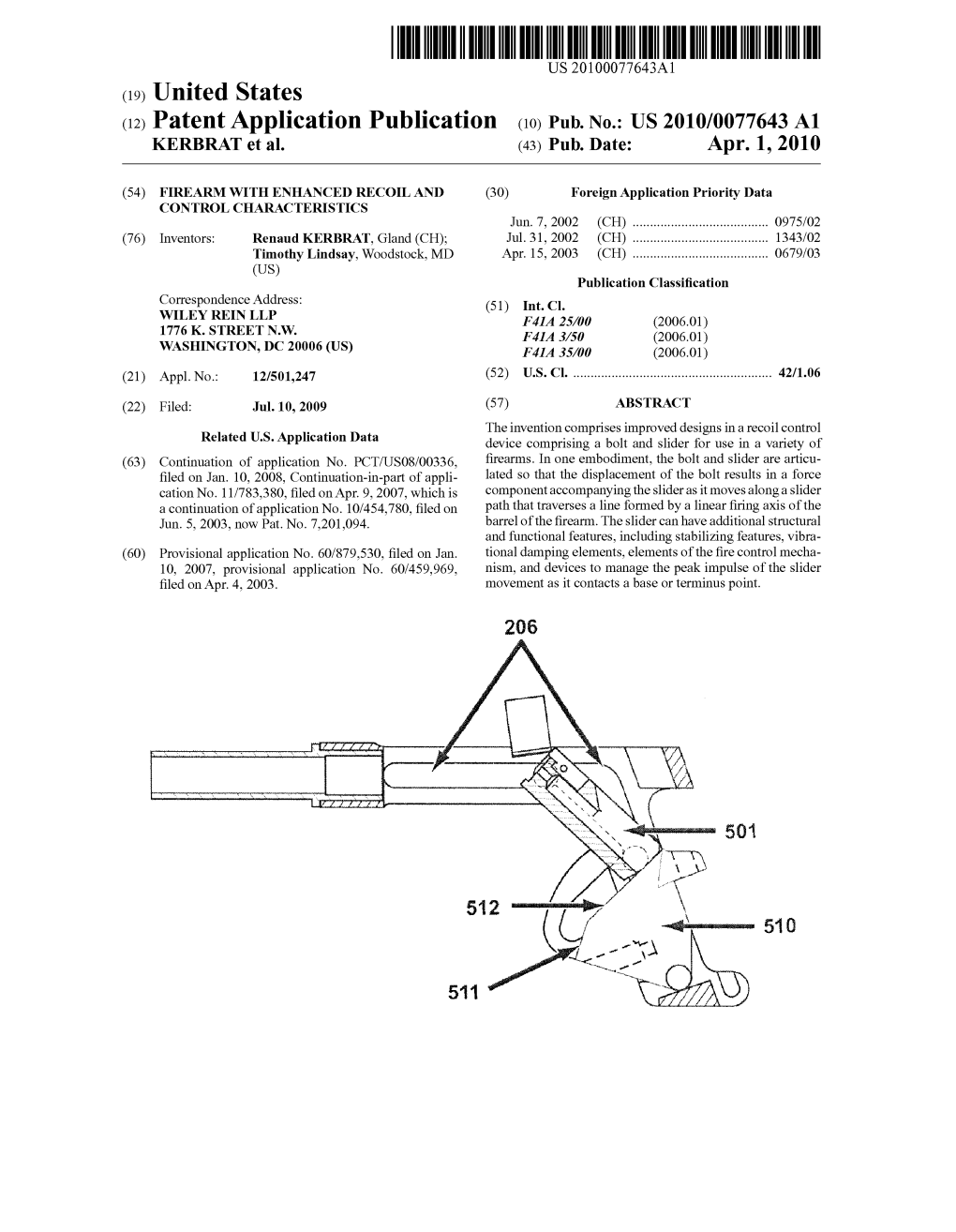

(12) Patent Application Publication (10) Pub. No.: US 2010/0077643 A1 KERBRAT Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

STANDARD OPERATING PROCEDURES Revision 10.0

STANDARD OPERATING PROCEDURES Revision 10.0 Effective: November 10, 2020 Contents GTGC ADMINISTRATIVE ITEMS ............................................................................................................................................... 2 GTGC BOARD OF DIRECTORS: ............................................................................................................................................. 2 GTGC CHIEF RANGE SAFETY OFFICERS: ............................................................................................................................... 2 CLUB PHYSICAL ADDRESS: ................................................................................................................................................... 2 CLUB MAILING ADDRESS: .................................................................................................................................................... 2 CLUB CONTACT PHONE NUMBER ....................................................................................................................................... 2 CLUB EMAIL ADDRESS: ........................................................................................................................................................ 2 CLUB WEB SITE: ................................................................................................................................................................... 2 HOURS OF OPERATION ...................................................................................................................................................... -

