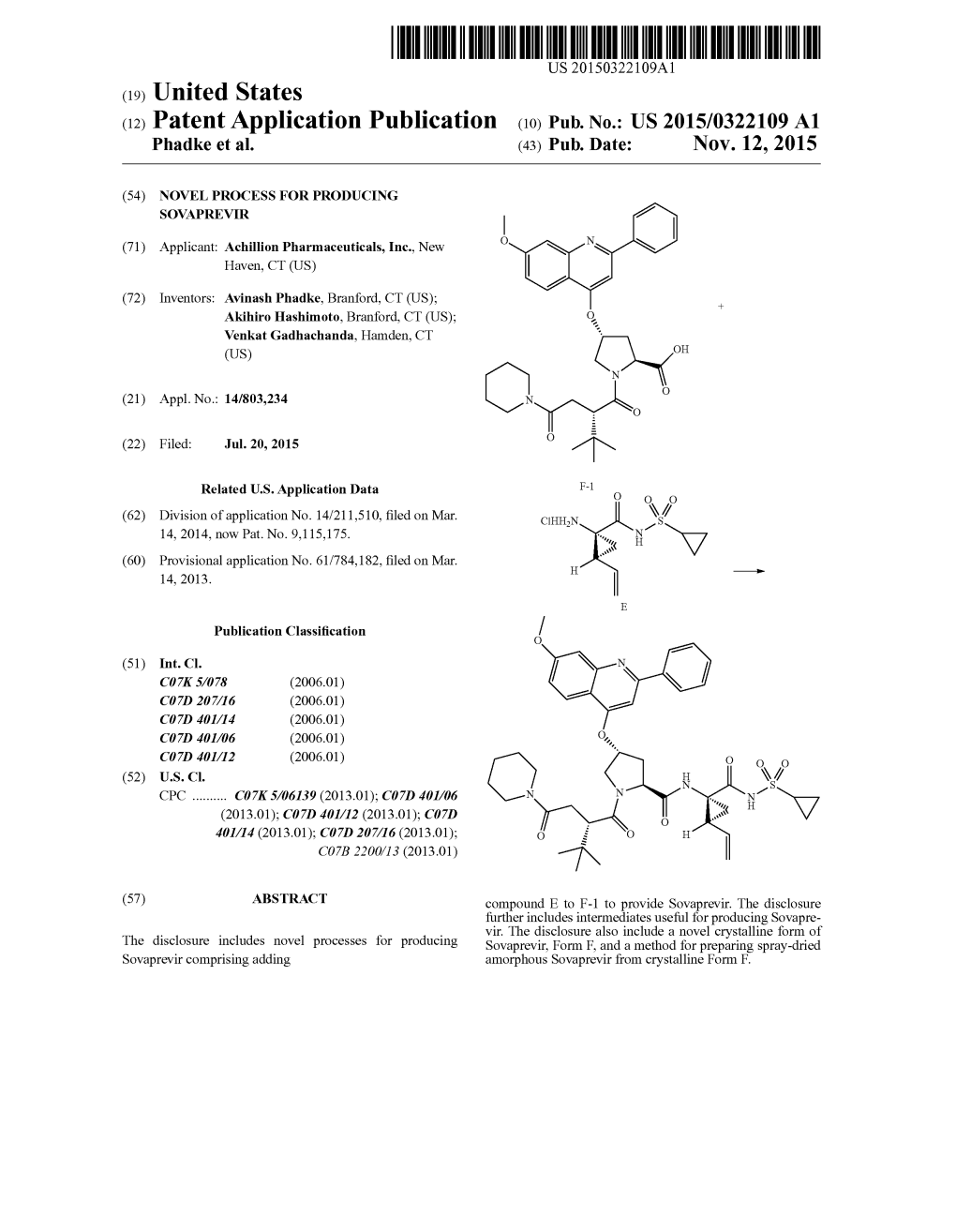

(12) Patent Application Publication (10) Pub. No.: US 2015/0322109 A1 Phadke Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Design and Synthesis of Hepatitis C Virus NS3 Protease Inhibitors

