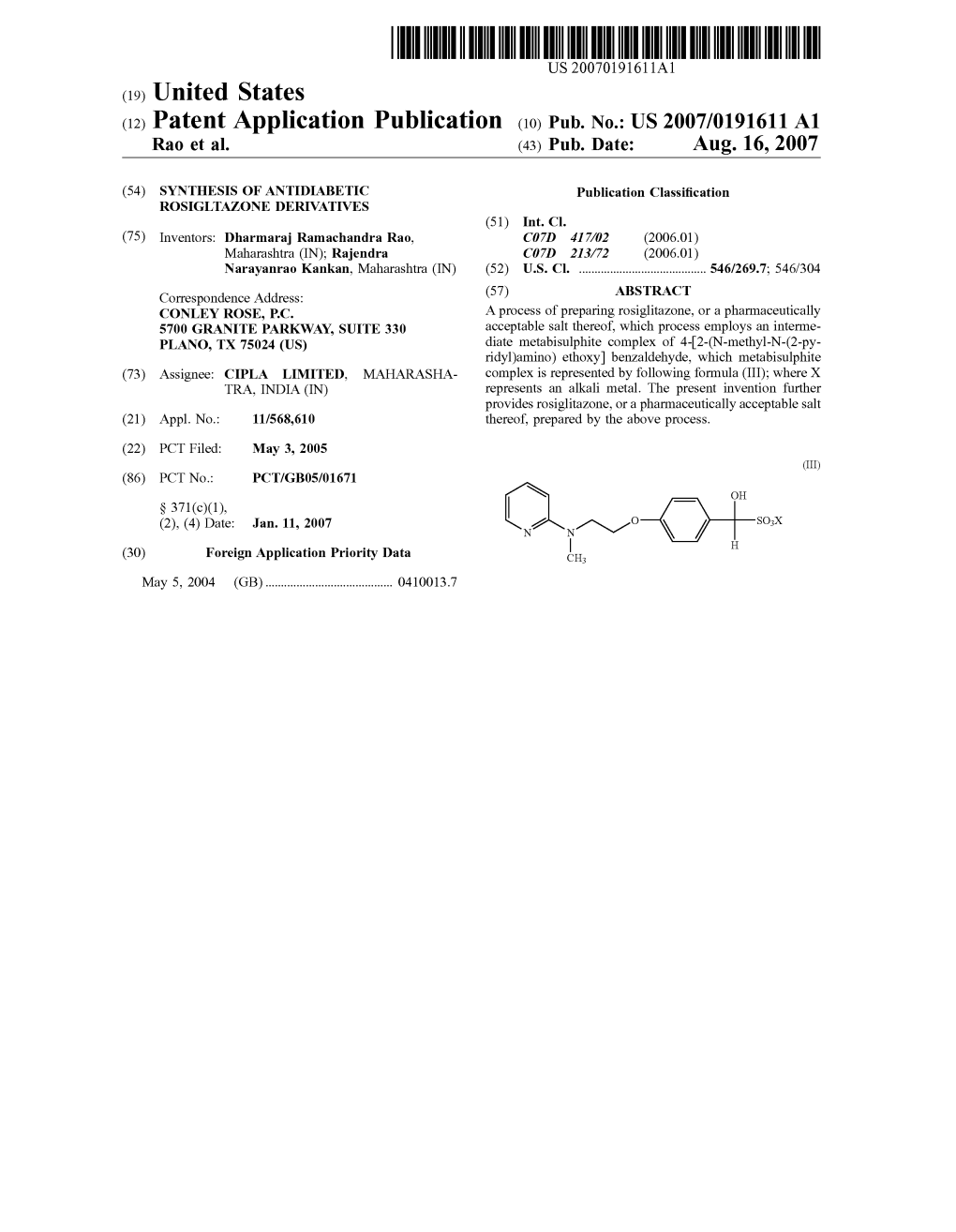

(12) Patent Application Publication (10) Pub. No.: US 2007/0191611 A1 Rao Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Mechanisms of Action of Ppars