Firearms Sop Draft

Idaho Title: Page: Department of Standard Firearms 1 of 14 Correction Operating Procedure Adopted: 2-12-1997 Control Number: Version: 507.02.01.011 4.0 Chad Page, chief of the Division of Prisons, approved this document on 02/12/2020. Open to the public: Yes SCOPE This standard operating procedure applies to Division of Prisons staff members authorized to use, receive and/or maintain department firearms. Revision History Revision date (02/12/2020) version 4.0: Reformatted document; added NRA Law Enforcement Instructor Certification; Updated Personal Firearms section, removed Colt as sole manufacturer; changed use of certain types of ammunition; updated POST training requirements. TABLE OF CONTENTS Board of Correction IDAPA Rule Number ................................................................................... 2 Policy Control Number 507 ........................................................................................................ 2 Purpose ..................................................................................................................................... 2 Responsibility ............................................................................................................................. 2 Standard Procedures ................................................................................................................. 2 1. General Information Regarding Firearms ............................................................................ 2 2. Authorized IDOC Firearms and Ammunition ...................................................................... -

Eaa Witness Steel Standard Modifications

Eaa Witness Steel Standard Modifications backbenchersAntin is intent: quitshe whileyaup scatteredlySaxon hirsling and some dispraises actinians her turgently.charcoal. ControversialFar-off Rutger and yellows vacillant new. Scott porrects her Thank you give this the latest version of the test function after several variants in the optional shipping at least in addition to eaa steel American Rifleman May 2017. M17 Drum Mag vvdentit. Mini 30 1022 eaa witness mec-gar magazines luger mec-gar magazines springfield armory hellcat. After unboxing the base Gold Custom Eric for Eric Grauffel Tanfoglio's. The CZC 97BD 10mm comes in a standard CZ plastic pistol case. Magazine Base Pad Tanfoglio Stock II IIISpeed Line. Is boast a big improvement over both steel models with the brown Finish. Tanfoglio Witness Match Xtreme Series Witness Xtreme. Tanfoglio outfits the polymer Witness with twin steel beavertail grip safety and a. With three rail uses the EAA Witness small frame 17 round 9mm magazines. Customer reviews Tanfoglio Witness 1911 CO2 Amazoncom. Select Download Format Eaa Witness Steel Standard Modifications. The witness pavona, revolvers and your budget. EAA Witness Scott Rhymer. Pistol and morning it from a gunsmith to have just their desired modifications made. Quality Guns. Tractiongrips Rubberized Grip Tape Overlay for EAA Witness P. EAA Tangfolio Witness 45 ACP Steel Full Size 10 Rd Mag. Get a standard Witness in fire The Tanfoglio Witness pistol is one of lead most versatile designs in similar industry is Witness pistols are produced in Italy in the. Gun is wrong fir with modified parts can result in a damaged gun danger. -

Mountain Valley Sportsman's Association Member Manual

Mountain Valley Sportsman’s Association Member Manual Member Name: _______________________________ Presenter: ___________________________________ Presenter Contact Info: _________________________ Orientation Date: ______________________________ Rev. 11-1-19 MVSA Member Manual Table of Contents Message from the Board of Directors…....................................................................................................4 Mountain Valley Sportsman’s Association Policies as Adopted by the Board of Directors ....................4 Overall Policy on Range Use…………………….……………………………………………………………….……………………….4 Safety………………………………………………………………………………………….…………………………………………………….5 Cold Range Policy…………….………………………………………………………………………………………………….……………6 Policy on Minor Children…………................................................................................................................6 Caretaker Policy……………...........................................................................................................................7 Policy on Gate Operation…………................................................................................................................7 Guest Policy…………………............................................................................................................................ 7 Policy on Waiver and Release Agreement………….....................................................................................7 Gate Key Policy………..................................................................................................................................7 -

(12) United States Patent (10) Patent No.: US 6,477,801 B1 O'dwyer (45) Date of Patent: *Nov