Digital Comprehensive Summaries of Uppsala Dissertations from the Faculty of Pharmacy 197 Design and Synthesis of Hepatitis C Virus NS3 Protease Inhibitors Targeting Different Genotypes and Drug-Resistant Variants ANNA KARIN BELFRAGE ACTA UNIVERSITATIS UPSALIENSIS ISSN 1651-6192 ISBN 978-91-554-9166-6 UPPSALA urn:nbn:se:uu:diva-243317 2015 Dissertation presented at Uppsala University to be publicly examined in B41 BMC, Husargatan 3, Uppsala, Friday, 27 March 2015 at 09:15 for the degree of Doctor of Philosophy (Faculty of Pharmacy). The examination will be conducted in Swedish. Faculty examiner: Ulf Ellervik (Lunds tekniska högskola). Abstract Belfrage, A. K. 2015. Design and Synthesis of Hepatitis C Virus NS3 Protease Inhibitors. Targeting Different Genotypes and Drug-Resistant Variants. Digital Comprehensive Summaries of Uppsala Dissertations from the Faculty of Pharmacy 197. 108 pp. Uppsala: Acta Universitatis Upsaliensis. ISBN 978-91-554-9166-6. Since the first approved hepatitis C virus (HCV) NS3 protease inhibitors in 2011, numerous direct acting antivirals (DAAs) have reached late stages of clinical trials. Today, several combination therapies, based on different DAAs, with or without the need of pegylated interferon-α injection, are available for chronic HCV infections. The chemical foundation of the approved and late-stage HCV NS3 protease inhibitors is markedly similar. This could partly explain the cross-resistance that have emerged under the pressure of NS3 protease inhibitors. The first-generation NS3 protease inhibitors were developed to efficiently inhibit genotype 1 of the virus and were less potent against other genotypes. The main focus in this thesis was to design and synthesize a new class of 2(1H)-pyrazinone based HCV NS3 protease inhibitors, structurally dissimilar to the inhibitors evaluated in clinical trials or approved, potentially with a unique resistance profile and with a broad genotypic coverage. -

Bristol-Myers Setback Another Blow to Hep C Field

August 24, 2012 Bristol-Myers setback another blow to hep C field Joanne Fagg The once-crowded field of candidates jostling to be part of the first all-oral hepatitis C antiviral cocktail got decidedly emptier today with the news that Bristol-Myers Squibb had cancelled development of its $2bn asset BMS-986094. The safety worries that had triggered a clinical hold on the drug turned out too deep to accept – a death in the original heart failure patient, plus nine other hospitalised subjects resulting from heart and kidney toxicity. Excitement around the space has already dissipated with Gilead Sciences’ seemingly uninterrupted march towards the all-oral holy grail and signs that the untreated population might be smaller than was originally believed. Failure of a closely watched candidate – and indeed one validated by a big pharma deal – will do nothing to reinvigorate the interest of investors whose interest may be turning elsewhere. Hefty price tag The news is not necessarily a setback for the nucleoside NS5B polymerase inhibitor class or for Bristol-Myers, which still has a decent pipeline in spite of some failures (see tables). However, it is another knock to sentiment for developers in the hep C space – at least, the ones that are not called Gilead (Signs are growing that the hep C ship is sailing, August 1, 2012). Hepatitis C nucleoside NS5B polymerase inhibitor pipeline Status Product Company Selected trial IDs NCT01497366 NCT01542788 Phase III GS-7977 Gilead Sciences NCT01604850 NCT01641640 NCT00869661 Phase II RG7128 Gilead Sciences/Roche NCT01057667 NCT01278134 IDX184 Idenix Pharmaceuticals Partial clinical hold Phase I RO5303253 Roche NCT01181024 NCT01371162 RO5428029 Roche NCT01345942 ALS-2200 Vertex Pharmaceuticals NCT01590407 ALS-2158 Vertex Pharmaceuticals NCT01554085 As if further confirmation were needed, California-based Gilead is now decisively in the lead to get a much- heralded all-oral hepatitis C combination to the market and address those patients thought to be awaiting a therapy free of interferon and its side effects. -

