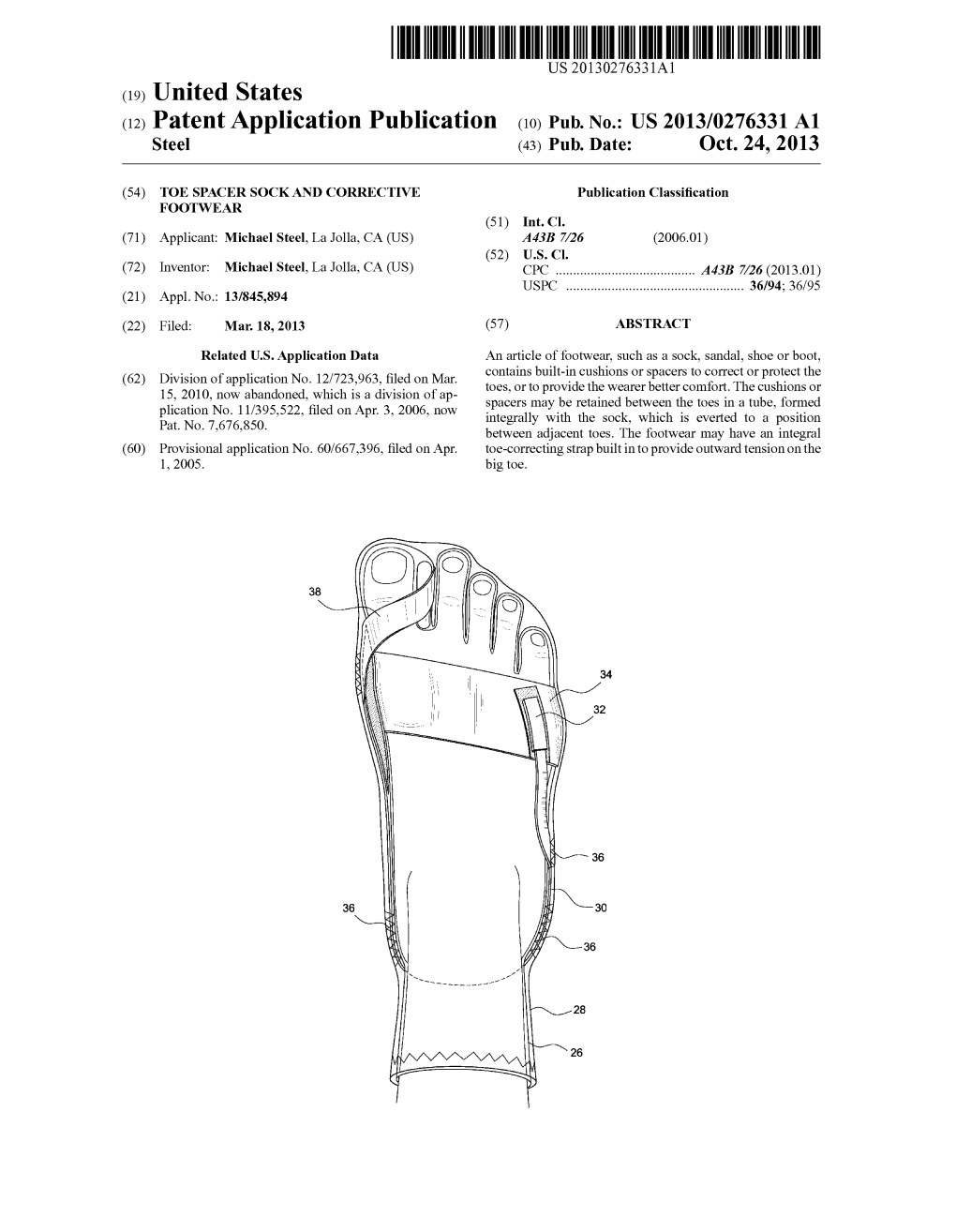

Patent Application Publication (10) Pub. No.: US 2013/0276331 A1 Steel (43) Pub

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Full-Line Compression Products New from CURAD®