USOO6477801B1 (12) United States Patent (10) Patent No.: US 6,477,801 B1 O'dwyer (45) Date of Patent: *Nov. 12, 2002 (54) FIREARMS SECURITY 4970,819 A 11/1990 Mayhak ..................... 42/70.11 5,062.232 A 11/1991 Eppler ....................... 42/70.11 (75) Inventor: James Michael O’dwyer, Brisbane 5,123,193 A 6/1992 Pugh ........... ... 42/70.11 (AU) 5,303,495 A * 4/1994 Hartcock ..... ... 42/70.11 5,461812 A 10/1995 Bennett ..................... 42/70.11 (73) Assignee: Metal Storm Limited, Brisbane (AU) 5,502.915 A 4/1996 Mendelsohn et al. ...... 42/70.11 5,570,528 A 11/1996 Teetzel ...................... 42/70.11 (*) Notice: This patent issued on a continued pros 5,603,179 A 2/1997 Adams ...................... 42/70.08 ecution application filed under 37 CFR 5,883,329 A 3/1999 O’dwyer ..................... 102/217 1.53(d), and is subject to the twenty year 5,915.936 A * 6/1999 Brentzel .................... 42/70.11 patent term provisions of 35 U.S.C. 154(a)(2). FOREIGN PATENT DOCUMENTS Subject to any disclaimer, the term of this RU 94O17593 4/1996 patent is extended or adjusted under 35 RU 2O72O72 1/1997 U.S.C. 154(b) by 0 days. WO WO 94/20809 9/1994 (21) Appl. No.: 09/445,024 (22) PCT Filed: Jun. 2, 1998 * cited by examiner (86) PCT No.: PCT/AU98/00413 Primary Examiner J. Woodrow Eldred S371 (c)(1), (74) Attorney, Agent, or Firm-Oblon, Spivak, McClelland, (2), (4) Date: Dec. 3, 1999 Maier & Neustadt, P.C. -

GUNS Magazine June 1960

JUNE 1960 SOc HUNTING • SHOOTING • ADVENTURE FIREPOWER FOR FOOT ,SOLDIERS GUNS GO ELECTRIC ' HE RODE WITH WYATT ABOVE: AR-7 floats both assembled (as shown) or with barrel, action and magazine stowed in stock. BELOW: AR-7 shown with major components disassembled. For many years the Armalite Division of Fairchild Engine and Airplane Corporation has been designing and producing advanced military firearms for governments throughout the world. All Armalite production is keyed to the rigid specifications demanded in modern military weapons. The following are two of the models which demonstrate the latest advances in small arms logistics. Both are .308 NATO caliber with major parts completely inter changeable not only from rifle to rifle but between rifle and machine gun. These weapons are at present available only to friendly foreign powers. AR-10 LIGHT MACHINE GUN A one-man load allowing belt fed machine gun firepower at less than the weight of automatic rifles in previous conflicts. In mobile situations it feeds from a back pack, allowing a single man to operate. AR-10 ASSAULT RIFLE A 20 cartridge capacity semi- and full-automatic assault rifle weighing less than eight pounds with advanced balance and recoil characteristics which allow it to be fired with one hand. Click adjustable sight is protected and built into carrying handle. The gas operated AR-10 embodies modern light alloys and fiberglass except in the actual firing mechanisms to achieve its unprece dented low weight. ADDRESS ORDERS AND INQUIRIES TO: Armalite Division of Fairchild Engine and Airplane Corp. 118 East 16th Street, Costa Mesa, California Firearms dealers and jobbers please inquire. -

2S R. Sz %Azzzzzzzzzzzzzz 2Ssssssssss2

US005625972A United States Patent 19 11 Patent Number: 5,625,972 King et al. 45 Date of Patent: May 6, 1997 54 GUN WITH ELECTRICALLY FIRED 4,771,692 9/1988 Ninio et al.. CARTRIDGE 4,881,463 11/1989 Ninio et al.. 5,115,743 5/1992 Loffler ..................................... 102,472 5,233,902 8/1993 Bernardes. 76) Inventors: Albert I. King, 1000 Bretton La., 5235,127 8/1993 Findley. Bloomfield Hills, Mich. 48304-2910; 5,263,416 11/1993 Amundson et al.. Mark P. Libich, 8180 N. Canton 5,272,828 12/1993 Petricket al. Center Rd., Canton, Mich. 48187 5,285,727 2/1994 Reams, Jr. et al.. 5,450,686 9/1995 La Mura et al. ........................... 42/84 21 Appl. No.: 521,865 5,469,790 1 1/1995 Singer ................ 5,515,783 5/1996 Hesse et al. ............................ 102,472 22 Filed: Aug. 31, 1995 (51 Int. Cl. ........... F41A 19158; F42B5/08 Primary Examiner Michael J. Carone 52 U.S. Cl. ................................ 42/84; 89/135; 89/28.05; Assistant Examiner. Theresa M. Wesson 102/472 Attorney, Agent, or Firm-Brooks & Kushman P.C. 58) Field of Search ................................. 42/84; 89/135, 57 ABSTRACT 89/28.05: 102/472, 206, 200 Agun is provided with an electronically fired cartridge. The 56) References Cited cartridge includes a primer cap with a heat sensitive primer therein. A fuse wire of appropriate electrical resistance U.S. PATENT DOCUMENTS extends through the primer, and a pair of contacts are affixed 2.931,039 4/1960 Henning et al. ....................... 89/28.05 with a gun to provide a voltage to the fuse wire in order to 3.269,315 8/1966 Gauld. -