Pessimism Infects Achillion As FDA Sustains Clinical Hold

September 30, 2013 Pessimism infects Achillion as FDA sustains clinical hold Jonathan Gardner Another disappointment for the hepatitis C project sovaprevir may have Achillion Pharmaceuticals feeling like it is starting all over again. At a time when the Connecticut-based group could be riding the bio-runup heading into the AASLD liver meeting in November, executives disclosed that the FDA would not lift the clinical hold imposed after liver enzyme elevations were detected in a drug interaction study (Another hep C safety worry buffets Achillion’s lead, July 2, 2013). Shares crashed 55% to a four-year low of $3.28 in early trading today on the news, released after Friday’s market close. Acknowledging the setback, executives signalled that they were prepared to move on, with phase II testing of alternative treatment regimens imminent; while that may be an attempt to reassure, it adds months if not years to investors’ assumptions about when Achillion will start generating a royalty stream. Just like starting over With first approval decisions for Gilead Sciences’ expected $11bn drug sofosbuvir due by December and combinations from Bristol-Myers Squibb and AbbVie making strides forward, the all-oral market looks to be well served by 2017. This year is the likely earliest point that any of Achillion’s assets could begin generating sales; in 2017, Gilead’s sofosbuvir-centred franchise is expected to yield $8.2bn in sales, according to EvaluatePharma's consensus. However, Achillion executives sought to portray the company's hep C activities as broader than sovaprevir, a protease inhibitor, highlighting the NS5A inhibitor ACH-3102, a second protease inhibitor, ACH-2684, which will report combination tests with ‘3102 next year, and a uridine-analog nucleotide, ACH-3422, which could be in the clinic next year. -

Meeting Report: 26Th International Conference on Antiviral Research Q

Antiviral Research 100 (2013) 276–285 Contents lists available at ScienceDirect Antiviral Research journal homepage: www.elsevier.com/locate/antiviral Review Meeting report: 26th International Conference on Antiviral Research q R. Anthony Vere Hodge Vere Hodge Antivirals Ltd, Old Denshott, Leigh, Reigate, Surrey, UK article info abstract Article history: The 26th International Conference on Antiviral Research (ICAR) was held in San Francisco, California from Received 2 August 2013 May 11 to 15, 2013. This article summarizes the principal invited lectures at the meeting. The opening Accepted 8 August 2013 symposium on the legacy of the late Antonín Holy´ included presentations on his pioneering work with Available online 21 August 2013 nucleotide analogs, which led to the development of several antiviral drugs including tenofovir. This drug has transformed the treatment of HIV infection and has recently become the first-line therapy for chronic Keywords: hepatitis B. The Gertrude Elion Award lecturer described the anti-HIV activities of the CCR5 inhibitor Human immunodeficiency virus cenicriviroc and the reverse transcriptase inhibitor festinavirÒ, and also reviewed the evaluation of bio- Hepatitis B degradable nanoparticles with adjuvant activity. The William Prusoff Award winner reported on the cre- Hepatitis C Herpesviruses ation of NAOMI, a computer model with 21 enzymes to predict the activity of nucleoside analogs against Antiviral therapy hepatitis C virus (HCV). Other invited lecturers discussed the development of countermeasures against severe dengue and the potential of RNA virus capping and repair enzymes as drug targets. Topics in the clinical symposium included the current status of the anti-HCV compounds sovaprevir, ACH-3102, miravirsen and ALS-2200; the evaluation of single-tablet regimens for HIV infection; and the investiga- tion of cytomegalovirus resistance to CMX001. -

HCV Eradication with Direct Acting Antivirals (Daas)?

