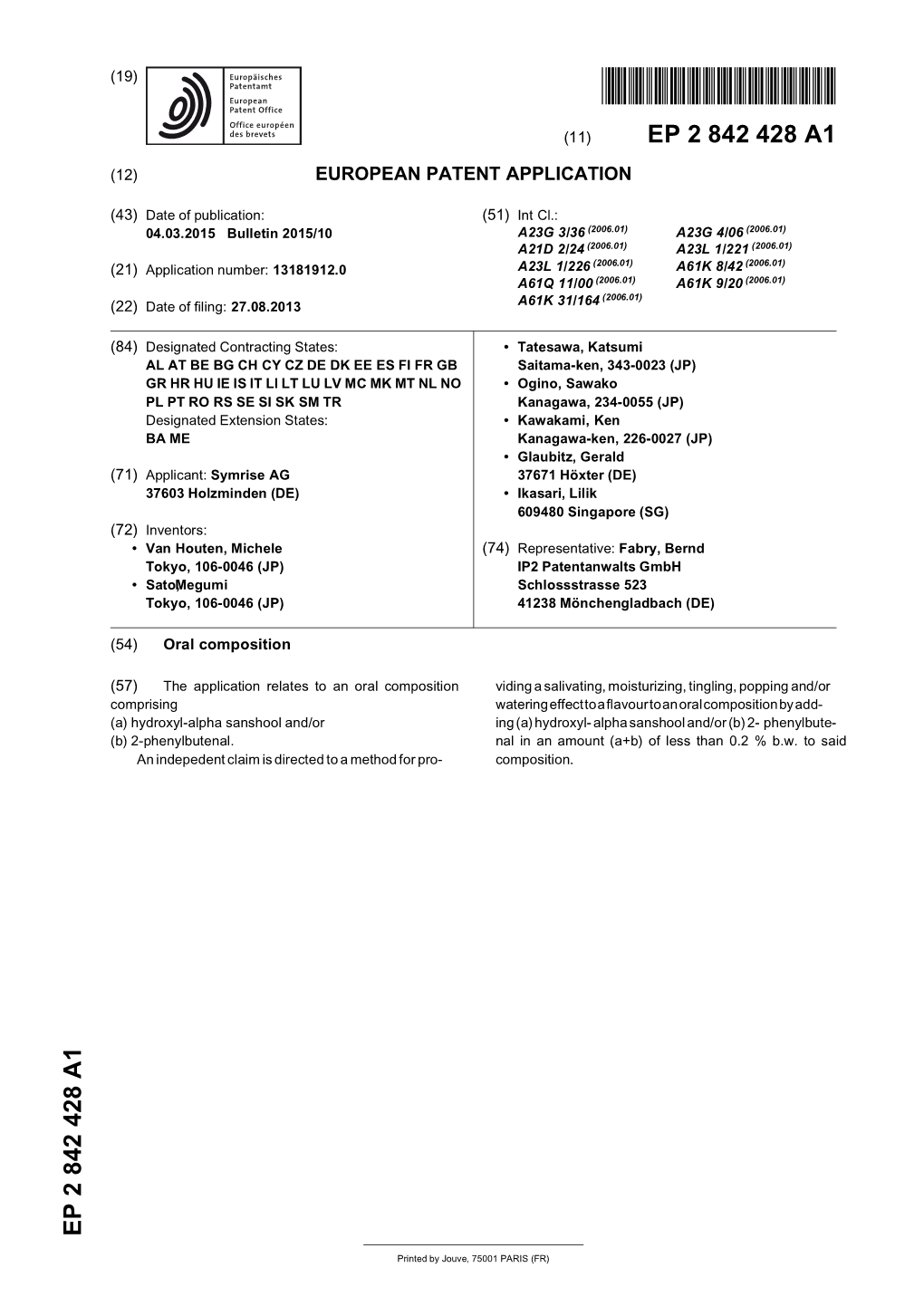

Oral Composition

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Technical Developments in the Use of Spices Dr David Baines Baines Food Consultancy Ltd

