( 12 ) United States Patent

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Food and Culture Around the World Handbook

The Food and Culture Around the World Handbook Helen C. Brittin Professor Emeritus Texas Tech University, Lubbock Prentice Hall Boston Columbus Indianapolis New York San Francisco Upper Saddle River Amsterdam Cape Town Dubai London Madrid Milan Munich Paris Montreal Toronto Delhi Mexico City Sao Paulo Sydney Hong Kong Seoul Singapore Taipei Tokyo Editor in Chief: Vernon Anthony Acquisitions Editor: William Lawrensen Editorial Assistant: Lara Dimmick Director of Marketing: David Gesell Senior Marketing Coordinator: Alicia Wozniak Campaign Marketing Manager: Leigh Ann Sims Curriculum Marketing Manager: Thomas Hayward Marketing Assistant: Les Roberts Senior Managing Editor: Alexandrina Benedicto Wolf Project Manager: Wanda Rockwell Senior Operations Supervisor: Pat Tonneman Creative Director: Jayne Conte Cover Art: iStockphoto Full-Service Project Management: Integra Software Services, Ltd. Composition: Integra Software Services, Ltd. Cover Printer/Binder: Courier Companies,Inc. Text Font: 9.5/11 Garamond Credits and acknowledgments borrowed from other sources and reproduced, with permission, in this textbook appear on appropriate page within text. Copyright © 2011 Pearson Education, Inc., publishing as Prentice Hall, Upper Saddle River, New Jersey, 07458. All rights reserved. Manufactured in the United States of America. This publication is protected by Copyright, and permission should be obtained from the publisher prior to any prohibited reproduction, storage in a retrieval system, or transmission in any form or by any means, electronic, mechanical, photocopying, recording, or likewise. To obtain permission(s) to use material from this work, please submit a written request to Pearson Education, Inc., Permissions Department, 1 Lake Street, Upper Saddle River, New Jersey, 07458. Many of the designations by manufacturers and seller to distinguish their products are claimed as trademarks. -

Trade Marks Journal No: 1770 , 07/11/2016 Class 28

Trade Marks Journal No: 1770 , 07/11/2016 Class 28 2006660 10/08/2010 RABINDER KRISHAN NIGAM trading as ;METRO PLAYING CARD COMPANY METRO HOUSE,METRO ESTATE,VIDYANAGRI MARG,MUMBAI-400 098 MANUFACTURERS AND MERCHANTS INDIAN NATIONAL Address for service in India/Agents address: UNITED LEGAL SERVICES 202, JAI SINGH BUSINESS CENTER, 119/120, PARSI WADA, SAHAR ROAD, ANDHERI (E), MUMBAI-400 099,INDIA Used Since :01/01/1971 MUMBAI PLAYING CARDS. REGISTRATION OF THIS TRADE MARK SHALL GIVE NO RIGHT TO THE EXCLUSIVE USE OF THE.EXPRESSION EXCELLENT EXCEPT AS SUBSTANTIALLY SHOWN.. 2566 Trade Marks Journal No: 1770 , 07/11/2016 Class 28 2078165 30/12/2010 M AND B ENGINEERING LIMITED MB HOUSE, 51, CHANDRODAYA SOCIETY, STADIUM ROAD, AHMEDABAD-380 014, GUJARAT STATE, INDIA. MANUFACTURER, MERCHANT, GENERAL TRADER, IMPORTERS AND EXPORTERS A COMPANY INCORPORATED UNDER THE COMPANIES ACT, 1956. Address for service in India/Agents address: RAJENDRA H. BHANSALI. 22, DHARAMNATH SOCIETY, NEAR C.L.HOSPITAL, OLD CAMP ROAD, SHAHIBAUG, AHMEDABAD - 380 004. Used Since :26/11/2007 AHMEDABAD GAMES AND PLAYTHINGS, GYMNASTIC AND SPORTING ARTICLES NOT INCLUDED IN OTHER CLASSES, DECORATIONS FOR CHRISTMAS TREES BEING INCLUDED IN CLASS-28. 2567 Trade Marks Journal No: 1770 , 07/11/2016 Class 28 TRIWIZARD CHESS 2208802 21/09/2011 ADITYA NIGAM & ASHISH NIGAM C-116, C-SECTOR SHAHPURA BHOPAL-462016 MANUFACTURER & TRADER Address for service in India/Attorney address: SMART BRAIN 88, GROUND FLOOR, DEFENCE ENCLAVE, OPP. CORPORATION BANK, VIKAS MARG, DELHI-92 Used Since :17/09/2011 MUMBAI CHESS GAMES & OTHER RELATED ARTICLES 2568 Trade Marks Journal No: 1770 , 07/11/2016 Class 28 2336424 23/05/2012 ASHRAF ANSARI trading as ;INDUS GYM EQUIPMENT UNIT NO 1, CHIPWALA COMPOUND, TUNGA VILLAGE, SAKI VIHAR ROAD, OPP. -

