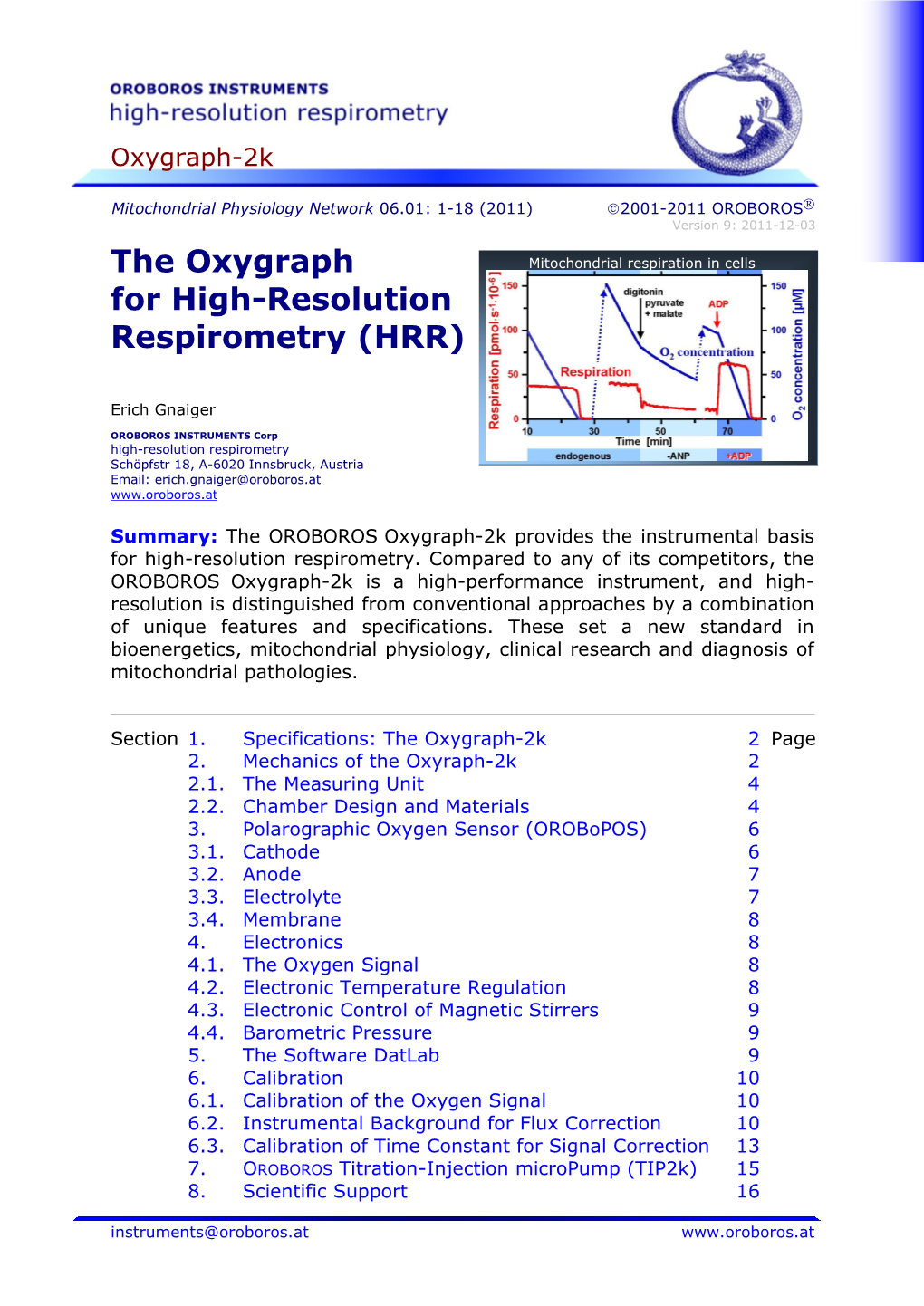

The Oxygraph for High-Resolution Respirometry (HRR)

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

SEARCH for EXTANT LIFE THROUGH HUMAN MISSION on the SURFACE of MARS P. Yun (El Camino College 16007 Crenshaw Blvd., Torrance, Ca