EUROPEAN SPICE ASSOCIATION GENERAL ASSEMBLY 2013 Technical Developments in the Use of Spices Dr David Baines Baines Food Consultancy Ltd Co-editor: Flavour Horizons TECHNICAL DEVELOPMENTS IN THE USE OF SPICES TOPICS: Recent health claims submitted to the EU for the use of spices Compounds in selected spices that have beneficial effects on health The use of spices to inhibit of carcinogen formation in cooked meats The growing use of spices in animal feeds Salt reduction using spices Interesting culinary herbs from Vietnam Recent Health Claims Submitted to the EU EU REGULATION OF HEALTH CLAIMS • The Nutrition and Health Claims Regulation, 1924/2006/EC is designed to ensure a high level of protection for consumers and legal clarity and fair competition for food business operators. • Claims must not mislead consumers; they must be, accurate, truthful, understandable and substantiated by science. • Implementation of this Regulation requires the adoption of a list of permitted health claims, based on an assessment by the European Food Safety Authority (EFSA) of the science substantiating the claimed effect and compliance with the other general and specific requirements of the Regulation. • This list of permitted health claims was adopted in May 2012 by the Commission and became binding on 14th December 2012. Food companies must comply from this date or face prosecution for misleading marketing. APPROVAL OF CLAIMS EU REGULATION OF HEALTH CLAIMS CLAIMS BY COMPONENT CLAIMS BY FUNCTION CLAIMS FOR SPICES – NOT APPROVED/ON HOLD SPICE CLAIM(S) Anise / Star Anise Respiratory Health, Digestive Health, Immune Health, Lactation Caraway Digestive Health, Immune Health, Lactation Cardamon Respiratory Health, Digestive Health, Immune Health, Kidney Health, Nervous System Health, Cardiovascular Health, Capsicum Thermogenesis, Increasing Energy Expenditure, Enhancing Loss of Calories, Body Weight Loss, Stomach Health, Reduction of Oxidative Stress, promotion of Hair Growth. -

Amplification of Oxidative Stress by a Dual Stimuli-Responsive Hybrid Drug

ARTICLE Received 11 Jul 2014 | Accepted 12 Mar 2015 | Published 20 Apr 2015 DOI: 10.1038/ncomms7907 Amplification of oxidative stress by a dual stimuli-responsive hybrid drug enhances cancer cell death Joungyoun Noh1, Byeongsu Kwon2, Eunji Han2, Minhyung Park2, Wonseok Yang2, Wooram Cho2, Wooyoung Yoo2, Gilson Khang1,2 & Dongwon Lee1,2 Cancer cells, compared with normal cells, are under oxidative stress associated with the increased generation of reactive oxygen species (ROS) including H2O2 and are also susceptible to further ROS insults. Cancer cells adapt to oxidative stress by upregulating antioxidant systems such as glutathione to counteract the damaging effects of ROS. Therefore, the elevation of oxidative stress preferentially in cancer cells by depleting glutathione or generating ROS is a logical therapeutic strategy for the development of anticancer drugs. Here we report a dual stimuli-responsive hybrid anticancer drug QCA, which can be activated by H2O2 and acidic pH to release glutathione-scavenging quinone methide and ROS-generating cinnamaldehyde, respectively, in cancer cells. Quinone methide and cinnamaldehyde act in a synergistic manner to amplify oxidative stress, leading to preferential killing of cancer cells in vitro and in vivo. We therefore anticipate that QCA has promising potential as an anticancer therapeutic agent. 1 Department of Polymer Á Nano Science and Technology, Polymer Fusion Research Center, Chonbuk National University, Backje-daero 567, Jeonju 561-756, Korea. 2 Department of BIN Convergence Technology, Chonbuk National University, Backje-daero 567, Jeonju 561-756, Korea. Correspondence and requests for materials should be addressed to D.L. (email: [email protected]). NATURE COMMUNICATIONS | 6:6907 | DOI: 10.1038/ncomms7907 | www.nature.com/naturecommunications 1 & 2015 Macmillan Publishers Limited. -

