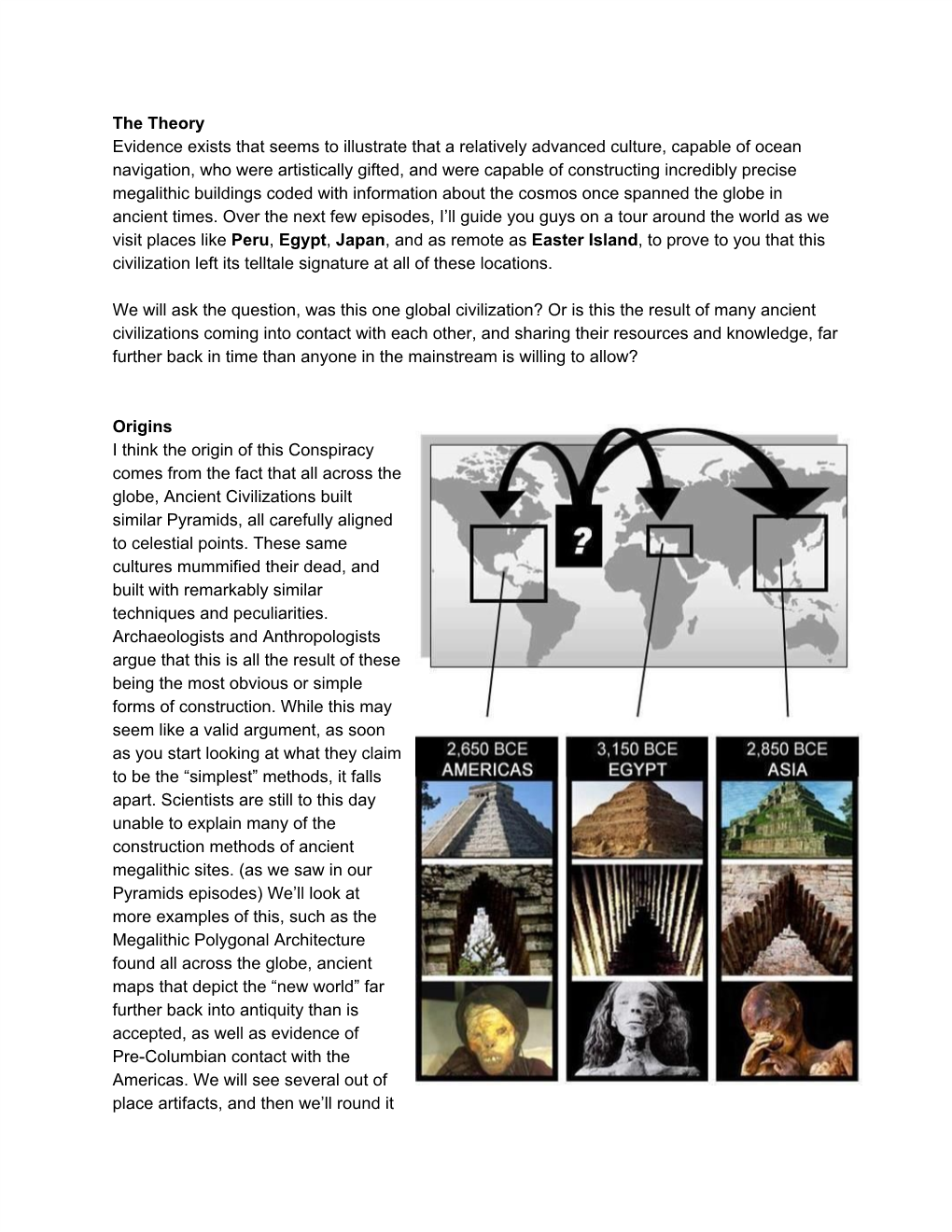

The Theory Evidence Exists That Seems to Illustrate That a Relatively

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Section 044200 - Exterior Stone Cladding