12 Dec 2001 8:6 AR AR149-24.tex AR149-24.SGM LaTeX2e(2001/05/10) P1: GSR Annu. Rev. Med. 2002. 53:409–35 Copyright c 2002 by Annual Reviews. All rights reserved THE MECHANISMS OF ACTION OF PPARS Joel Berger and David E. Moller Department of Molecular Endocrinology, Merck Research Laboratories, P.O. Box 2000, Rahway, New Jersey 07065; e-mail: joel [email protected]; david [email protected] Key Words PPAR, nuclear receptors, diabetes, dyslipidemia ■ Abstract The peroxisome proliferator-activated receptors (PPARs) are a group of three nuclear receptor isoforms, PPAR ,PPAR, and PPAR, encoded by different genes. PPARs are ligand-regulated transcription factors that control gene expression by binding to specific response elements (PPREs) within promoters. PPARs bind as heterodimers with a retinoid X receptor and, upon binding agonist, interact with co- factors such that the rate of transcription initiation is increased. The PPARs play a critical physiological role as lipid sensors and regulators of lipid metabolism. Fatty acids and eicosanoids have been identified as natural ligands for the PPARs. More potent synthetic PPAR ligands, including the fibrates and thiazolidinediones, have proven effective in the treatment of dyslipidemia and diabetes. Use of such ligands has allowed researchers to unveil many potential roles for the PPARs in pathological states including atherosclerosis, inflammation, cancer, infertility, and demyelination. Here, we present the current state of knowledge regarding the molecular mechanisms of PPAR action and the involvement of the PPARs in the etiology and treatment of several chronic diseases. INTRODUCTION The peroxisome proliferator-activated receptors (PPARs) form a subfamily of the nuclear receptor superfamily. -

Diabetes-Related Biomarkers and Methods of Use Thereof

(19) TZZ _ _T (11) EP 2 541 254 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention (51) Int Cl.: of the grant of the patent: G01N 21/76 (2006.01) G01N 21/64 (2006.01) 12.11.2014 Bulletin 2014/46 G01N 33/66 (2006.01) G01N 33/74 (2006.01) G01N 33/68 (2006.01) (21) Application number: 12175286.9 (22) Date of filing: 18.04.2008 (54) Diabetes-related biomarkers and methods of use thereof Diabetesassoziierte Biomarker und Verfahren zur deren Verwendung dafür Biomarqueurs associés aux diabètes et procédés d’utilisation correspondants (84) Designated Contracting States: • HANLEY ANTHONY J G ET AL: "Metabolic and AT BE BG CH CY CZ DE DK EE ES FI FR GB GR inflammation variable clusters and prediction of HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT type 2 diabetes: factor analysis using directly RO SE SI SK TR measured insulin sensitivity.", DIABETES JUL 2004, vol. 53, no. 7, July 2004 (2004-07), pages (30) Priority: 18.04.2007 US 788260 1773-1781, XP002486180, ISSN: 0012-1797 08.11.2007 US 2609 P • EDELMAN DAVID ET AL: "Utility of hemoglobin A1c in predicting diabetes risk", JOURNAL OF (43) Date of publication of application: GENERAL INTERNAL MEDICINE, vol. 19, no. 12, 02.01.2013 Bulletin 2013/01 December 2004 (2004-12), pages 1175-1180, XP002502995, ISSN: 0884-8734 (62) Document number(s) of the earlier application(s) in • INOUE ET AL: "The combination of fasting accordance with Art. 76 EPC: plasma glucose and glycosylated hemoglobin 08746276.8 / 2 147 315 predicts type 2 diabetes in Japanese workers", DIABETES RESEARCH AND CLINICAL (73) Proprietor: Health Diagnostic Laboratory, Inc. -

