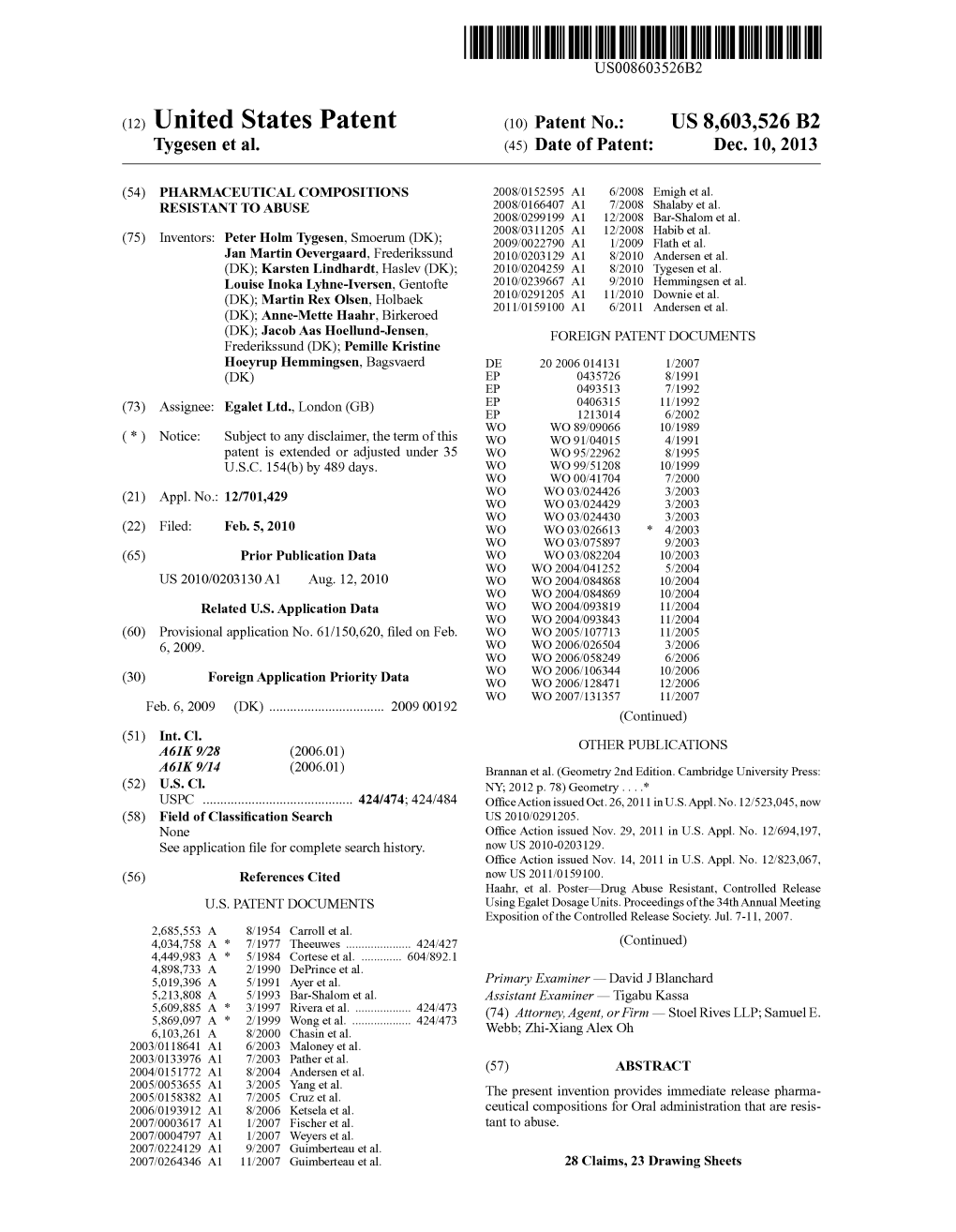

(12) United States Patent (10) Patent No.: US 8,603,526 B2 Tygesen Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Automated Annotation of Structurally Uncharacterized Metabolites in Human Metabolomics Studies by Systems Biology Models