METRO MASONRY ANNUAL CONTRACT 2018- 2023 SECTION 044200 - EXTERIOR STONE CLADDING PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. 1.2 SUMMARY A. Section includes all possible situations that may be encountered at Metro Properties and the several solutions for maintenance of stone masonry restoration and cleaning. The Metro Project Coordinator will direct the Contractor as to portions of the specification for each project. The Project may require the following: 1. Dimension stone panels set with individual anchors. 2. Dimension stone panels mechanically anchored on steel trusses. 3. Dimension stone panels mechanically anchored on steel strongback frames. 4. Dimension stone panels mechanically anchored on steel stud frames. 5. Dimension stone panels mechanically anchored (field installed) on a metal-grid system. 6. Dimension stone panels set in architectural precast concrete. 7. Dimension stone trim units, including bands; copings; sills; jambs; and soffits. 8. Dimension stone with carving or inscriptions. B. Related Requirements: 1. Division 03 Section "Precast Architectural Concrete" for setting dimension stone panels in architectural precast concrete units. 2. Division 04 Section "Unit Masonry" for installing inserts in unit masonry for anchoring dimension stone cladding and for stone trim in unit masonry walls. 3. Division 05 Section "Cold-Formed Metal Framing" for steel stud frames supporting dimension stone cladding. 4. Division 07 Section "Joint Sealants" for sealing joints in dimension stone cladding system with elastomeric sealants. 1.3 DEFINITIONS A. Definitions contained in ASTM C 119 apply to this Section. -

Walls and Foundations of Historic Buildings

District of Columbia Historic Preservation Guidelines WALLS AND FOUNDATIONS OF HISTORIC BUILDINGS Government of the District of Columbia Office of Planning Historic Preservation Office 1100 4th Street, SW Suite 650 Washington, DC 20024 202-442-8800 Designs of Walls and Foundations Walls and above ground foundations are among the most important character-defining elements of historic buildings. The design of walls and foundations is influenced by the types of materials used, the location, proportions and scale of openings for doors and windows, massing and rhythm of features such as bays and porches, and details and ornamentation. The exterior walls of most free-standing buildings are also structural, that is they carry the weight of the floors and roof to the foundation. Conversely, the front and rear walls of rowhouses and other party-wall buildings are usually not load bearing; rather the side walls carry the weight of floors and roofs to foundations. Altering, repairing or replacing primary character-defining walls and foundations -those facing major public streets or sidewalks- must be carefully considered so as not to detract from a building's character. Changes to secondary non-character-defining walls and foundations (typically on the sides and rear of buildings) should also be carefully considered. Greater flexibility in selecting methods of construction and materials is possible for changes to non-character-defining than for character-defining walls and foundations. Above ground foundation walls are often visually distinguished from the main wall by a change of plane. For example, brick and stone foundation walls are often visually separated from the wall above by a belt course of molded brick or shaped stone. -

Stone Source Glossary of Terms.Indd

GLOSSARY OF TERMS This glossary provides you with commonly used terms for each of our material UPDATED ON: 9.13.2012 categories. The guide is divided into 5 sections: • Natural Stone • Porcelain tile + Ceramic tile • Glass Tile • Engineered Stone • Wood New York Boston Chicago Los Angeles New Jersey Washington DC Natural Stone Porcelain Tile Glass Tile Engineered Stone Reclaimed Wood 1 of 21 - stone source Glossary of terms GLOSSARY OF TERMS: Natural stone These are the terms most commonly used in relation to Natural Stone: Bleed Staining caused by corrosive metals, oil-based putties, mastics, caulking, or Abrasion resistance sealing compounds. The ability of a material to resist surface wear. Book Matched Absorption Layout wherein slabs are cut to create a mirror image of each other. The relative porosity of the material. Materials with low absorption will be less prone to staining. Materials with high-absorption may not be suitable for all applications, specifically kitchen countertops that come into regular contact with oils or pigmented acidic liquids such as wine or balsamic vinegar. Acid etching Materials that contain calcium or magnesium carbonate (marble, travertine, limestone and onyx) will react to acidic foods such as lemons or tomatoes. This reaction will result in a change in surface sheen, otherwise referred to as “acid etching”. Lighter stones and honed surfaces will typically diminish the appearance of acid etching. Antiqued finish Brushed finish A finish with a worn aged appearance, achieved by mechanically rubber- A smooth finish achieved by brushing a stone with a coarse rotary-type wire brushing the tile. brush. Buttering / Back buttering bullnose edge The process of slathering the back of a stone tile with thinset material to ensure (see edge profiles on page 8) proper mortar coverage. -

Installation Details for Kerb & Edgings

INSTALLATION DETAILS FOR KERB & EDGINGS Health and Safety Information Safe working practices should be employed at all times during the construction process and all necessary Personal Protective Equipment (PPE) should be worn. Drainage All paved surfaces require drainage. Where kerbs or edging are laid, this will restrict natural water flow off the paved area, so provision needs to be made to dispose of this water. This can be in the form of using cross fall and longitudinal fall to run water into areas of soft landscaping (i.e. a flowerbed or grassed area). However, where this is not possible, some form of drainage channel will need to be utilised. If laying kerbs or edgings next to a building, then care should be taken that the laid products are at least 150mm below the damp proof course level. Excavation To allow new kerb or edging to be installed correctly a certain amount of excavation will normally be required. The depth of this excavation will depend on several factors; the height of the kerb or edging selected, which way up it will be laid, and what upstand is intended. (i.e. the difference in height between the top of the kerb or edging and the paved surface in front of it). All organic materials such as grass should be removed from the excavation as this will rot and could cause possible settlement of the kerbs or edging and paving at a later stage. When the desired level has been reached the bottom of the excavation should be compacted to give an even surface. -