Snack Menu Is Subject to Change

Should you have any specific dietary requirements or food preferences we will be more than happy to oblige. Simply speak to a member of the team for assistance creating your bespoke culinary experience. Flavors of Maldives Regionally sourced and inspired cuisine Chef’s special PP Pork product Chili Our dishes are freshly prepared in kitchens that handle gluten, seafood, nuts, eggs and other food products. Should you have any specific allergies, dietary requirements or concerns, we will be more than happy to assist. All prices are in US Dollars & subject to 10% service charge and 12% G.S.T. Snack menu is subject to change. North Huvadhoo, Gaafu Alifu Atoll, Republic of Maldives, Tel: +960 682 1234 Fax: +960 682 1235 Email: [email protected] THE BAR SNACK MENU Available in The Bar from 12:00 pm – 10:30 pm SHORT EATS Truffle Steak Fries 16 Rustic potato, parmesan and garlic crumble Maldivian Hedika Tasting 16 Bajiyaa, biskeemiyaa and gulha Gambas al Alio 16 Sauteed shrimp, garlic, white wine Chili and parsley sauce Spicy Fried Calamari 16 Lemon aioli, garlic crumble Coconut Shrimp 18 Raspberry and mustard coulis Pan Fried Beef Mince Sticker "Guo Tie" 29 Garlic vinegar, soy sauce, and chili paste SUBSTANTIAL Greek Salad Wrap 22 Grilled tortilla, Greek salad Hadahaa’s Fish and Chips 25 Tartar sauce, lemon cheek PP Club Sandwich 25 Roasted chicken breast, fried egg and crispy bacon Our dishes are freshly prepared in kitchens that handle gluten, seafood, nuts, eggs and other food products. Should you have any specific allergies, dietary requirements or concerns, we will be more than happy to assist. -

Erythrina Variegata (Coral Tree) Fabaceae (Legume Family)

Annex 914 Edward Balfour, Cyclopædia of India and of Eastern and Southern Asia (2d Supp.) (1862) Annex 915 “Trema species”, Firewood Crops: Shrub and Tree Species for Energy Production (1980) Annex 916 Jim Croft, “An Introduction to the Structure of Ferns and their Allies”, Australian National Botanic Gardens (1999), available at https://www.anbg.gov.au/fern/structure.html (accessed 31 May 2016) Home > Gardens | CANBR > ferns > Structure SEARCH An Introduction to the Structure of Ferns and their Allies Prepared by Jim Croft ([email protected]) Introduction Habit, Lifeform Stems, Rhizomes Leaves, fronds Sporophyte fertility Cytology . Life Cycle . Terrestrial . Growth form . Stipe . Sori . Chromosomes . Gametophyte . Epiphyte . Branching . Branching . Sporangia . Polyploidy . Sporophyte . Aquatic . Protection . Rachis . Spores . Internal . Lamina . Heterospory . Roots . Venation . Dimorphism . Polymorphism . Sporocarps . Bulbils Introduction The ferns and their allies share a lot of commom morphlogy with the other vascular plants and in many cases the same descriptive terminology is used. However, there are some fundamental and significant differences of structure unique to the pteridophytes and a specialized terminology has evolved to descdribe these. The most obvious difference between the pteridophytes and the remainder of the vascular plants is that the ferns and their allies do not produce large floral or reproductive structures that give rise to seeds which eventually develop into the next generation of plants. Pteridophytes reproduce and disperse by means of microscopic spores, the structure and development of which is every bit as intricate and amazing as the flowers of the higher plants. This outline covers the easily recognised features of the ferns and their alies and mentions many of the technical terms used to describe them. -