Technische Universität München Automated annotation of structurally uncharacterized metabolites in human metabolomics studies by systems biology models Jan-Dominik Bernd Quell 2019 Fakultät Wissenschaftszentrum Weihenstephan für Ernährung, Landnutzung und Umwelt Technische Universität München Lehrstuhl für Experimentelle Bioinformatik Automated annotation of structurally uncharacterized metabo- lites in human metabolomics studies by systems biology models Jan-Dominik Bernd Quell Vollständiger Abdruck der von der Fakultät Wissenschaftszentrum Weihenstephan für Er- nährung, Landnutzung und Umwelt der Technischen Universität München zur Erlangung des akademischen Grades eines Doktors der Naturwissenschaften (Dr. rer. nat.) genehmigten Dissertation. Vorsitzender: Prof. Dr. Dmitrij Frischmann Prüfer der Dissertation: 1. Prof. Dr. Hans-Werner Mewes 2. Prof. Dr. Bernhard Küster Die Dissertation wurde am 28.11.2018 bei der Technischen Universität München eingereicht und durch die Fakultät Wissenschaftszentrum Weihenstephan für Ernährung, Landnutzung und Umwelt am 28.01.2019 angenommen. „Der Mensch muß bei dem Glauben verharren, daß das Unbegreifliche begreiflich sei; er würde sonst nicht forschen.“ Johann Wolfgang von Goethe i Danksagung Zunächst möchte ich mich ganz besonders bei meinem Doktorvater (Hans-)Werner Mewes bedanken, der mir nicht nur die Möglichkeit gegeben hat an seinem Institut des Helmholtz Zentrums München sowie seinem Lehrstuhl an der Technischen Uni- versität München in Forschung und Lehre zu arbeiten, sondern auch meine Laufbahn -

Title Effects of N-Acetyl-Leucine and Its Enantiomers in Niemann-Pick

bioRxiv preprint doi: https://doi.org/10.1101/826222; this version posted October 31, 2019. The copyright holder for this preprint (which was not certified by peer review) is the author/funder. All rights reserved. No reuse allowed without permission. Title Effects of N-Acetyl-Leucine and its enantiomers in Niemann-Pick disease type C cells Danielle te Vruchte1, Anthony Galione2, Michael Strupp3 and Michiko Mann1 1IntraBio Ltd, Oxford University Begbroke Science Park, Woodstock Road, Oxford, UK 2Department of Pharmacology, University of Oxford, Mansfield Road, Oxford, UK 3Department of Neurology and German Center for Vertigo and Balance Disorders, Ludwig Maximilians University, Munich, Germany Corresponding author Danielle te Vruchte Email: [email protected] bioRxiv preprint doi: https://doi.org/10.1101/826222; this version posted October 31, 2019. The copyright holder for this preprint (which was not certified by peer review) is the author/funder. All rights reserved. No reuse allowed without permission. Conflicts of Interest A.G. is a cofounder, shareholder and consultant to IntraBio. M.Y-M and D.t.V. are shareholders in IntraBio. M.S. acts as a consultant for Abbott, Actelion, AurisMedical, Heel, IntraBio and Sensorion, is a shareholder of IntraBio and Joint Chief Editor of the Journal of Neurology, Editor in Chief of Frontiers of Neuro-otology and Section Editor of F1000. M.S. has received speaker’s honoraria from Abbott, Actelion, Auris Medical, Biogen, Eisai, Grunenthal, GSK, Henning Pharma, Interacoustics, Merck, MSD, Otometrics, Pierre-Fabre, TEVA, UCB. bioRxiv preprint doi: https://doi.org/10.1101/826222; this version posted October 31, 2019. The copyright holder for this preprint (which was not certified by peer review) is the author/funder. -

(12) Patent Application Publication (10) Pub. No.: US 2006/0110428A1 De Juan Et Al

US 200601 10428A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0110428A1 de Juan et al. (43) Pub. Date: May 25, 2006 (54) METHODS AND DEVICES FOR THE Publication Classification TREATMENT OF OCULAR CONDITIONS (51) Int. Cl. (76) Inventors: Eugene de Juan, LaCanada, CA (US); A6F 2/00 (2006.01) Signe E. Varner, Los Angeles, CA (52) U.S. Cl. .............................................................. 424/427 (US); Laurie R. Lawin, New Brighton, MN (US) (57) ABSTRACT Correspondence Address: Featured is a method for instilling one or more bioactive SCOTT PRIBNOW agents into ocular tissue within an eye of a patient for the Kagan Binder, PLLC treatment of an ocular condition, the method comprising Suite 200 concurrently using at least two of the following bioactive 221 Main Street North agent delivery methods (A)-(C): Stillwater, MN 55082 (US) (A) implanting a Sustained release delivery device com (21) Appl. No.: 11/175,850 prising one or more bioactive agents in a posterior region of the eye so that it delivers the one or more (22) Filed: Jul. 5, 2005 bioactive agents into the vitreous humor of the eye; (B) instilling (e.g., injecting or implanting) one or more Related U.S. Application Data bioactive agents Subretinally; and (60) Provisional application No. 60/585,236, filed on Jul. (C) instilling (e.g., injecting or delivering by ocular ion 2, 2004. Provisional application No. 60/669,701, filed tophoresis) one or more bioactive agents into the Vit on Apr. 8, 2005. reous humor of the eye. Patent Application Publication May 25, 2006 Sheet 1 of 22 US 2006/0110428A1 R 2 2 C.6 Fig. -

