of Black Diamond Equipment, Ltd. SALT LAKE CITY, Sept. 27, 2016 (GLOBE NEWSWIRE) -- Black Diamond Equipment, Ltd. a global innovator in climbing, skiing, mountain sports equipment and apparel, and a subsidiary of Black Diamond, Inc. (NASDAQ:BDE) (the “Company”), has appointed John Walbrecht as President, effective October 3, 2016. Walbrecht brings more than 30 years of executive leadership experience from several strong active outdoor brands. Most recently he served as President and CEO of Mountain Hardwear, a manufacturer of high-tech active outdoor clothing, equipment and camping accessories and a subsidiary of Columbia Sportswear. Prior to his role with Mountain Hardwear, Walbrecht served as President and CEO of Fenix Outdoor, an international group of outdoor clothing and equipment brands. He has also served in senior leadership roles at Spyder Active Sports, Timberland, and Dr. Martens, among others. Black Diamond Executive Chairman Warren B. Kanders commented: “John is a seasoned industry veteran who brings a wealth of experience and leadership in the outdoor equipment and apparel space. Over the course of his 30-plus year career, he has provided the strategic vision to improve brand equity and drive growth for some of the industry’s most reputable and dynamic companies. Given his strong background, we look forward to leveraging his expertise and enthusiasm as we continue to grow Black Diamond Equipment. I would like to thank Mark Ritchie, our outgoing President of Black Diamond Equipment for his dedication and years of service. Mark will be assisting John in his transition and working with the team in additional ways in the future.” Walbrecht holds a Master of Business Administration and a Bachelor of Science in Economics from Brigham Young University, a Bachelor of Arts in Marketing from the University of Maryland and understudies in International Trade and Finance at Cambridge University - Trinity College. -

Victorian Climbing Management Guidelines

Victorian Climbing Management Guidelines Compiled for the Victorian Climbing Community Revision: V04 Published: 15 Sept 2020 1 Contributing Authors: Matthew Brooks - content manager and writer Ashlee Hendy Leigh Hopkinson Kevin Lindorff Aaron Lowndes Phil Neville Matthew Tait Glenn Tempest Mike Tomkins Steven Wilson Endorsed by: Crag Stewards Victoria VICTORIAN CLIMBING MANAGEMENT GUIDELINES V04 15 SEPTEMBER 2020 2 Foreword - Consultation Process for The Victorian Climbing Management Guidelines The need for a process for the Victorian climbing community to discuss widely about best rock-climbing practices and how these can maximise safety and minimise impacts of crag environments has long been recognised. Discussions on these themes have been on-going in the local Victorian and wider Australian climbing communities for many decades. These discussions highlighted a need to broaden the ways for climbers to build collaborative relationships with Traditional Owners and land managers. Over the years, a number of endeavours to build and strengthen such relationships have been undertaken; Victorian climbers have been involved, for example, in a variety of collaborative environmental stewardship projects with Land Managers and Traditional Owners over the last two decades in particular, albeit in an ad hoc manner, as need for such projects have become apparent. The recent widespread climbing bans in the Grampians / Gariwerd have re-energised such discussions and provided a catalyst for reflection on the impacts of climbing, whether inadvertent or intentional, negative or positive. This has focussed considerations of how negative impacts on the environment or cultural heritage can be avoided or minimised and on those climbing practices that are most appropriate, respectful and environmentally sustainable. -

Waypoint Namibia

Majka enjoys a perfect crack on Southern Crossing. Big wall Waypoint Namibia What makes a climb impassable? I’m 215-meters up a first ascent of a granite crack climb in the heart of Namibia, and all I have to hold onto is a bush. Lots of bushes. Trees, too. In order to get where I’m going - the summit - I need what’s behind the bushes, the thing these bushes are choking, the thing that I have travelled 15,400 kilometers by plane, truck, and foot for: a perfect crack. amibia is not known for its climbing, which is exactly why I wanted to go there. It’s better known as Africa’s newest Nindependent country, the source of the continent’s largest stores of uranium and diamonds, the Namib Desert, the Skeleton Coast, and its tribal peoples. Previously known as Southwest Africa, this former German colony and South African protectorate holds some of the most coveted, and least visited, natural sites in Africa. In the middle of all of these lies Spitzkoppe, a 500-meter granite plug with over eighty established climbs. When I learned about Spitzkoppe in December 2007, I automatically started wondering what else might be possible to climb in Namibia. I pick unlikely climbing destinations because I want to learn what happens on the margins of adventure. War, apartheid, and remoteness have all combined to keep many of Namibia’s vertical landscapes relatively unexplored. When I found an out-of-focus photo of a 1,000-meter granite prow with a mud Himba hut in the foreground, I knew I had found my objective. -