Mars Extant Life: What's Next? 2019 (LPI Contrib. No. 2108) 5024.pdf SEARCH FOR EXTANT LIFE THROUGH HUMAN MISSION ON THE SURFACE OF MARS P. Yun (El Camino College 16007 Crenshaw Blvd., Torrance, California 90506 USA, [email protected]) Introduction: NASA Mars missions focus on in- vestigating life in past and present Mars, understanding geological history and climate of Mars, and preparing human mission on the surface of Mars. If Martian ex- tant life exists, then it is expected to be a microorgan- ism due to a high level of radiation and the limited amount of liquid water on surface as well as a high level of carbon dioxide in atmosphere. Through human mission, currently available microbiological sensing technologies on Earth can be implemented on Mars with necessary modification and adjustment to Martian Figure 2. Scanning electron micrographs(SEM) of environment which has a high level of radiation on bacteria found in ice in Greenland and Antarctica surface and a high level of carbon dioxide in atmos- (Credit: Knowlton) phere as well as a low gravity compared to Earth. Mar- Water: Some liquid water may occur transiently on tian extant life may make a home in atmosphere, water, the Martian surface today.[6] Currently available de- ice, soil, or rock of surface or subsurface. tection techniques of microorganism in water include Atmosphere: Microbes consuming carbon- Biosensors, Vibrational Spectroscopy, MALDI/TOF containing chemicals exist in the in the middle-to- mass spectrometry, and Adenosine Tri-phosphate as- upper troposphere (8–15 km altitude) of Earth, and the say.[7] proportion of some microbes in atmosphere is higher Conclusion: Through human mission, currently than in soil and dust.[1] MSL Curiosity’s detection of a available sensing technologies to find microbes in at- seasonal methane cycle suggests that microbes may mosphere, water, ice, soil, rock of surface or subsur- exist in Martian atmosphere, which is composed of face on Earth can be utilized on Mars with necessary 96% carbon dioxide. -

A Novel Technique for the Precise Measurement of CO2 Production Rate in Small Aquatic Organisms As Validated on Aeshnid Dragonfly Nymphs Till S

© 2017. Published by The Company of Biologists Ltd | Journal of Experimental Biology (2017) 220, 964-968 doi:10.1242/jeb.150235 METHODS & TECHNIQUES A novel technique for the precise measurement of CO2 production rate in small aquatic organisms as validated on aeshnid dragonfly nymphs Till S. Harter*, Colin J. Brauner and Philip G. D. Matthews Ṁ in vitro ABSTRACT measuring small aquatic CO2 was validated both and in vivo The present study describes and validates a novel yet simple system using aeshnid dragonfly nymphs. for simultaneous in vivo measurements of rates of aquatic CO2 ̇ ̇ MATERIALS AND METHODS production (MCO2) and oxygen consumption (MO2), thus allowing the calculation of respiratory exchange ratios (RER). Diffusion of CO Animal collection and husbandry 2 Aeshna Anax junius from the aquatic phase into a gas phase, across a hollow fibre Aeshnid dragonfly nymphs ( spp. and ; wet mass ̇ 2.17 mg–1.46 g; n=15) were caught in the experimental ponds at the membrane, enabled aquatic MCO2 measurements with a high- ̇ University of British Columbia (summer 2016), and were held in the precision infrared gas CO2 analyser. MO was measured with a 2 laboratory for several weeks before experiments. Housing was in 1 l PO optode using a stop-flow approach. Injections of known amounts 2 glass containers connected to a recirculation system supplied with of CO2 into the apparatus yielded accurate and highly reproducible 2 dechlorinated Vancouver tap water at room temperature (22°C). measurements of CO2 content (R =0.997, P<0.001). The viability of in vivo measurements was demonstrated on aquatic dragonfly Animals were fed various wild-caught aquatic insects, twice a week. -

Discontinuous Co2 Emission in a Small Insect, the Formicine Ant Campoxotus Vicixus