HCV eradication with direct acting antivirals (DAAs)? Emilie Estrabaud Service d’Hépatologie et INSERM UMR1149, AP-HP Hôpital Beaujon, Paris, France. [email protected] HCV eradication with direct acting antivirals (DAAs)? HCV replication HCV genome and DAAs targets NS3 inhibitors NS5A inhibitors NS5B inhibitors Take home messages HCV viral cycle Asselah et al. Liver Int. 2015;35 S1:56-64. Direct acting antivirals 5’NTR Structural proteins Nonstructural proteins 3’NTR Metalloprotease Envelope Serine protease Glycoproteins RNA Capsid RNA helicase Cofactors Polymerase C E1 E2 NS1 NS2 NS3 NS4A NS4B NS5A NS5B Protease Inhibitors NS5A Inhibitors Polymerase Inhibitors Telaprevir Daclatasvir Nucs Non-Nucs Boceprevir Ledipasvir Simeprevir ABT-267 Sofosbuvir ABT-333 Faldaprevir GS-5816 VX-135 Deleobuvir Asunaprevir Direct Acting Antivirals: 2015 Asselah et al. Liver Int. 2015;35 S1:56-64. Genetic barrier for HCV direct acting antivirals High Nucleos(t)ide 1 mutation= high cost to Analog Inhibitors fitness, 2-3 additional mutations to increase fitness 2 st generation Protease Inhibitors n Non Nucleos(t)ide Analog Inhibitors : NS5 A Inhibitors 1 st generation Protease Inhibitors 1 mutation= low cost to fitness Low Halfon et al. J Hepatol 2011. Vol 55(1):192-206. HCV protease inhibitors (PI) Inhibit NS3/NS4A serine protease responsible for the processing of the polyprotein 1st generation 1st generation, 2nd wave 2nd generation Resistance low low high barrier Genotype activity 1: 1 a< 1b All except 3 all Drug drug Important Less Less interaction Drugs Boceprevir Simeprevir (Janssen) MK-5172 Telaprevir Faldaprevir (BI) ACH-2684 Paritaprevir (ABT-450)/r (AbbVie) Vedroprevir (Gilead) Vaniprevir (Merck) Sovaprevir (Achillion) Asunaprevir (BMS) NS3/NS4A structure Repositioning of helicase domain Self cleavage Lipid Bilayer Inactive Insertion of the Active carboxy-terminal tail Bartenschlager et al. -

ABT-450/R (Abbott) – GS-9451 (Gilead) • Second Generation (Pan-Genotype, High Barrier to Resistance) – MK-5172 (Merck) – ACH-2684 (Achillion)

Paris Hepatitis Conference New Therapeutic Strategies Second Generation Protease inhibitors David R Nelson MD Professor and Associate Dean Director, Clinical and Translational Science Institute University of Florida Gainesville, USA Outline • HCV protease structure and drug targeting • First generation PIs – Major step forward – Major limitations • PIs in development – Second wave – Second generation • Clinical trial data – IFN-containing PI regimens – IFN-free PI containing regimens • Timelines and treatment paradigms NS3 protease targeting active site “catalytic triad” NS4A TARGETING . Substrate- and product analogs . Tri-peptides . Serine-trap inhibitors subdomain . Ketoamides (boceprevir, telaprevir) boundary . Macrocyclic inhibitors (e.g. Simeprevir, Danoprevir, Vaniprevir, etc.) zinc-finger . NS4A inhibitors Lorenz et al., Nature 2006 Kronenberger et al., Clin Liver Dis 2008 Welsch et al. Gut in press A Major Step Forward: First Generation PIs PegIFN/RBV BOC or TVR + pegIFN/RBV 100 69-83 80 63-75 40-59 60 38-44 29-40 SVR SVR (%) 40 24-29 20 7-15 5 0 Naive[1,2] Relapsers[3,4] Partial Null Responders[3,4] Responders[3,4] 1. Poordad F, et al. N Engl J Med. 2011;364:1195-1206. 2. Jacobson IM, et al. N Engl J Med. 2011;364:2405-2416. 3. Bacon BR, et al. N Engl J Med. 2011;364:1207-1217. 4. Zeuzem S, et al. N Engl J Med. 2011;364:2417-2428. 3. Bronowicki JP, et al. EASL 2012. Abstract 11. Limitations of First Generation PI-Based Therapy • Efficacy – Very dependent on the IFN response – Limited to gen 1 (1b>1a) • Low genetic barrier to -