Englitazone Administration to Late Pregnant Rats Produces Delayed Body Growth and Insulin Resistance in Their Fetuses and Neonates

Biochem. J. (2005) 389, 913–918 (Printed in Great Britain) 913 Englitazone administration to late pregnant rats produces delayed body growth and insulin resistance in their fetuses and neonates Julio SEVILLANO, Inmaculada C. LOPEZ-P´ EREZ,´ Emilio HERRERA, Mar´ıa DEL PILAR RAMOS and Carlos BOCOS1 Facultad de Farmacia, Universidad San Pablo-CEU, Montepr´ıncipe, Ctra. Boadilla del Monte Km 5.300, E-28668 Boadilla del Monte (Madrid), Spain The level of maternal circulating triacylglycerols during late preg- pregnant rats was corroborated, since they showed higher plasma nancy has been correlated with the mass of newborns. PPARγ NEFA [non-esterified (‘free’) fatty acid] levels, ketonaemia and (peroxisome-proliferator-activated receptor γ ) ligands, such as liver LPL (lipoprotein lipase) activity and lower plasma IGF-I TZDs (thiazolidinediones), have been shown to reduce triacyl- (type 1 insulin-like growth factor) levels, in comparison with glycerolaemia and have also been implicated in the inhibition those from control mothers. Moreover, at the molecular level, an of tissue growth and the promotion of cell differentiation. increase in Akt phosphorylation was found in the liver of neonates Therefore TZDs might control cell proliferation during late fetal from EZ-treated mothers, which confirms that the insulin pathway development and, by extension, body mass of pups. To investigate was negatively affected. Thus the response of fetuses and neonates the response to EZ (englitazone), a TZD, on perinatal develop- to maternal antidiabetic drug treatment is the opposite of what ment, 0 or 50 mg of englitazone/kg of body mass was given as an would be expected, and can be justified by the scarce amount of oral dose to pregnant rats daily from day 16 of gestation until either adipose tissue impeding a normal response to PPARγ ligands and day 20 for the study of their fetuses, or until day 21 of gestation by hyperinsulinaemia as being responsible for a major insulin- for the study of neonates. -

Possible Role of Rivoglitazone Thiazolidine Class of Drug As Dual

Medical Hypotheses 131 (2019) 109305 Contents lists available at ScienceDirect Medical Hypotheses journal homepage: www.elsevier.com/locate/mehy Possible role of rivoglitazone thiazolidine class of drug as dual-target therapeutic agent for bacterial infections: An in silico study T ⁎ Vidyasrilekha Yele , Niladri Saha, Afzal Azam Md Department of Pharmaceutical Chemistry, JSS College of Pharmacy, Ootacamund, JSS Academy of Higher Education & Research, Mysuru 643001, India ARTICLE INFO ABSTRACT Keywords: Infections due to resistant bacteria are the life-threatening and leading cause of mortality worldwide. The Rivoglitazone current therapy for bacterial infections includes treatment with various drugs and antibiotics. The misuse and ParE over usage of these antibiotics leads to bacterial resistance. There are several mechanisms by which bacteria MurE exhibit resistance to some antibiotics. These include drug inactivation or modification, elimination of antibiotics Docking through efflux pumps, drug target alteration, and modification of metabolic pathway. However, it is difficult to MM-GBSA treat infections caused by resistant bacteria by conventional existing therapy. In the present study binding af- Molecular dynamic simulations fi Anti-bacterial agent nities of some glitazones against ParE and MurE bacterial enzymes are investigated by in silico methods. As evident by extra-precision docking and binding free energy calculation (MM-GBSA) results, rivoglitazone ex- hibited higher binding affinity against both ParE and MurE enzymes compared to all other selected compounds. Further molecular dynamic (MD) simulations were performed to validate the stability of rivoglitazone/4MOT and rivoglitazone/4C13 complexes and to get insight into the binding mode of inhibitor. Thus, we hypothesize that structural modifications of the rivoglitazone scaffold can be useful for the development of an effective antibacterial agent. -

