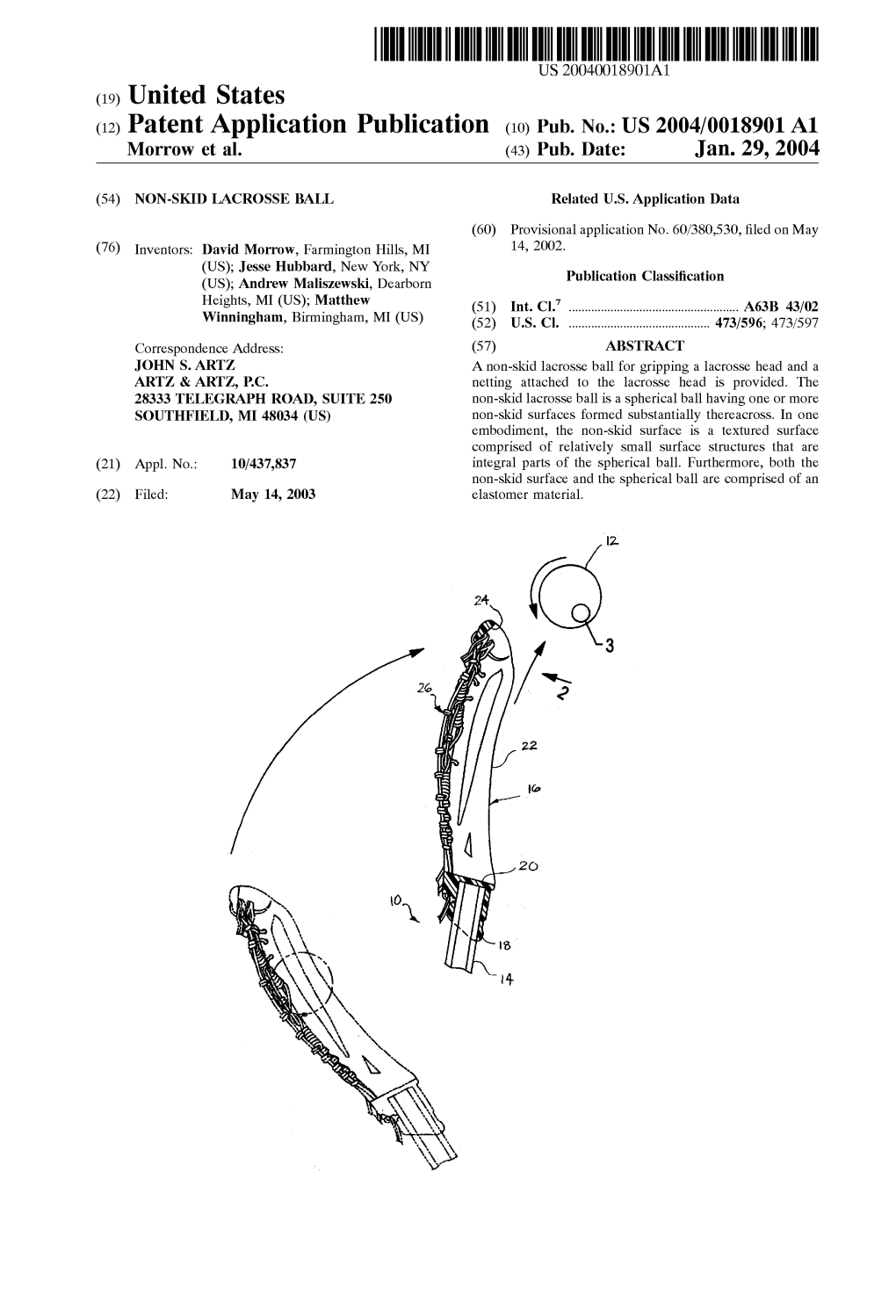

(12) Patent Application Publication (10) Pub. No.: US 2004/0018901 A1 Morrow Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Section Header