An Update on the Management of Chronic Hepatitis C: 2015 Consensus Guidelines from the Canadian Association for the Study of the Liver

SPECIAL ARTICLE An update on the management of chronic hepatitis C: 2015 Consensus guidelines from the Canadian Association for the Study of the Liver Robert P Myers MD MSc1*, Hemant Shah MD MScCH HPTE2*, Kelly W Burak MD MSc1, Curtis Cooper MD3, Jordan J Feld MD MPH2* RP Myers, H Shah, KW Burak, C Cooper, JJ Feld. An update Mise à jour sur la prise en charge de l’hépatite C on the management of chronic hepatitis C: 2015 Consensus chronique : les lignes directrices consensuelles guidelines from the Canadian Association for the Study of the 2015 de l’Association canadienne pour l’étude Liver. Can J Gastroenterol Hepatol 2015;29(1):19-34. du foie Chronic hepatitis C remains a significant medical and economic bur- L’hépatite C chronique demeure un fardeau médical et économique den in Canada, affecting nearly 1% of the population. Since the last important au Canada, car il touche près de 1 % de la population. Canadian consensus conference on the management of chronic hepa- Depuis la dernière conférence consensuelle canadienne sur la prise en titis C, major advances have occurred that warrant a review of recom- charge de l’hépatite C chronique, on a réalisé des progrès marqués qui mended management approaches for these patients. Specifically, justifient une analyse des démarches de prise en charge recomman- direct-acting antiviral agents with dramatically improved rates of dées. Notamment, on a mis au point des antiviraux à action directe au virological clearance compared with standard therapy have been taux de clairance virologique bien supérieur à celui du traitement developed and interferon-free, all-oral antiviral regimens have been standard et on a homologué des antiviraux sans interféron par voie approved. -

13. Approved and Experimental Therapies

APPROVED AND EXPERIMENTAL THERAPIES FOR TREATMENT OF HEPATITIS B AND C, AND MUTATIONS 13. ASSOCIATED WITH DRUG RESISTANCE • Luis Menéndez-Arias HEPATITIS B Table 13.1. CURRENT DRUGS FOR TREATMENT OF HEPATITIS B Drug name Drug class Manufacturer Status Pegasys (peginterferon α-2a) Interferon Genentech FDA-approved Intron A (interferon a-2b) Interferon Merck FDA-approved Hepsera (adefovir Nucleotide analogue Gilead Sciences FDA-approved dipivoxil)a Viread (tenofovir Nucleotide analogue Gilead Sciences FDA-approved b disoproxil fumarate) a Epivir-HBV, Zeffix and Nucleoside analogue Glaxo SmithKline FDA-approved Heptodin (lamivudine) a Baraclude (entecavir) Nucleoside analogue Bristol-Myers Squibb FDA-approved Tyzeka, Sebivo Nucleoside analogue Novartis FDA-approved (telbivudine) Vemlidy (TAF, tenofovir Tenofovir prodrug Gilead Sciences FDA-approved alafenamide, GS-7340) Emtriva (emtricitabine; Nucleoside analogue Gilead Sciences FDA-approved b FTC) a Levovir, Revovir Nucleoside analogue Bukwang Studies cancelled c (clevudine, L-FMAU) pharmaceuticals, Eisai (Japan) Besivo (LB80380, Nucleoside analogue IIDong Pharmaceutical Approved in S ANA380) Co. Ltd. Korea Zadaxin (thymosin alpha) Immune enhancer SciClone Approved outside U.S. ABX 203 Therapeutic vaccine ABIVAX Phase IIb/III ARC-520 RNAi gene silencer Arrowhead Research Phase II/III 641 Drug name Drug class Manufacturer Status Myrcludex B Entry inhibitor Hepatera (Russia), Phase IIa Myr-Gmbh (Germany) (Russia) NVR-1221 (NVR 3-778) Capsid inhibitor Novira Therapeutics Phase IIa AGX-1009 -