United States Securities and Exchange Commission Washington, D.C

United States Securities and Exchange Commission Washington, D.C. 20549 Form 8-K Current Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 Date of Report (Date of earliest event reported): June 7, 2012 Black Diamond, Inc. (Exact name of registrant as specified in its charter) Delaware 0-24277 58-1972600 (State or other jurisdiction (Commission File Number) (IRS Employer of incorporation) Identification Number) 2084 East 3900 South, Salt Lake City, Utah 84124 (Address of principal executive offices) (Zip Code) Registrant’s telephone number, including area code: (801) 278-5552 N/A (Former name or former address, if changed since last report.) Check the appropriate box below if the Form 8-K filing is intended to simultaneously satisfy the filing obligation of the registrant under any of the following provisions: ¨ Written communications pursuant to Rule 425 under the Securities Act (17 CFR 230.425) ¨ Soliciting material pursuant to Rule 14a-12 under the Exchange Act (17 CFR 240.14a-12) ¨ Pre-commencement communications pursuant to Rule 14d-2(b) under the Exchange Act (17 CFR 240.14d-2(b)) ¨ Pre-commencement communications pursuant to Rule 13e-4(c) under the Exchange Act (17 CFR 240.13e-4(c)) Item 7.01 Regulation FD Disclosure. On June 7, 2012, Black Diamond, Inc. (the “Company” or “Black Diamond”) issued a press release announcing that it had entered into a Share Transfer Agreement dated June 7, 2012, to acquire POC Sweden AB (“POC”), a Stockholm-based developer and manufacturer of protective gear for action sports athletes. A copy of the press release is attached as Exhibit 99.1 to this Current Report on Form 8-K (the “Report”) and is incorporated herein by reference. -

10 Climbing Areas in Crisis Page 8

VERTICAL TIMES The National Publication of Access Fund Winter 18/Volume 113 www.accessfund.org 10 Climbing Areas in Crisis page 8 CLIMB LIKE A LOCAL: COCHISE STRONGHOLD 5 WILLIAMSON ROCK ON PATH TO REOPENING 7 Protect America’s Climbing INNOVATING FOR SUSTAINABLE BOLT REPLACEMENT 12 AF Perspective It takes two flints to make a fire. But alongside the excitement and positivity was a common thread of concern: Our world-class climbing areas are “ – LOUISA MAY ALCOTT suffering from world-class impacts and problems. It’s ” becoming harder and harder to mitigate impacts from the ere’s a fun experiment: Throw a group of dedicated, growing number of climbers. While this has been a long- passionate climbers in a room and ask them, “How term battle, the problem is more acute than ever. So few of Hare we going to save our climbing areas?” our climbing areas are built or managed for the number of climbers using them today. I heard the same phrase again No, this isn’t Access Fund’s origin story (although it’s pretty and again: “Our climbing areas are being loved to death.” close). But it’s the premise behind Access Fund’s summits, trainings, and conferences, which we’ve been hosting for Our charge now is to love these areas back to life. And that more than 25 years. starts with getting real about the impacts, acknowledging the need for recreation infrastructure to protect these I went to my first Access Fund summit in 2009. It was in places, and bringing a whole heck of a lot more resources to Dr. -

Outdoor Retailer Snow Show 2020 Colorado Convention Center | Denver, Co Exhibitor List