Retention Indices for Frequently Reported Compounds of Plant Essential Oils

Retention Indices for Frequently Reported Compounds of Plant Essential Oils V. I. Babushok,a) P. J. Linstrom, and I. G. Zenkevichb) National Institute of Standards and Technology, Gaithersburg, Maryland 20899, USA (Received 1 August 2011; accepted 27 September 2011; published online 29 November 2011) Gas chromatographic retention indices were evaluated for 505 frequently reported plant essential oil components using a large retention index database. Retention data are presented for three types of commonly used stationary phases: dimethyl silicone (nonpolar), dimethyl sili- cone with 5% phenyl groups (slightly polar), and polyethylene glycol (polar) stationary phases. The evaluations are based on the treatment of multiple measurements with the number of data records ranging from about 5 to 800 per compound. Data analysis was limited to temperature programmed conditions. The data reported include the average and median values of retention index with standard deviations and confidence intervals. VC 2011 by the U.S. Secretary of Commerce on behalf of the United States. All rights reserved. [doi:10.1063/1.3653552] Key words: essential oils; gas chromatography; Kova´ts indices; linear indices; retention indices; identification; flavor; olfaction. CONTENTS 1. Introduction The practical applications of plant essential oils are very 1. Introduction................................ 1 diverse. They are used for the production of food, drugs, per- fumes, aromatherapy, and many other applications.1–4 The 2. Retention Indices ........................... 2 need for identification of essential oil components ranges 3. Retention Data Presentation and Discussion . 2 from product quality control to basic research. The identifi- 4. Summary.................................. 45 cation of unknown compounds remains a complex problem, in spite of great progress made in analytical techniques over 5. -

Tips to Roast Vegetables Spice Guide

Tips to Roast Vegetables • Roast at a high oven temp- 400 to 450 degrees F • Chop vegetables in uniform size so they cook evenly • Don’t over crowd the pan, otherwise they will become soft • Roasting veggies with some oil will help them become crispier • To get the most flavor/crispier roast them on the top rack • Seasoning before putting them in the oven will add flavor • Flip veggies halfway through to ensure even cooking • When roasting multiple types of veggies, ensure they have similar cooking times. Good pairs include: Cauliflower and Broccoli cc Carrots and Broccoli Baby potatoes and Butternut Squash Onions and Bell Peppers Zucchini and Yellow Squash Asparagus and Leeks Spice Guide Table of Contents Spices by Cuisine Herbs and Spices 1 Mexican Coriander, Cumin, oregano, garlic powder, cinnamon, chili powder Herbs and Spices that Pair well with Proteins 2 Caribbean Chicken Fajita Bowl Recipe 3 All spice, nutmeg, garlic powder, cloves, cinnamon, ginger Shelf life of Herbs and Spices 4 French Nutmeg, thyme, garlic powder, rosemary, oregano, Herbs de Provence Spices by Cuisine 5 North African Tips to Roast Vegetables BP Cardamum, cinnamon, cumin, paprika, turmeric, ginger Cajun Cayenne, oregano, paprika, thyme, rosemary, bay leaves, Cajun seasoning Thai Basil, cumin, garlic, ginger, turmeric, cardamum, curry powder Mediterranean Oregano, rosemary, thyme, bay leaves, cardamum, cinnamon, cloves, coriander, basil, ginger Indian Bay leaves, cardamum, cayenne, cinnamon, coriander, cumin, ginger, nutmeg, paprika, turmeric, garam masala, curry powder Middle Eastern Bay leaves, cardamum, cinnamon, cloves, cumin, ginger, coriander, oregano, za’atar, garlic powder 5 Shelf Life of Herbs and Herbs and Spices Spices Herbs Herbs are plants that’s leaves can be used to add flavor to foods. -

Antibacterial Activity and Mechanism of Linalool Against Shewanella Putrefaciens

molecules Article Antibacterial Activity and Mechanism of Linalool against Shewanella putrefaciens Fengyu Guo 1,2,3, Qiong Liang 1, Ming Zhang 1, Wenxue Chen 1,2,3, Haiming Chen 1,2,3 , Yonghuan Yun 1,2,3 , Qiuping Zhong 1,2,3,* and Weijun Chen 1,2,3,* 1 College of Food Science and Technology, Hainan University, Haikou 570228, China; [email protected] (F.G.); [email protected] (Q.L.); [email protected] (M.Z.); [email protected] (W.C.); [email protected] (H.C.); [email protected] (Y.Y.) 2 Key Laboratory of Food Nutrition and Functional Food of Hainan Province, Haikou 570228, China 3 Hainan Provincial Engineering Research Center of Aquatic Resources Efficient Utilization in the South China Sea, Haikou 570228, China * Correspondence: [email protected] (Q.Z.); [email protected] (W.C.) Abstract: The demand for reduced chemical preservative usage is currently growing, and natural preservatives are being developed to protect seafood. With its excellent antibacterial properties, linalool has been utilized widely in industries. However, its antibacterial mechanisms remain poorly studied. Here, untargeted metabolomics was applied to explore the mechanism of Shewanella putrefaciens cells treated with linalool. Results showed that linalool exhibited remarkable antibacterial activity against S. putrefaciens, with 1.5 µL/mL minimum inhibitory concentration (MIC). The growth of S. putrefaciens was suppressed completely at 1/2 MIC and 1 MIC levels. Linalool treatment reduced the membrane potential (MP); caused the leakage of alkaline phosphatase (AKP); and released the DNA, RNA, and proteins of S. putrefaciens, thus destroying the cell structure and expelling the cytoplasmic content. -