January 2020 Meet Me in the Maldives

EVERYWHERE YOU GO Director HUYEN NGUYEN Managing Director JIMMY VAN DER KLOET [email protected] Managing Editor & CHRISTINE VAN Art Director [email protected] Online Editor JAMES PHAM [email protected] This Month’s Cover Staff Photographer VY LAM [email protected] Image provided by LUX* South Ari Atoll Resort & Villas Graphic Designer LAM SON VU See our review on pages 38, 39 [email protected] www.luxresorts.com For advertising, please contact: ƠI VIỆT NAM (tập End of Year) English 0948 779 219 NHIỀU TÁC GIẢ Vietnamese 0932 164 629 Ngôn ngữ: tiếng Việt - Anh NHÀ XUẤT BẢN THANH NIÊN 64 Bà Triệu - Hoàn Kiếm - Hà Nội ĐT (84.04) 39424044-62631719 Fax: 04.39436024. Website: nxbthanhnien.vn Email: [email protected] Chi nhánh: 145 Pasteur Phường 6, Quận 3, TP. Hồ Chí Minh ĐT: (08) 62907317 Chịu trách nhiệm xuất bản: Giám đốc, Tổng biên tập Lê Thanh Hà Biên tập: Tạ Quang Huy Thực hiện liên kết xuất bản: Cty TNHH Truyền thông và Quảng cáo Ơi Việt Nam 14 D1 Đường Thảo Điền, Phường Thảo Điền, Quận 2, TP. Hồ Chí Minh Số lượng 6000 cuốn, khổ 21cm x 29,7cm Đăng ký KHXB: 2445-2019/CXBIPH/36-73/TN QĐXB số: 841/QĐ - TN ISBN số: 978-604-9846-66-3 General [email protected] Chế bản và in tại Công ty TNHH In - Thương mại Trần Châu Phúc Inquiries [email protected] 509 Tân Hòa Đông, P. Bình Trị Đông, Q. Bình Tân, Tp.HCM Website: www.oivietnam.com 4 01/2020 Contents WINE & DINE RESTAURANT REVIEWS An inside look at Chickita, a farm-to-restaurant concept restaurant that’s growing in popularity among diners VY LAM CHICKITA RESTAURANT / IMAGE -

1961 1C Per Copy VOLUME 22-NO, 10 at the Post Ouice at Detroit, Mlcn

_1£1&1&.£.£11I5.5.&.&"511&11I&.& •• 11I&••• 1 •• 1ISIZ.£IS.'.Q;lk.5.a.S&. 5&.U.SIIII.5.C.,.a_dllll. _, .&.,.&"••._ ...(...11II..... $....S?1IlI4111111..... .-.?~.... -=..._ ....P .......'!'._----P----~~~-...,......,..--~-_.. AU the News of All the Pointes • • • Every Thursday ross~ ews Morning Complete News Coverag'e of All rite Poiutes Home 01 the News '4.00 Per Vesr 20 PAGES - THREE SECTIONS - SECTION I Entered as Second Class Matter GROSSE POINTE, MICHIGAN, MARCH 9, 1961 1c Per COpy VOLUME 22-NO, 10 at the Post OUice at Detroit, Mlcn. Small Town Holiday Celebration? IIEADLINES Water Rate Boost City, County 01 tbe · f S d Involved in \VEEK Su b]ect 0 tu Y Claims Fight As Compiled by tbe Grosse Poiute Netvs By Farms and City :~:rJe~~':~1~~;i~~;.I~; . Seek Settlements Thursday, March 2 Accountants Who Annually Review Factors Determin- i A VIGOROUS FIGHT against Woods Council (ook ex~ President Kennedy's school-aid ing Rates Will Furnish Answer; Attorneys ception March 6 to two program is expected from the Hold Meetings communications from the hierarchy of the Roman Catho- Wayne County Drain Com- The amount of a proposed increase in the cost of lic Church. The National Catho- missioner's 0 f f ice which water sold by Grosse Pointe Farms to the City of Grosse stated tllat there are only lic Welfare conference held 2'\ Pointe, its lone customer, will be determined by the unpublicized meeting yesterday eight outstanding claims Farms' official and public accountants, who annually presumably to draft a "Cathol~c from Woods property own~ review factors that determine the rates. -