SECTION HEADER 2009 NLL Media Guide and Record Book 1 SECTION HEADER Follow the Entire 2010 NLL Season Live on the NLL Network at NLL.com 2010 NLL MEDIA GUIDE Table of Contents NLL Introduction Table of Contents/Staff Directory ........................1 Gait Introduction to the NLL.......................................2 2010 Division and Playoff Formats......................3 Lacrosse Talk.......................................................4 Team Information Boston Blazers .................................................5-9 Buffalo Bandits............................................10-16 Calgary Roughnecks ....................................17-22 Colorado Mammoth.....................................23-29 Edmonton Rush ...........................................30-34 Minnesota Swarm........................................35-40 Orlando Titans..............................................41-45 Philadelphia Wings......................................46-52 Rochester Knighthawks ...............................53-59 Toronto Rock................................................60-65 Washington Stealth.....................................66-71 History and Records League Award Winners and Honors .............72-73 League All-Pros............................................74-78 All-Rookie Teams ..............................................79 Individual Records/Coaching Records ...............80 National Lacrosse League All-Time Single-Season Records........................81 Staff Directory Yearly Leaders..............................................82-83 -

NEI Focus: City Creatives Economy Initiative, Round Two

20140203-NEWS--0001-NAT-CCI-CD_-- 1/31/2014 6:25 PM Page 1 ® www.crainsdetroit.com Vol. 30, No. 5 FEBRUARY 3 – 9, 2014 $2 a copy; $59 a year ©Entire contents copyright 2014 by Crain Communications Inc. All rights reserved Page 3 ROUND-TWO FUNDERS OF NEI Here are the 10 funders of the New Budget cuts put defense NEI focus: City creatives Economy Initiative, round two. Ⅲ The John S. and James L. Knight contracts in line of fire Foundation (Miami): $5 million “Entrepreneurship and innova- Ⅲ Ford Foundation (New York): $5 million 2nd funding round tion, as stand-alones, are valuable Ⅲ The Kresge Foundation (Detroit): in growing the economy,” said $5 million LARRY PEPLIN NEI Executive Director Dave Eg- Ⅲ W.K. Kellogg Foundation (Battle to target innovation, ner. “But the more we can con- Creek): $5 million nect them, the greater we can ac- Ⅲ The William Davidson Foundation celerate each. (Troy): $5 million entrepreneurism “In the end, without innova- Ⅲ Hudson-Webber Foundation tion, there are no new ideas to (Detroit): $2.5 million Amid financial emergency, BY SHERRI WELCH commercialize. And without en- Ⅲ Charles Stewart Mott Foundation CRAIN’S DETROIT BUSINESS Egner trepreneurs at the ready, there’s (Flint): $2 million Highland Park’s hopeful no one to commercialize them.” Ⅲ Community Foundation for After seven years and nearly $100 million in invest- NEI’s initial funders and one new foundation have Southeast Michigan (Detroit): Calif. firm poised to buy ment, the New Economy Initiative has figured out the committed a second-round investment of $33 million $1.5 million types of projects that will give it the most bang for its toward a $40 million target, Egner told Crain’s last Ⅲ The Max M. -

(12) United States Patent (10) Patent No.: US 7,695,382 B2 Morrow Et Al

US007695382B2 (12) United States Patent (10) Patent No.: US 7,695,382 B2 Morrow et al. (45) Date of Patent: *Apr. 13, 2010 (54) REINFORCED LACROSSE HEAD 2,274,788 A 3/1942 Hatton ....................... 473/544 (75) I nVentOrS: Davidavi M orrow, MMetamora, MI (US) 2.902,072 A 9, 1959 Reuter Jesse Hubbard, New York, NY (US); 3,479,030 A 1 1/1969 Merola Andrew Maliszewski, Dearborn 3,701,374. A 10/1972 McGillvary Heights, MI (US); Matthew 3,910,578 A * 10/1975 Brine, Jr. .................... 473,513 Winningham, Royal Oak, MI (US) 4,098,508 A * 7, 1978 Gandy ........................ 473,513 4,119,313 A 10/1978 Popplewell et al. (73) Assignee: Warrior Sports, Inc., Warren, WI (US) (*) Notice: Subject to any disclaimer, the term of this patent is extended or adjusted under 35 (Continued) U.S.C. 154(b) by 0 days. FOREIGN PATENT DOCUMENTS This patent is Subject to a terminal dis claimer. GB O424742 2, 1935 (21) Appl. No.: 11/832,753 (22) Filed: Aug. 2, 2007 (Continued) (65) Prior Publication Data OTHER PUBLICATIONS US 2007/027O254A1 Nov. 22, 2007 Web Page Download, Devco Design and Development, 1998, http:// Related U.S. Application Data www.devco-design.com/mi-mold.htm, 3 pp. (63) Continuation of application No. 10/437,842, filed on Primary Examiner Gene Kim May 14, 2003, now Pat. No. 7,258,634. Assistant Examiner M Chambers (74) Attorney, Agent, or Firm Warner Norcross & Judd LLP (51) Int. Cl. A63B 59/02 (2006.01) (57) ABSTRACT A63B 65/12 (2006.01) (52) U.S. -