Chapter 6—Clove Oil (Eugenol)

Chapter 6—Clove Oil (Eugenol) OH CH3 O Eugenol Chapter 6: Clove oil 6-2 6 Table of Contents — Clove Oil (Eugenol) 6.1 INTRODUCTION ......................................................................................................................................... 6-4 6.2 CLOVE OIL AND EUGENOL TOXICITY TO HUMANS AND LEVELS OF CONCERN ................ 6-6 6.2.1 HEALTH EFFECTS ...................................................................................................................................... 6-7 6.2.1.A Acute Effects—Sensitization ........................................................................................................... 6-7 6.2.1.B Acute Effects—Skin, Eyes and Respiratory System ........................................................................ 6-7 6.2.1.C Acute Effects—Systemic Poisoning ................................................................................................ 6-7 6.2.1.D Effects in Human Cells .................................................................................................................... 6-8 6.2.1.E Levels of Concern for Humans ........................................................................................................ 6-8 6.2.2 PESTICIDE ILLNESS REPORTS .................................................................................................................... 6-9 6.3 EUGENOL TOXICITY TO ANIMALS AND PLANTS AND LEVELS OF CONCERN .................... 6-10 6.3.1 MAMMALS ............................................................................................................................................. -

FEMA GRAS 29 December 2019 SUPPLEMENTARY INFORMATION 1

SUPPLEMENTARY INFORMATION 1: Identity for Natural Flavor Complexes as Evaluated by the Expert Panel The Identification Description as Reviewed by the FEMA FEMA No.1 FEMA Primary Name Expert Panel Rebaudioside M ≥80%; Rebaudioside D 5-20%; Total 4895 Rebaudioside M steviol glycosides ≥95%. Glutamic acid 35-40%; Other amino acids 1-2%; Total Corynebacterium glutamicum corn nitrogen 6-7%; Aliphatic primary alcohols, aldehydes, 4907 syrup fermentation product carboxylic acids, acetals and esters containing additional oxygenated functional groups 1-2%; Minerals 9-11% Inosine 5´-monophosphate 20-25%; Amino acids 7-8%; Corynebacterium stationis corn 4908 Minerals 23-25%; water 28-37%; Other nucleotides 1-2%; syrup fermentation product Total nitrogen 5-8% Supraglucosylated steviol glycosides 70-80%; Rebaudioside Glucosylated steviol glycosides, 4909 A 14-20%; Steviol glycosides not further glucosylated, each 70-80% individually, not to exceed 3%; Maltodextrin 3-10% Supraglucosylated steviol glycosides 30-40%; Rebaudioside Glucosylated steviol glycosides, A 5-8%; Not more than 4% stevioside; All other individual 4910 40% steviol glycosides not further glucosylated <3%; Maltodextrin 45-60% Stevioside 70-80%; Rebaudioside A 13-18%; Steviobioside 1- 3%; Rebaudioside C 2-3%; Total glycosides (including 4911 Stevia extract stevioside, 70% Rebaudioside D, Rebaudioside B, Rebaudioside F, Dulcoside A, and Rubusoside) <3% Derived from hibiscus blossom calyces (Hibiscus sabdariffa L.) , Hibiscus blossom extract is measured as water 30-60%; 4912 Hibiscus -