Full-line Compression Products New From CURAD® 1-800-MEDLINE1-800-MEDLINE | www.medline.comwww.medline.com Hospital-Quality Compression Hosiery from a Brand People Trust Compression therapy is recommended by hospitals and physicians to help prevent DVT and for other indications. Today, consumers are seeking relief on their own for tired, achy legs. Athletes, travelers, pregnant women and workers on their feet all day are all looking for the kind of added leg support that CURAD compression hosiery delivers. The CURAD name boosts sales In a survey, 77 percent of all participants recognized the CURAD brand name.1 As a dealer of CURAD compression garments, you will be providing instant name recognition for your customers. In addition, a $4 million national marketing campaign integrating TV and radio spots, magazine print ads, billboards and promotional events is reinforcing the CURAD name and familiar green box even further in consumers’ minds. That’s an added bonus for retailers. Reference: 1 TNS Survey. Sponsored by TABS Group. August 2008. Data on file. The 2' (61cm) valance board, item CURCOMPVAL2, perfectly tops off this two foot planogram. 2 www.curad.com | 800-633-5463 Venous Disease: Know the Risks Varicose veins are caused by damaged Venous disease occurs when the walls and one-way valves in veins, usually or diseased valves, in the legs, become damaged. This damage allows blood to pool and causes which result in back- veins to swell, making the problem worse. The resulting venous disease can ward flow of blood in be relatively minor, such as with varicose veins or tired, achy legs. -

A. Uniform Details

UNIFORM DRESS CODE 2014/2015 QUICK REFERENCE A. Uniform Details: 1. Uniform Source: Uniforms must be purchased from French Toast School Wear online at www.frenchtoast.com . Our source code for the online catalogue is QS5GVHS. 2. Girls “Daily Wear” Uniform Selections a. Choices for tops: (i) Peter pan collar (plain) blouse in white (long or short sleeve) (ii) Pique polo shirt in white, gray, or black (long or short sleeve) (iii) Anti-pill crew neck cardigan sweater in black b. Choices for bottoms: (i) Pleated hem jumper in black or khaki (ii) Pleated skirt in heather gray (iii) Adjustable flat front pant in khaki or gray (iv) Bermuda Short in khaki (v) Black/brown dress belt (vi) WITH SKIRTS and JUMPERS - white tights OR white knee socks (vii) WITH PANTS - white tights OR white knee socks OR white bobby socks (bobby socks may only be worn with pants). (viii) WITH SHORTS - May wear Mary Janes and cuffed socks - NO KNEE HIGHS - May wear with boat shoes (brown, no plaid or other colors) and no show socks 3. Boys “Daily Wear” Uniform Selections a. Choices for tops: (i) Oxford shirt in white (long sleeve only) (ii) Pique polo shirt in white, gray, or black (long or short sleeve) (iii) V-neck sweater vest in black b. Choices for bottoms: (i) Flat front double-knee pant in khaki or gray (ii) Flat front adjustable pant in khaki or gray (iii) Flat front khaki shorts (iv) Black/brown dress belt (v) Boys black or navy dress socks (black or white “no show” socks with shorts) 4. -

Truform Catalog

COMPRESSION THERAPY COLLECTION Contents Compression Profile ...................................................... 3 Therapy Guide .............................................................. 4 Measuring ................................................................... 5 Fashion Wear Ladies’ Pattern Sheer .................................................... 6 Ladies’ Sheer ............................................................... 8 Ladies’ Opaque .......................................................... 12 Ladies’ Pattern Socks ................................................. 16 Men’s Dress Socks ..................................................... 18 Men’s & Ladies’ Casual .............................................. 20 Unisex Travel Series .................................................... 22 Medical Leg Wear Classic Medical .......................................................... 24 Anti-Embolism ............................................................ 30 Specialty Wear Diabetic & Health Socks .............................................. 32 Upper Extremity .......................................................... 35 TRUFORM Accessories .................... 36 TRUFORM Product Summary ..... 38 Compression Profile TRUFORM’s 6 Points of Compression Proximal Thigh 3 To be therapeutically effective, medical stockings must provide a pressure reduction from the ankle upwards. Mid Thigh 3 Truform takes compression measurements at precise intervals between the ankle and proximal end of the stocking - 4 points for below -