Medicines Regulations 1984 (SR 1984/143)

Reprint as at 1 July 2014 Medicines Regulations 1984 (SR 1984/143) David Beattie, Governor-General Order in Council At the Government House at Wellington this 5th day of June 1984 Present: His Excellency the Governor-General in Council Pursuant to section 105 of the Medicines Act 1981, and, in the case of Part 3 of the regulations, to section 62 of that Act, His Excellency the Governor-General, acting on the advice of the Minister of Health tendered after consultation with the organisations and bodies that ap- peared to the Minister to be representatives of persons likely to be substantially affected, and by and with the advice and consent of the Executive Council, hereby makes the following regulations. Contents Page 1 Title and commencement 5 Note Changes authorised by subpart 2 of Part 2 of the Legislation Act 2012 have been made in this official reprint. Note 4 at the end of this reprint provides a list of the amendments incorporated. These regulations are administered by the Ministry of Health. 1 Reprinted as at Medicines Regulations 1984 1 July 2014 2 Interpretation 5 Part 1 Classification of medicines 3 Classification of medicines 11 Part 2 Standards 4 Standards for medicines, related products, medical 11 devices, cosmetics, and surgical dressings 5 Pharmacist may dilute medicine in particular case 12 6 Colouring substances [Revoked] 12 Part 3 Advertisements 7 Advertisements not to claim official approval 13 8 Advertisements for medicines 13 9 Advertisements for related products 15 10 Advertisements for medical devices 15 11 Advertisements -

Classification of Medicinal Drugs and Driving: Co-Ordination and Synthesis Report

Project No. TREN-05-FP6TR-S07.61320-518404-DRUID DRUID Driving under the Influence of Drugs, Alcohol and Medicines Integrated Project 1.6. Sustainable Development, Global Change and Ecosystem 1.6.2: Sustainable Surface Transport 6th Framework Programme Deliverable 4.4.1 Classification of medicinal drugs and driving: Co-ordination and synthesis report. Due date of deliverable: 21.07.2011 Actual submission date: 21.07.2011 Revision date: 21.07.2011 Start date of project: 15.10.2006 Duration: 48 months Organisation name of lead contractor for this deliverable: UVA Revision 0.0 Project co-funded by the European Commission within the Sixth Framework Programme (2002-2006) Dissemination Level PU Public PP Restricted to other programme participants (including the Commission x Services) RE Restricted to a group specified by the consortium (including the Commission Services) CO Confidential, only for members of the consortium (including the Commission Services) DRUID 6th Framework Programme Deliverable D.4.4.1 Classification of medicinal drugs and driving: Co-ordination and synthesis report. Page 1 of 243 Classification of medicinal drugs and driving: Co-ordination and synthesis report. Authors Trinidad Gómez-Talegón, Inmaculada Fierro, M. Carmen Del Río, F. Javier Álvarez (UVa, University of Valladolid, Spain) Partners - Silvia Ravera, Susana Monteiro, Han de Gier (RUGPha, University of Groningen, the Netherlands) - Gertrude Van der Linden, Sara-Ann Legrand, Kristof Pil, Alain Verstraete (UGent, Ghent University, Belgium) - Michel Mallaret, Charles Mercier-Guyon, Isabelle Mercier-Guyon (UGren, University of Grenoble, Centre Regional de Pharmacovigilance, France) - Katerina Touliou (CERT-HIT, Centre for Research and Technology Hellas, Greece) - Michael Hei βing (BASt, Bundesanstalt für Straßenwesen, Germany). -