NCAA Men's Lacrosse Championship Finals Records 1971-2011

NCAA Men’s Lacrosse Championship Finals Records 1971-2011 The history of the Men’s Lacrosse Championship Finals for all three divisions, including Single-Game, Year, Career Records, Coaching Records and Attendance Records. THE NATIONAL COLLEGIATE ATHLETIC ASSOCIATION P.O. Box 6222 Indianapolis, Indiana 46206-6222 317/917-6222 May 2012 Researched and compiled by Kristen Jacob Smith, Assistant Director of Online Properties and Media for Championships and Kevin Buerge, Statistics Assistant Table of Contents Notable Dates in Championship History ............................9 Division I Championship Highlights ...................................13 Division I Championship Results / Records .....................45 Division II Championship Highlights ................................. 61 Division II Championship Results / Records ....................71 Division III Championship Highlights ................................77 Division III Championship Results / Records ................103 Championship Coaching Records .....................................113 Championship Attendance Records ................................125 Notable Dates Notable Dates in NCAA Men’s Lacrosse Championship History ..............10-11 10 NOTABLE DATES IN MEN’S LACROSSE CHAMPIONSHIP HISTORY Notable Dates In NCAA Men’s Lacrosse Championship History 1971 1994 • The National Collegiate Lacrosse Championship was initiated with an • Hobart loses a Division III championship game for the fi rst time, falling eight-team fi eld. to Salisbury, 15-9. Hobart moved into Division I the next year. Salisbury, which fi nished 16-0, becomes the fi rst undefeated Division III champion. 1973 • First overtime championship game: Maryland 10, Johns Hopkins 9, in 1995 double overtime. • For the fi rst time, the crowd exceeds 30,000 for a session (Division I semi- • First triple overtime game: Washington & Lee 13, Navy 12 (fi rst round). fi nals–30,392 at Maryland). • ESPN airs the Division I semifi nals (ESPN2) and fi nal (ESPN) live for the fi rst 1974 time. -

NCAA Men's Lacrosse Championships Records 1971-2013

NCAA Men’s Lacrosse Championships Records 1971-2013 The history of the Men’s Lacrosse Championships for all three divisions, including Single-Game, Year, Career Records, Coaching Records and Attendance Records. THE NATIONAL COLLEGIATE ATHLETIC ASSOCIATION P.O. Box 6222 Indianapolis, Indiana 46206-6222 317/917-6222 NCAA.org April 2014 Researched and compiled by Kristen Jacob Smith, Assistant Director of Online Properties and Media for Championships, and Jennifer Rodgers, Assistant Director of Media Coordination and Statistics. Table of Contents Notable Dates in Championship History ............................3 Division I Championship Highlights ......................................7 Division I Championship Results / Records ..................... 51 Division II Championship Highlights ................................. 71 Division II Championship Results / Records .................... 85 Division III Championship Highlights ................................ 93 Division III Championship Results / Records ................130 Championship Coaching Records .....................................145 Championship Attendance Records ................................157 Notable Dates Notable Dates in NCAA Men’s Lacrosse Championship History ................... 4-6 4 NOTABLE DATES IN MEN’S LacrOSSE ChamPIONSHIP HISTORY Notable Dates In NCAA Men’s Lacrosse Championship History 1971 1992 • The National Collegiate Lacrosse Championship was initiated with an • The Division III championship is held at the Division I site for the first eight-team field. time at Penn. The game draws a then-record crowd of 6,741. 1973 • Nazareth beats Roanoke to become the first team other than Hobart, which won the 12 previous championships, to claim the Division III • First overtime championship game: Maryland 10, Johns Hopkins 9, in crown. double overtime. • First triple overtime game: Washington & Lee 13, Navy 12 (first round). 1993 • The Division II championship is reinstated and is played for the first time 1974 since 1981. -