Idaho Youth Challenge Academy Packing List Class 2021-2

Idaho Youth ChalleNGe Academy Packing List Class 2021-2 This list is for information only. It is a copy of required personal items that applicants, who have been accepted and invited to report to the Idaho Youth ChalleNGe Academy, must bring on Registration Day. This list is for planning and is not required until after receiving an acceptance /invitation letter. Always keep your receipts. Candidates are required to report wearing a plain white t-shirt under a white long-sleeve oxford type button dress shirt, black slacks, black tie (males), black belt, black cotton dress socks and running shoes. MALES: □ (1) Shaving kit bag (6”x6”x10”, black, grey, navy blue, camo) FEMALES: □ (30) Elastic hair bands - Same color as hair (Clips are allowed, but must be same color as hair. NO Scrunchies, elastic headbands, or plastic headbands.) □ (1) Package of bobby pins (Must match hair color) □ (1) Large bottle of hair gel (Without alcohol) NO Hair spray (Good: Aussie, Gorella Snot, Joico PG, Eco, Garnier Fuctis) (Poor performance in IDYCA Environment: Xcess Styling Gel and LA products) □ (2)Donut shaped Sock buns (Same color as hair) □ (1) Hygiene Bag (same as shaving kit bag, 6”x6”x10”) (black, gray, navy blue, camo) □ (2) Bottles of shampoo/conditioner □ (1) Hair brush/comb □ (5-month) Supply of feminine hygiene products □ (6) Sports bras (Lace bras and underwear are NOT authorized) - Black, grey, or white in color. If your cup size is D or larger, also required are (2) black, grey or white non-lace underwire bras to wear under the sports bra for additional support. -

Compression Hosiery

advanced-orthopaedics.comadvanced-orthopaedics.com Ladies' Knee Highs Ladies' Support Socks Ladies’ Pantyhose Ladies' Thigh Highs 15-20 mm Hg Compression 15-20 mm Hg Compression Anti-Embolism15-20 mm Hg Compression Stockings 15-20 mm Hg Compression Specify colors: BL-Black, SF-Fawn,pecify colors: NU-Nude, BL-Black, P-Pearl T-Tan, (no PearlW-White in XXL) Specify18 mm colors: Hg BL-Black,Compression F-Fawn, BE-Beige, NU-Nude Specify colors: BL-Black, F-Fawn, NU-Nude Example:Example: 9313-T 9323-BL Example: 9343-NU Example: 9333-F Specify colors: W-White, BE-Beige •• Ribbed-Style Sheer Therapy Ladies Trouser Dress Socks MaternityExample: 9353-BE Pantyhose • Sheer Therapy •• Comfortable Light, Silky Look Balloon and Toe Feel and Heel Pocket • Lace Top with Silicone Beads •15-20 Available mm in Hg Knee Compression or Thigh High Lengths •• Thin, Reinforced Lightweight Toe and Nylon/Spandex Foot • Reinforced Toe and Foot • Thrombo-Embolic Deterrent •• Non-Binding, Thin, Lightweight Comfort Nylon/Spandex Top Band Specify colors: BL-Black, BE-Beige Example: M-9343-BE • Use for Pre and Post-Operative • Non-Binding, Comfort Top Band • Sheer Therapy • Control Top • Reinforced Toe Small Medium Large X-Large XX-Large Small Medium Large X-Large • Available in Open or Closed Toe Order # 9333 9335 9337 9338 9339 Order # Small Medium Large X-Large XX-Large Order # 9313 9315 9317 9318 Small Medium Large X-Large XX-Large • Non-Binding, Comfort Top Band Shoe Size 4 - 5 5½ - 7½ 8 - 10½ 11+ 11+ Pantyhose 9343 9345 9347 9348 9349 Shoe Size 4 - 5 5½ - 7½ 8 - -