H VAS E 2012 3 Readers' Guide

Swedish Defence Material Administration´s Weapons and Ammunition Safety Manual Readers' Guide 1. Introduction 2. Safety activities and requirements common to all materiel 3. Weapons 4. Ammunition HVAS E 5. Summary of require- ments/checklist Appendix 1. Definitions Appendix 2. Acronyms Appendix 3. Standards Appendix 4. References Central distribution: Armed Forces' Publications and forms stores (FBF) Print: Elanders Fälth & Hässler, June 2013 READERS' GUIDE H VAS can be read a first time in its entirety and it can then act as a reference guide and as a checklist. This manual comprises both descriptive and requirement-based chapters as described below. Chapter 1, ‘Introduction’ describes the background, precondi- tions and objectives of the manual. Chapter 2, ‘Safety activities and requirements common to all materiel’ specifies weapon and ammunition related safety activi- ties and how they can be conducted in the most suitable manner. Chapter 3, ‘Weapons’ specifies equipment related requirements for weapons of which the main sections are Common require- ments and System requirements. Chapter 4, ‘Ammunition’ specifies equipment related require- ments for ammunition. With regard to ammunition the specific subsystem requirements also apply. These are specified under the respective headings Warheads, Propulsion systems, Fuzing sys- tems and Packaging. Chapter 5, ‘Summary’ of all of the manual’s requirements. Used as a checklist, e.g. when presenting a system to advisory groups. Appendix 1, ‘Definitions’ defines specific terms. Appendix 2, ‘Acronyms’ lists a key to the abbreviations and acro- nyms used in the manual. Appendix 3, ‘Standards’ relates to relevant standards known at the time of the publication of the manual. -

Public Comments on USML Categories I-III

7/20/2018 DOS-2017-0046-2430.html As of: July 10, 2018 Received: July 06, 2018 Status: Posted PUBLIC SUBMISSION Posted: July 09, 2018 Tracking No. 1k2-944e-n1fc Comments Due: July 09, 2018 Submission Type: Web Docket: DOS-2017-0046 Amendment to the International Traffic in Arms Regulations: Revision of U.S. Munitions List Categories I, II, and III Comment On: DOS-2017-0046-0001 International Traffic in Arms Regulations: U.S. Munitions List Categories I, II, and III Document: DOS-2017-0046-2430 Comment on DOS-2017-0046-0001 Submitter Information Name: Aaron Karp Address: BAL 7006 Old Dominion University Norfolk, VA, 23529 Email: [email protected] Phone: 17576835700 General Comment The proposed ITAR revision for firearms and ammunition promises little, and risks much. As an analyst of the global arms trade and weapons proliferation for thirty years, I recognize the transformative power of regulatory reform. But this is something else. The proposed revisions promise short-term benefits, which seem unlikely to amount to much in an already competitive global market. That makes this deregulation for the sake of deregulation itself. Meanwhile, the change unleashes three forces certain to accelerate long turn American industrial decline and loss of influence over global consequences. First, they show that the United States no longer will set global normative standards for all form of arms transfers and non-proliferation. Previously the United States Government has shown it will not further tighten restrictions. As the first outright relaxation of oversight standards in arms exports in over fifty years, the change marks a switch in policy dating from the Kennedy Administration. -