614.252.0955 Or 800.845.7644 Visit Our Website at Oberfields.Com PAVER S • R E TAINING WALLS • PATIO STONES • ACCESSORIES

614.252.0955 or 800.845.7644 Visit our website at oberfields.com PAVER S • R E TAINING WALLS • PATIO STONES • ACCESSORIES CORPORATE OFFICE Oberfield’s is Ohio’s premier manufacturer and marketer SALES 528 London Road P.O. Box 362 of high-quality concrete masonry, landscape, sitescape and Delaware, OH 43015 614.252.0955 740.369.7644 building material products. We invite you to visit one of our 800.845.7644 Fax 740.363.7644 five showrooms or many distributors throughout the region. SALES & MANUFACTURING 1165 Alum Creek Drive Columbus, OH 43209 614.252.0955 Simply call us for a convenient location near you. Fax 614.252.5858 SALES 450 W. Fair Avenue Lancaster, OH 43130 740.653.3074 Fax 740.653.7285 SALES 1190 S. Prospect Street Marion, OH 43302 740.382.8888 Fax 740.382.3110 SALES & MANUFACTURING 980 Shawnee Road Lima, OH 45805 419.225.6761 Fax 419.225.6121 O©2009 bOberfield’s,er Inc. field’s RESIDENTIAL Walkways/Patios................................................ 2 Driveways ........................................................ 3 Steps & Stairways ............................................ 4 Fire Pits & Grills .............................................. 5 Water Features ................................................. 6 Columns & Borders ......................................... 7 Monroe Pavers ................................................. 8-9 Washington Pavers ........................................... 10-11 Washington Circle Pavers ................................. 12-13 Lincoln Pavers ................................................. -

Concrete Repair Mortars Pocket Guide © 2020 the Euclid 4 Hour 3,000 (21) 2,000 (14) Chemical Company

The Euclid Chemical Company The Euclid Chemical Company VERTICAL & OVERHEAD VERTICAL & OVERHEAD SURFACES For more than a century, The Euclid SURFACES Chemical Company has served as a TROWELABLE & leading supplier to the concrete and PLACEMENT CATEGORY FORM AND POUR/PUMP CEMENTITIOUS TROWELABLE SPRAYABLE UNDERWATER FORM AND POUR/PUMP Verticoat Supreme SPRAYABLE masonry industry offering a full line EucoRepair SCC Microsilica and latex modified, non-sag of engineered concrete admixture Self-consolidating structural repair mortar repair mortar for trowel applied vertical and construction products marketed CONCRETE EucoRepair SCC Tamms Verticoat Speed Crete Tamms Speed Crete and overhead repairs requiring high Eucocrete EucoRepair V100 Eucopatch Tammscrete Verticoat Speed Crete PM Eucoshot under the EUCO brand name. These that is shrinkage compensated and PRODUCT NAME EucoRepair SCC Fast Form and Pour Supreme Red Line Structural Mortar Blue Line REPAIR contains polymer, microfiber, and corrosion performance. products include concrete admixtures, block and masonry additives, curing inhibitor. Can be placed from 1 inch (25 Verticoat and sealing compounds, epoxy MORTARS mm) to full depth without aggregate Two part latex modified mortar that sets Self-Consolidating, Fiber adhesives, floor and wall coatings, extension. Also available in a faster setting rapidly for quick and easy repair of vertical High Strength, Smaller Aggregate, Low Shrinkage, Versatile, Color Polymer Modified, Corrosion Inhibitor, Fast Setting, Can be Underwater PRODUCT Fiber Reinforced, Low Two Part, Polymer Reinforced, structural grouts for columns, version, EucoRepair SCC Fast. Full Depth Repairs Enhanced Fiber Reinforced, Similar to Plain Smooth Consistency Polymer and Shaved to Desired Polymer Modified Silica Fume Modified Patching Material, or overhead concrete surfaces. -