Sugar-Lowering Drugs for Type 2 Diabetes Mellitus and Metabolic Syndrome—Review of Classical and New Compounds: Part-I

pharmaceuticals Review Sugar-Lowering Drugs for Type 2 Diabetes Mellitus and Metabolic Syndrome—Review of Classical and New Compounds: Part-I Raquel Vieira 1 , Selma B. Souto 2, Elena Sánchez-López 3,4 , Ana López Machado 4, Patricia Severino 5,6 , Sajan Jose 7 , Antonello Santini 8 , Ana Fortuna 9,10, Maria Luisa García 3,4, Amelia M. Silva 11,12 and Eliana B. Souto 1,13,* 1 Department of Pharmaceutical Technology, Faculty of Pharmacy, University of Coimbra (FFUC), Pólo das Ciências da Saúde, 3000-548 Coimbra, Portugal; [email protected] 2 Department of Endocrinology, Hospital São João, Prof. Alameda Hernâni Monteiro, 4200-319 Porto, Portugal; [email protected] 3 Department of Pharmacy, Pharmaceutical Technology and Physical Chemistry, Faculty of Pharmacy and Food Sciences, University of Barcelona, Institute of Nanoscience and Nanotechnology (IN2UB), 08028 Barcelona, Spain; [email protected] (E.S.-L.); [email protected] (M.L.G.) 4 Centro de Investigación Biomédica en Red de Enfermedades Neurodegenerativas (CIBERNED), University of Barcelona, 08028 Barcelona, Spain; [email protected] 5 Laboratory of Nanotechnology and Nanomedicine (LNMED), Institute of Technology and Research (ITP), Av. Murilo Dantas, 300, Aracaju 49010-390, Brazil; [email protected] 6 University of Tiradentes (UNIT), Industrial Biotechnology Program, Av. Murilo Dantas 300, Aracaju 49032-490, Brazil 7 Department of Pharmaceutical Sciences, Mahatma Gandhi University, Cheruvandoor Campus, Ettumanoor, Kerala 686631, India; [email protected] 8 -

Pancreatic Hormones and Antidiabetic Drugs. In

Chapter 41 Pancreatic Hormones & Antidiabetic Drugs Contents Pancreatic Hormones & Antidiabetic Drugs The endocrine pancreas Antidiabetic Drugs The Pancreas An organ that makes insulin and enzymes for digestion. Both endocrine system and digestive system (exocrine). Function of the hormones Insulin: the storage and anabolic hormone of the body (glyco-metabolism) Amylin: modulates appetite, gastric emptying, and glucagon and insulin secretion Glucagon: the hyperglycemic factor that mobilizes glycogen stores Disorders of the Pancreas: Diabetes Mellitus Caused by: Insufficient secretion of insulin Resistance of body cells to the effects of insulin Diabetes Mellitus Type1 Type2 Type3 Type4 Insulin- Noninsulin- Gestational Diabetes Other dependent dependent specific diabetes diabetes Mellitus (GDM) types elevated blood glucose Type Ⅰ Diabetes --- develops suddenly, usually before age 15 results in insulin dependence severe or absolute insulin deficiency In response to high levels of glucose in the blood, the insulin-producing cells in the pancreas secrete the hormone insulin. Type I diabetes occurs when these cells are destroyed by the body’s own immune system. Treatment of Type Ⅰ Diabetes Injection of insulin Surgery: replacing the pancreas or just the beta cells pancreas-kidney transplant Stem cell research Type Ⅱ Diabetes --- adult onset, usually occurs after age 40 Etiology: Insulin resistance; relative deficiency in insulin secretion. blood glucose levels rise due to : 1) Lack of insulin production 2) Insufficient insulin -

Peroxisome Proliferator-Activated Receptors As Superior Targets to Treat Diabetic Disease, Design Strategies - Review Article