(19) United States (12) Patent Application Publication (10) Pub

US 20130289061A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0289061 A1 Bhide et al. (43) Pub. Date: Oct. 31, 2013 (54) METHODS AND COMPOSITIONS TO Publication Classi?cation PREVENT ADDICTION (51) Int. Cl. (71) Applicant: The General Hospital Corporation, A61K 31/485 (2006-01) Boston’ MA (Us) A61K 31/4458 (2006.01) (52) U.S. Cl. (72) Inventors: Pradeep G. Bhide; Peabody, MA (US); CPC """"" " A61K31/485 (201301); ‘4161223011? Jmm‘“ Zhu’ Ansm’ MA. (Us); USPC ......... .. 514/282; 514/317; 514/654; 514/618; Thomas J. Spencer; Carhsle; MA (US); 514/279 Joseph Biederman; Brookline; MA (Us) (57) ABSTRACT Disclosed herein is a method of reducing or preventing the development of aversion to a CNS stimulant in a subject (21) App1_ NO_; 13/924,815 comprising; administering a therapeutic amount of the neu rological stimulant and administering an antagonist of the kappa opioid receptor; to thereby reduce or prevent the devel - . opment of aversion to the CNS stimulant in the subject. Also (22) Flled' Jun‘ 24’ 2013 disclosed is a method of reducing or preventing the develop ment of addiction to a CNS stimulant in a subj ect; comprising; _ _ administering the CNS stimulant and administering a mu Related U‘s‘ Apphcatlon Data opioid receptor antagonist to thereby reduce or prevent the (63) Continuation of application NO 13/389,959, ?led on development of addiction to the CNS stimulant in the subject. Apt 27’ 2012’ ?led as application NO_ PCT/US2010/ Also disclosed are pharmaceutical compositions comprising 045486 on Aug' 13 2010' a central nervous system stimulant and an opioid receptor ’ antagonist. -

Interplay Between Gating and Block of Ligand-Gated Ion Channels

brain sciences Review Interplay between Gating and Block of Ligand-Gated Ion Channels Matthew B. Phillips 1,2, Aparna Nigam 1 and Jon W. Johnson 1,2,* 1 Department of Neuroscience, University of Pittsburgh, Pittsburgh, PA 15260, USA; [email protected] (M.B.P.); [email protected] (A.N.) 2 Center for Neuroscience, University of Pittsburgh, Pittsburgh, PA 15260, USA * Correspondence: [email protected]; Tel.: +1-(412)-624-4295 Received: 27 October 2020; Accepted: 26 November 2020; Published: 1 December 2020 Abstract: Drugs that inhibit ion channel function by binding in the channel and preventing current flow, known as channel blockers, can be used as powerful tools for analysis of channel properties. Channel blockers are used to probe both the sophisticated structure and basic biophysical properties of ion channels. Gating, the mechanism that controls the opening and closing of ion channels, can be profoundly influenced by channel blocking drugs. Channel block and gating are reciprocally connected; gating controls access of channel blockers to their binding sites, and channel-blocking drugs can have profound and diverse effects on the rates of gating transitions and on the stability of channel open and closed states. This review synthesizes knowledge of the inherent intertwining of block and gating of excitatory ligand-gated ion channels, with a focus on the utility of channel blockers as analytic probes of ionotropic glutamate receptor channel function. Keywords: ligand-gated ion channel; channel block; channel gating; nicotinic acetylcholine receptor; ionotropic glutamate receptor; AMPA receptor; kainate receptor; NMDA receptor 1. Introduction Neuronal information processing depends on the distribution and properties of the ion channels found in neuronal membranes. -