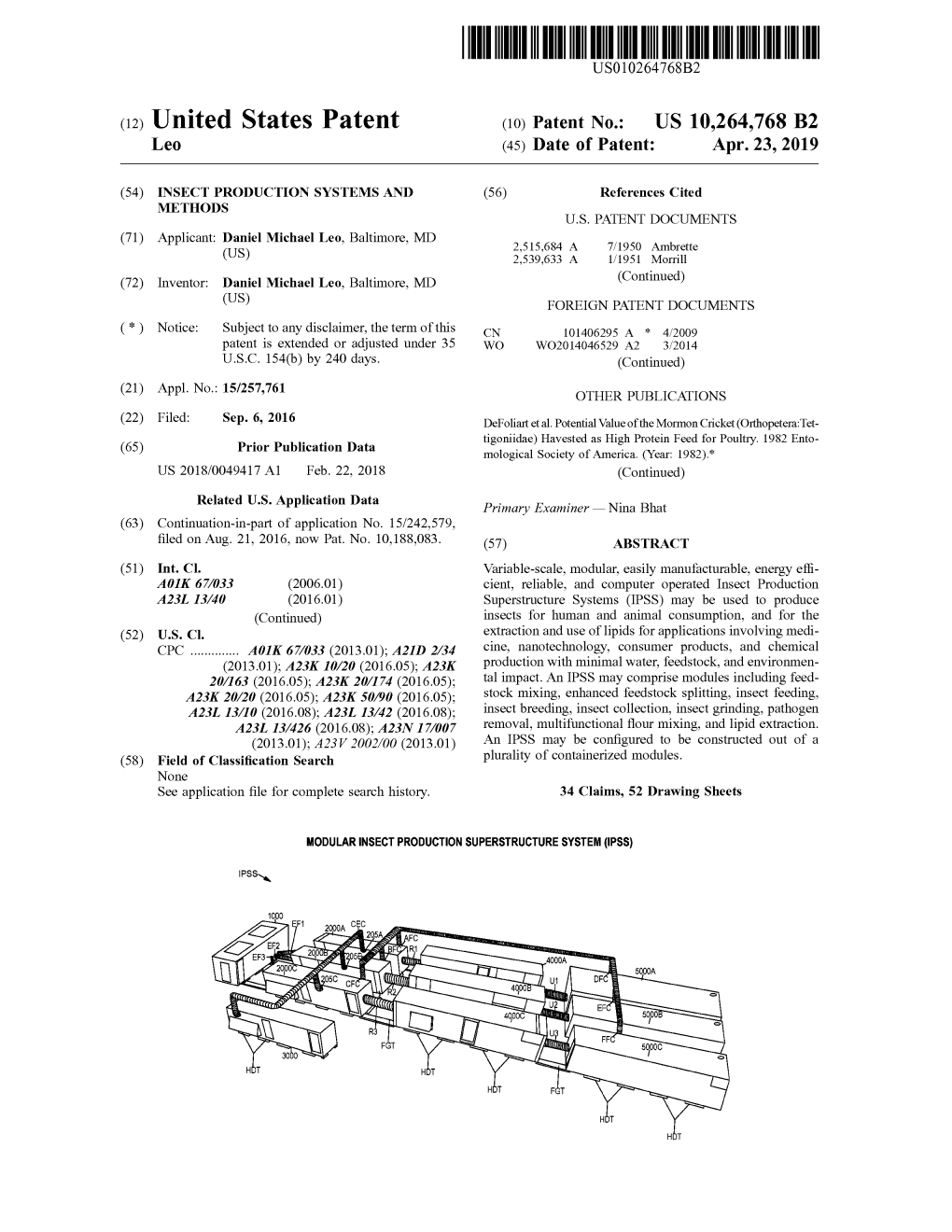

( 12 ) United States Patent

US010188086B2 (12 ) United States Patent (10 ) Patent No. : US 10 , 188 , 086 B2 Leo ( 45 ) Date of Patent: * Jan . 29 , 2019 ( 54 ) INSECT PRODUCTION SYSTEMS AND ( 58 ) Field of Classification Search METHODS USPC .. .. 426 / 557 , 615, 635 ; 47 / 58 . 1 ; 119 /6 . 5 , 15 See application file for complete search history . (71 ) Applicant : Daniel Michael Leo, Baltimore , MD (US ) ( 56 ) References Cited ( 72 ) Inventor: Daniel Michael Leo , Baltimore , MD (US ) U . S . PATENT DOCUMENTS 4 ,438 ,725 A * 3 / 1984 O 'Sullivan . .. A01K 61 / 54 ( * ) Notice : Subject to any disclaimer, the term of this 119 / 238 patent is extended or adjusted under 35 9 ,642 , 344 B2 * 5 / 2017 Unger . .. .. .. A01K 67 /033 U . S . C . 154 ( b ) by 0 days. 2009 /0277076 A1 * 11/ 2009 Boston . .. .. A01M 1 / 106 43 / 132 . 1 This patent is subject to a terminal dis 2012 /0017834 A1 * 1 /2012 Holland .. .. .. A01M 1 / 106 claimer. 119 /6 . 5 2012/ 0107475 A1 * 5 / 2012 Kolb .. .. .. A23L 1 / 1041 ( 21) Appl. No .: 15 /664 , 490 426 / 507 (Continued ) (22 ) Filed : Jul. 31, 2017 Primary Examiner — Nina Bhat (65 ) Prior Publication Data US 2017 /0325431 A1 Nov. 16 , 2017 (57 ) ABSTRACT Related U . S . Application Data Variable - scale , modular, easily manufacturable , energy effi cient, reliable , and computer operated Insect Production (63 ) Continuation - in -part of application No . 15 / 257, 854 , Superstructure Systems (IPSS ) may be used to produce filed on Sep . 6 , 2016 , which is a continuation - in - part insects for human and animal consumption , and for the of application No . 15 /242 , 579 , filed on Aug . -