Stembook 2018.Pdf

The use of stems in the selection of International Nonproprietary Names (INN) for pharmaceutical substances FORMER DOCUMENT NUMBER: WHO/PHARM S/NOM 15 WHO/EMP/RHT/TSN/2018.1 © World Health Organization 2018 Some rights reserved. This work is available under the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 IGO licence (CC BY-NC-SA 3.0 IGO; https://creativecommons.org/licenses/by-nc-sa/3.0/igo). Under the terms of this licence, you may copy, redistribute and adapt the work for non-commercial purposes, provided the work is appropriately cited, as indicated below. In any use of this work, there should be no suggestion that WHO endorses any specific organization, products or services. The use of the WHO logo is not permitted. If you adapt the work, then you must license your work under the same or equivalent Creative Commons licence. If you create a translation of this work, you should add the following disclaimer along with the suggested citation: “This translation was not created by the World Health Organization (WHO). WHO is not responsible for the content or accuracy of this translation. The original English edition shall be the binding and authentic edition”. Any mediation relating to disputes arising under the licence shall be conducted in accordance with the mediation rules of the World Intellectual Property Organization. Suggested citation. The use of stems in the selection of International Nonproprietary Names (INN) for pharmaceutical substances. Geneva: World Health Organization; 2018 (WHO/EMP/RHT/TSN/2018.1). Licence: CC BY-NC-SA 3.0 IGO. Cataloguing-in-Publication (CIP) data. -

Achillion Pharmaceuticals 2013 Annual Report

ACHILLION PHARMACEUTICALS DESTINATION: 2013 ANNUAL REPORT CURING HCV WORLDWIDE ACHILLION PHARMACEUTICALS, INC. PHARMACEUTICALS, ACHILLION 2013 ANNUAL REPORT ANNUAL 2013 Achillion Pharmaceuticals, Inc. 300 George Street • New Haven, CT 06511 www.achillion.com 87933_ACH_2013_outsidecover.indd 1 4/8/14 12:20 PM DEAR ACHILLION SHAREHOLDER CORPORATE INFORMATION Milind S. Deshpande, Ph.D. President and Chief Executive Officer In my fi rst letter to you as Chief Executive Offi cer of Achillion, Our strategic and tactical responses to the clinical hold on sovapre- EXECUTIVE MANAGEMENT BOARD OF DIRECTORS CORPORATE COUNSEL I am pleased to review the past year, share with you our plans and vir were swift. Recall that in June 2013, sovaprevir was put on clin- AND CORPORATE OFFICERS David I. Scheer, Wilmer Cutler Pickering Hale anticipated milestones, and outline my vision for the Company. ical hold by the FDA due to elevations in sovaprevir concentrations Milind S. Deshpande, Ph.D. Chairman of the Board and Dorr LLP At Achillion, we are dedicated to conducting rigorous scientifi c and elevations in liver enzymes observed in drug-drug interaction President and President New York, NY discovery and development. Thanks to our extremely talented studies with ketoconazole and with ritonavir-boosted atazanavir. Chief Executive Offi cer Scheer & Co., Inc. employees, I am proud to say that all the compounds in our pipe- As we work with the FDA to resolve the clinical hold on sovapre- INDEPENDENT AUDITORS vir, we rapidly integrated ACH-2684 into our clinical development David Apelian, M.D., Ph.D. Milind S. Deshpande, Ph.D. line were discovered and advanced from our research laboratories. -