Review article DOI: 10.4274/tjps.galenos.2021.70105 Peroxisome proliferator-activated receptors as superior targets to treat diabetic disease, design strategies - review article Diyabetik hastalığı tedavi etmek için üstün hedefler olarak peroksizom proliferatör ile aktive edilmiş reseptörler, tasarım stratejileri - inceleme makalesi Mohammed T Qaoud1, Ihab Al-masri2, Tijen Önkol1 1Department of Pharmaceutical Chemistry, Faculty of Pharmacy, Gazi University, Ankara- Turkey 2Department of Pharmaceutical Chemistry and Pharmacognosy, Faculty of Pharmacy, Al Azhar University, Gaza Strip, Palestine proof Corresponding Author Mohammed T Qaoud, Department of Pharmaceutical Chemistry, Faculty of Pharmacy, Gazi University, Ankara-Turkey [email protected] +90 552 634 15 56 https://orcid.org/0000-0002-9563-9493 09.12.2020 31.05.2021 09.06.2021 Abstract Thiazolidinedione (TZD), a class of drugs that are mainly used to control type II diabetes mellitus (T2DM), acts fundamentally as a ligand of peroxisome proliferator-activated receptors (PPARs). Besides activating pathways responsible for glycemic control via enhancing insulin sensitivity and lipid homeostasis, activating PPARs leads to exciting other pathways related to bone formation, inflammation, and cell proliferation. Unfortunately, this diverse effect via activating several pathways may show in some studies adverse health outcomes as osteological, hepatic, cardiovascular, and carcinogenic effects. Thus, an argent demand is present to find and develop new active and potent antiglycemic drugs for the treatment of T2DM. To achieve this goal, the structure of TZD for research is considered as a leading structure domain. This review would guide future research in the design of novel TZD derivatives through highlighting the general modifications conducted to the structure component of TZD scaffold affecting their potency, binding efficacy, and selectivity for the control of type II diabetes mellitus. -

Regulation of Signal Transducers and Activators of Transcription

Biochimica et Biophysica Acta 1452 (1999) 188^196 www.elsevier.com/locate/bba Regulation of signal transducers and activators of transcription (STATs) by e¡ectors of adipogenesis: coordinate regulation of STATs 1, 5A, and 5B with peroxisome proliferator-activated receptor-Q and C/AAAT enhancer binding protein-K William C. Stewart a, Ron F. Morrison b, Sherry L. Young a, Jacqueline M. Stephens c;* a Middle Tennessee State University, Department of Biology, Murfreesboro, TN 37132, USA b Boston University Medical Center, Department of Biochemistry, 80 East Concord St., Boston, MA 02118, USA c Louisiana State University, Department of Biological Sciences, Life Sciences Bldg., Room 508, Baton Rouge, LA 70803, USA Received 29 July 1999; accepted 16 September 1999 Abstract We have recently demonstrated that three signal transducers and activators of transcription (STAT) family members are induced during adipocyte differentiation (Stephens et al., J. Biol. Chem. 271 (1996) 10441^10444). Since STATs 1, 5A, and 5B are induced during adipocyte differentiation, we have examined the ability of these proteins to be regulated by components of the differentiation cocktail. In addition, we have examined the effects of potent effectors of differentiation on STAT protein expression during adipogenesis. A negative effector, tumor necrosis factor-K (TNFK), and a positive effector, a thiazolidinedione, were used in these experiments. Our results demonstrate that the expression of STATs 1, 5A, and 5B is not dramatically influenced by individual components of the differentiation cocktail. However, the expression of these three STAT family members tightly correlates with lipid accumulation. Moreover, the expression of STATs 1, 5A, and 5B, but not STATs 3 and 6, are regulated in an identical fashion to both C/AAAT enhancer binding proteins K and peroxisome proliferator-activated receptor-Q by TNFK and a thiazolidinedione. -