)&F1y3x PHARMACEUTICAL APPENDIX to THE

)&f1y3X PHARMACEUTICAL APPENDIX TO THE HARMONIZED TARIFF SCHEDULE )&f1y3X PHARMACEUTICAL APPENDIX TO THE TARIFF SCHEDULE 3 Table 1. This table enumerates products described by International Non-proprietary Names (INN) which shall be entered free of duty under general note 13 to the tariff schedule. The Chemical Abstracts Service (CAS) registry numbers also set forth in this table are included to assist in the identification of the products concerned. For purposes of the tariff schedule, any references to a product enumerated in this table includes such product by whatever name known. Product CAS No. Product CAS No. ABAMECTIN 65195-55-3 ACTODIGIN 36983-69-4 ABANOQUIL 90402-40-7 ADAFENOXATE 82168-26-1 ABCIXIMAB 143653-53-6 ADAMEXINE 54785-02-3 ABECARNIL 111841-85-1 ADAPALENE 106685-40-9 ABITESARTAN 137882-98-5 ADAPROLOL 101479-70-3 ABLUKAST 96566-25-5 ADATANSERIN 127266-56-2 ABUNIDAZOLE 91017-58-2 ADEFOVIR 106941-25-7 ACADESINE 2627-69-2 ADELMIDROL 1675-66-7 ACAMPROSATE 77337-76-9 ADEMETIONINE 17176-17-9 ACAPRAZINE 55485-20-6 ADENOSINE PHOSPHATE 61-19-8 ACARBOSE 56180-94-0 ADIBENDAN 100510-33-6 ACEBROCHOL 514-50-1 ADICILLIN 525-94-0 ACEBURIC ACID 26976-72-7 ADIMOLOL 78459-19-5 ACEBUTOLOL 37517-30-9 ADINAZOLAM 37115-32-5 ACECAINIDE 32795-44-1 ADIPHENINE 64-95-9 ACECARBROMAL 77-66-7 ADIPIODONE 606-17-7 ACECLIDINE 827-61-2 ADITEREN 56066-19-4 ACECLOFENAC 89796-99-6 ADITOPRIM 56066-63-8 ACEDAPSONE 77-46-3 ADOSOPINE 88124-26-9 ACEDIASULFONE SODIUM 127-60-6 ADOZELESIN 110314-48-2 ACEDOBEN 556-08-1 ADRAFINIL 63547-13-7 ACEFLURANOL 80595-73-9 ADRENALONE -

The Evaluation of Drug Regulation - Economic Approaches Into the Valuation and Evaluation of the Drug Regulatory Framework

The Evaluation of Drug Regulation - Economic approaches into the valuation and evaluation of the drug regulatory framework Jacoline Bouvy The evaluation of drug regulation – Economic approaches into the valuation and evaluation of the drug regulatory framework Bouvy, JC. ISBN 000000 Author Jacoline Bouvy Cover photo Bigstock.com Printed by Drukkerij Mostert en Van Onderen! The evaluation of drug regulation – Economic approaches into the valuation and evaluation of the drug regulatory framework Evaluatie van geneesmiddelenregulering – Economische toepassingen in de waardering en evaluatie van het regulatoire geneesmiddelensysteem (met een samenvatting in het Nederlands) Proefschrift ter verkrijging van de graad van doctor aan de Universiteit Utrecht op gezag van de rector magnificus, prof.dr. G.J. van der Zwaan, ingevolge het besluit van het college voor promoties in het openbaar te verdedigen op woensdag 23 januari 2013 des middags te 12.45 uur door Jacoline Catharina Bouvy geboren op 27 maart 1985 te Rotterdam Promotor: Prof. dr. H. Schellekens Co-promotor: Dr. M.A. Koopmanschap The studies presented in this thesis were performed in the context of the Escher project (T6- 202), a project of the Dutch Top Institute Pharma. ‘It is our choices, Harry, that show what we truly are, far more than our abilities.’ Albus Dumbledore (In J.K. Rowling’s Harry Potter and the Chamber of Secrets) Glossary ADR Adverse drug reaction CBG-MEB Dutch Medicines Evaluation Board CKD Chronic Kidney Disease DCE Discrete Choice Experiment DHPC Direct Healthcare -