Dream Maldives Menus Sample

Dream Maldives Menus sample Tuesday Breakfast: Bread Toast, Butter Jam, Coffee, Tee, Juice, Fresh Fruit Lunch: Spaghetti, Grilled Fish, Green Salad, French Fries, Fresh Fruit, Tea & Coffee Tea time: Tuna Sandwich, Tea & Coffee Dinner: Vegetable Noodles, Diced Beef, Boiled Vegetable, Bread, Pineapple, Tea & Coffee Wednesday Breakfast: Bread Toast, Butter Jam, Coffee, Tee, Juice, Fresh Fruit Lunch: Singapore Rice, Roast Chicken, Brinajal Masala, Russian Salad, Fruit Salad, Tea & Coffee Tea time: Chocolate Cake, Tea & Coffee Dinner: Spaghetti, Olive OU, Grilled ReefFish, Bread, Cheese Powder, Caramel Pudding, Tea & Coffee Thursday (BEACH BUFFET for dinner if weather permits) Breakfast: Bread Toast, Butter Jam, Coffee, Tee, Juice, Fresh Fruit Lunch: Yellow Rice, Beef Curry, Vegetable Salad, Papadom, Fresh Fruit, Tea & Coffee Tea time: Coconut & Biscuit, Tea & Coffee Dinner: Spaghetti, Grilled ReefFish Whole, BBQ Chicken, Fried Sausage, Boiled Egg, Japanese Salad, Grilled Potato, Bread, Cheese Powder, BBQ Sauce, Rice Pudding, Banana Friday Breakfast: Bread Toast, Butter Jam, Coffee, Tee, Juice, Fresh Fruit Lunch: Spice Rice, Devilled Chicken, Mashed Potato, Green Salad, Pineapple, Tea & Coffee Tea time: Egg Samosa, Biscuit, Tea & Coffee Dinner: Mushroom Pasta, Grilled in Brown Sauce & Cashew nuts, Chicken Soup, Bread, Biscuit, Pudding, Tea & Coffee. Saturday Breakfast: Bread Toast, Butter Jam, Coffee, Tee, Juice, Fresh Fruit Lunch: White Rice, Chicken Curry, Pappadom, Mixed Vegetable Salad, Fried Brinjal, Watermelon, Tea & Coffee Tea time: -