C H a P T E R 4 3 Glitazones Are Superior Oral Antidiabetics

C h a p t e r 4 3 Glitazones are Superior Oral Antidiabetics Sidhartha Das1, Jayanta K Panda2 1 Professor 2 Faculty Member Post Graduate Department of Medicine, S.C.B.Medical College, Cuttack Glitazones or thiazolidinediones (TZDs) are a class of oral insulin sensitizing agents. They act on the nuclear receptor of the target cells called as Peroxisome Proliferator Activated Receptor- γ (PPAR-γ). They were introduced into clinical practice in 1997. The first agent troglitazone was extensively studied, later withdrawn for association with hepatotoxicity.Second generation TZDs are rosiglitazone and pioglitazone. Other members of the group are ciglitazone and englitazone. These compounds show qualitatively similar metabolic activity but vary in potency.1 Site and Mechanism of Action (Fig. 1) PPAR γ is a nuclear receptor found predominantly in adipose tissue, also present in skeletal muscle and liver. Natural ligands of PPAR γ include fatty acids (FA), prostaglandin metabolites and leukotrienes. TZDs are synthetic ligands of the intracellular PPAR- γ. TZDs are lipophilic drugs which readily enter cells and bind to PPAR γ with high affinity. PPAR γ is complexed with the retinoid X receptor (RXR) and their activation results in activation of regulatory sequences of DNA that control the expression of specific genes.Besides pioglitazone also works through PPAR α at liver for regulation of lipid homeostasis. Thiazolidinedione Glucose Fatty acids GLUT 4 FATP Glucose uptake aP2, acyl- and utilization CoA synthase + Lipogenesis PPAR- RXR and adipocyte -

(10) Patent No.: US 9309235 B2

US0093 09235B2 (12) United States Patent (10) Patent No.: US 9,309,235 B2 m et al. (45) Date of Patent: Apr. 12, 2016 (54) SGC STIMULATORS 9,061,030 B2 * 6/2015 Kim ..................... CO7D 401/04 9,139,564 B2 * 9/2015 Kim ..................... CO7D 413/14 (71) Applicant: IRONWOOD PHARMACEUTICALS, 2010/0.144864 A1* 6, 2010 Currie .................... A61K 31/04 514,470 INC., Cambridge, MA (US) 2013/O123354 A1* 5, 2013 Currie .................... A61K 31/04 514,470 (72) Inventors: G-Yoon Jamie Im, Cambridge, MA 2013,01784.75 A1* 7, 2013 Moore ................. CO7D 401/04 (US); Rajesh Iyengar, West Newton, 514,245 MA (US); Joel Moore, Lexington, MA 2014/0088071 A1 3/2014 Nakai .................. CO7D 401/04 ...i. s 514,2102 (US); Angelika Fretzen, Somerville, 2014/0323448 A1* 10/2014 Kim ................... A61K 31/4155 MA (US) 514,171 2015,0018353 A1 1/2015 Kim ..................... CO7D 413/14 (73) Assignee: IRONWOOD PHARMACEUTICALS, 514,236.5 INC., Cambridge, MA (US) 2015,0250795 A1* 9, 2015 Kim ..................... CO7D 401/04 424,613 (*) Notice: Subject to any disclaimer, the term of this patent is extended or adjusted under 35 FOREIGN PATENT DOCUMENTS U.S.C. 154(b) by 0 days. WO WO 2011 126903 A2 * 10, 2011 ......... A61K 31,4427 WO 2012OO3405 A1 1, 2012 (21) Appl. No.: 14/428,844 WO 2012O64559 A1 5, 2012 WO 2012O75678 A1 6, 2012 (22) PCT Filed: Sep. 18, 2013 (86). PCT No.: PCT/US2O13/06O295 OTHER PUBLICATIONS S371 (c)(1), International Search Report for PCT/US2013/060295 dated Oct. 25, (2) Date: Mar. 17, 2015 2013. -