J. exp. Biol. 134, 363-376 (1988) 363 Printed in Great Britain © The Company of Biologists Limited I9SS DISCONTINUOUS CO2 EMISSION IN A SMALL INSECT, THE FORMICINE ANT CAMPOXOTUS VICIXUS BY JOHN R. B. LIGHTON Department of Biology, University of California at Los Angeles, Los Angeles, CA 90024, USA Accepted 21 July 1987 SUMMARY Standard rates of oxygen consumption (VO2) and CO2 production (VCO2) were measured by constant-volume respirometry in the formicine ant, Camponotus vicinus Mayr, at temperatures ranging from 10 to 40°C. Over this range, the Q10 with regard to VO2 was 1-79, and with regard to VCO2, 1-84. Multiple regression equations relating VO2 and VCO2 of inactive ants to mass (0016-0088g) and temperature were calculated. Periodic CO2 emissions ('bursts') were monitored with flow-through respirometry. Burst frequency increased exponentially with tempera- ture (QiO = 3-05), from 814h"' at 15°C to 81-4h~' at 35°C, and was not significantly correlated with body mass over the mass range (0041-0086g) investigated. Burst volume, which could be accurately measured in one ant, decreased with temperature (Qio = 0'61). thus yielding the observed Vcc>2 Q10 °f 1-84. INTRODUCTION The dynamics of external gas exchange in insects has important implications in the measurement of insect metabolic rates; it also provides insights into the functioning of a respiratory system that is complex, efficient, and unique to insects and a few other arthropods. One of the most striking aspects of external gas exchange in insects is its discontinuous, or intermittent, nature. Reports of periodic emissions, or bursts, of CO2 from large insects have been present in the literature for many years (Schneiderman, 1953; Punt, Parser & Kuchlein, 1957; Hamilton, 1964), and such reports have now become commonplace (see reviews by Miller, 1981; Kaars, 1981). -

O2k-Protocols SOP: O2k Quality Control 1

O2k-Protocols SOP: O2k Quality Control 1 Mitochondrial Physiology Network 06.03(19):1-19 (2021) Version 19: 2021-08-19 ©2001-2021 Oroboros Updates: http://wiki.oroboros.at/index.php/MiPNet06.03_POS-Calibration-SOP O2k Quality Control 1: Polarographic oxygen sensors and accuracy of calibration Erich Gnaiger Oroboros Instruments High-Resolution Respirometry Schoepfstrasse 18, 6020 Innsbruck, Austria Email: [email protected] www.oroboros.at Contents 1. Oxygen concentration and partial pressure ............................................................................ 2 2. Polarographic oxygen sensor ........................................................................................................ 2 2.1. Cathode ................................................................................................................................................... 3 2.2. Anode ...................................................................................................................................................... 3 2.3. Electrolyte ............................................................................................................................................. 3 2.4. Membrane ............................................................................................................................................. 4 3. Calibration and quality control (O2k-SOP) .............................................................................. 4 3.1. The O2 sensor test .............................................................................................................................. -

BM Respirometry Applied to a Novel Control Strategy of Nitrification in a Wastewater Biological Treatment

BM Respirometry applied to a novel control strategy of nitrification in a wastewater biological treatment Emilio Serrano - Surcis, S.L. Email: [email protected] Abstract In wastewater treatment plants, the biological nitrogen removal (BNR) has acquired critical importance, which makes that in the majority of the cases the overall process control largely depends on the control of this treatment. The normal aerobic process of nitrification is performed by specific aerobic living microorganisms and a lack of information on their bioactivity may be cause of confusion in terms of control and monitoring criteria. For this reason, the application of the BM Respirometry, for the goal of getting a determined performance within the frame of energy optimization, has achieved an important role for essential information about the actual nitrification situation but also in other situations under different conditions for the process development. 1. Introduction The nitrification processes control must be based on a sufficient removal substrate rate to fit the actual hydraulic retention time of the biological reactor available for nitrification: Nitrification rate = ammonium- nitrogen uptake rate (AUR) Either the nitrification rate is the correct on which the process has to run, the plant operator should find its value. He also has to know if it is enough or not; and in case of not enough, he has to find out the causes and the possible solutions. For that purpose, a BM respirometer can be the perfect instrument to measure the actual nitrification rate and also to analyze if this has a higher or lower value than it is required in any specific process. -

Microtiter Plate, Optode Respirometry, and Inter-Individual Variance in Metabolic Rates Among Nauplii of Artemia Sp