Comprehensive English Examination

COMPREHENSIVE ENGLISH SESSION ONE The University of the State of New York REGENTS HIGH SCHOOL EXAMINATION COMPREHENSIVE EXAMINATION IN ENGLISH SESSION ONE Wednesday, August 13, 2008 — 8:30 to 11:30 a.m., only The last page of this booklet is the answer sheet for the multiple-choice questions. Fold the last page along the perforations and, slowly and carefully, tear off the answer sheet. Then fill in the heading of your answer sheet. Now circle “Session One” and fill in the heading of each page of your essay booklet. This session of the examination has two parts. Part A tests listening skills; you are to answer all six multiple-choice questions and write a response, as directed. For Part B, you are to answer all ten multiple-choice questions and write a response, as directed. When you have completed this session of the examination, you must sign the statement printed at the end of the answer sheet, indicating that you had no unlawful knowledge of the questions or answers prior to the session and that you have neither given nor received assistance in answering any of the questions during the session. Your answer sheet cannot be accepted if you fail to sign this declaration. The use of any communications device is strictly prohibited when taking this examination. If you use any communications device, no matter how briefly, your examination will be invalidated and no score will be calculated for you. DO NOT OPEN THIS EXAMINATION BOOKLET UNTIL THE SIGNAL IS GIVEN. COMPREHENSIVE ENGLISH SESSION ONE SESSION ENGLISH COMPREHENSIVE Part A Overview: For this part of the test, you will listen to an account about the electric guitar, answer some multiple-choice questions, and write a response based on the situation described below. -

Menls Lacrosse

MEN’S LACROSSE Updated After 2015 Season First Game: 1882 — exact date unkown (vs. New York Lacrosse Club ) All-Time Record: 664-460-19 (.587) Head Coaching Register: W L T Pct. Al Nies (1921-35) 74 39 7 .646 Bill Logan (1936-45) 49 31 0 .613 Dick Colman (1946-49) 28 15 0 .651 Ernie Ransome (1950) 7 2 1 .750 Ferris Thomsen (1951-70) 115 99 7 .536 Art Robinson (1971-76) 32 49 0 .395 Mike Hanna (1977-81) 31 31 0 .500 Jerry Schmidt (1982-87) 27 58 0 .318 Bill Tierney (1988-2009) 238 86 0 .735 Chris Bates (2010-present) 51 35 0 .593 Ivy League Championships (26): 1957, 1958, 1959, 1960, 1961, 1962, 1963, 1964, 1965, 1967, 1992, 1993, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2006, 2009, 2010, 2012, 2015 Ivy League Tournament Championships (1): 2010 NCAA Tournament Appearances (20): 1990, 1991, 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2006, 2007, 2009, 2010, 2012 NCAA Championships (6): 1992, 1994, 1996, 1997, 1998, 2001 Ivy League Player of the Year (9): Kevin Lowe (1994), Jesse Hubbard (1996), Jon Hess (1997), Josh Sims (2000), Ryan Mollett (2001), Ryan Boyle (2002), Ryan Boyle (2004), Tyler Fiorito (2012), Mike MacDonald (2015) Ivy League Rookie of the Year (11): Torr Marro (1990), Scott Bacigalupo (1991), Jesse Hubbard (1995), B.J. Prager (1999), Ryan Boyle (2001), Peter Trombino (2004(, Dan Cocoziello (2005), Jack McBride (2008), Mike Chanenchuk (2010), Tom Schreiber (2011), Jake Froccaro (2013) Quick Facts: • Chris Bates has led Princeton to three Ivy League championships, two NCAA tournament appearances and four Ivy League tournaments, including the outright league championship in 2012, when Princeton went 6-0 in the league and outscored its opponents 81-35. -

Victory Honda’S Kyle Trip Breaks in on Honeybaked Goalie Katrina Hodgeson in the MAHA Sr