3D QSAR Analysis of PPAR-Γ Agonist and PTPIB Antagonist As Anti-Hyperglycemic Agents

Asian Journal of Chemistry Vol. 19, No. 4 (2007), 2490-2496 3D QSAR Analysis of PPAR-γ Agonist and PTPIB Antagonist as Anti-hyperglycemic Agents SHWETA KAPOOR, GOPAL GARG and SWARNLATA SARAF* Institute of Pharmacy, Pt. Ravishankar Shukla University, Raipur, India E-mail: [email protected] A quantitative structure activity relationship studies were observed on series of N-(2-benzoylphenyl)-L-tyrosine for Peroxisome Proliferator Activated Receptor (PPARγ) agonist and new azolidinediones for Protein Tyrosine Phosphatase 1B (PTP1B) antagonist. Various physi- cochemical parameters were calculated by chem 3D Ultra version 6.0. Several statistical regression expressions were obtained by using multiple regression analysis. Steric descriptor (PMI-X, Ovality, CMA, PMI-Z); electronic descriptor (DD, total energy); and thermodynamic descriptor (Gibb's energy, HF) were found to have significant correla- tion ship in both of the series. Value of correlation coefficient (r) in series 1 is found to be 0.799, statistical significance is 99 % and in series 2 r = 0.869, statistical significance is 99.9 %. Key Words: Antihyperglycemic, 3D-QSAR, PPAR-γ, PTP1B, PMI-X, Azolidinediones, N-(2-benzoylphenyl)-L-tyrosine. INTRODUCTION Diabetes mellitus1 is a disorder of glucose metabolism classified under insulin dependent diabetes mellitus (IDDM) and non-insulin dependent diabetes mellitus (NIDDM). By peripheral insulin resistance, β-cell dysfunction, hyperglycaemia and often hyperlipidemia is characteristic feature of NIDDM (Type-II)2. Insulin deficiency further leads to chronic diseases such as ketocidosis, retinopathy, nephropathy, neuropathy and cardiovascular disease3. Earlier, treatment of NIDDM done by bi-guanides, sulphonylureas, insulin secreatogogues, α-glucosides inhibitor, one novel class of anti- diabetic agent that appear to be effective as a treatment for diabetes are PPAR-γ agonist viz., thiazolidinediones (TZDs) such as ciglitazone, englitazone, pioglitazone and rosiglitazone4. -

Stembook 2018.Pdf

The use of stems in the selection of International Nonproprietary Names (INN) for pharmaceutical substances FORMER DOCUMENT NUMBER: WHO/PHARM S/NOM 15 WHO/EMP/RHT/TSN/2018.1 © World Health Organization 2018 Some rights reserved. This work is available under the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 IGO licence (CC BY-NC-SA 3.0 IGO; https://creativecommons.org/licenses/by-nc-sa/3.0/igo). Under the terms of this licence, you may copy, redistribute and adapt the work for non-commercial purposes, provided the work is appropriately cited, as indicated below. In any use of this work, there should be no suggestion that WHO endorses any specific organization, products or services. The use of the WHO logo is not permitted. If you adapt the work, then you must license your work under the same or equivalent Creative Commons licence. If you create a translation of this work, you should add the following disclaimer along with the suggested citation: “This translation was not created by the World Health Organization (WHO). WHO is not responsible for the content or accuracy of this translation. The original English edition shall be the binding and authentic edition”. Any mediation relating to disputes arising under the licence shall be conducted in accordance with the mediation rules of the World Intellectual Property Organization. Suggested citation. The use of stems in the selection of International Nonproprietary Names (INN) for pharmaceutical substances. Geneva: World Health Organization; 2018 (WHO/EMP/RHT/TSN/2018.1). Licence: CC BY-NC-SA 3.0 IGO. Cataloguing-in-Publication (CIP) data.