MARINE ECOLOGY PROGRESS SERIES Vol. 296: 281–289, 2005 Published July 12 Mar Ecol Prog Ser Microtiter plate, optode respirometry, and inter-individual variance in metabolic rates among nauplii of Artemia sp. Tracy L. Szela, Adam G. Marsh* College of Marine Studies, University of Delaware, 700 Pilottown Road, Smith Laboratory, Rm 114, Lewes, Delaware 19958, USA ABSTRACT: Understanding the potential metabolic lifespan of a cohort of marine invertebrate embryos or larvae requires not just precise measurements of respiration rates, but also requires a large number of individual-level measurements to accurately describe the distribution of metabolic rate potentials within that cohort. To this end, we have developed a simple protocol for converting a 384-well microtiter plate into a 384-chamber, microrespirometer, optode using a plate-reading fluorometer for continuous, real-time data acquisition. We have ground-truthed this high-throughput technique using Artemia sp. nauplii at ~48 h post-hydration. In this paper we present >1000 separate respiration rate measurements on nauplii, providing a novel look at the distribution of metabolic rates within a cohort of larvae. At this high level of individual sampling, we have applied a Shan- non–Weaver information entropy statistic to describe the ‘complexity’ of these rate distributions and to show that the range of metabolic phenotypes expressed in a group of nauplii is responsive to the salinity in which they are rehydrated. Understanding the nature and mechanisms by which variations in metabolic rate intensities can be so large within a cohort and can be responsive to environmental parameters represents a real challenge in larval biology, which will require high-throughput method- ologies at both molecular and biochemical levels to decipher. -

Respirometry Test Manual: WEERC Laboratory Sepideh Sadeghi South Dakota State University, [email protected]

South Dakota State University Open PRAIRIE: Open Public Research Access Institutional Repository and Information Exchange Civil and Environmental Engineering Reports and Department of Civil and Environmental Manuals Engineering 8-2018 Respirometry Test Manual: WEERC Laboratory Sepideh Sadeghi South Dakota State University, [email protected] Suzette Burckhard South Dakota State University, [email protected] Christopher Schmit South Dakota State University, [email protected] Follow this and additional works at: https://openprairie.sdstate.edu/cvlee_manual Part of the Civil and Environmental Engineering Commons Recommended Citation Sadeghi, Sepideh; Burckhard, Suzette; and Schmit, Christopher, "Respirometry Test Manual: WEERC Laboratory" (2018). Civil and Environmental Engineering Reports and Manuals. 1. https://openprairie.sdstate.edu/cvlee_manual/1 This Other is brought to you for free and open access by the Department of Civil and Environmental Engineering at Open PRAIRIE: Open Public Research Access Institutional Repository and Information Exchange. It has been accepted for inclusion in Civil and Environmental Engineering Reports and Manuals by an authorized administrator of Open PRAIRIE: Open Public Research Access Institutional Repository and Information Exchange. For more information, please contact [email protected]. Respirometry Test Manual WEERC Laboratory Sepideh Sadeghi South Dakota State University, [email protected] Suzette Burckhard South Dakota State University, -

Cockroaches Breathe Discontinuously to Reduce Respiratory Water Loss

2773 The Journal of Experimental Biology 212, 2773-2780 Published by The Company of Biologists 2009 doi:10.1242/jeb.031310 Cockroaches breathe discontinuously to reduce respiratory water loss Natalie G. Schimpf*, Philip G. D. Matthews, Robbie S. Wilson and Craig R. White School of Biological Sciences, Faculty of Biological and Chemical Sciences, University of Queensland, Brisbane 4000, Australia *Author for correspondence (e-mail: [email protected]) Accepted 8 June 2009 SUMMARY The reasons why many insects breathe discontinuously at rest are poorly understood and hotly debated. Three adaptive hypotheses attempt to explain the significance of these discontinuous gas exchange cycles (DGCs), whether it be to save water, to facilitate gas exchange in underground environments or to limit oxidative damage. Comparative studies favour the water saving hypothesis and mechanistic studies are equivocal but no study has examined the acclimation responses of adult insects chronically exposed to a range of respiratory environments. The present research is the first manipulative study of such chronic exposure to take a strong-inference approach to evaluating the competing hypotheses according to the explicit predictions stemming from them. Adult cockroaches (Nauphoeta cinerea) were chronically exposed to various treatments of different respiratory gas compositions (O2, CO2 and humidity) and the DGC responses were interpreted in light of the a priori predictions stemming from the competing hypotheses. Rates of mass loss during respirometry were also measured for animals acclimated to a range of humidity conditions. The results refute the hypotheses of oxidative damage and underground gas exchange, and provide evidence supporting the hypothesis that DGCs serve to reduce respiratory water loss: cockroaches exposed to low humidity conditions exchange respiratory gases for shorter durations during each DGC and showed lower rates of body mass loss during respirometry than cockroaches exposed to high humidity conditions. -