Uniform Policy

Go to LandsEnd.com to order items Use School Code: 900156647 * Regular uniforms are always allowed, hot weather uniforms are only allowed from the second week of school up to Oct. 1 and after May 1. PreK-5 Girls Uniform PreK-5 Boys Uniform White shirt with Peter-pan collar Mesh or Interlock Evergreen Polo with Logo (Long sleeve Optional) (Long sleeve Optional) Plaid (Hunter / Classic Navy) Jumper Flat front or Pleated front navy shorts or pants with a black belt with Logo with any navy shorts worn (hidden) under the jumper. • White ankle sock or navy tights (no leggings) • White crew or ankle sock • Solid white (non-marking) athletic shoe • Solid black (non-marking) athletic shoe (No PE uniform for PreK-5) (No PE uniform for PreK-5) We encourage all students (except 9-12 boys, who have blazers) to purchase a navy cardigan with Logo, which can be worn any time. Other sweaters, jackets, hoodies, etc. are not allowed in the building. Go to LandsEnd.com to order items Use School Code: 900156647 * Regular uniforms are always allowed, hot weather uniforms are only allowed from the second week of school up to Oct. 1 and after May 1. PE Uniforms for 6-12 graders (Boys and Girls) 6-8 Boys Uniform Navy, knee-length mesh shorts, Gray Donahue Catholic t-shirt or any Donahue Spiritwear shirt Short/long sleeve No-Iron Pinpoint or Oxford 6-8 Girls All-year uniform with navy pants and dress belt and school tie • Navy or brown solid dress socks or white crew socks white Peter-pan with pleated or A-line skirt • Brown flat shoe (ex: Sperry, or Topsider - no tennis shoes) collar polo with Logo (Long sleeve Optional) 6-8 Boys Hot Weather Uniform • Girls may opt to wear a navy sweater vest with logo at any time throughout the year. -

DRESS CODES for STUDENTS PK, Jr. K & K: the Children Should Come Dressed Comfortably for School. Remember That We Paint, Gl

DRESS CODES FOR STUDENTS PK, Jr. K & K: The children should come dressed comfortably for school. Remember that we paint, glue, and use various art and craft materials. Gym shoes are required as we exercise inside and outside. For the safety of the children, please no flip flops, clogs, or backless shoes. Kindergarteners are to wear their gym uniform and gym shoes on days when they have gym. GRADES 1 – 8 A school uniform is a symbol of pride for oneself and for the school community. It also allows a student to focus on schoolwork, not clothing. We need your support and cooperation to enforce the uniform regulations. The school reserves the right to prohibit any fashion article that may distract from the learning environment. Wearing a uniform allows students to focus on their intellectual pursuits. A student’s appearance should be neat and clean and be in uniform from the first day to the last day of school. Clothes should be clean, not torn, fit properly, and be modest and appropriate for school. It is assumed that if the clothing is not listed below, it should not be worn to school. Students may wear gym uniforms to school on their scheduled gym days. Gym uniforms should be cleaned regularly and repaired as necessary. Students in grades K-8 are expected to wear the St. Cletus PE uniform. This uniform includes a gray St. Cletus logo t-shirt and red St. Cletus logo sweatpants or shorts (August through October and April through June). Students may wear a red St. Cletus School logo sweatshirt. -

Hosiery Glossary

Hosiery Glossary Everyone loves the silkiness of microfiber and the body-smoothing support and stretch of spandex...but did you ever wonder what microfiber and spandex actually are? Here’s a hosiery glossary to explain those terms and other terms related to our famous L’eggs and Hanes pantyhose. We’ve included helpful definitions about socks, too. Get the facts from the experts! Anklets Socks with a top designed to cover the anklebone. Extends less than one-third of the way up the largest part of the calf. Argyle Balanced, geometrically-knit pattern of multi-colored diamonds against a solid color background. Athletic Socks Socks designed for active sports, often having a ribbed top and plain foot construction. Frequently includes a high percentage of cotton. May include performance features like extra cushioning or moisture wicking. Basics The traditional or classic styles you depend on every day. Basics vary seasonally only in color. The bulk of the sock and sheer hosiery business. Cable A knitted pattern usually made up of two vertically intertwined bands. Casuals A broad hosiery term used to describe all socks, trouser socks, or knee-highs except dress, athletic and work styles. Control Top Hosiery with spandex in the panty area. Slims and supports hips and bottom. Gives you a smoother, firmer look under slinky styles. Cotton Count A yarn numbering system generally used for yarns spun on the cotton system. The count gives the number of 840-yard lengths of yarn required to weigh one pound. The higher the number, the finer the yarn. Crochet A process that creates a design or garment by interlocking looped stitches. -