OUTDOOR RETAILER SNOW SHOW 2020 COLORADO CONVENTION CENTER | DENVER, CO EXHIBITOR LIST 180S, LLC ARMS OF ANDES BLACK DIAMOND EQUIPMENT, LLC 21ST CENTURY BRANDS LIMITED DBA BLANC NOIR ARTESANIA, INC. BLACKSTRAP INDUSTRIES INC. 22 DESIGNS ARVA EQUIPMENT / NIC IMPEX ARVA CORP. ENDURANCE ENTERPRISES 32 DEGREES ARZARF, LLC BLUNDSTONE 686 WESTLIFE DISTRIBUTION ASCENT TEXTILE CO., LTD BOARD RETAILERS ASSOCIATION A&E GUTERMANN ASHEVILLE BOTANICALS BODY GLIDE A+ GROUP ASNOWHA BOGS FOOTWEAR A+ PRODUCTS ASPEN GREEN BOLLE’ ABMT TEXTILES ASSOCIATION OF OUTDOOR RECREATION & EDUCATION BORDAN SHOE COMPANY ABOM, INC. ASTIS BORGO 28 ABS PROTECTION GMBH ATHALON SPORTGEAR INC. BORN FOOTWEAR ABSOLUTE CANADA, LTD. ATLAS SNOWSHOES BOS & CO/GROUNG HOGS ACCESS FUND ATOMIC BOUNDLESS NORTH ACLI-MATE FORMULATION, LLC AUCLAIR SPORTS BRANDO GLOBAL ACORN A DIVISION OF TOTES ISOTONER AUCLAIRE ET MARTINEAU BRIGHTEX LTD ADAPTIVE SPIRIT AVALANCHE FOOTWEAR BRIKO ADHESIVE FILMS INC. AVAMETRIX BROOKLYN CLOTH ADIDAS TERREX AVENTURA CLOTHING BROOKWOOD COMPANIES, INC. ADTN INTERNATIONAL AXESSIMO INTERNATIONAL BRRR AESTHETICTEX, INC. AXINN BRUMATE, LLC AFRC /RAWIK/SNOW DRAGONS - OUTDOOR GEAR, INC. B FRESH GEAR BUFF, INC. AIRBLASTER B2Z PRODUCTS, INC. BULA SPORTS AIRHEAD SPORTS GROUP BACKCOUNTRY ACCESS, INC. BURLINGTON INDUSTRIES AKASO TECH, LLC BACKPACKER MAGAZINE - AIM MEDIA BURT’S BEES AKINZ BACKPACKER’S PANTRY BUTTON INTERNATIONAL CO., LTD. AKSELS, INC. BAFFIN LTD. C.A.M.P. USA, INC. ALASHAN CASHMERE COMPANY BASIC OPTIONS C3 WORLDWIDE ALCHEMY EQUIPMENT LTD. BATES ACCESSORIES, INC. CAB 54 SAS BLACK CROWS ALEGRIA SHOES BE BOUNDLESS CABLZ, INC. ALIBABA.COM BEARPAW CAKE ALIGN TEXTILE CO., LTD. BEIJING TENGXIN SPORTS PRODUCTS CO,. LTD CALIFORNIA COWBOY ALL RESORT FURNISHINGS INSIDE OUTDOOR MAGAZINE CALIPER FOODS ALOE CARE INTERNATIONAL, LLC BENISTI IMPORT EXPORT INC. -

1958 Journals

34. 0434 LOSING THE WAY ON A NEEDLE C. B. MACHIN Time dims memories. My story commences a number of seasons ago when a party of three quietly made their way at dawn from a Dolomite Hut, the leader carrying a small rucksack into which he had modestly tucked such climbing equipment as a piton hammer, piton, spare rope, slings and karabiners. Later some of this equipment was to be worn on the person, giving the wearer the appearance of a Lord Mayor of the sixth degree, though privately he felt equal to about one degree. From the col above the hut the approach to the Needle is made by traversing as airy a terrace as any climber could wish for. After crossing two steep snow couloirs, the start of the climb is reached and though we had gained height considerably the pinnacle rose sheer for a thousand feet above the ridge. The ordinary route, which is the easiest, offers a climb of the most extreme difficulty that can be overcome without the use of pitons as climbing aids, though pitons are used as belays. We were told that the Needle was not the place for careless or clumsy climbers since there is no margin of safety for such, and balance and neatness are absolutely essential. The climb started with a ten foot chimney sloping obliquely to the right and finishing on a small terrace with a pulpit at the base of a vertical yellow wall. This wall was one of the most difficult bits of the ascent; three problems arose, how to get on, how to stay on, and how to get off at the other end. -

Modern Yosemite Climbing 219

MODERN YOSEMITE CLIMBING 219 MODERN YOSEMITE CLIMBING BY YVON CHOUINARD (Four illustrations: nos. 48-5r) • OSEMITE climbing is the least known and understood, yet one of the most important, schools of rock climbing in the world today. Its philosophies, equipment and techniques have been developed almost independently of the rest of the climbing world. In the short period of thirty years, it has achieved a standard of safety, difficulty and technique comparable to the best European schools. Climbers throughout the world have recently been expressing interest in Yosemit e and its climbs, although they know little about it. Until recently, even most American climbers were unaware of what was happening in their own country. Y osemite climbers in the past had rarely left the Valley to climb in other areas, and conversely few climbers from other regions ever come to Yosemite; also, very little has ever been published about this area. Climb after climb, each as important as a new climb done elsewhere, has gone completely unrecorded. One of the greatest rock climbs ever done, the 1961 ascent of the Salethe Wall, received four sentences in the American Alpine Journal. Just why is Y osemite climbing so different? Why does it have techniques, ethics and equipment all of its own ? The basic reason lies in the nature of the rock itself. Nowhere else in the world is the rock so exfoliated, so glacier-polished and so devoid of handholds. All of the climbing lines follow vertical crack systems. Nearly every piton crack, every handhold, is a vertical one. Special techniques and equipment have evolved through absolute necessity. -