Understanding and Managing the Transition Using Essential Oils Vs

MENOPAUSE: UNDERSTANDING AND MANAGING THE TRANSITION USING ESSENTIAL OILS VS. TRADITIONAL ALLOPATHIC MEDICINE by Melissa A. Clanton A thesis submitted in partial fulfillment of the requirements for the Diploma of Aromatherapy 401 Australasian College of Health Sciences Instructors: Dorene Petersen, Erica Petersen, E. Joy Bowles, Marcangelo Puccio, Janet Bennion, Judika Illes, and Julie Gatti TABLE OF CONTENTS List of Tables and Figures............................................................................ iv Acknowledgments........................................................................................ v Introduction.................................................................................................. 1 Chapter 1 – Female Reproduction 1a – The Female Reproductive System............................................. 4 1b - The Female Hormones.............................................................. 9 1c – The Menstrual Cycle and Pregnancy....................................... 12 Chapter 2 – Physiology of Menopause 2a – What is Menopause? .............................................................. 16 2b - Physiological Changes of Menopause ..................................... 20 2c – Symptoms of Menopause ....................................................... 23 Chapter 3 – Allopathic Approaches To Menopausal Symptoms 3a –Diagnosis and Common Medical Treatments........................... 27 3b – Side Effects and Risks of Hormone Replacement Therapy ...... 32 3c – Retail Cost of Common Hormone Replacement -

Beneficial Effects of Stevioside on Ages, Blood Glucose, Lipid Profile and Renal Status in Streptozotocin-Induced Diabetic Rats

J Appl Biomed journal homepage: http://jab.zsf.jcu.cz DOI: 10.32725/jab.2019.013 Journal of Applied Biomedicine Original research article Beneficial effects of Stevioside on AGEs, blood glucose, lipid profile and renal status in streptozotocin-induced diabetic rats Urmila Aswar 1 *, Vinayak Gogawale 2, Pankaj Miniyar 2, Yugendra Patil 3 1 Bharati Vidyapeeth (Deemed to be University), Poona College of Pharmacy, Erandwane, Pune, Maharashtra, India 2 STES’s Sinhgad Institute of Pharmacy, Savitribai Phule Pune University, Narhe, Pune, Maharashtra, India 3 National Chemical Laboratory, Pune, Maharashtra, India Abstract The advanced glycated end products (AGEs) are formed in the diabetic patients; it is a major cause of macrovascular and microvascular complications in diabetes. Clinically there is no treatment available for the AGEs. Stveoside (Stv), a sweetener has potent anti-diabetic and anti-oxidant activity. Hence, we investigated its use in prevention of AGEs formation using in vitro and in vivo models. Diabetes was induced by streptozotocin (STZ). These rats were kept without treatment till blood HbA1c was markedly increased. They were then divided into 5 groups and treated orally with vehicle or Metformin (MET) or Stv respectively for 28 days. Every 7th day, animals were tested for body weight and blood glucose (BG). On the last day of treatment, all the groups were evaluated for physiological and biochemical parameters, histopathology and AGEs; N-carboxymethyl-lysine (CML) estimation. Stv showed inhibition of AGEs in in vitro as well as in in vivo respectively. Positive effects were seen on the BG, lipid profile and urine parameters as well it showed reduced formation of CML. -

Oxidation of Geraniol Using Niobia Modified With

Revista Facultad de Ingeniería, Universidad de Antioquia, No.91, pp. 106-112, Apr-Jun 2019 Oxidation of geraniol using niobia modified with hydrogen peroxide Oxidación de geraniol utilizando niobia modificada con peróxido de hidrógeno Jairo Cubillos 1*, Jose J. Martínez 1, Hugo Rojas 1, Norman Marín-Astorga2 1Grupo de Catálisis, Escuela de Ciencias Químicas, Universidad Pedagógica y Tecnológica de Colombia UPTC. Avenida Central del Norte 39-115. A.A. 150003 Tunja. Boyacá, Colombia. 2Eurecat U.S. Incorporated. 13100 Bay Park Rd. C.P. 77507. Pasadena, Texas, USA. ABSTRACT: Nb2O5 bulk and Nb2O5 modified with H2O2 were studied in the epoxidation of geraniol at 1 bar and room temperature. The structural and morphological properties ARTICLE INFO: for both catalysts were very similar, indicating that the peroxo-complex species were not Received: April 27, 2018 formed. The order of the reaction was one with respect to geraniol and close to zero respect Accepted: April 16, 2019 to H2O2, these values fit well with the kinetic data obtained. The geraniol epoxidation is favored by the presence of peroxo groups, which is reached using an excess of H2O2. Moreover, the availability of the geraniol to adopt the three-membered-ring transition state AVAILABLE ONLINE: was found as the best form for this type of compound. April 22, 2019 RESUMEN: El óxido de niobio (niobia), Nb2O5 y Nb2O5 modificado con H2O2 fue explorado como catalizador en la epoxidación de geraniol a 1 bar y temperatura ambiente. Las KEYWORDS: propiedades estructurales y morfológicas de ambos catalizadores fueron muy similares, Niobium oxide, peroxo lo cual sugiere que no se formaron especies de complejo peroxo. -