Altar Server Dress Code

St. Joseph Altar Server Ministry Dress Code Policy Attending Mass is a very special part of your week and dressing up is an important part of altar serving. All altar servers must adhere to this dress code each and every time they serve. We are appreciative of your dedication and devotion to this ministry. Thank you for serving! Ladies Please wear: * Dresses, skirts, dress slacks * Dressy tops * Dress socks, dress tights, hosiery in a neutral color may be worn Dress shoes. Dress shoes must have a closed heel or secure strap around the back of heel. No high heels. * Necklaces (if worn) are worn under the vestments. Only post earrings may be worn. No large, flashy jewelry, no long/dangly earrings * Clear or a neutral/natural shade of pink/peach/beige nail polish may be worn Keep makeup (if worn) natural and to a minimum * Hair to be worn in a manner that will not temp the server to play with, fix, or in any way adjust. Ladies please note: Flip-flops, slides (defined as any shoe without a closed heel or secure strap around heel), tennis shoes, athletic shoes, and beach wear/sandals of any kind are NOT ACCEPTABLE. In addition, absolutely no shorts, no jeans of any color, no t-shirts, no mini-skirts, no mini-dresses, no form-fitting/midriff showing/low-cut tops. Gentlemen Please wear: * Dress slacks (black, navy, grey, brown, or khaki) with dress belt * Collared dress shirt (short or long sleeved) tucked in * Dress shoes and dress socks * Hair – neatly brushed/combed Gentlemen please note: Flip-flops, slides (defined as any shoe without a closed heel), tennis shoes, athletic shoes, and beach wear/sandals of any kind are NOT ACCEPTABLE. -

Trade Marks Inter Partes Decision O/724/18

BL O/724/18 TRADE MARKS ACT 1994 IN THE MATTER OF TRADE MARK APPLICATION 3253575 BY EVIE ABBOTT-WILCOX TO REGISTER THE FOLLOWING TRADE MARK IN CLASS 25: Horse of London AND OPPOSITION THERETO (NO. 411535) BY MANUEL JACINTO, LDA Background and pleadings 1. Evie Abbott-Wilcox (the applicant) applied to register the trade mark: Horse of London in the UK on 30 August 2017. It was accepted and published in the Trade Marks Journal on 03 November 2017, in respect of an extremely broad list of goods in classes 18 and 25. Following publication, the applicant requested deletion of the entire class 18 element of the application. The application stands now only in respect of class 25. The full list of applied for goods is set out at the end of this decision in Annex A. 2. Manuel Jacinto, Lda (the opponent) opposes the trade mark on the basis of Section 5(2)(b) of the Trade Marks Act 1994 (the Act). This is on the basis of an earlier UK Trade Mark, namely: 3. UK 2438534, filed on 15 November 2006 and registered on 22 February 2008, for the mark: 4. The earlier mark is registered for the following goods, all of which are relied upon in this opposition: Class 18: Goods made from leather, none being for equine use; luggage, bags and handbags; wallets and purses. 5. In its statement of grounds, the opponent claims that: 2 • The applied for mark is highly similar to its earlier right. The word element ‘HORSE’ of the earlier mark is fully contained within the later mark and is the dominant element of both marks. -

Mute Attire 3577595 23/06/2017 JIGAR.R.MANDVIA 301/A Raj Sagar, IC Colony Extension, Near D-Mart, Dahisar(W)