A2 – Dressed Quarry Stone Wall

Building techniques : A2 – Dressed Quarry Stone Wall Coutry: Lebanon PRÉSENTATION Geographical Influence Definition Dressed quarry stone wall - traditional masonry tools: chisel, picks and hammers. - 4, 5, 6 faces-sometimes 2 faces - naturally squared. - stone laying with or without wedging. - stones are laid straight, same size or not. - mortar laying Environment In the MEDA area, we find dressed quarry stone in all environments: urban, rural, in mountain, plain and sea side. Its presence is generally common. In Lebanon, dressed quarry stone (Moqassab) is often used everywhere: rural environment, urban, plain, mountain and sea side. Illustrations General view: Details close-up: This project is financed by the MEDA programme of the European Union. The opinions expressed in the present document do not necessarily reflect the position of the European Union or of its member States. 1/8 A2 Lebanon – Dressed quarry stone wall CONSTRUCTION PRINCIPLE Foundations Illustrations Finding a "firm base" or “good ground” is a preliminary for the builder. If rock shows on the surface, the wall is built directly above. If not, all countries dig a small trench (~ 50 cm deep), practically never deeper than 1m. the width can be equal to the thickness of the wall above-ground, but it can also be up to twice this thickness. Combination of 2 factors : width of the trench and type of filling materials: adjustments and adaptation to each spot and ground. The materials are always stony: the trench is filled with stones, generally linked with mortar. If the module is small, the trench is broader. Several countries reported construction over ruins used as foundation. -

The Monumental Architecture of Iklaina

The Monumental Architecture of Iklaina Michael B. Cosmopoulos1 Abstract: The excavations of the Athens Archaeological Society at Iklaina have brought to light a major LH settle- ment that is identified with *a-pu2, one of the district capitals of the Mycenaean state of Pylos. One of the most striking features of the site is its monumental architecture, which includes at least two large buildings, two paved roads, a paved piazza, and massive built stone drains. The presence of this kind of monumentality outside the traditionally defined ‘palaces’, combined with other markers of advanced socio-political complexity, opens up a number of questions regard- ing the processes of the unification of the Mycenaean state of Pylos. In the present paper I review the relevant archi- tectural and stratigraphic evidence and assess its possible implications for this issue. It is concluded that the emergence of monumental architecture at Iklaina could have been initiated either by the Palace of Nestor following a peaceful annexation of Iklaina in the early Mycenaean period, or by the local Iklaina rulers following a period of continuous growth before a forced annexation in LH IIIB. Keywords: Monumentality, state formation, Mycenaean, Pylos, Iklaina Introduction The excavations at Iklaina are conducted under the auspices of the Archaeological Society at Athens.2 Over the course of nine field seasons we have unearthed a significant part of a LH settle- ment, which can be identified with *a-pu2, one of the district capitals of the Mycenaean state of Pylos.3 The site includes three general areas: residential, industrial, and administrative (marked as R, I, and A in Fig. -

Mortar Mix No

Mortar Mix No. 1102 PRODUCT DESCRIPTION when they become "thumb print" hard. This will make the mortar joint water-tight and provide a Basic use: QUIKRETE® Mortar Mix (#1102) is neat appearance. a type N masonry mortar for use in laying brick, Coverage: Refer to table 1 for approximate block or stone; and repairing of masonry walls. coverage for each bag size. Use for brick or stone fireplaces, brick walls, block walls, parge coats, tuck pointing, stucco Table 1: Mortar Mix Usage Chart and plaster. Bag Size Standard Block Standard ® 8" X 8" X 16" Brick Composition and materials: QUIKRETE (200 mm X 200 mm X 8" X 2" X 4" Mortar (Masonry) Mix consists of a uniformly 410 mm) (200 mm X 50 blended mixture of fine sand, and type N mm X 100 mm) masonry cement. 80-lb. 12 37 Packaging: Available in three sizes: 80 lbs. (36.3 kg) (36.3 kg), 60 lbs. (27.2 kg), and 40 lbs. (18.1 28 kg). 60 lbs. 9 (27.2 kg) Technical Data QUIKRETE® Mortar Mix meets and exceeds the 40 lbs. 6 19 physical property requirements of ASTM (18.1 kg) designation 387 (Standard Specifications for Packaged, Dry, Combined Materials for Mortar Tuck Pointing or Repointing and Concrete) and ASTM C 270 for Type N Mortar. Product achieves a compressive Mixing: Mix QUIKRETE Mortar Mix with just strength in excess of 750 psi (5.17 MPa) in 28 enough water to form a damp unworkable mix day. that retains its form when pressed into a ball in the hand. -

The Art of Stone Masonry in the Rockbridge County Area (1700 to Present)