Africa Middle East Indian Ocean Replace with Woman in a Veil Or African Woman Rabat ISRAEL 1 MOROCCO Jerusalem Amman JORDAN

The World at Your Doorstep Africa Middle East Indian Ocean replace with woman in a veil or african woman Rabat ISRAEL 1 MOROCCO Jerusalem Amman JORDAN EGYPT UAE Abu Dhabi Muscat about MIDDLE EAST OMAN TBi Trail Blazer Tours India Pvt. Ltd. was established in 2007 by travel industry professionals and taken over in 2010 by the well known Katgara Group, pioneers in tourism, setting new standards of innovation and excellence. Our core services include inbound tourism, corporate travel, conferences, MALDIVES SRI LANKA incentives, domestic and international holidays. With over 250 experienced professionals at offices Colombo Laccadive Sea in major cities, we offer quality services at the best price. TBi has won several prestigious awards including the National Tourism Award in recognition of its outstanding performance. AFRICA KENYA Nairobi We Believe TANZANIA • That travel promotes peace and understanding Dodoma SEYCHELLES • That integrity, innovation and service excellence are crucial to success We Offer MOZAMBIQUE • The best of personalised services, backed by years of knowledge and experience Harare MAURITIUS • Quality services and superior value ZIMBABWE NAMIBIA MADAGASCAR • The highest professional and ethical standards REUNION ISLAND BOTSWANA Mozambique Gabarone Windhoek Maputo Channel Pretoria South Atlantic Sea INDONESIASOUTH AFRICA TBi The Indian Ocean Your guide to Africa, Middle East and the Indian Ocean Islands Welcome to the world of TBi, a world of carefree, memorable holidays. Explore Africa, the Middle East and the Indian Ocean Islands like never before. Choose from popular destinations or discover lesser known ones. See as much or as little as you like. We’ll take you to on exciting wildlife and desert safaris, let you explore historical sites, enjoy adventures across the stunning landscapes and leave you to unwind at your own pace. -

1769 , 31/10/2016 Class 29 1772999 12/01/2009 Trading As ;M/S. WESTERN OIL INDUSTRISES Address

Trade Marks Journal No: 1769 , 31/10/2016 Class 29 1772999 12/01/2009 MR. MOHANLAL J. VACHHANI MR. MOHANLAL J. VACHHANI MR. ASHOKKUMAR M. VACHHANI MR. SANJAYKUMAR M. VACHHANI trading as ;M/S. WESTERN OIL INDUSTRISES BEDESHWAR, JAMNAGAR 361002 MANUFACTURE & MERCHANT Address for service in India/Agents address: A R SHAH & CO. 401, ANUSHREE BUILDING, NR. BANK OF BARODA, USMANPURA, AHMEDABAD 380013 Used Since :01/04/1996 AHMEDABAD EDIBLE OILS. 3904 Trade Marks Journal No: 1769 , 31/10/2016 Class 29 1911399 20/01/2010 SHREE RAM SPICES PVT.LTD. PLOT NO.10,BMC INDUSTRIAL ESTATE,M.G.CROSS ROAD NO.1,SAI NAGAR,KANDIVALI(W)MUMBAI-400 067. MANUFACTURERS AND MERCHANTS (A COMPANY REGISTERED UNDER THE INDIAN COMPANIES ACT, 1961 Proposed to be Used MUMBAI DRY FRUITS, FRUITS(FROSTED),FRUITS(CRYSTALLIZED),BEANS, PRESERVED, FROZEN FRUITS. 3905 Trade Marks Journal No: 1769 , 31/10/2016 Class 29 1932147 08/03/2010 SANJAY KUMAR trading as ;NARELA OIL TRADERS 2098, NAI BASTI, NARELA, DELHI - 110040 MANUFACTURER & TRADER Address for service in India/Agents address: LALJI ADVOCATES A - 48, (LALJI HOUSE) YOJNA VIHAR, DELHI -110092. Used Since :01/08/2008 DELHI ALL KINDS OF MUSTARD OIL & EDIBLE OILS INCLUDED IN CLASS 29 3906 Trade Marks Journal No: 1769 , 31/10/2016 Class 29 2029930 28/09/2010 SAKTHI MASALA PRIVATE LIMITED trading as ;SAKTHI MASALA PRIVATE LIMITED NO. 6, MAMARATHUPALAYAM, ERODE- 638 004. MANUFACTURERS AND MERCHANTS A COMPANY INCORPORATED UNDER THE INDIAN COMPANIES ACT Address for service in India/Agents address: V. VEERARAGHAVAN, ADVOCATE. NO.10, SECOND MAIN ROAD, C. I. -