Poveda E Aplicaciones Clínicas Resistencias HCV 1Enerovigo 2014

Hepatitis C: Aplicaciones Clínicas de la Resistencia Eva Poveda Division of Clinical Virology INIBIC-Complexo Hospitalario Universitario de A Coruña DAA agents approved or in more advanced stages of clinical development DAA family NS5B nucleos(t)ide NS5B non-nucleoside analogues NS3/4A inhibitors NS5A inhibitors analogues inhibitors inhibitors ∗∗∗ Sofosbuvir (GS-7977) ̷̷̷ Deleobuvir (BI-207127; NNI-site 1 inhibitor) Telaprevir Daclatasvir (BMS-790052) Mericitabine (RG-7128) ABT-333 (NNI-site 3 inhibitor) Boceprevir ∗∗∗ Ledipasvir (GS-5885) VX-135 IDX-184 VX-222 (NNI-site 2 inhibitor) Simeprevir (TMC-435) ̷̷̷ ABT-267 VX-135 ABT-072 (NNI-site 3 inhibitor) Faldaprevir (BI-2011335) MK-8742 GS-6620 Setrobuvir (ANA-598; NNI-site 3 inhibitor) Asunaprevir (BMS-650032) Samatasvir (IDX-719) INX-189 GS-9669 (NNI-site 2 inhibitor) Vaniprevir (MK-7009) ACH-3102 Tegobuvir (GS-9190; NNI-site 5 inhibitor) Danoprevir (RG-7227) Filivubir (PF-868554; NNI-site 2 inhibitor) Sovaprevir (ACH-1625) ABT-450/r GS-9451 MK-5172 ∗∗∗Approved by the FDA and EMA in 2011. Adapted from Poveda E et al. Future Virology 2012 Ϯ Approved by the FDA November/December 2013. Rapid Evolution of HCV Regimens: Easier to take/tolerate, Short Duration, Pangenotypic, Higher SVR, Eventually Oral for all patients 2013 2014 2015 Genotype 2&3 Genotype 2 Genotypes 1-4 P/R Sofosbuvir+RBV 12 weeks Sofosbuvir+Ledipasvir ± RBV Genotypes 1 Genotype 3 ABT-450+ABT-267+ABT-333 Telaprevir + P/R Sofosbuvir+RBV 24 weeks +RBV Boceprevir + P/R Genotypes 1-4 Daclatasvir+Asunaprevir Sofosbuvir + P/R Genotypes 1 Simeprevir + P/R HCV Resistance to DAA During DAA-based treatment: ■ Rapid selection of resistance mutation may occur, eventually leading to viral break-through. -

HEPATITIS C MEDICINES Technology and Market Landscape

2015 HEPATITIS C MEDICINES Technology and Market Landscape FEBRUARY 2015 UNITAID Secretariat World Health Organization Avenue Appia 20 CH-1211 Geneva 27 Switzerland T +41 22 791 55 03 F +41 22 791 48 90 [email protected] www.unitaid.org UNITAID is hosted and administered by the World Health Organization © 2015 World Health Organization (Acting as the host organization for the Secretariat of UNITAID) The designations employed and the presentation of the material in this publication do not imply the expression of any opinion whatsoever on the part of the World Health Organization concerning the legal status of any country, territory, city or area or of its authorities, or concerning the delimitation of its frontiers or boundaries. The mention of specific companies or of certain manufacturers’ products does not imply that they are endorsed or recommended by the World Health Organization in preference to others of a similar nature that are not mentioned. All reasonable precautions have been taken by the World Health Organization to verify the information contained in this publication. However, the published material is being distributed without warranty of any kind either expressed or implied. The responsibility and use of the material lies with the reader. In no event shall the World Health Organization be liable for damages arising from its use. This report was prepared by Mike Isbell and Renée Ridzon (Ahimsa) and Karin Timmermans (UNITAID). All reasonable precautions have been taken by the authors to verify the information contained in this publication. However, the published material is being distributed without warranty of any kind, either expressed or implied.