Rock Climbing Fundamentals Has Been Crafted Exclusively For

Disclaimer Rock climbing is an inherently dangerous activity; severe injury or death can occur. The content in this eBook is not a substitute to learning from a professional. Moja Outdoors, Inc. and Pacific Edge Climbing Gym may not be held responsible for any injury or death that might occur upon reading this material. Copyright © 2016 Moja Outdoors, Inc. You are free to share this PDF. Unless credited otherwise, photographs are property of Michael Lim. Other images are from online sources that allow for commercial use with attribution provided. 2 About Words: Sander DiAngelis Images: Michael Lim, @murkytimes This copy of Rock Climbing Fundamentals has been crafted exclusively for: Pacific Edge Climbing Gym Santa Cruz, California 3 Table of Contents 1. A Brief History of Climbing 2. Styles of Climbing 3. An Overview of Climbing Gear 4. Introduction to Common Climbing Holds 5. Basic Technique for New Climbers 6. Belaying Fundamentals 7. Climbing Grades, Explained 8. General Tips and Advice for New Climbers 9. Your Responsibility as a Climber 10.A Simplified Climbing Glossary 11.Useful Bonus Materials More topics at mojagear.com/content 4 Michael Lim 5 A Brief History of Climbing Prior to the evolution of modern rock climbing, the most daring ambitions revolved around peak-bagging in alpine terrain. The concept of climbing a rock face, not necessarily reaching the top of the mountain, was a foreign concept that seemed trivial by comparison. However, by the late 1800s, rock climbing began to evolve into its very own sport. There are 3 areas credited as the birthplace of rock climbing: 1. -

Public Chat from 02.25.21 Community Forum on Winter Climbing

17:59:29 From Sarah Garlick to Everyone : Welcome! 18:11:07 From Sarah Garlick to Everyone : Statement https://www.nhledges.org/projects-campaigns/ Comment Form https://tinyurl.com/FriendsComment Thank you to the many climbers who have helped shape the initial winter practices statement and the gathering tonight, including: Nick Aiello-Popeo Sam Bendroth Liam Byrer Peter Doucette Justin Guarino Meg Hoffer Mike Morin Jon Nicolodi Brian O'leary Zac St. Jules Jim Surette Mark Synnott Michael Wejchert Freddie Wilkinson Kurt Winkler 18:15:52 From Sarah Garlick to Everyone : Sign up for Friends of the Ledges email list: https://www.nhledges.org/get-involved/ 18:15:58 From Sarah Garlick to Everyone : Indigenous New Hampshire Collaborative Collective: https://indigenousnh.com/ 18:21:52 From Sarah Garlick to Everyone : I love seeing all your faces - thank you all for being here! 18:23:34 From Bruce Franks to Everyone : Thanks a lot Sarah, I appreciate all the work you do and the work to get this event tonight working. 18:32:19 From Justin Preisendorfer to Everyone : Way to power your way through Bayard! 18:46:06 From Sarah Garlick to Everyone : https://rockandice.com/opinion/style- matters-cryokinesis-and-the-new-ethics-in-new-hampshire-winter-climbing/ 18:50:48 From nickaiello to Everyone : Think past what I want to do at a moment? How quaint. 18:53:14 From Sarah Garlick to Everyone : But isn’t one of the problems that you don’t think you’re doing any “real” damage when you head up on a piece of granite? One of the problems is that the impact is really tiny… but it adds up…. -

What the New NPS Wilderness Climbing Policy Means for Climbers and Bolting Page 8

VERTICAL TIMES The National Publication of the Access Fund Summer 13/Volume 97 www.accessfund.org What the New NPS Wilderness Climbing Policy Means for Climbers and Bolting page 8 HOW TO PARK LIKE A CHAMP AND PRESERVE ACCESS 6 A NEW GEM IN THE RED 11 WISH FOR CLIMBING ACCESS THIS YEAR 13 AF Perspective “ The NPS recognizes that climbing is a legitimate and appropriate use of Wilderness.” — National Park Service Director Jonathan Jarvis his past May, National Park Service (NPS) Director Jonathan Jarvis issued an order explicitly stating that occasional fixed anchor use is T compatible with federally managed Wilderness. The order (Director’s Order #41) ensures that climbers will not face a nationwide ban on fixed anchors in NPS managed Wilderness, though such anchors should be rare and may require local authorization for placement or replacement. This is great news for anyone who climbs in Yosemite, Zion, Joshua Tree, Canyonlands, or Old Rag in the Shenandoah, to name a few. We have always said that without some provision for At the time, it seemed that fixed anchors, technical roped climbing can’t occur — and the NPS agrees. the tides were against us, The Access Fund has been working on this issue for decades, since even before we officially incorporated in 1991. In 1998, the U.S. Forest Service (USFS) that a complete ban on fixed issued a ban on fixed anchors in Wilderness (see photo inset) — at the time, it anchors in all Wilderness seemed that the tides were against us, that a complete ban on fixed anchors in all Wilderness areas was imminent.