C el eb ra tin g ou r 4 0 y t ea HOCK EY WEEK LY h r! MARCH 12, 2014 Vol. 40, Issue 16 $2. 00 HCelebrW ating our year! 12 PAGES OF TRYOUTS INSIDE - 380 SKATES! 40 th www.hockeyweekly.com JJooyy ttoo tthhee wwoorrlldd ! Yes, it’s March, and that means madness on ice – from AAU Mites to MAHA Midgets and Senior Women who all kicked off the opening weekend of state playoffs Feb. 28-March 2. There will be plenty more celebrations to come like the one at left by the Troy Sting Midget AA players. They defeated the Mt. Clemens Wolves March 2 at the Taylor Sportplex for the state title and a trip to the USA Hockey Nationals. Stories and photos of all the first week’s championships start on Page 3. Photo by ZRPhoto.net Photo by ZRPhoto.net CHAMPS R US: At left, the DSC Civil Warriors U8 Mites celebrate their AAU championship. Above, Victory Honda’s Kyle Trip breaks in on HoneyBaked goalie Katrina Hodgeson in the MAHA Sr. B Women's final. Trip scored a goal en route to Victory Honda’s 3-2 win. The story on the AAU HWAP Photo by Dan Shriner championships with team photos is on Page 9; the Senior Women’s story is on Page 8. RREESSEERRVVEE YYOOUURR HHSS AALLLL--SSTTAATTEE TTIICCKKEETTSS – – DDEETTAAIILLSS OONN PP.. 1111 PAGE 2 HOCKEY WEEKLY MARCH 12, 2014 THE MAHA STATE CHAMPIONSHIPS HOCKEY WEEKLY / MARCH 12, 2014 PAGE 3 Litchard leads Belle Tire Warriors to Squirt A state title By Fred Costello Hockey Weekly Special Writer Scoring one goal in the state championship game would be a thrill for any hockey player. -

Canadian Lacrosse Association Announces Sponsorship with New Balance Athletics and Warrior Sports

Canadian Lacrosse Association Announces Sponsorship with New Balance Athletics and Warrior Sports OTTAWA, ON (June 30, 2016) - The Canadian Lacrosse Association (CLA) is proud to announce that it has signed multi-year sponsorship agreements with both New Balance Athletics and Warrior Sports. With these new sponsorships, Warrior and New Balance are making a significant investment in Canada’s national summer sport. Their commitment to the CLA, which is centred on the national team programs, will help support all levels of lacrosse in Canada. Over the course of the multi-year deal, New Balance and Warrior will work alongside our male and female athletes as they compete in a total of five FIL World Championships, including two events that will be played on home soil, the 2016 Men’s U19 World Championship in Coquitlam, BC and the 2019 World Indoor Lacrosse Championship in Langley, BC. “We are thrilled to have these two internationally recognized companies on board” said Joey Harris, CLA President. “Their commitment to our organization will certainly help us in our efforts to grow the game across the country and to maintain our success on the international stage”. Both New Balance and Warrior have rich histories, which align well with the storied past of the CLA and the sport of lacrosse in Canada. Warrior has been at the forefront of the sporting goods industry for over 20 years, becoming a dominant force in the world of lacrosse thanks to its ability to create innovative and cutting-edge equipment. New Balance has been in the footwear and sport apparel business for more than a century, having grown into a global leader because of its ability to develop products that successfully combine function and fashion. -

20 15 Men's Lacrosse Records Book 20 16

Men’s Lacrosse Records Book 20 20 15 16 TABLE OF CONTENTS All-time Champions ................................................. 1 Ivy Standings .........................................................2-4 Individual Records (Season, Career, Game) ........5-6 Ivy League Tournament Results / All-tournament .... 7 Ivy League Tournament Records ..........................8-9 Ivy League Teams in NCAA Championship ......10-11 Ivy League Players & Rookies of the Year ............ 12 All-Ivy Teams ....................................................13-19 Ivy League All-Americans ..................................20-23 Ivy League Academic All-Americans ...................... 24 * - Last updated on April 7, 2016. If you have updates or possible edits to the men’s locrosse records book, please email Trevor Rutledge-Leverenz, Assistant Executive Director, Communications & Championships: trevor [email protected] 15 1 16 Ivy League Records Book MEN’S LACROSSE All-Time Champions YEAR CHAMPION(S) IVY CHAMPIONS 1956 Yale 1957 Princeton 2007 Cornell Total Outright First Last 1958 Princeton 2008 Brown 1959 Princeton Cornell Team Champ. Champ. Champ. Champ. 1960 Princeton 2009 Cornell Brown 9 4 1969 2015 1961 Princeton Princeton Cornell 29 18 1966 2015 1962 Princeton 2010 Brown Dartmouth 3 -- 1964 2003 1963 Dartmouth Cornell Harvard 4 -- 1964 2014 Princeton Princeton Penn 4 2 1983 1988 1964 Harvard Yale Princeton 27 18 1957 2015 2011 Cornell Princeton Yale 6 2 1956 2010 1965 Dartmouth 2012 Princeton Princeton 2013 Cornell Totals 82 (in 59 seasons) 44 1956 2015 1966 Cornell 2014 Cornell 1967 Princeton Harvard 1968 Brown 2015 Brown Cornell Cornell NCAA / Ivy League Championship Notes 1969 Cornell Princeton Yale l Cornell’s winning of the title in 2015 gave the Big Red at least a share of the Ivy crown 1970 Cornell in 12 of the last 13 seasons. -