Trade Marks Journal No: 2003 , 07/06/2021 Class 25 Mute Attire 3577595 23/06/2017 JIGAR.R.MANDVIA 301/A Raj Sagar, IC colony extension, Near D-mart, Dahisar(w). Mumbai:400068 Individual Address for service in India/Attorney address: LABDHI KOCHAR & ASSOCIATES C/O LEGAL WIZ.IN PVT.LTD FIRST FLOOR PIPARA CORPORATE HOUSE, OPP. URVASHI APARTMENT, MITHAKALI, AHMEDABAD 380006 Proposed to be Used MUMBAI Clothing, footwear, headgear all included in class 25 2940 Trade Marks Journal No: 2003 , 07/06/2021 Class 25 UlkaVahini 3719878 05/01/2018 KOPAL AGRAWAL C 33/52, B-103, Banshidhar Apartment, Chhitupur, Sigra, Varanasi – 221010, Uttar Pradesh Proprietor Address for service in India/Attorney address: ANJALI MOTHA F-97, 4th Floor, Anna Nagar (East), Chennai – 600102, Tamil Nadu Proposed to be Used DELHI CLOTHING, FOOTWEAR, HEADGEAR PROPOSED TO BE USED. 2941 Trade Marks Journal No: 2003 , 07/06/2021 Class 25 Bella Bella 3731773 19/01/2018 URBANMANIA APPARELS (PROPRIETOR : RAVI SHANKAR) Urbanmania Apparels, 2nd Floor, Above Keshav Medical, Vgp Layout Road, Kudlu Main Road, Bangalore - 560068, Karnataka Proprietorship Firm Address for service in India/Attorney address: ANJALI MOTHA F-97, 4th Floor, Anna Nagar (East), Chennai – 600102, Tamil Nadu Proposed to be Used CHENNAI CLOTHING, FOOTWEAR, HEADGEAR Proposed To Be Used. 2942 Trade Marks Journal No: 2003 , 07/06/2021 Class 25 MAYA FASHION 3740489 31/01/2018 MR. ROHIT AGGARWAL WZ-405, RAM VILLA, JANAK PARK, HARI NAGAR CLOCK TOWER, MAYAPURI, NEW DELHI-110064 MANUFACTURERS AND MERCHANTS Proposed to be Used DELHI ALL TYPES OF FOOTWEAR INCLUDED IN CLASS-25. -

Heartland Farm Catalog Alpaca Goods

Alpaca Fleece Dryer Balls ca Alpaca Fleece Dryer Balls $15 Handmade by the sisters at the Farm with Heartland Farm’s Alpaca Fleece. These laundry drying aids are made with felted alpaca and wool fiber. As a natural drying solution for laundry, dryer balls shorten drying time by 1/3 the time and softens clothes without harmful chemicals and residues. Can be used over and over again. Alpaca Fleece Wrist Warmers Alpaca Fleece Wrist Warmers $40 Crocheted by the sisters with Heartland Farm’s hand spun Alpaca Fleece, the wrist warmers are cozy warm and stylish for the seasons of cooler weather. 100% Alpaca Colors: Brown, Grey, Tan, White Size: One Size Fits Most Merino Wool Wrist Warmers Merino Wool Wrist Warmers $35 Crocheted by the sisters, the merino wool wrist warmers are warm and practical, seeing as a nice compliment to your fall and winter wardrobe. 100% Merino Wool Colors: Brown, Tan Size: One Size Fits Most Alpaca Socks Alpaca Super Warm Socks $25 Naturally soft, luxurious, strong and warm alpaca sock, perfect for cold weather. Naturally breathable fiber wicks away sock moisture 47% Alpaca, 38% Acrylic, 13% Nylon, 2% Spandex Color: Grey, Cocoa Brown, Beige Size: Small, Medium Alpaca Dress Socks $15 Classic dress sock for every occasion. Warm, comfortable and no slip. Calf length. 47% Alpaca, 38% Acrylic, 13% Nylon, 2% Spandex Colors:, Charcoal Grey, Blue Melange, Grey, Cocoa Brown, Beige Size: Medium (male sizes: 6-8 1/2), Large( male sizes: 9-12 1/2) Alpaca Gifts - Alpaca Fleece Boot Inserts Alpaca Foot Warmers $15 The alpaca fiber shoe insert keeps feet warm in cold weather with its natural fibers that wick away moisture.