Oxygen Consumption Rate V. Rate of Energy Utilization of Fishes: a Comparison and Brief History of the Two Measurements

Journal of Fish Biology (2016) 88, 10–25 doi:10.1111/jfb.12824, available online at wileyonlinelibrary.com Oxygen consumption rate v. rate of energy utilization of fishes: a comparison and brief history of the two measurements J. A. Nelson* Towson University, Department of Biological Sciences, 8000 York Road, Towson, MD 21252, U.S.A. Accounting for energy use by fishes has been taking place for over 200 years. The original, andcon- tinuing gold standard for measuring energy use in terrestrial animals, is to account for the waste heat produced by all reactions of metabolism, a process referred to as direct calorimetry. Direct calorime- try is not easy or convenient in terrestrial animals and is extremely difficult in aquatic animals. Thus, the original and most subsequent measurements of metabolic activity in fishes have been measured via indirect calorimetry. Indirect calorimetry takes advantage of the fact that oxygen is consumed and carbon dioxide is produced during the catabolic conversion of foodstuffs or energy reserves to useful ATP energy. As measuring [CO2] in water is more challenging than measuring [O2], most indirect calorimetric studies on fishes have used the rate of2 O consumption. To relate measurements of O2 consumption back to actual energy usage requires knowledge of the substrate being oxidized. Many contemporary studies of O consumption by fishes do not attempt to relate this measurement backto 2 ̇ actual energy usage. Thus, the rate of oxygen consumption (MO2) has become a measurement in its own right that is not necessarily synonymous with metabolic rate. Because all extant fishes are obligate aerobes (many fishes engage in substantial net anaerobiosis, but all require oxygen to complete their life cycle), this discrepancy does not appear to be of great concern to the fish biology community, and reports of fish oxygen consumption, without being related to energy, have proliferated. -

Polarographic Oxygen Sensors, the Oxygraph, and High-Resolution Respirometry to Assess Mitochondrial Function

12 POLAROGRAPHIC OXYGEN SENSORS, THE OXYGRAPH, AND HIGH-RESOLUTION RESPIROMETRY TO ASSESS MITOCHONDRIAL FUNCTION ERICH GNAIGER Department of General and Transplant Surgery, D.Swarovski Research Laboratory, Medical University of Innsbruck, Innsbruck, Austria; Oroboros Instruments, Innsbruck, Austria 1. Introduction 2. Polarographic oxygen sensor and traditional oxygraphy 3. High-resolution respirometry: the Oxygraph-2k 3.1. Calibration of polarographic oxygen sensors and oxygen concentration in respiration media at air saturation 3.2. From oxygraph slopes to respiratory flux corrected for background effects 4. Phosphorylation control protocol with intact cells 4.1. Titration steps of the PC protocol 4.2. Experimental example for the PC protocol 4.3. Flux control ratios from the PC protocol 5. Intact cells, permeabilized cells and tissue, or isolated mitochondria 5.1. Intact cells 5.2. Permeabilized cells and tissue 5.3. Isolated mitochondria 6. Titration protocols in permeabilized cells, permeabilized tissue preparations, and isolated mitochondria 7. Multisensor applications Drug-Induced Mitochondrial Dysfunction, Edited by James Dykens and Yvonne Will Copyright ©2008 John Wiley & Sons, Inc.: pp. 327-352. POLAROGRAPHIC OXYGEN SENSORS; THE OXYGRAPH-2k 328 1. INTRODUCTION Recent developments in high-resolution respirometry, combining advanced instrumentation with multiple substrate-uncoupler-inhibitor titration protocols, provide standardized and routine analyses of metabolic flux through various mitochondrial pathways. This technology allows assessments of membrane integrity (coupling of oxidative phosphorylation; cytochrome c release), of respiratory inhibition resulting from effects on the phosphorylation or on the electron transport systems, as well as activities of dehydrogenases, and metabolite transport across the inner mitochondrial membrane. These assessments are done via selective permeabilization of the cell membrane while leaving the mitochondrial membranes intact, or isolation of mitochondria, and can reveal acute drug effects on mitochondria. -