Visual Communication: Urban Representations in Latin America

Editor geral Maurício Azevedo Visual Communication: urban representations in Latin America Preparação de originais Eduardo Melo Comunicación Visual: Revisão representaciones urbanas en América Latina Bruno Germer Comunicação Visual: Fotos da capa representações urbanas na América Latina Above below, de hlobo (hamilton lobo) David William Foster Porto Alegre, dezembro de 2008 Denize Correa Araujo ISBN 978-85-62069-11-6 (orgs.) Alguns direitos reservados. Venda proibida. Contents Preface .....................................................................................7 Chicalense way of life, los usos y costumbres de los mexicalenses a través de la mirada del documental. ...............20 Adolfo Soto y Manuel Ortiz “Mirar(nos) nos vuelve libres u oprimidos”: análisis ideológico de algunas formas de representación visual recientes en América Latina, sus supuestos, premisas y repercusiones morales. ............................................................41 Adrián Ferrero editoraplus.org info 3 Orfandades, fúrias e amores nas costuras das cidades: uma análise subjetivista dos filmes “Linha de Passe” e “Última Parada 174” ..............................................................62 Ana Amélia Brasileiro Medeiros Silva The many faces of Buenos Aires: migrants, foreigners and immigrants in contemporary argentine cinema (1996-2008) ....110 Carolina Rocha Of gay caballeros and other noble heroes................................139 David William Foster Molduras urbanas: cenas do subdesenvolvimento ..................187 Denize Correa Araujo -

Cardammom Lounge Dinner

HAVAADHU DINNER AT CARDAMOM LOUNGE Behold to the fairytale beauty of Cardamom. The soft dim of candlelight and torch-fire light the way to your private sunken table retreat. Moonlight casts through the overhead trees. Marvel over the awe-inspiring setting and surroundings. A banquet of authentic Maldivian cuisine awaits you, new tastes to behold with every mouthful. SHORT EATS (S) CONDIMENTS Gulha (Fish Ball) Theyo Roshi (Chapatti) (V) Bajiya (Tuna Samosa) Theluli Faiy (Fried Drumstick Leaf) (GF) (V) Ma’s roshi (Flat Tuna Bread) Mango Asaara (Pickled Mango) (GF) (V) Lunbo and Fiya (Lime Cheek and Raw Onion) (GF) (V) SOUP (S) Githeyo Mirus (Maldivian Chopped Chili) (GF) (V) Garudhiya (Maldivian Traditional Fish Soup) Mas Mirus (Kata Sambal) (GF) (S) Kaashi Huni (Grated Fresh Coconut) (GF) (V) SALADS (GF) (V) Dhiyaa Hakuru (Local Palm Sugar) (GF) (V) Kuhlafilla Fathu Mashuni (Maldivian Rocket Leave Fenukehkki Ala (Boiled Yam) (GF) (V) Salad) & An’bu Satani (Raw Mango Salad) Paa Paru (Papadam) (GF) (V) MAINS DESSERT (V) Roosia Baiy (Patna Rice) (GF) (V) Dhonkiyo Kaju (Banana Fritters) & Pandan Ice-Cream (D) Kukulhu Riha (Chicken Curry) (GF) Kandu Kukulhu (Tuna Curry) (GF) (S) Bashi Hiki Riha (Eggplant Dry Curry) (GF) (V) USD $250++ per person A – Alcohol D - Dairy Products GF - Gluten Free N – Nuts P – Pork RP - Raw Protein S – Seafood V -Vegetarian Should you have any specific dietary requirement or food preferences we will be more than happy to oblige. Simply refer to the our restaurant team for assistance creating your bespoke culinary experience. Prices are quoted in US dollars and subject to 10% service charge and 12% government taxes.