The Art of Stone Masonry In the Rockbridge County Area (1700 to present) Steven Connett Archaeology 377 5/25/83 Dr. McDaniel The art of stone masonry in the Shenandoah valley seems to be somewhat of a mystery prior to the nineteenth century. However, as some of us have learned from the anthropology 101 course: The absence of artifacts (documents in this case) is just as important as the presence of artifacts. In order to make sure that the lack of information was not due to my possible incompetence in research, I spoke with a current day stone masoner named Alvis Reynolds. Mr. Reynolds relayed t o me that when he was trying to learn the skills of stone masonry he, too, had great difficulty in obtaining information and thus decided to teach himself this art through the process of trial and error. Although this information did not directly aid me in my research, Mr. Reynolds did provide me with a bit of information that allowed me to derive a hypothesis on why there is this unusual lack of information in this line of study. I will state my hypothesis in this paper, however, I will not be able to prove it or disprove it due to the deficiency in available information. Mr. Reynolds explained to me that in the eighteenth century there were nomadic stone masoners. These nomadic workers went from valley to valley in search of people who needed help with building their houses. Since these people did not know how to cut stone themselves (after all, stone cutting is not the type of thing that is innate to most people) they had no choice but to p~y these men for their services or go unsheltered. -

How to Build a Dry Stone Wall an Instructional Guide for Beginners

Do- It-Yourself: How to Build a Dry Stone Wall An instructional guide for beginners © Copyright Stephen Burton and licensed for reuse under this Creative Commons License. By: Stephen T. Kane Table of Contents: INTRODUCTION………………………………………………….3 TOOLS, EQUIPMENT, AND SUPPLIES………………………4 GROUNDWORK…………….…………………………………….7 FOUNDATION…………………………………………………….8 COURSING.…………………………………………………………9 COPING.……………………………………………………………10 GLOSSARY………………………………………………………..11 Introduction: Whether for pure aesthetics or practical functionality, dry stone walls employ the craft of carefully stacking and interlocking stones without the use of mortar to form earthen boundaries, residential foundations, agricultural terraces, and rudimentary fences. If properly constructed, these creations will stand unabated for countless years, requiring only minimal maintenance and repairs. The ability to harness the land and shape it in a way that meets one’s needs through stone walling allows endless possibility and enjoyment after fundamental steps and basic techniques are learned. How to Build a Dry Stone Wall provides a comprehensive reference for beginners looking to start and finish a wall project the correct way. A list of essential resources and tools, a step-by-step guide, and illustrations depicting proper construction will allow readers to approach projects with a confidence and a precision that facilitates the creation of beautiful stonework. If any terminology poses an issue, simply reference the glossary provided in the back of the booklet. NOTE: Depending on property laws and building codes, many areas do not permit stone walls. Check with respective sources to determine if all residential rules and regulations will abide stonework. Also, before building anything on a property line, always consult your neighbor(s) and get their written consent. -

Masonry Constructions As Built Archives: an Innovative Analytical Approach to Reconstructing the Evolution of Imperial Opus Testaceum Brickwork in Rome

Masonry Constructions as Built Archives: An Innovative Analytical Approach to Reconstructing the Evolution of Imperial Opus Testaceum Brickwork in Rome Gerold Eßer Vienna University of Technology, Austria The Colosseum, Trajan’s Market, the Baths of buil dings are to be regarded as the outcome of Caracalla and the Basilica of Maxentius: the monu- rational decisions made on the basis of economy, mental ruins of the imperial representational build- durability and functionality. Particularly in the ings mark the crystallisation points in a profound, area of important imperial public buildings, where centuries- long recasting of the appearance of the the pressure to be successful was exceptionally city of Rome (Fig. 1). The cores consist of practi- high, the conditions imposed by the market were cally indestructible opus caementitium, faced with certainly strictly observed. Large imperial buil- hard, quasi- industrially produced fired bricks. This ding projects in which often many thousands of construction method, later called opus testaceum, workers had to be organised and directed required was uniquely suited to surviving the passage of the definition and implementation of standards time. For us today, this means that we have at our applicable right across the site. To ensure the suc- disposal an extraordinary wealth of evidence for the cess of a major project these standards had to be building construction methods used in those times. laid down in series of technical regulations. The Given that even the building sites of classi- doctoral thesis on which the present paper is based cal antiquity were subject to market forces, the examined the extent to which the organisation of large building sites influenced masonry construc- tions and whether, using the characteristics of the masonry that will be defined below, this influence can be read as a regulative on the erection of the structures.