The Role of Discontinuous Gas Exchange in Insects: the Chthonic Hypothesis Does Not Hold Water Allen G

The Journal of Experimental Biology 207, 3477-3482 3477 Published by The Company of Biologists 2004 doi:10.1242/jeb.01168 The role of discontinuous gas exchange in insects: the chthonic hypothesis does not hold water Allen G. Gibbs1,* and Robert A. Johnson2 1Department of Ecology and Evolutionary Biology, 1041 E. Lowell Street, University of Arizona, Tucson, AZ 85721 USA and 2School of Life Sciences, Arizona State University, Tempe, AZ 85287-4501, USA *Author for correspondence (e-mail: [email protected]) Accepted 29 June 2004 Summary Insects breathe through valved openings (spiracles) in the chthonic hypothesis by simultaneously measuring their cuticle. Many insects open and close their spiracles in water loss and CO2 release in reproductive females a cyclic pattern (discontinuous gas-exchange cycles, or (queens) of the seed-harvester ant Pogonomyrmex DGC). These cycles were observed over half a century ago, barbatus, a burrowing species from North American their hypothesized function being to minimize loss of deserts. Queens used one of three patterns of gas water from the tracheal system. However, numerous exchange, discontinuous, cyclic and continuous. We recent studies have found that respiration accounts for a resolved the problem of separating cuticular transpiration small fraction of total water loss, and that insects stop and respiratory water loss for individuals that used performing DGC at times when this pattern would be continuous gas exchange by developing a regression most useful. Thus, the importance of cyclic gas exchange method that can be used across all patterns of gas for water conservation has been challenged. The leading exchange. The ratio of respiratory water loss to CO2 alternative is the chthonic hypothesis, which proposes that release did not differ among ants using different patterns DGC originated in insects from hypercapnic (high CO2) of gas exchange, in contrast to the expectation of the environments (e.g. -

Effect of Closed Versus Intermittent-Flow Respirometry on Hypoxia Tolerance in the Shiner Perch Cymatogaster Aggregata

Journal of Fish Biology (2016) 88, 252–264 doi:10.1111/jfb.12837, available online at wileyonlinelibrary.com Effect of closed v. intermittent-flow respirometry on hypoxia tolerance in the shiner perch Cymatogaster aggregata S. Snyder*†,L.E.Nadler‡, J. S. Bayley§, M. B. S. Svendsen‖, J. L. Johansen¶, P. Domenici** and J. F. Steffensen‖ *Scripps Institution of Oceanography, La Jolla, CA 92093-0208, U.S.A., ‡College of Marine and Environmental Sciences, ARC Centre of Excellence for Coral Reef Studies, James Cook University, Townsville, Qld 4811, Australia, §University of Aarhus, Aarhus 8000, Denmark, ‖University of Copenhagen, Marine Biological Laboratory, Biological Institute, Strandpromenaden 5, DK-3000 Helsingør, Denmark, ¶University of Texas Marine Science Institute, Port Aransas, TX 78373, U.S.A. and **CNR–IAMC, Istituto per l’Ambiente Marino Costiero, Località Sa Mardini, 09072 Torregrande, Oristano, Italy This study compares the critical oxygen saturation (O2crit) levels of the shiner perch Cymatogaster aggregata obtained using two different methods wherein hypoxia is induced either by the fish’s res- piration (closed respirometry) or by degassing oxygen with nitrogen (intermittent-flow respirometry). Fish exhibited loss of equilibrium at a higher O2 saturation in the closed respirometry method when compared with the intermittent-flow method. Utilization of closed respirometry yielded2crit O measure- ments that were almost twice as high as those obtained with intermittent-flow respirometry. The lower hypoxia tolerance in closed respirometry is consistent with additional stress, caused by a build-up of ammonia and carbon dioxide and a faster rate in dissolved oxygen decline. The results indicate that these two methods of determining hypoxia tolerance in aquatic organisms are not comparable, and that much care should be given to method choice.