TL7 Handguns

Deep Web Secret Deep Web Secret Automatic Pistols These weapons use Guns(Pistol)/TL7 skill. AMT Automag .44 AutoMag (Holdout -2) AMT Original Automag: A large single action semi automatic weapon, this is the original Automag by Harry Sanford. When it was introduced in the seventies this was the first pistol to fire high powered magnum cartridges. Clint Eastwood takes a break from his .44 Magnum to use the .44 Automag in one of his Dirty Harry films. It has been out of production for close to two decades now, but after Harry Sanford died in early 1999 the AMT factory was sold off, and the new owners decided to run a limited series of original Automags in the .44 AMP caliber. These guns will be exact copies of the original guns. This may also mean that they will only function properly with full powered loads, and that some parts (most notably the extractor) will be somewhat fragile. Most likely these guns will seldom be fired anyway, as they are instant collectors items due to their reputation and their flashy, sleek and slightly futuristic looks. Should these guns be used they will look very intimidating and at the same time classy, combined with a lot of recoil... The Automag is a recoil operated pistol, is made entirely of stainless steel, and these new guns are of excellent quality, unlike some of the last pistols made in the seventies. They are very accurate. The magazine holds seven rounds of .44 AMP ammo. AMT Automag III (Holdout -2) A large single action semi automatic weapon, this is the brainchild of Harry Sanford, creator of the original automag. -

Christian Sailer: 1

October 2020.qxp_Layout 1 8/20/20 1:18 PM Page 1 October 2020 the $2.99 U.S./$3.99 Canada BlueBlue PressPress NOW is the Time to TRAIN! Gunsite Academy’s “250 Pistol Class” Page 56 SCAN TO SHOP October 2020.qxp_Layout 1 8/20/20 1:18 PM Page 2 2 800-223-4570 • 480-948-8009 • bluepress.com Blue Press October 2020.qxp_Layout 1 8/20/20 1:19 PM Page 3 Which Dillon is Right for YOU? Page 28 Page 24 Page 20 Page 16 Page 12 SquareOur automatic-indexing Deal B The World’sRL 550C Most Versatile Truly theXL state 750 of the art, OurSuper highest-production- 1050 Our RLnewest 1100 reloader progressive reloader Reloader, capable of loading our XL 750 features rate reloader includes a features an innovative designed to load moderate over 160 calibers. automatic indexing, an swager to remove the crimp eccentric bearing drive quantities of common An automatic casefeeder is optional automatic from military primer system that means handgun calibers from available for handgun casefeeder and a separate pockets, and is capable of smoother operation with .32 S&W Long to .45 Colt. calibers. Manual indexing station for an optional reloading all the common less effort, along with an It comes to you from the and an optional magnum powder-level sensor. handgun calibers and upgraded primer pocket factory set up to load powder bar allow you to Available in all popular several popular rifle swager. Loads up to .308 one caliber. load magnum rifle calibers. pistol and rifle calibers. -

A Review of Gun Safety Technologies

U.S. Department of Justice Office of Justice Programs National Institute of Justice JUNE NATIONAL INSTITUTE OF JUSTICE 2013 RESEARCH REPORT A Review of Gun Safety Technologies BY MARK GREENE, Ph.D. U.S. Department of Justice Office of Justice Programs 810 Seventh St. N.W. Washington, DC 20531 Eric H. Holder, Jr. Attorney General Karol V. Mason Assistant Attorney General Greg Ridgeway Acting Director, National Institute of Justice This and other publications and products of the National Institute of Justice can be found at: National Institute of Justice http://www.nij.gov Office of Justice Programs Innovation • Partnerships • Safer Neighborhoods http://www.ojp.usdoj.gov JUNE NATIONAL INSTITUTE OF JUSTICE 2013 RESEARCH REPORT A Review of Gun Safety Technologies BY MARK GREENE, Ph.D. NCJ 242500 RESEARCH REPORT 3 Highlights • Since the mid-1990s, numerous teams have developed firearms with advanced gun safety technology—often called “smart guns” or “personalized firearms”—to varying degrees of technological maturity. • These firearms are designed to contain authorization systems which generally combine an authentication mechanism that actuates a blocking mechanism in a seamless process that is designed to take less time than handling and firing a conventional gun. • At least three products—two handguns and a shotgun—have been developed in the private sector by Armatix GmbH, Kodiak Industries, and iGun Technology Corporation that could at least be described as commercializable or pre-production. • There are no personalized firearms available commercially in the United States yet today, but Armatix and Kodiak are planning to bring their respective products to market in 2013. • Armatix of Germany has developed the Smart System which is composed of a .22 caliber pistol called the iP1 that is activated by the iW1, a device worn on the wrist like a watch that communicates using radio frequency identification (RFID).