Study of Adulterants and Diluents in Some Seized Captagon-Type Stimulants

MedDocs Publishers ISSN: 2638-1370 Annals of Clinical Nutrition Open Access | Mini Review Study of Adulterants and Diluents in Some Seized Captagon-Type Stimulants Ali Zaid A Alshehri1,2*; Mohammed saeed Al Qahtani1,3; Mohammed Aedh Al Qahtani1,4; Abdulhadi M Faeq1,5; Jawad Aljohani1,6; Ammar AL-Farga7 1Department of Medical Laboratory Technology, College of Applied Medical Sciences, University of Jeddah, Saudi Arabia 2Poison Control and Medical Forensic Chemistry Center, Ministry of Health, Riyadh, Saudi Arabia 3Khammis Mushayte Maternity & Children Hospital, Ministry of Health, Saudi Arabia 4Ahad Rufidah General, Hospital, Aseer, Ministry of Health, Saudi Arabia 5Comprehensive Specialized Clinics of Security Forces in Jeddah, Ministry of Interior, Saudi Arabia 6Compliance Department, Yanbu Health Sector, Ministry of Health, Saudi Arabia 7Department of Biochemistry, Faculty of Science, University of Jeddah, Saudi Arabia *Corresponding Author(s): Ali Zaid A Alshehri Department of Medical Laboratory Technology, College of Applied Medical Sciences, University of Jeddah, Saudi Arabia Email: [email protected] Received: Apr 27, 2020 Accepted: Jun 05, 2020 Published Online: Jun 10, 2020 Journal: Annals of Clinical Nutrition Publisher: MedDocs Publishers LLC Online edition: http://meddocsonline.org/ Copyright: © Alshehri AZA (2020). This Article is distributed under the terms of Creative Commons Attribution 4.0 International License Introduction ATS are synthetic compounds belonging to the class of stimu- and heroin users combined [3,4]. Fenethylline, 7-(2-amethyl lants that excite the Central Nervous System (CNS) to produce phenyl-amino ethyl)-theophylline, is a theophylline derivative of adrenaline-like effects such as amphetamine, methamphet- amphetamine. It is a psychoactive drug which is similar to am- amine, fenethylline, methylphenidate and dextroamphetamine phetamine in many ways [5]. -

Federal Controlled Substances Checklist

Federal Controlled Substances Checklist Introduction By Norton Tooby & Joseph Justin Rollin We have reprinted here an alphabetical list of all controlled substances forbidden under federal drug laws, taken from the official website of the U.S. Department of Justice, Drug Enforcement Administration, Office of Diversion Control, at http://www.justice.gov/dea/pubs/scheduling.html. No copyright is asserted to this information. This list changes frequently. The official list is contained at 21 CFR § 1308, as supplemented by final rules published in the Federal Register. The attached checklist of controlled substances has been compiled into one list, and placed in alphabetical order, for ease of reference. If a controlled substance is listed in the federal drug schedules, it triggers deportation, INA § 237(a)(2)(B)(i), 8 U.S.C. § 1227(a)(2)(B)(i), and inadmissibility. INA § 212(a)(2)(A)(i)(II), 8 U.S.C. § 1182(a)(2)(A)(i)II). In addition, there is an aggravated felony defined as illicit trafficking in a controlled substance. INA § 101(a)(43)(B), 8 U.S.C. § 1101(a)(43)(B). The same controlled substance lists apply to this ground of deportation as well. If a drug is not listed on the federal controlled substances schedules, it does not trigger removal under these grounds. In addition, because the government has the burden of proof in deportation removal proceedings by clear and convincing evidence, if the record of conviction is ambiguous as to whether the specific substance involved in the particular case was listed on the federal schedules, the government cannot obtain a deportation removal order on this ground. -

Pharmacy and Poisons (Third and Fourth Schedule Amendment) Order 2017

Q UO N T FA R U T A F E BERMUDA PHARMACY AND POISONS (THIRD AND FOURTH SCHEDULE AMENDMENT) ORDER 2017 BR 111 / 2017 The Minister responsible for health, in exercise of the power conferred by section 48A(1) of the Pharmacy and Poisons Act 1979, makes the following Order: Citation 1 This Order may be cited as the Pharmacy and Poisons (Third and Fourth Schedule Amendment) Order 2017. Repeals and replaces the Third and Fourth Schedule of the Pharmacy and Poisons Act 1979 2 The Third and Fourth Schedules to the Pharmacy and Poisons Act 1979 are repealed and replaced with— “THIRD SCHEDULE (Sections 25(6); 27(1))) DRUGS OBTAINABLE ONLY ON PRESCRIPTION EXCEPT WHERE SPECIFIED IN THE FOURTH SCHEDULE (PART I AND PART II) Note: The following annotations used in this Schedule have the following meanings: md (maximum dose) i.e. the maximum quantity of the substance contained in the amount of a medicinal product which is recommended to be taken or administered at any one time. 1 PHARMACY AND POISONS (THIRD AND FOURTH SCHEDULE AMENDMENT) ORDER 2017 mdd (maximum daily dose) i.e. the maximum quantity of the substance that is contained in the amount of a medicinal product which is recommended to be taken or administered in any period of 24 hours. mg milligram ms (maximum strength) i.e. either or, if so specified, both of the following: (a) the maximum quantity of the substance by weight or volume that is contained in the dosage unit of a medicinal product; or (b) the maximum percentage of the substance contained in a medicinal product calculated in terms of w/w, w/v, v/w, or v/v, as appropriate.