S:\#Orders to File\Hh518warrior.P216valid. Nd

2:04-cv-70363-JAC-VMM Doc # 270 Filed 06/12/06 Pg 1 of 15 Pg ID 10431 UNITED STATES DISTRICT COURT EASTERN DISTRICT OF MICHIGAN SOUTHERN DIVISION WARRIOR LACROSSE, INC., A Michigan Corporation, Plaintiff, Case Nos. 04-70363 & 04-71842 v. Honorable Julian Abele Cook, Jr. STX, L.L.C., a Maryland Limited Liability Company, Defendant. ORDER On January 30, 2004, the Plaintiff, Warrior Lacrosse, Inc. (“Warrior”), filed a Complaint with this Court, in which it accused the Defendant, STX, L.L.C. (“LLC”), of infringing upon two of its patents; namely, U.S. Patent No. 6,561,932 (“932 Patent”) and U.S. Patent RE 38, 216 (“216 Patent”). On October 12, 2005, Warrior filed a motion for summary judgment, arguing “that the 216 Patent is not invalid or unenforceable in view of any purported activities by Robert J. Rule.” Two days later, STX filed a motion, seeking the entry of a partial summary judgment of unenforceability of the “216 Patent” due to the “inequitable conduct” of Warrior’s attorney, John S. Artz (“Artz”), who, in its opinion, had (1) intentionally mischaracterized an alleged critical prior art reference and (2) knowingly failed to disclose information that contradicted his patent application to the United States Patent and Trademark Office (“PTO”). On February 8, 2006, Warrior filed another motion, in which it sought to obtain leave from the Court to file a “supplemental brief in opposition to STX’s motion for partial summary judgment of un unenforceability of the ‘216 Patent’ due to inequitable conduct.” 1 2:04-cv-70363-JAC-VMM Doc # 270 Filed 06/12/06 Pg 2 of 15 Pg ID 10432 I. -

Men's Lacrosse

Senior SSDM Christian McHugh Preseason All-Patriot League LEHIGH MEN’S LACROSSE SCHEDULE/RESULTS GAME 1: UTAH AT NO. 19 LEHIGH (0-0, 0-0 PATRIOT LEAGUE) UTAH UTES (1-0) at February LEHIGH MOUNTAIN HAWKS (0-0, 0-0 PATRIOT LEAGUE) 8 UTAH 1:00 15 at Virginia 1:00 SATURDAY, FEBRUARY 8, 2020 • 1 P.M. 20 VMI 5:00 ULRICH SPORTS COMPLEX • BETHLEHEM, PA. 22 at NJIT 12:00 29 NAVY* 3:00 PATRIOT LEAGUE NETWORK March SETTING THE SCENE 7 HOLY CROSS* 1:00 The 19th ranked Lehigh men’s lacrosse team will open its season at home for the fifth time in the 14 at Army West Point* 12:00 21 at Penn State 1:00 last six seasons when the Mountain Hawks host Utah on Saturday afternoon. Opening faceoff is 24 WAGNER 7:00 set for 1 p.m. on the Patriot League Network. Like it’s become accustomed around the program, 28 at Lafayette* 7:00 Lehigh enters the year with high hopes and aspirations, eying a third consecutive trip to the Patriot League Championship Game and first title since 2013. April 4 BUCKNELL* 1:00 11 at Colgate* 12:00 With their big-picture mission in mind, the Mountain Hawks are focused on the short term and 18 BOSTON UNIVERSITY* 1:00 winning the day. Lehigh features a strong mix of returning standouts and talented newcomers. 24 at Loyola* 7:00 The Mountain Hawks placed five members on the preseason All-Patriot League team, most in the 28 Patriot League Quarterfinals league.