Cinnamaldehyde Induces Release of Cholecystokinin and Glucagon-Like

animals Article Cinnamaldehyde Induces Release of Cholecystokinin and Glucagon-Like Peptide 1 by Interacting with Transient Receptor Potential Ankyrin 1 in a Porcine Ex-Vivo Intestinal Segment Model Elout Van Liefferinge 1,* , Maximiliano Müller 2, Noémie Van Noten 1 , Jeroen Degroote 1 , Shahram Niknafs 2, Eugeni Roura 2 and Joris Michiels 1 1 Laboratory for Animal Nutrition and Animal Product Quality (LANUPRO), Department of Animal Sciences and Aquatic Ecology, Ghent University, 9000 Ghent, Belgium; [email protected] (N.V.N.); [email protected] (J.D.); [email protected] (J.M.) 2 Centre for Nutrition and Food Sciences, Queensland Alliance for Agriculture and Food Innovation, The University of Queensland, St. Lucia, QLD 4072, Australia; [email protected] (M.M.); [email protected] (S.N.); [email protected] (E.R.) * Correspondence: [email protected] Simple Summary: The gut is able to “sense” nutrients and release gut hormones to regulate diges- tive processes. Accordingly, various gastrointestinal cell types possess transient receptor potential channels, cation channels involved in somatosensation, thermoregulation and the sensing of pungent and spicy substances. Recent research shows that both channels are expressed in enteroendocrine Citation: Van Liefferinge, E.; Müller, M.; Van Noten, N.; Degroote, J.; cell types responsible for the release of gut peptide hormones such as Cholecystokinin (CCK) and Niknafs, S.; Roura, E.; Michiels, J. Glucagon-like Peptide-1 (GLP-1). A large array of herbal compounds, used in pig nutrition mostly for Cinnamaldehyde Induces Release of their antibacterial and antioxidant properties, are able to activate these channels. Cinnamaldehyde, Cholecystokinin and Glucagon-Like occurring in the bark of cinnamon trees, acts as an agonist of Transient Receptor Potential Ankyrin 1 Peptide 1 by Interacting with (TRPA1)-channel. -

Liquid−Liquid Extraction of Linalool from Methyl Eugenol with 1-Ethyl-3-Methylimidazolium

Open Chem., 2019; 17: 564–570 Research Article Tuğba Erkoç, Lutfullah M. Sevgili*, Selva Çavuş* Liquid−Liquid Extraction of Linalool from Methyl Eugenol with 1-Ethyl-3-methylimidazolium Hydrogen Sulfate [EMIM][HSO4] Ionic Liquid https://doi.org/10.1515/chem-2019-0067 received January 22, 2018; accepted January 9, 2019. present such as membrane separation [3], pervaporation [3] and extraction [4]. Because of the significant Abstract: The liquid–liquid equilibrium (LLE) data for advantages of ionic liquids, they have a great potential a ternary system {methyl eugenol + linalool +1-ethyl-3- to be investigated for extraction and other separation methylimidazolium hydrogen sulfate [EMIM][HSO4]} processes [5, 6]. Detailed economic analysis of hydrogen (Meu-Lin-IL) were measured at 298.2 K and atmospheric sulfate based ILs was performed [7]. It was reported that pressure. The Othmer–Tobias correlation was used to large volume-IL based applications may be commercially verify the reliability of the experimental tie-line data. The feasible and also, ILs can be as inexpensive as typical solubility curves were obtained using the cloud point organic solvents [7]. Studies on the liquid-liquid titration indicating the liquid-liquid equilibrium of the extraction with ionic liquids showed that ionic liquid ternary system was in Type II class where two immiscible is an efficient solvent for the separation process. [8-14]. curve pairs were attained. Distribution coefficients, ILs can easily be synthesized with a conceivable cost separation factors and selectivity were calculated for [9] and ILs also have advantages in terms of economy the immiscibility regions. The calculated results were such as decrease in purification steps and reduced compared with the experimental data.